Have you ever wondered about the fascinating world of metal stamping? In this blog post, we’ll embark on an exciting journey to explore the intricacies of this essential manufacturing process. As an experienced mechanical engineer, I’ll guide you through the key concepts, sharing valuable insights and real-world examples. Get ready to discover how metal stamping shapes our everyday lives and learn the secrets behind its remarkable efficiency and versatility.

Metal stamping is a high-volume manufacturing process that transforms flat metal sheets into specific shapes using mechanical forces. This versatile technique is crucial in various industries, including automotive, aerospace, electronics, and consumer goods production. The process involves several key components and stages:

What is stamping?

Stamping, also known as pressing, is a manufacturing process where flat sheet metal or non-metallic materials are formed into specific shapes using specialized tools and equipment. This process typically occurs at room temperature, distinguishing it as a cold-forming technique. The definition of stamping can be articulated as follows:

At ambient temperature, a metal (or non-metal) sheet is subjected to controlled force using a stamping press and a precision-engineered die. This action induces either material separation or plastic deformation, resulting in components with predetermined shapes, dimensions, and mechanical properties.

Key aspects of the stamping process include:

Temperature: Stamping is predominantly performed at room temperature, classifying it as a cold-working process. This eliminates the need for heating, enhancing energy efficiency and material handling.

Raw Material: The primary workpiece in stamping is sheet material, typically metal, earning it the alternate term “sheet metal stamping.” Common materials include steel, aluminum, brass, and various alloys.

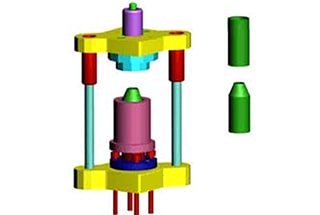

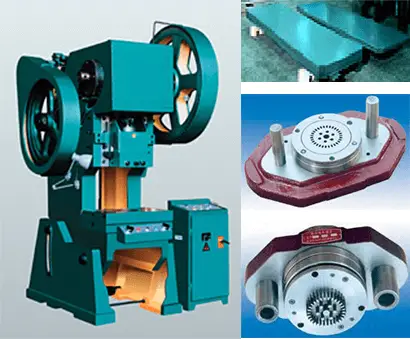

Equipment and Tooling: Stamping requires three essential components:

Deformation Mechanism: Stamping relies on plastic deformation, where the material is stressed beyond its yield point but below its ultimate tensile strength. This allows for permanent shape change without material failure.

Versatility: Stamping can produce a wide range of parts, from simple flat washers to complex automotive body panels, through various operations such as blanking, piercing, bending, and deep drawing.

Production Efficiency: Stamping is particularly suited for high-volume production, offering fast cycle times and consistent part quality when properly tooled and operated.

Metal stamping characteristics and applications:

(1) High productivity with streamlined operation, facilitating seamless mechanization and automation integration.

(2) Exceptional dimensional accuracy and superior part-to-part consistency, ensuring optimal interchangeability.

(3) Impressive material utilization rates, typically ranging from 70% to 85%, with some advanced processes achieving up to 95% efficiency.

