Imagine fusing two very different metals seamlessly. This article unveils seven effective methods for welding brass and red copper, metals known for their unique properties and challenges. From gas welding to argon arc welding, discover the techniques, tools, and tips necessary for achieving perfect welds. By the end, you’ll understand how to handle these metals with confidence, ensuring strong, high-quality joints in your projects. Dive into the world of welding and elevate your skills with these essential insights.

Brass

Brass is a versatile copper-zinc alloy renowned for its distinctive golden hue. Standard brass comprises primarily copper and zinc, while specialty brasses incorporate additional elements such as lead, tin, manganese, nickel, iron, and silicon to enhance specific properties.

The copper content in brass typically ranges from 62% to 68%, resulting in a melting point between 934°C and 967°C (1713°F to 1773°F). This composition confers excellent wear resistance and favorable mechanical properties, making brass an ideal material for pressure vessel fabrication and other demanding applications.

Specialty brasses exhibit superior strength, hardness, and chemical corrosion resistance compared to standard alloys. These enhanced properties make them particularly suitable for manufacturing seamless pipes used in critical applications such as heat exchangers, condensers, cryogenic pipelines, and subsea transportation systems.

The versatility of brass extends beyond piping applications. Its excellent formability and machinability make it an optimal choice for producing sheet metal, bars, precision castings, and intricate components. The high copper content contributes to brass’s exceptional plasticity, enabling complex forming operations often required in pressure equipment manufacturing.

Furthermore, brass offers additional advantages such as antimicrobial properties, electrical conductivity, and acoustic characteristics, expanding its utility across various industries. Modern alloying techniques and heat treatments allow for tailored brass compositions to meet specific performance requirements, ensuring its continued relevance in advanced engineering applications.

Red copper

Red copper, also known as industrial pure copper or electrolytic tough pitch (ETP) copper, is a high-purity copper alloy composed of at least 99.90% copper. Its distinctive reddish-orange color is a result of its high copper content and the formation of a thin oxide film on its surface when exposed to air.

With a melting point of 1084.62°C (1984.32°F), red copper maintains excellent thermal stability without undergoing phase transformations. Its density is approximately 8.94 g/cm³ at 20°C, making it significantly denser than many common structural materials. For comparison, it is about 4.9 times denser than magnesium (1.738 g/cm³) and approximately 14% heavier than mild steel (7.85 g/cm³).

The surface of red copper readily forms a protective oxide layer when exposed to oxygen, resulting in its characteristic reddish-orange appearance. This natural patina, primarily composed of copper(I) oxide (Cu2O), not only contributes to its aesthetic appeal but also provides some corrosion resistance. The oxygen content in red copper typically ranges from 0.02% to 0.04% by weight, which is intentionally maintained to enhance certain mechanical and electrical properties, such as improved ductility and electrical conductivity.

The methods for welding brass include gas welding, carbon arc welding, manual arc welding, and argon arc welding.

