Sheet metal shears, as the name implies, is a machine used for cutting sheet metal. The material selection is based on the general Q235 plate. If cutting Q345 plate, then the model should be chosen 1.4 times larger. If cutting stainless steel, the model should be chosen 1.6-2 times larger. If cutting 10-40mm plate, a […]

Sheet metal shears, as the name implies, is a machine used for cutting sheet metal.

The material selection is based on the general Q235 plate.

If cutting Q345 plate, then the model should be chosen 1.4 times larger. If cutting stainless steel, the model should be chosen 1.6-2 times larger. If cutting 10-40mm plate, a guillotine shear is a better choice.

Check out How to distinguish the steel plate from Q235 and Q345.

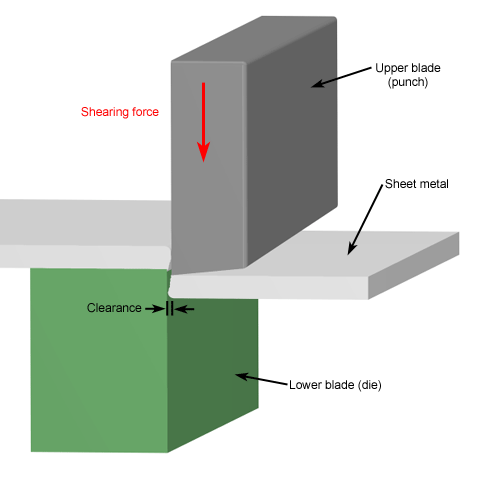

Metal shears are indispensable tools in the sheet metal fabrication industry, capable of cutting steel plates of various thicknesses with precision. The primary machine used for this purpose is known as a squaring shear, power shear, or guillotine. These machines can be operated through foot pedals, manual levers (less common), or more advanced mechanical or hydraulic systems. The cutting process involves first securing the material with a clamping mechanism or ram, followed by a moving blade descending across a fixed blade to execute the shear.

Classification of Metal Shears:

Plate cutting machines can be broadly categorized into several types:

Hydraulic shears operate by precisely controlling the movement of the upper blade relative to the fixed lower blade, maintaining an optimal blade gap. This configuration allows for the application of a calculated shearing force to metal plates of varying thicknesses, resulting in clean cuts to the required dimensions.

Sheet metal shears excel in producing straight-edged blanks. The shearing process must ensure that the cut surface is linear and parallel to the specified requirements while minimizing sheet distortion. This precision is crucial for producing high-quality workpieces that meet tight tolerances and surface finish standards.

Definition of plate shear

According to the Machinery Industry Standard of the People’s Republic of China, a plate shear is defined as:

A machine tool that utilizes a linear-moving upper blade in conjunction with a stationary lower blade to perform shearing operations on sheet metal or plate materials. The cutting action occurs when the upper blade descends in a straight-line motion, creating a progressive shearing force along the length of the workpiece against the fixed lower blade. This process results in a clean, precise cut with minimal deformation of the material.

Plate shears are typically characterized by:

These machines are essential in metalworking industries for producing accurately sized sheets and plates, often as a preparatory step for further fabrication processes like bending, welding, or forming.

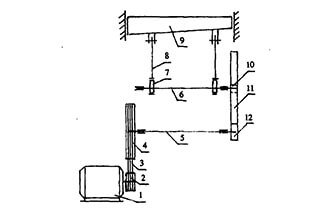

Metal shears are often integrated into specialized production systems to optimize specific manufacturing processes:

Cold-formed line plate cutting machines: These precision shears are tailored for automotive manufacturing, specifically in cold-bending lines for longitudinal beams, side panel production, and color-coated sheet forming. They offer tight tolerances and high repeatability essential for automotive components.

Steel structure production line shears: Designed for heavy-duty applications, these shears are crucial in angle steel and H-beam automatic production lines. They provide clean, square cuts on structural steel members, ensuring dimensional accuracy for subsequent welding and assembly processes.

Plate uncoiling line shears: Engineered for high-speed coil processing lines, these shears facilitate rapid and precise cutting of metal sheets as they are uncoiled. They incorporate advanced synchronization systems to maintain cut quality at varying line speeds, crucial for downstream operations.

Material-specific shearing solutions:

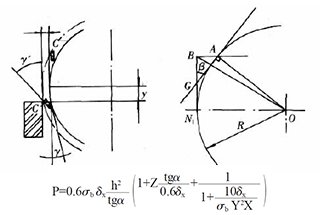

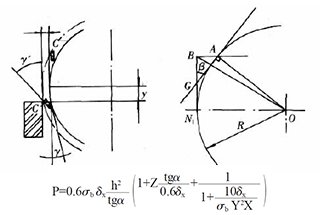

The inclined blade shear design in metal shearing machines incorporates angled upper and lower blades, with the upper blade typically set at an inclination angle ranging from 1° to 6°. This configuration offers several advantages over traditional flat blade designs.

The primary benefit of the inclined blade arrangement is the reduction in cutting force required. As the blades engage the material progressively along the cut line, rather than simultaneously across the entire width, the peak force is significantly reduced. This progressive shearing action results in a 20-30% decrease in the maximum cutting force compared to flat blade designs.

The reduced cutting force translates to multiple operational benefits:

Additionally, the inclined blade configuration often results in improved cut quality, with less deformation of the workpiece edges. This is particularly beneficial when working with thinner gauge materials or when maintaining tight tolerances is crucial.

It’s important to note that the optimal inclination angle depends on factors such as material thickness, type, and desired cut quality. Manufacturers often provide adjustable blade angles within the specified range to accommodate various cutting requirements.

Flat blade shearing is a precision cutting process that produces high-quality cuts with minimal twisting deformation. This method employs parallel cutting edges that engage the workpiece simultaneously, resulting in clean, straight cuts. While it offers superior shearing quality, it demands significant force and energy input due to the large contact area between the blades and the material.

Most flat blade shear machines utilize mechanical transmission systems, leveraging gears, cams, or hydraulic mechanisms to generate the required force. This robust design ensures stability and repeatability in high-volume production environments.

Flat blade shears find extensive application in rolling mills, particularly for hot billet and slab shearing in steel production. The process can be categorized into two primary methods:

Ironworker machine (multi-function punching and shearing machine): This versatile machine is designed to perform multiple metal fabrication processes, primarily focusing on shearing plates, cutting profiles, and punching holes. It excels in blanking operations, offering precision and efficiency in producing flat metal components. Modern ironworkers often feature programmable controls, allowing for quick setup changes and improved productivity across various metalworking tasks.

Combination shear and press brake: This integrated machine combines the capabilities of shearing and bending in a single unit, streamlining sheet metal fabrication. It can perform precise cuts on metal sheets and then bend the cut pieces to desired angles, all without transferring the workpiece between separate machines. This consolidation of processes enhances workflow efficiency, reduces handling time, and ensures greater consistency in part production. Advanced models may incorporate CNC controls for complex bend sequences and automated material handling systems for optimized throughput.