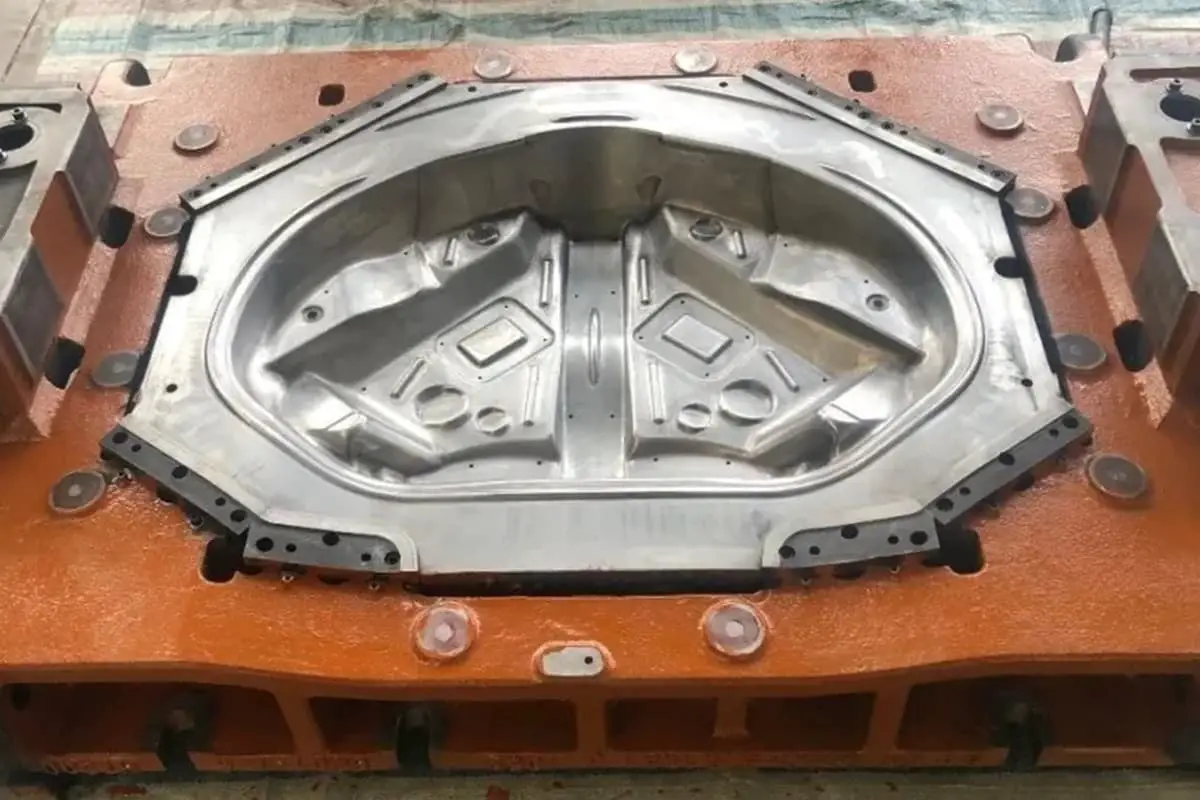

(4) Capability to produce complex geometries challenging or impossible for conventional machining methods, such as thin-walled deep-drawn components with intricate features.

(5) Enables the production of lightweight parts with excellent rigidity-to-weight ratios and high structural integrity.

(6) Cold-forming process eliminates the need for heating, resulting in energy savings and superior surface finish quality.

(7) Significantly reduced per-unit costs in high-volume production scenarios.

These attributes position metal stamping as a uniquely versatile manufacturing process, combining high quality, efficiency, energy conservation, and cost-effectiveness in a manner unmatched by alternative metalworking methods.

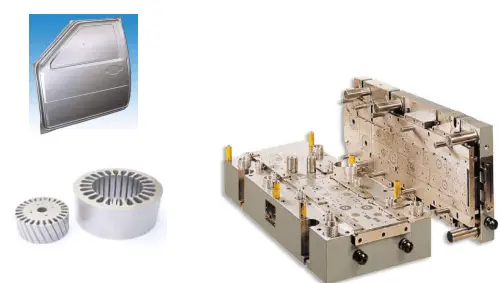

Consequently, metal stamping finds extensive applications across diverse industries. In the automotive and agricultural machinery sectors, stamped components constitute 60% to 70% of parts. Similarly, the instrumentation and metering industry relies on stamping for 60% to 70% of its components. The process is equally prevalent in producing a wide array of stainless steel kitchenware and daily-use items.

The versatility of metal stamping spans an impressive range of applications, from miniature electronic components and precision instrument pointers to large-scale automotive body panels and structural beams. Even in the aerospace industry, critical components like aircraft skins are manufactured using advanced stamping techniques. This breadth of application underscores the process’s adaptability to diverse scale and complexity requirements across multiple sectors.