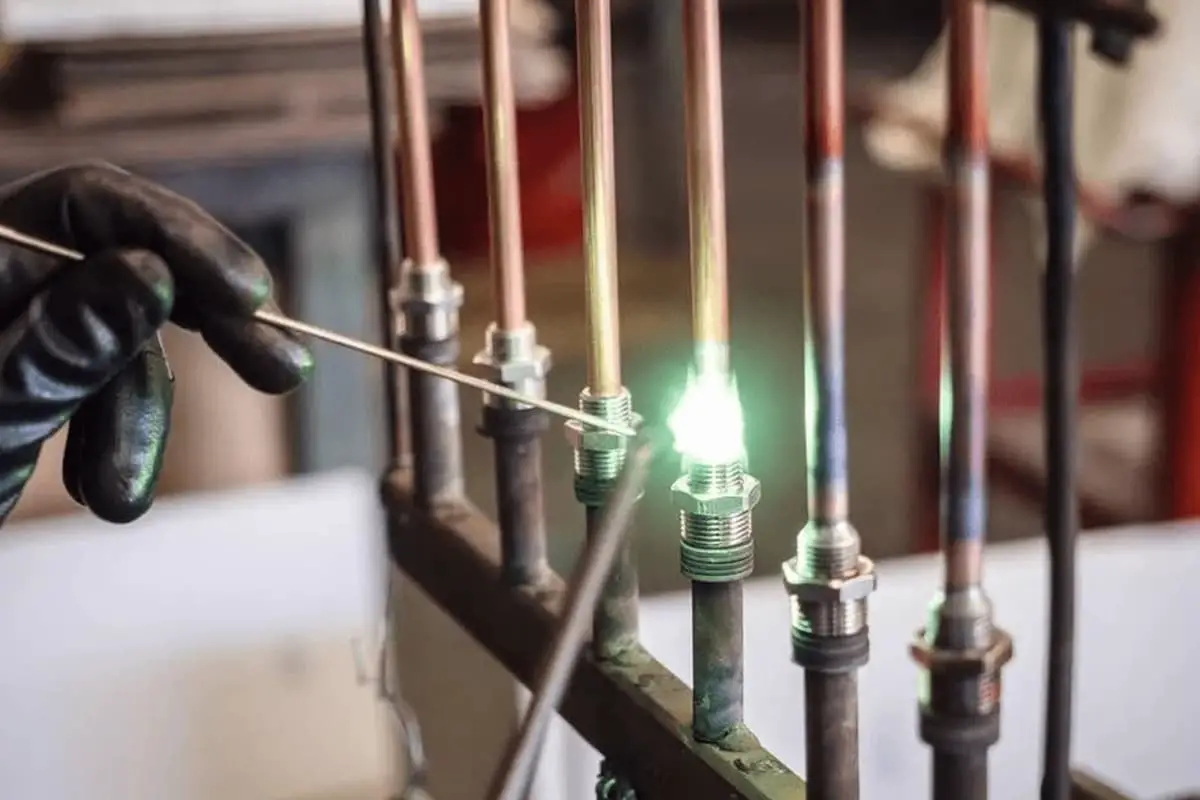

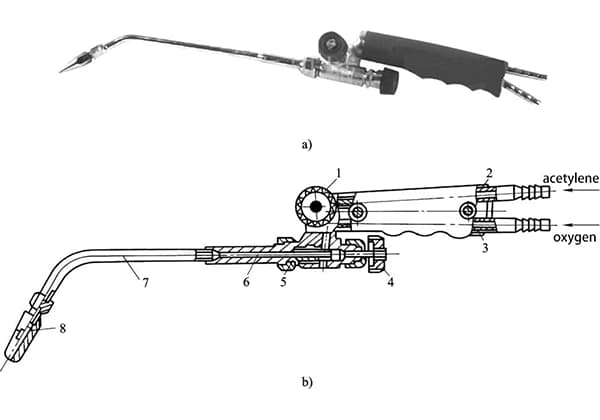

Gas welding remains the preferred method for joining brass components due to its lower flame temperature compared to electric welding processes. This characteristic significantly reduces zinc volatilization, a critical concern when working with brass alloys.

The selection of appropriate filler materials is crucial for successful brass gas welding. Commonly used welding wires include grades 221, 222, and 224. These alloys are specifically formulated with elements such as silicon (0.15-0.5%), tin (0.5-1%), and iron (0.1-0.5%). These additives serve multiple purposes:

Two types of flux are essential for brass gas welding:

Proper flux application is critical for:

When performed correctly, gas welding of brass can produce high-quality, corrosion-resistant joints with excellent mechanical properties and minimal distortion.

Manual arc welding of brass requires specific techniques and considerations due to the material’s unique properties. In addition to commercially available electrodes such as copper 227 and copper 237, custom-made electrodes can be effectively utilized for brass welding. For optimal results, it is recommended to use a DC power supply with straight polarity configuration – connecting the positive electrode to the workpiece and the negative electrode to the welding rod.

Prior to welding, thorough surface preparation is crucial. The workpiece surface must be meticulously cleaned to remove any oxides, contaminants, or organic residues that could compromise weld integrity. To ensure proper weld penetration and fusion, the groove angle should be precisely machined between 60 to 70 degrees.

