This blog post explores the fascinating world of pipe bending techniques. As a seasoned mechanical engineer, I’ll share my insights on various methods used to shape pipes for diverse applications. Discover the science behind creating smooth curves and precise angles that make pipe systems efficient and aesthetically pleasing.

Conventional mandrel-free bending refers to a non-filling bending method that is commonly used in room temperature production.

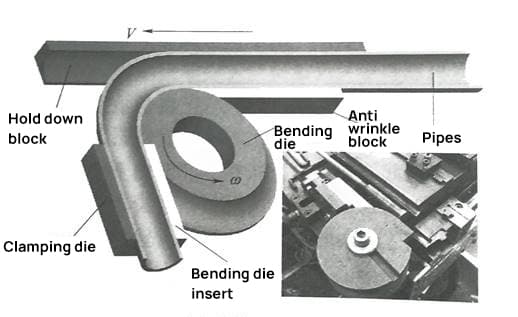

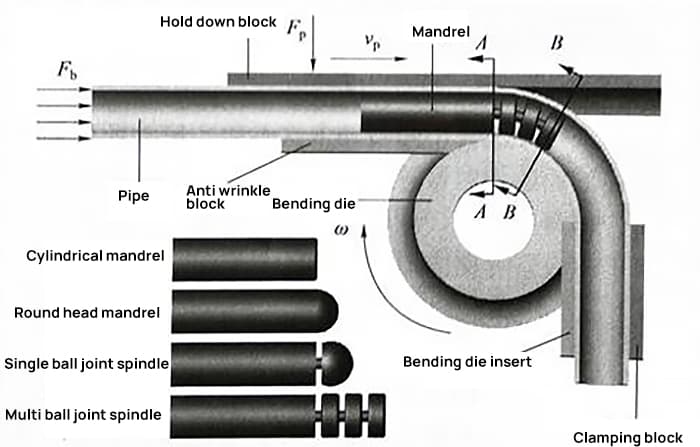

The primary bending die and principle are illustrated in the figure below. This technique involves stretch bending, press bending, bypass bending, push bending, and roll bending processes.

Main bending die and bending principle

Related reading: The Ultimate Guide to Pipe Bender

Tube bending can be achieved by adding an axial tension based on pure bending moment. This can generally be categorized as tension bending and rotary traction bending.

All stretch bending processes share a common characteristic. The additional tensile stress reduces a portion of the tangential compressive stress on the concave side during pure bending. This results in the suppression of wall thickness and wrinkling in the bend. However, the possibility of wall thickness thinning or even cracking on the convex side of the bend inevitably increases.

(1) Stretch bending

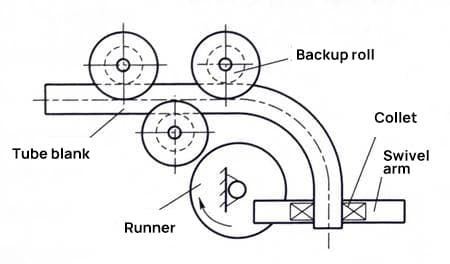

The simplified working principle of a common stretch bending forming is shown in the figure below.

During tube bending, the tube blank is passed through three horizontal support rollers and secured to the rotary arm via a chuck. When the rotary arm rotates, it drives the tube blank to undergo bending deformation.

The radius of curvature of the bend can be altered during stretch bending forming by adjusting the distance between the support roll and the chuck, as well as the axis of the runner.

If a heating device is installed prior to the tube blank entering the bending zone, such as a medium-frequency induction current for preheating the tube blank, its plastic deformation ability can be enhanced. This enables the realization of heating stretch bending forming.

Simplified working principle of four common stretch bending forming

(2) Slewing traction bending

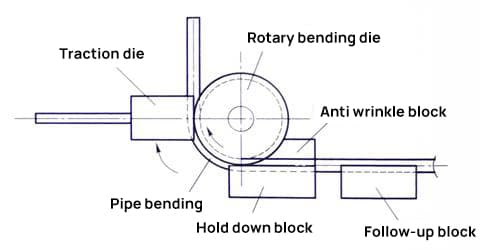

The figure below illustrates rotary traction bending, in which each working part of the bending die has a groove that matches the shape of the pipe.

The length of the cross-section curve is slightly less than the semicircle of the pipe blank. It is used to clamp or press the pipe blank during bending.

The bending radius can be changed by replacing the rotary bending die.

The tube blank is pressed against the rotary bending die that can rotate around the axis by the traction die and the clamping block.

The traction die rotates on the circular arc track with a fixed radius and the axis of the rotary bending die, which drives the tube blank to rotate with the rotary bending die under the radial pressure and tangential friction of the clamping block to achieve bending forming.

Due to the increase in the tangential stretch deformation of the tube blank on the convex side of bending, it has the property of stretch bending.

Currently, most pipe bending equipment and CNC pipe bending machines in production operate based on the principle of rotary traction bending.

CNC pipe bender rotary traction bending

Compression bending is the counterpart of tension bending, which is achieved through the joint action of additional or derived axial thrust and bending moment in tube bending.