Disadvantages of stamping

The mold manufacturing cycle is long and the cost is high. Because it uses traditional processing methods and means and traditional mold materials

However, with the advent of advanced mold processing technology and non-traditional mold materials, this shortcoming can be gradually overcome.

Such as:

In short, the mold industry is a country’s basic industry, the level of mold design and mold manufacturing has become a measure of the level of product manufacturing in a country.

Developed countries attach great importance to the development of molds.

Japan believes that “mold is the driving force for entering a wealthy society”;

Germany: “the emperor in the metal processing industry”;

Romania: “the mold is Golden Touch”; the mold is considered to be a stone in the international arena industry.

However, the molds here also include molds, forging dies, die-casting dies, rubber molds, food molds, building materials molds, etc., but currently the cold dies and plastic molds are the most widely used, each accounting for about 40%.

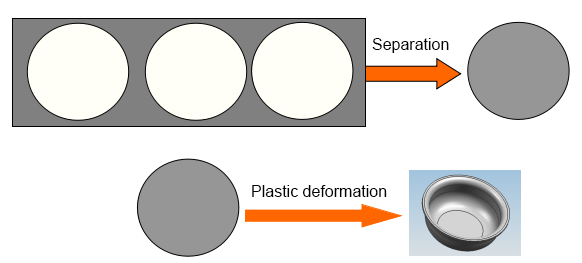

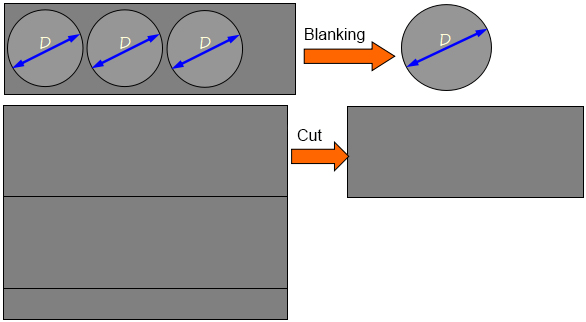

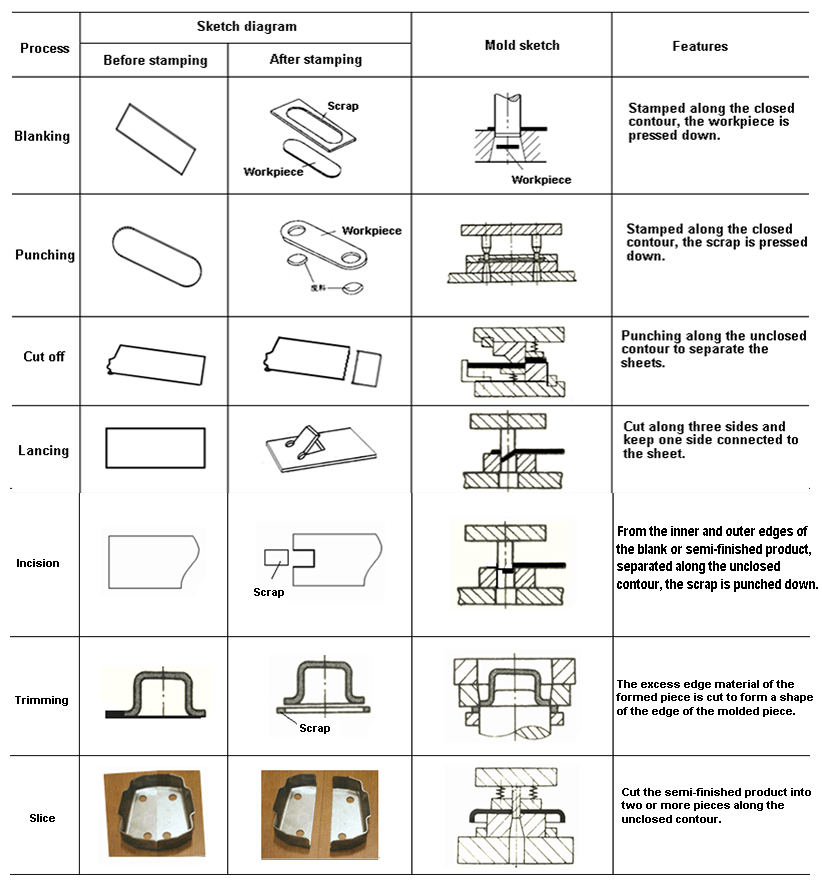

(1)Separation process

During stamping, the material to be processed is deformed by external force.