Preheating the workpiece to a temperature range of 150 to 250°C is essential to mitigate thermal shock and reduce the risk of cracking. This preheating process also helps to lower the cooling rate, thereby minimizing internal stresses in the weldment.

During the welding process, maintaining a short arc length is critical to control heat input and minimize zinc vaporization, a common issue in brass welding. The welding technique should employ a linear movement without any transverse or oscillatory motions. A relatively high welding speed is recommended to prevent excessive heat accumulation and maintain optimal weld pool fluidity.

For brass weldments exposed to corrosive environments, such as seawater or ammonia-rich atmospheres, post-weld heat treatment is imperative. Annealing the welded component after welding helps to relieve residual stresses, homogenize the microstructure, and enhance the overall corrosion resistance of the joint.

It is worth noting that proper ventilation and personal protective equipment are essential during brass welding to mitigate the risks associated with zinc fume exposure. Additionally, monitoring and controlling the interpass temperature can further improve weld quality and mechanical properties.

For manual TIG welding of brass, specialized filler materials such as AWS A5.7 ERCuSi-A (wire 221), ERCuSn-A (wire 222), and ERCuAl-A1 (wire 224) are commonly employed. These alloys are designed to match the composition and mechanical properties of various brass grades. Alternatively, autogenous welding or using filler materials with a composition identical to the base metal can be utilized for optimal metallurgical compatibility.

Both Direct Current Electrode Positive (DCEP) and Alternating Current (AC) can be applied in this process. AC welding is often preferred as it minimizes zinc volatilization compared to DCEP, thereby reducing porosity and maintaining the alloy’s composition. The balance between electrode positive and negative half-cycles in AC welding can be adjusted to optimize cleaning action and heat input.

Preheating is generally not required for brass TIG welding due to the alloy’s good thermal conductivity. However, for components with significant thickness variations (typically exceeding a 4:1 ratio) or for large, complex assemblies, preheating to 150-200°C may be necessary to prevent thermal shock and ensure uniform heat distribution.

To achieve optimal weld quality, it is crucial to maintain a high travel speed while ensuring adequate fusion. This approach minimizes the heat-affected zone (HAZ) and reduces the risk of dezincification in zinc-rich brass alloys. Proper shielding gas flow (typically pure argon at 10-15 L/min) is essential to protect the weld pool from atmospheric contamination.

Post-weld heat treatment is recommended to alleviate residual stresses and enhance the mechanical properties of the weldment. Annealing at 300-400°C for 1-2 hours, followed by slow cooling, effectively relieves welding stress, improves ductility, and mitigates the risk of stress corrosion cracking during service. For critical applications, solution annealing at higher temperatures (650-750°C) may be considered to fully homogenize the microstructure, followed by rapid quenching and age hardening if required.

Carbon arc welding of brass requires careful selection of filler materials and welding techniques to ensure optimal joint quality and minimize zinc loss. The choice of welding wire depends on the base metal composition, with options including wire 221 (high copper content), wire 222 (balanced copper-zinc ratio), and wire 224 (higher zinc content). For specialized applications, custom-made brass welding wires can be formulated to match specific alloy requirements.

To protect the weld pool and improve arc stability, gas flux 301 is recommended. This flux helps to control oxidation, reduce porosity, and enhance weld bead appearance.

Short arc welding is the preferred technique for brass carbon arc welding. This method minimizes heat input, reducing zinc evaporation and burning loss, which are critical concerns when welding brass alloys. The lower heat input also helps to control distortion and maintain the mechanical properties of the base metal.

To further optimize the welding process:

By carefully controlling these parameters, high-quality brass welds with minimal zinc loss and optimal mechanical properties can be achieved using the carbon arc welding process.