The additional axial thrust can reduce or counteract the tangential tension on the convex side of the bend, thereby preventing the wall thickness of the bend from thinning or cracking. However, the increase in tangential compression stress on the concave side of the bend can cause the pipe wall to thicken or even wrinkle.

Tube compression bending is mainly categorized into compression bending, rotary compression bending, and axial force bending.

(1) Press Bending

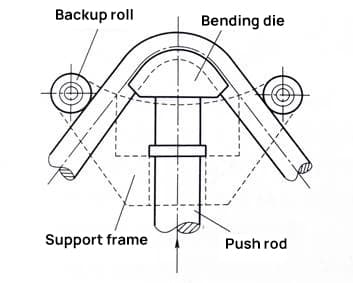

Pipe bending, as illustrated in the figure below, is similar to sheet V-bending and is used to bend and shape medium and small diameter elbow products with straight pipe segments.

The bending die and support roller have a working groove with the same diameter as the pipe and slightly smaller than the semicircle.

The bending die, consolidated with the push rod and with a specific bending radius, pushes the pipe blank out and rolls two bending forms between the support rollers on both sides.

Replacing the bending die can change the bending radius of the pipe, while the size of the two bending internal angles is determined by the pushing out stroke of the bending die.

Tube bending boasts high production efficiency, and the die adjustment is simple.

However, the disadvantage is that the bending force applied during bending is concentrated between the two support rollers. The initial contact between the tube blank and the bending die is likely to distort the travel section, affecting the bending quality.

(2) Rotary compression bending

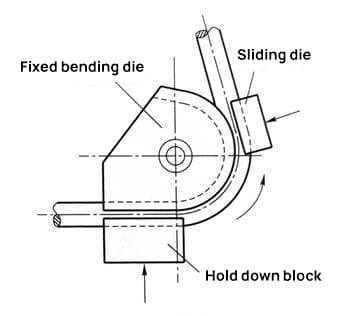

Rotary compression bending is similar in form to rotary traction bending, but the mechanism for bending the pipes is different.

As shown in the figure below, during the bending process, the sliding die or roller applies radial pressure to the tube blank while rotating around the axis of the fixed bending die, gradually forcing the straight tube blank to adhere to the groove surface of the fixed bending die under tangential friction to bend and form.

Unlike rotary traction bending, the bending deformation zone is generated between the sliding die and the fixed bending die. The surface of the convex tube blank is always subject to the combined action of radial pressure and tangential friction, which can to some extent reduce the tangential tensile deformation of the convex tube blank.

(3) Axial force push bending

The mold shown in the figure below consists of two halves that are centered by the bending plane.

Under the axial thrust of the die, the tube blank is forced to be bent and formed by pressing into the mold cavity after passing through the guide sleeve.

The bending deformation process of the tube blank in the mold is complex. In addition to being subjected to the bending torque, it is also subjected to the axial thrust and the friction force opposite to its running direction.

Push bending is different from ordinary bending, as the neutral layer of the pipe wall strain may move to the outside of the bending, which helps to alleviate thinning of the outside wall.

To avoid wrinkling or twisting inside the elbow, the relative wall thickness of pipe pushing bending should be greater than 0.06.

To reduce friction, it is often necessary to lubricate the tube blank or bending mold cavity.

For thin-walled elbows, push bending with a core is usually adopted to avoid buckling and wrinkling.

Apart from the methods mentioned above, there are also detour bending, roll bending, and others.

However, most of these methods may not meet the stringent requirements for bending accuracy and quality. Therefore, they are typically utilized for bending pipe fittings that do not require high precision in terms of their shape and size.

(1) Tube bending forming

Pipe bending is a common manufacturing process that can be performed manually or by using a pipe bender machine.

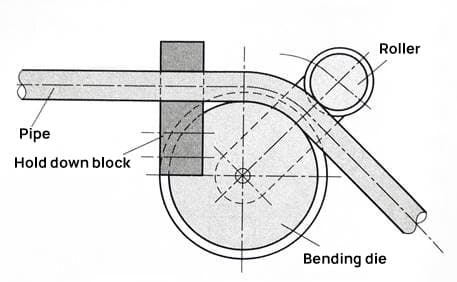

Bypass bending, as shown in the diagram below, is similar to rotary compression bending, except that rolling friction occurs between the working groove of the roller and the surface of the tube blank.

During the bending process, one end of the tube blank is clamped in the clamping head of the bending die, while the side pressing wheel presses it against the groove surface of the bending die and rotates around the bending die. The clamping head also rotates along with the tube blank.

(2) Tube roll forming

Tube roll bending is commonly used for bending thick-walled tubes, as depicted in the diagram below.

The tube blank is placed between three or more rollers, each having a groove with an inner diameter slightly larger than the outer diameter of the tube and a section circumference slightly smaller than the semicircle of the tube blank.

Each roller rotates and moves in different directions, which allows the tube blank to be rolled into a specific bending shape. Multi-roll bending can enhance the bending accuracy of tubes, reduce the distortion of the bending cross-section, and improve the degree of uniform bending deformation of the tube.

