How can you produce high-quality threads efficiently? Thread milling offers three distinct methods: arc cutting for smooth, precise results, radial cutting for simplicity, and tangential cutting for external threads. This article explores these methods, their applications, and tips for optimizing each to improve your machining processes and achieve perfect threads every time. Dive in to discover which thread milling method suits your needs and learn how to implement it effectively.

To perform thread milling, the machine tool must have the capability for three-axis linkage.

CNC machines have the capability for spiral interpolation, which is controlled by the machine tool to produce the spiral path.

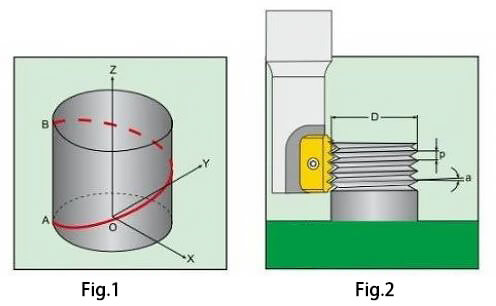

Spiral interpolation is created by the combination of plane arc interpolation and linear motion perpendicular to the plane.

For example, the spiral path from point A to point B (as shown in Figure 1) is produced by combining the X-Y plane arc interpolation motion with the linear Z axis motion.

Most CNC systems can achieve this function using two different commands:

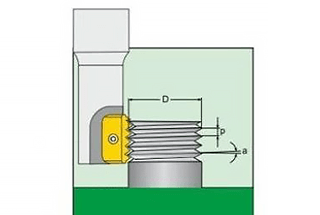

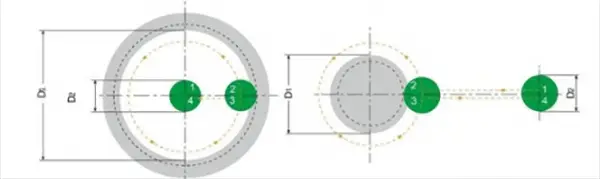

The display of thread milling motion (as shown in Figure 2) is produced by the rotation of the tool and the spiral interpolation motion of the machine tool.

During the egger circle interpolation process, the shape of the tool is used to process the required thread by combining the movement of the tool moving along the z-axis direction with the egger pitch.

There are three cutting methods that can be used for thread milling: arc cutting method, radial cutting method, and tangential cutting method.

With this method, the cutting tool cuts smoothly, resulting in no visible cutting marks and reducing vibrations even when machining hard materials.

However, the programming of this method is more complex compared to the radial cutting method.

It is recommended to use this method when producing precise threads.

This method is the simplest, but there may be two situations that arise:

To avoid vibration during close-to-full-tooth cuts, it is recommended to reduce the feed rate to 1/3 of the spiral interpolation feed rate as much as possible.

This method is straightforward and has the benefits of the arc cutting method, but it is only suitable for milling external threads.