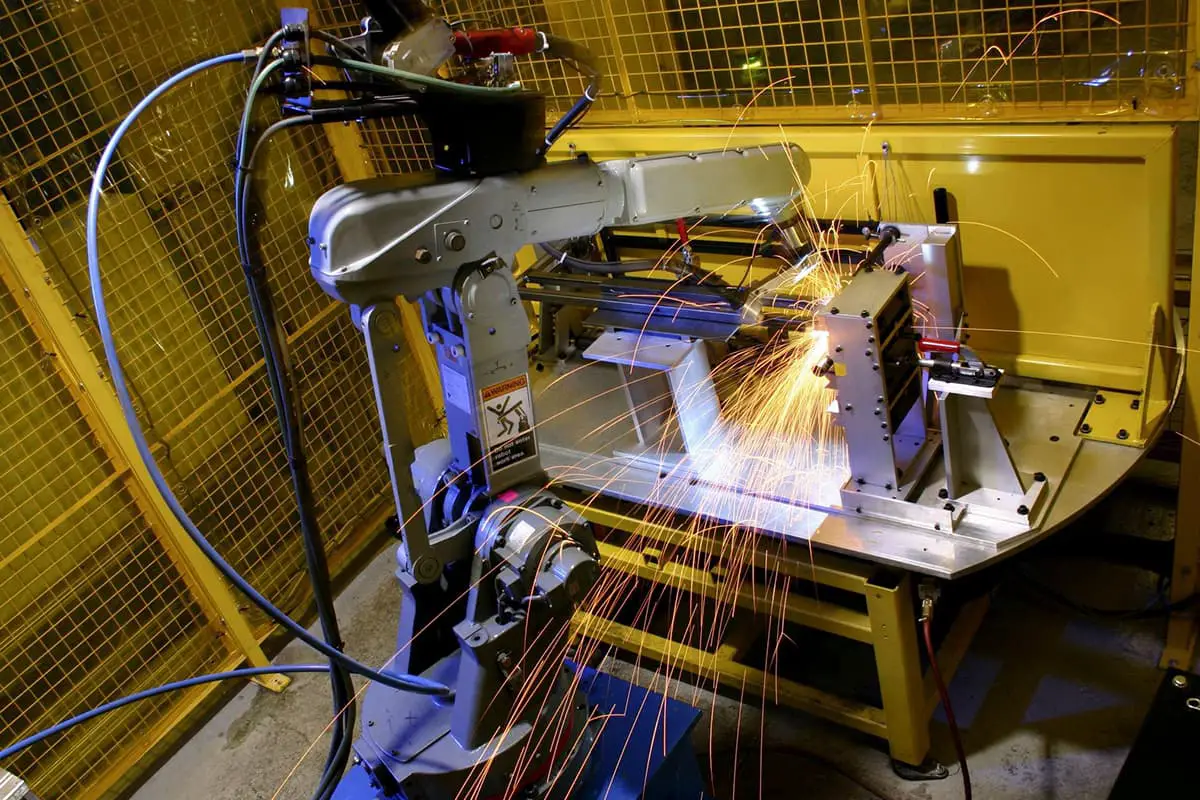

Red copper, also known as industrial pure copper or oxygen-free copper (OFC), can be joined using various welding techniques, each suited to specific applications and production scales. For small to medium-sized components, gas welding and manual arc processes are often employed, while automated methods are preferred for larger structures or high-volume production.

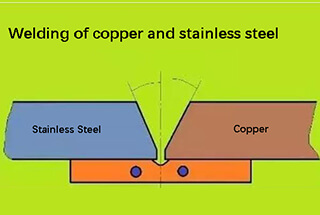

Butt joints are the preferred method for welding red copper, offering optimal strength and minimal distortion. Lap joints and T-joints are employed only when necessitated by specific design requirements or accessibility constraints. For gas welding of red copper, two primary options exist for filler materials:

A neutral flame, characterized by a balanced ratio of oxygen to acetylene, is crucial for gas welding red copper. This flame type maintains a temperature of approximately 3200°C (5792°F) and prevents both oxidation and carbon impregnation of the weld pool. Proper flame adjustment is essential, as an oxidizing flame can lead to porosity and reduced joint strength, while a carburizing flame may cause brittleness in the weld.

When performing gas welding on red copper, it’s important to preheat the workpiece to about 300-500°C (572-932°F) to reduce thermal gradients and minimize the risk of cracking. Additionally, maintaining cleanliness of the joint surfaces and controlling heat input are critical factors in achieving high-quality welds in this highly thermally conductive material.