When the shear stress of the material in the deformation zone reaches the shear strength of the material, the material is sheared and separated to form a part of a certain shape and size.

The separation process mainly includes cutting, punching, blanking, notching, slicing etc.

The separation process is indicated as below:

Separation occurs but does not change the shape of the space.

Table 1-1 Separation process

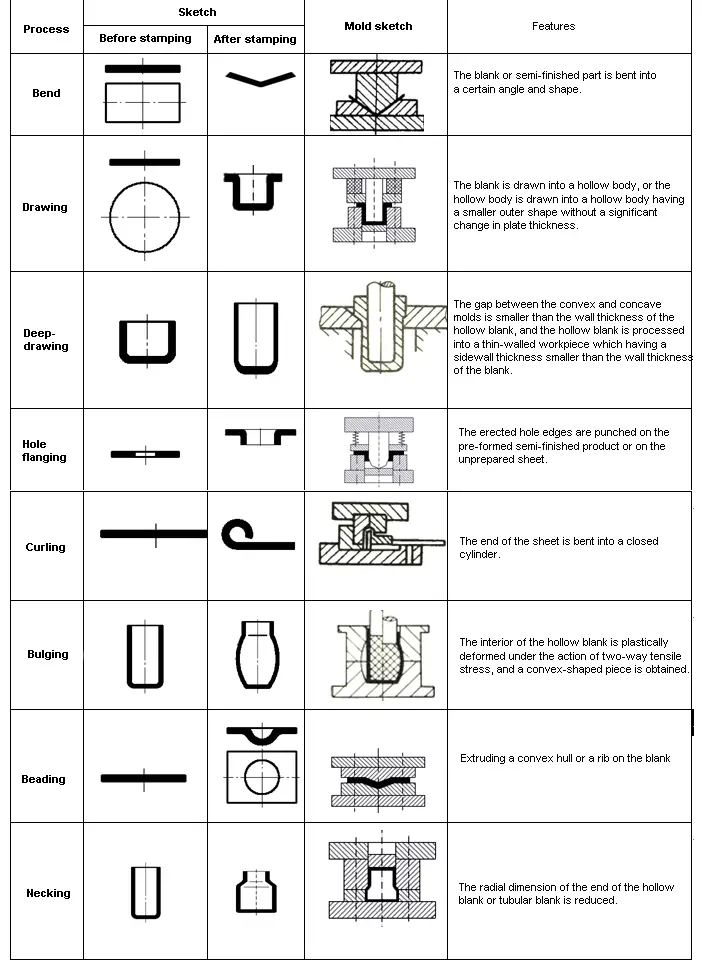

(2)Metal forming process

During stamping, the material under the action of the external force, the equivalent stress of the material in the deformation zone reaches the yield limit σs of the material, but does not reach the strength limit σb, so that the material only plastically deforms, thus obtaining parts of certain shape and size.

The forming process mainly includes bending, deep drawing, turning, shrinking, bulging, etc.

The forming process is shown as follows:

Only change the shape of the blank, no separation occurs.

Table 1-2 Forming process

Basic requirements for stamping on sheets

Satisfying the performance requirements is the first, and meets the stamping process requirements as much as possible while meeting the performance requirements.

1.3.1 Process requirements for stamping materials

1.Stamping forming performance

Stamping forming performance refers to the ability of the sheet to adapt to the stamping process.

Two kinds of instability:

The former is like the necking phenomenon in the low carbon steel tensile test, and the latter is the instability phenomenon of the pressure bar.

Thus, there is a forming limit, which is divided into an overall forming limit and a local forming limit. The higher the forming limit, the better the press forming performance.