Although primarily used for thick-walled tube bending, it can sometimes be utilized for bending thin-walled tubes as well.

(a) Schematic diagram of asymmetric three roll bending

(b) Schematic diagram of side roll swing four roll bending

Tube filling bending, also known as mandrel bending, is a common process for bending medium to large diameter thin-walled tubes.

To minimize or eliminate defects such as cross-sectional flattening, wall collapse, and wrinkling during the bending process, a method called filling bending is used. This involves filling various mandrels or fillers into the tube blank to be bent to provide support during the bending process.

Mandrel bending is a bending process that provides precise control over the cross-sectional shape of elbows.

The key difference between mandrel bending and ordinary mandrel-free bending is that a mandrel is pre-placed inside the tube blank during the bending process.

In actual production, mandrels or mandrel rods are categorized into two types: rigid mandrels and solid flexible mandrels.

Rigid mandrels include round head mandrels, spoon-shaped mandrels, and bullhorn mandrels.

Flexible mandrels include single-section flexible mandrels and multi-section flexible mandrels.

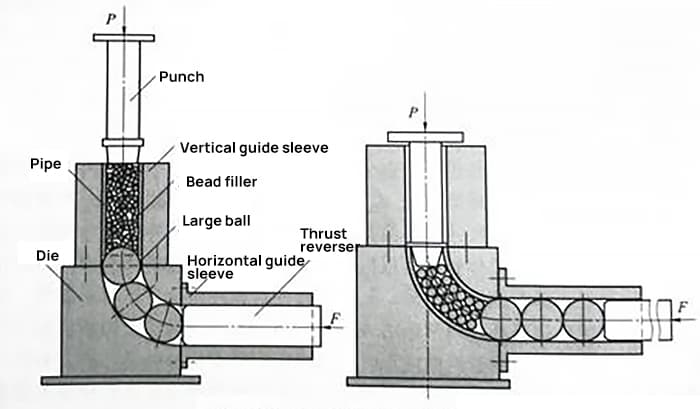

Solid particle filling and push bending forming is a common process for bending thin-walled members or elbows with small wall thickness.

Traditionally, quartz sand was used as filler, but it has been gradually replaced by resin particles or metal beads.

Before the push bending process, large diameter balls slightly smaller than the outer view of the tube blank are placed in the bending die to prevent the bead filler from slipping. Then, the tube blank is filled with small diameter beads.

During push bending, the slider of the press drives the push bending punch to extrude the bead filler in the tube blank. However, it should be noted that solid particles cannot be considered as a continuous medium and their flow deformation under pressure cannot be approximated to a constant volume.

Moreover, the use of hard steel balls may cause defects such as indentation on the inner wall of the elbow.

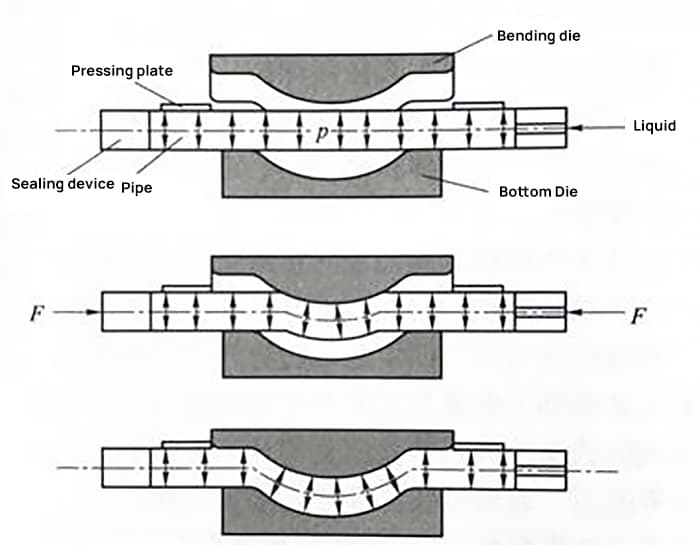

The filling and bending method of using liquid as a filler for pipes has been developed, with two relatively mature processes: pipe punching hydraulic bending and pipe punching and feeding push bending.

While liquid filling bending overcomes some of the shortcomings of solid particle filling bending, medium sealing remains a technological challenge.

In the process of liquid filling bending, a curable liquid is injected into the tube blank while it is in liquid state. Once both ends are sealed, the liquid substance solidifies and becomes an integral filler that is used for bending.

Solidified filler materials can include water, rosin, low melting point alloy, and various types of resins.

Heating bending is an advanced metal forming technique employed when conventional cold bending methods are inadequate for achieving complex geometries or when working with high-strength alloys. This process leverages thermal energy to enhance the material’s plasticity, reducing the required bending force and minimizing springback effects.

The procedure typically encompasses three critical stages: controlled heating, precision bending, and regulated cooling. The heating phase can be accomplished through various methods, each offering distinct advantages:

The choice of method depends on factors such as material properties, desired bend radius, production volume, and quality requirements. Advanced process control systems and computer simulations are often employed to optimize heating patterns, bending forces, and cooling rates, ensuring consistent product quality and minimizing material waste.