In manual arc welding of red copper, ERCu or ECu welding rods (e.g., copper 107) are utilized with a matching red copper (T2, T3) base metal. Prior to welding, thorough cleaning of the joint edges is crucial to remove oxides and contaminants, ensuring optimal weld quality.

For workpieces exceeding 4mm in thickness, preheating is essential to prevent thermal shock and reduce the risk of cracking. The recommended preheat temperature range is 400 to 500°C, which should be monitored using a calibrated pyrometer. Welding should be performed using a DC reverse polarity (DCEP) power source to enhance arc stability and penetration.

During the welding process, maintain a short arc length to minimize heat input and oxidation. The electrode should be manipulated in a straight line without lateral movement. A slight reciprocating motion can improve weld pool control and fusion. For extended welds, employ the back-step welding technique to manage heat distribution and reduce distortion.

Welding speed should be optimized to balance heat input and weld quality. Faster speeds generally produce better results in copper welding, as they limit the heat-affected zone (HAZ) and reduce the risk of porosity.

In multi-pass welding, thorough inter-pass cleaning is critical. Remove all slag and oxides between layers using a stainless steel wire brush to prevent inclusions and ensure proper fusion.

Adequate ventilation is paramount when welding copper to prevent exposure to potentially harmful fumes. Use local exhaust ventilation or wear appropriate respiratory protection to mitigate the risk of copper poisoning.

Post-weld treatment involves stress relief through peening. Gently hammer the weld bead while it’s still hot to induce compressive stress, which can help counteract shrinkage stresses and improve weld mechanical properties. However, exercise caution to avoid excessive deformation or cracking.

For critical applications, consider post-weld heat treatment (PWHT) to further relieve residual stresses and optimize the microstructure of the weld and HAZ.

Related reading: How to Choose the Right Welding Rod?

In manual TIG welding of red copper, specialized filler wires such as ER Cu (wire 201), ERCu-A1 (wire 202), and T2 red copper wire are employed. Prior to welding, it is crucial to meticulously clean the welding edges and filler wire surfaces to remove oxide films, oils, and other contaminants. This preparation prevents defects like porosity and slag inclusions, which can compromise weld integrity. Cleaning can be accomplished through mechanical methods (e.g., wire brushing, grinding) or chemical processes (e.g., acid pickling).

Joint preparation varies with material thickness. For thicknesses below 3mm, a square butt joint suffices. Plates 3-10mm thick require a single V-groove with a 60-70° included angle. For thicknesses exceeding 10mm, an X-groove (double V) with 60-70° angles is recommended. Sharp edges are preferred over blunt ones to ensure full penetration. The root gap for butt joints should be precisely controlled, ranging from 0.5 to 1.5mm, correlating with plate thickness and groove geometry to optimize fusion and minimize distortion.

TIG welding of red copper typically utilizes Direct Current Electrode Positive (DCEP) polarity, with the tungsten electrode connected to the positive terminal. This configuration promotes oxide removal and enhances weld pool fluidity. To mitigate porosity and ensure reliable fusion, particularly at the weld root, it’s essential to:

Preheating temperatures should be carefully controlled: 150-300°C for thicknesses under 3mm, and 350-500°C for thicker sections. Excessive preheating must be avoided as it can degrade the mechanical properties of the welded joint through excessive grain growth and potential precipitation hardening in certain copper alloys.

The welding process should be executed with precise heat input control, maintaining a short arc length and employing a slight backward torch angle to improve penetration and reduce oxidation. Post-weld heat treatment may be necessary for thick sections to relieve residual stresses and optimize mechanical properties.

Carbon arc welding is a viable technique for joining red copper components. This process utilizes either carbon or graphite electrodes as the primary heat source, with the welding wire composition matching that used in gas welding operations. The method offers versatility, allowing for both welding and cutting of the base metal.

For optimal results, a specialized flux such as gas flux 301 is recommended. This flux aids in shielding the weld pool from atmospheric contamination, improving flow characteristics, and enhancing overall weld quality. The choice between carbon and graphite electrodes depends on specific application requirements, with graphite generally offering better arc stability and lower contamination risks.