How to measure the stamping forming performance of the sheet?

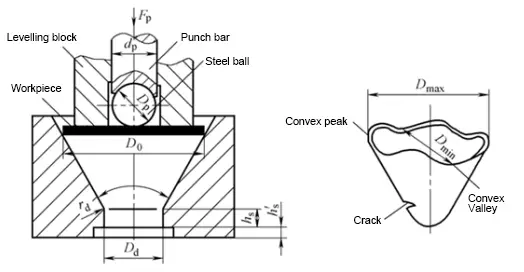

(1) Crack resistance refers to the ability of a sheet to resist damage during deformation.

(2) Pasteability refers to the ability of the sheet to conform to the shape of the mold during the press forming process.

(3) Shapeability refers to the ability of a part to retain its shape in the mold after demolding.

The stamping forming properties of the sheet can be measured by the mechanical properties of the sheet. Mechanical properties can be obtained through experiments.

Sheet metal forming performance test method:

(1) Direct test method

Like cone cup test(GB/T 15825.6-2008)

(2) Indirect test method

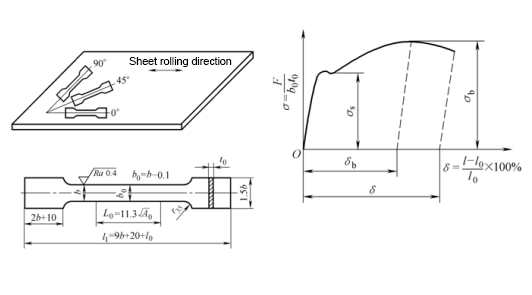

Such as tensile test of low carbon steel, etc.

Mechanical indicators affecting press forming properties

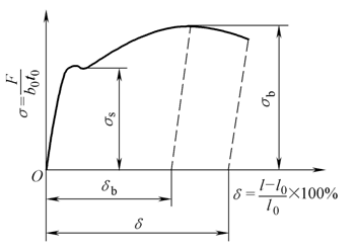

(1) Total elongation δ and uniform elongation δb

δ is good → Allows for large plastic deformation

(2) Yield ratio σs /σb

σs/σb is small → good crack resistance, shape fixing, and good moldability

(3) Modulus of elasticity E

Large elastic modulus E → good shape

(4) Hardening index n

n is large → not easy to crack

(5) Plastic strain ratio γ

γ = εb /εt is big → Good resistance to cracking

(6) Plastic strain specific anisotropy coefficient

Δγ =(γ0 +γ90 – 2γ45 )/2 is big → The more different the anisotropy

1.3.2 Common stamping materials and cutting methods

A.Common stamping materials

Related reading: Ferrous vs Non-ferrous Metals

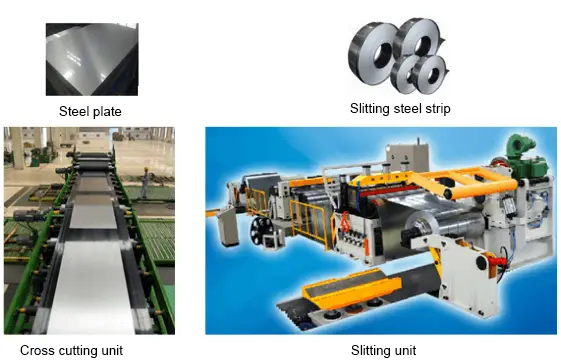

Metal sheet specifications: steel strip, steel plate, slit steel strip, etc.

Size range of steel plates and strips (GB/T708-2006)

1) The nominal thickness of steel plate and steel strip (including slitting steel strip) is between 0.3mm and 4.0mm, and the steel plate and steel with nominal thickness below 1mm have any size in multiples of 0.05mm; the nominal thickness is above 1mm. Steel plates and steel are available in any size in multiples of 0.1 mm.

2) The nominal width of steel plates and steel strips is between 600mm and 2050mm, and there are any sizes in multiples of 10mm.

3) The nominal length of the steel plate is between 1000mm and 6000mm, and any size in multiples of 50.