When welding red copper using this method, it’s crucial to consider the material’s high thermal conductivity. Preheating the workpiece and maintaining proper inter-pass temperatures can help prevent heat-related defects and ensure uniform penetration. Additionally, controlling the heat input is essential to minimize distortion and maintain the copper’s desirable properties.

Proper ventilation is necessary during the welding process due to potential fume generation. Operators should also be aware of the specific challenges associated with welding copper, such as its tendency to absorb gases when molten, which can lead to porosity if not properly managed.

During equipment installation, a company needed to weld six copper tubes (model T2) with dimensions of Φ180mm×10mm. For this task, manual tungsten inert gas welding was employed with great success. The welding process steps were as follows:

1. Pre-Welding Preparation

1.1 The welding equipment used was a WSE-350 AC/DC TIG welding machine with DC positive polarity. The chosen welding material was copper welding wire (wire 201), with a diameter of 3mm. The purity of the argon gas was ≥99.96%.

1.2 The bevels were aligned with no gaps left between them.

1.3 The welding area of the copper tube and the copper wire were kept free from oil, oxidation layers, moisture, and other contaminants, and exhibited a metallic luster.

1.4 Welding parameters: A Φ3mm cerium tungsten electrode was used along with a Φ14mm nozzle. The welding current was set between 160~180A, and the argon gas flow was 15L/min.

1.5 Preheating: Due to copper’s high thermal conductivity and coefficient of thermal expansion, as well as its brittleness when heated, the bevel of the copper tube and the 60mm area on either side were preheated prior to welding. This preheating was performed using an oxy-acetylene flame, reaching a temperature of approximately 500℃. The temperature was measured with a point contact thermometer.

1.6 Two areas of the tube were tack welded (dividing the circumference of the tube into three equal parts, two of which were tack welded and one was the starting point of the weld). The tack welds had a required length ≥10mm and a suitable weld height of 3mm.

2. Welding Procedure

The welding process was done in two layers: a root run and a cap run. All welding was done in the rotational welding position, specifically between 10 and 11:30 on a clock face, with a random upward rotation during welding.

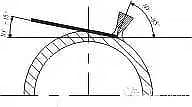

2.1 Root Run: The root run was carried out using a leftward welding technique. During welding, steps were taken to prevent the formation of gas pockets, slag inclusions, weld spatter, and incomplete penetration. The angle between the welding wire and the tube surface was kept as small as possible to improve the effectiveness of the argon shielding, as shown in Figure 7.

Ensure smooth movement of the welding gun and appropriate control of the weld pool temperature. It should be neither too high nor too low for the welding process to proceed smoothly. It is crucial to closely monitor the flow of the molten copper in the weld pool and master the timing of melting and penetration.

When the molten metal in the weld pool starts to sink slightly, it indicates penetration (with basic good root formation).

Adopt an “interrupted” wire feeding method for filler wire insertion, that is, the copper welding wire advances and retreats alternately. The wire should feed “swiftly” and retreat “cleanly”, maintaining this state while welding uniformly forward. If the welding speed is slightly slow or penetration is uneven, incomplete penetration or burn-through may occur, resulting in welding nodules. The arc striking, joint, and operation method are the same as the previously mentioned argon arc welding method.

2.2 Welding of the cover layer: The welding gun swings left and right, and the welding wire feeds with the movement of the welding gun. When the arc moves to both sides of the groove, pause slightly and add welding wire to fill the groove and rise 1.5~2mm above the tube surface. The welding gun and welding wire should cooperate appropriately and swing evenly to control the consistency of the weld pool shape and produce a weld of excellent quality inside and out.

1) During welding, “tungsten touching” (i.e., the tungsten electrode contacts the welding wire or the weld pool) is strictly forbidden. If “tungsten touching” occurs during welding, a large amount of metallic dust and vapors will enter the weld pool, resulting in numerous honeycomb-shaped pores or cracks in the weld. If “tungsten touching” occurs, stop welding, treat it by grinding clean, and replace the tungsten electrode or resharpen the tungsten tip until the metal is free of copper spots.

2) Ensure firm contact of the overlapping lines and avoid scratching the tube surface.

3) After the weld cools slightly, rotate the pipe and pad it firmly.

4) Control the interlayer temperature. If welding fusion becomes difficult, it indicates a low temperature. Reheat to above 500℃ before welding again to prevent incomplete fusion or poor fusion defects.

5) Ensure good fusion, slightly faster welding speed, and suitable wire feeding. Pay attention to the simultaneous melting of the base metal and welding wire to merge into one to prevent incomplete fusion or poor fusion defects.

6) When extinguishing the welding arc, the welding gun should not be lifted immediately. Continue to use the post-flow shielding gas function to protect the weld pool to prevent the formation of pores.

After inspection, if there are no defects such as pores, cracks, or slag inclusions, reheat the welded pipe joint’s welding area to 600~700℃, and then quench it with tap water to increase the plasticity of the welding area.

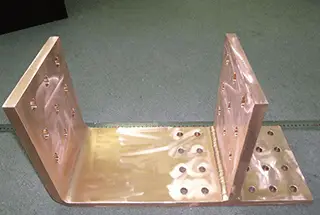

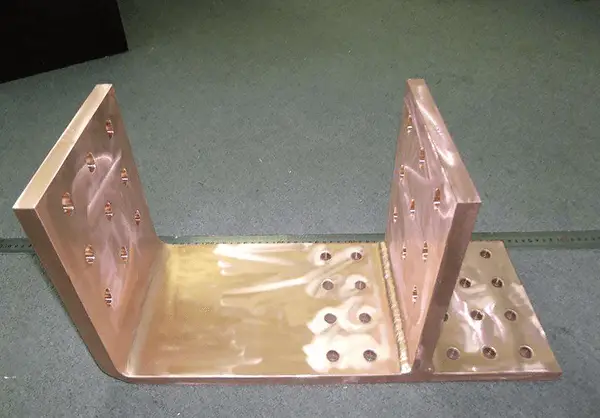

The waterstop in the cooling pool of the blast furnace is composed of δ=2mm thin purple copper sheets welded together. Welding is challenging due to the excellent thermal conductivity of copper.

Either the temperature is insufficient to form a melt pool, resulting in unmerged or poorly fused metal in the weld, or the temperature is too high, causing a large area of the welding zone to melt, resulting in welding defects such as burn-through or weld lumps. Welding thin purple copper sheets is a rather “tricky” problem.

The problem can be effectively solved by using “brass brazing” welding method. The preparations before welding and the welding operation process are as follows:

1) Decontaminate 60mm on each side of the weld seam and use a steel wire brush to polish it to reveal the metallic luster.

2) The workpieces are paired without a groove, and the pairing gap should be less than 1mm.

3) Use Ф3mm silicon brass welding wire (wire 224) with welding flux 301.

4) Level the area to be welded (the pad is made of flat steel plate, which should be thicker to prevent thermal deformation).

5) Preheat. Two welders use medium welding torches and neutral flames to heat the welding area simultaneously, reaching a temperature of 500~600℃. One person welds, and the other continues to heat the welding location to ensure the stable progress of the welding process.

6) The preheating welder uses a neutral flame, and the welding welder uses a slight oxidizing flame.

7) Spot welding and formal welding should be carried out continuously, with a spot welding distance of 60~80mm. The spot welding point should be smaller.

8) Pay close attention to the temperature changes in the welding area during heating and welding to prevent it from being too high or too low. Generally, visually judge by dark red (550~600℃).

9) The movement of the welding nozzle should be steady, and move forward at a uniform speed. The flame core (white point) should be 5~8mm above the melt pool. The outline of the flame should always cover the melt pool to avoid contact with air. Ensure the brass liquid naturally and smoothly spreads to both sides of the weld and penetrates into the gap.

10) To make the crystalline structure of the welded joint denser and improve its strength and toughness, tap the weld with a small hammer after welding.

11) Perform a leak-tightness test after welding.