4) According to the requirements of the purchaser, steel plates and strips of other sizes can be supplied through negotiation between the supplier and the buyer.

(1) Shearing machine cutting

(2) Disc shearing

(3) Other cutting methods

Selection principle of stamping equipment:

Stamping equipment type:

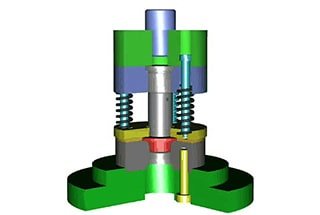

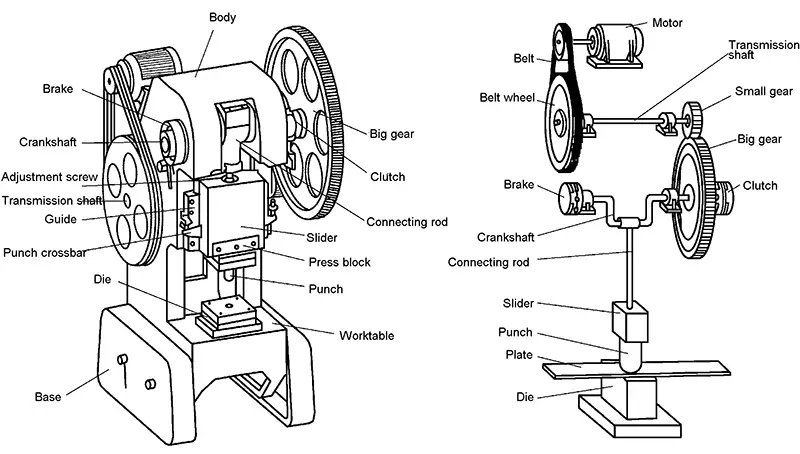

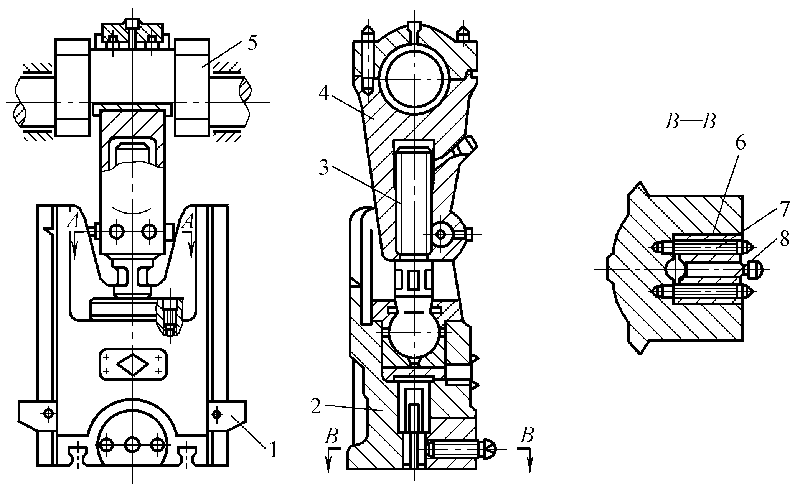

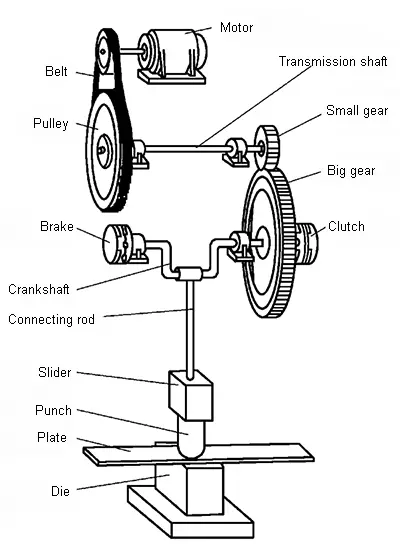

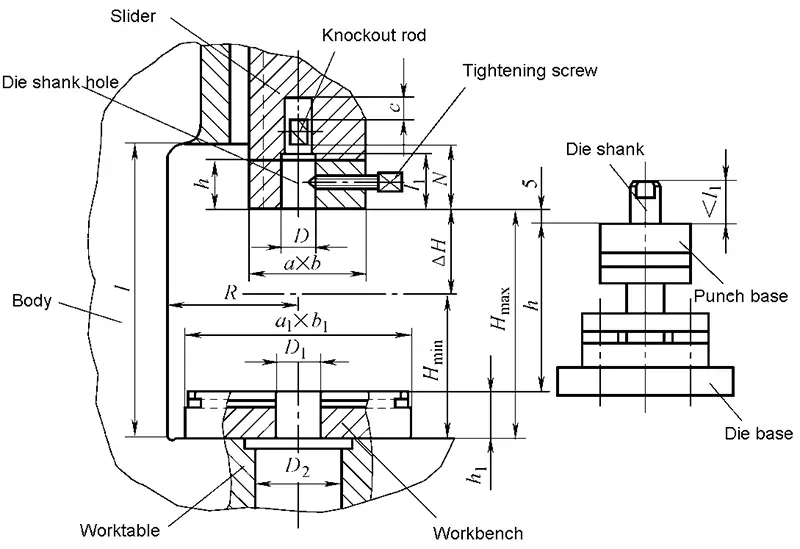

Working principle and main components of crank press

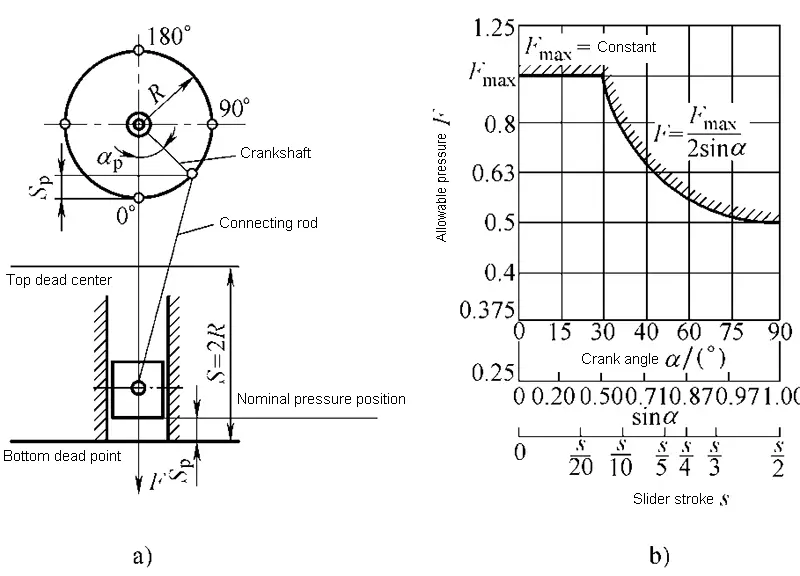

(1) Working mechanism

Crank and link mechanism: The crank link mechanism is composed of a crankshaft, a connecting rod and a slider. The length of the connecting rod can be adjusted to suit different sizes of molds.

Motor, belt, flywheel, gear, etc.

(3) Operating system

Air distribution system, clutches, brakes, electrical control boxes, etc.

(4) Supporting parts

Body: open, closed

(5) Auxiliary system

Pneumatic system, lubrication system

(6) Attachment

Press model and technical parameters

(1) Model

1) Forging machine type:

2) Crank press code description JB23-63A

(2) Technical parameters

Different materials have different plasticity under the same deformation condition, and the same material will have different plasticity under different deformation conditions.

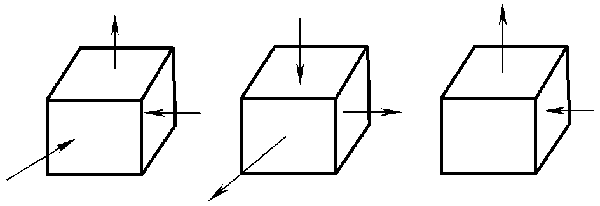

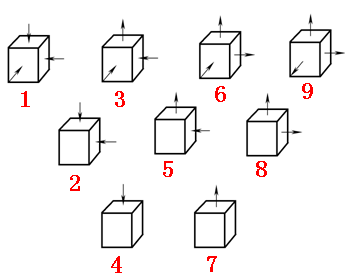

3 main strain states:

9 types of principal stress states:

Now, let’s dive into the following four fundamental metal stamping processes, each playing a crucial role in modern manufacturing:

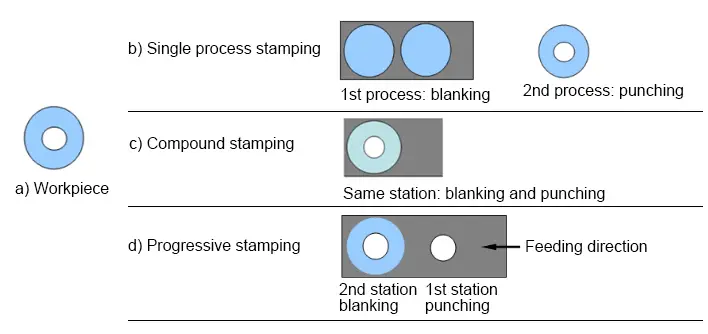

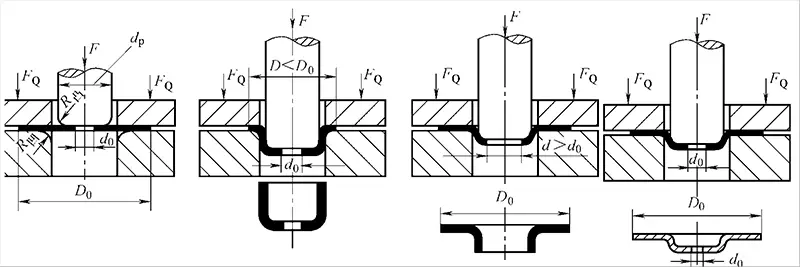

Blanking is a precision cutting operation where a flat piece of metal is separated from a larger sheet. This process utilizes a die and punch to create a two-dimensional shape, often serving as the initial step for subsequent forming operations. The resulting piece, called a blank, can be the final product or undergo further processing.

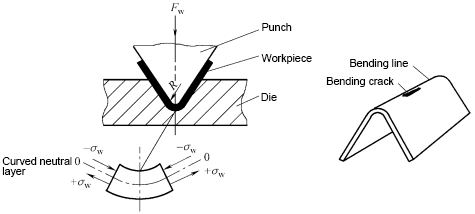

Bending involves the plastic deformation of metal along a straight axis, creating angles, U-shapes, or V-shapes. This process employs various techniques such as air bending, bottoming, and coining, each offering different levels of precision and force control. The choice of bending method depends on factors like material properties, desired bend angle, and production volume.

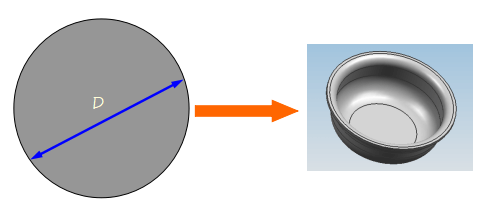

Deep Drawing is a complex forming process that transforms a flat metal blank into a hollow, three-dimensional shape. This technique is widely used in manufacturing items like automotive body panels, beverage cans, and kitchen sinks. The process involves drawing the material into a die cavity using a punch, often requiring multiple stages for intricate shapes. Careful consideration of material flow, lubrication, and die design is crucial to prevent defects like wrinkling or tearing.

Forming encompasses a variety of operations that shape metal without significantly altering its thickness. This includes processes like embossing, coining, and stretching. Forming operations can create complex geometries, add structural rigidity, or impart decorative features to the workpiece. Advanced techniques like hydroforming and rubber pad forming allow for the creation of intricate shapes with improved material distribution and surface finish.

Click the link below to learn all the details: