Imagine welding two metals seamlessly while achieving high efficiency and minimal waste. This is the magic of MIG/MAG welding, a technique that combines advanced shielding gases with precise arc control to deliver superior welds. In this article, you will explore the principles, characteristics, and applications of MIG/MAG welding, learning how different gases and wire selections can impact weld quality. Get ready to uncover practical insights and tips that can enhance your welding projects, whether you are working with aluminum, copper, or steel.

Gas Metal Arc Welding (GMAW)

1. Definition: Gas Shielded Arc Welding that uses gas as the arc medium to protect the arc and weld area is called Gas Shielded Arc Welding, or simply Gas Welding.

2. Classification

Gas tungsten arc welding can be classified according to the shielding gas used as follows: inert gas shielded welding (MIG) (Ar, He, Ar+He), oxidizing gas mixture shielded welding (MAG) (Ar+O2, Ar+CO2, Ar+CO2+O2), and CO2 gas shielded welding.

According to the welding wire, it can be divided into solid MIG/MAG/CO2 welding wire and flux-cored welding wire (FCAW).

This chapter will focus on CO2 Gas Shielded Welding and MIG/MAG Welding.

1. The arc and molten pool are highly visible, allowing welding parameters to be adjusted according to the conditions of the molten pool during welding.

2. The welding process is easy to operate, with little or no slag, and there is basically no need to clean the slag after welding.

3. Under the compression of the protective gas flow, the heat of the arc is concentrated, resulting in a faster welding speed, smaller molten pool, narrow heat-affected zone, and less deformation of the welded workpiece.

4. It is conducive to the mechanization and automation of the welding process, especially for the mechanized welding of spatial positions.

5. It can weld magnesium, aluminum, copper, and their alloys, which are chemically active and prone to the formation of high-melting-point oxide films.

6. It can be used to weld thin plates.

7. When working outdoors, a wind barrier device is needed, otherwise the gas shielding effect may be poor or even ineffective.

8. The light radiation from the arc is very strong.

9. The welding equipment is relatively complex and more expensive than that used for shielded metal arc welding.

In the early 1950s, MIG/MAG welding was first applied to aluminum and its alloys, and later expanded to include copper and its alloys. In fact, it is suitable for almost all materials.

However, due to its high cost, it is generally used in the welding of non-ferrous metals and their alloys, as well as in the welding of stainless steel.

MIG welding uses Ar or He as the shielding gas.

MAG welding adds active gases, such as O2 and CO2, to Ar or He.

In terms of arc form, droplet transition, and arc characteristics, MAG welding is similar to argon arc welding, with active gas content generally less than 30%.

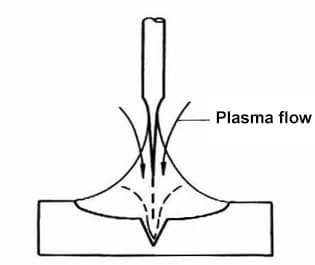

MAG welding can eliminate finger-like penetration.

Due to the presence of oxidizing gases in MAG welding, metal oxidation is unavoidable. Therefore, care should be taken to choose a welding wire that provides the necessary composition.

MAG welding is mainly used for welding high-strength steel and high-alloy steel.

(1) Shielding Gas:

Single gas: Ar or He

Mixed gas: Ar+He

(2) Requirements for Shielding Gas:

Ar gas purity: 99.9%

(3) Wire Selection:

The composition of the MIG welding wire should be similar to that of the base metal. (Metallurgical reactions are relatively simple, and alloying elements are not burned off.)

Ar+CO2+O2

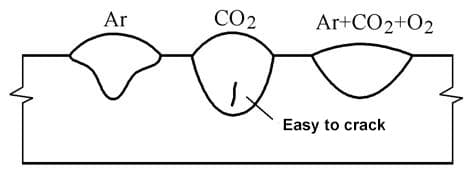

Using a mixed gas of 80% Ar, 15% CO2, and 5% O2 for welding low carbon steel and low alloy steel can result in excellent weld bead formation, joint quality, and metal droplet transfer and arc stability.

This gas mixture provides the benefits of argon and CO2 while also introducing a small amount of oxygen to improve penetration and reduce spatter.

The specific composition of the shielding gas should be carefully chosen based on the material being welded and the desired welding characteristics.

For MAG welding, high Mn and high Si welding wire should be used to supplement the burning loss.

MIG Welding:

Uses Ar or He as a shielding gas, does not have metallurgical reactions with the metal. Argon is a byproduct of oxygen production, and exceeding oxygen content can cause oxidation reactions.

MAG Welding:

Contains oxidizing gases such as O2 and CO2, causing oxidation reactions with the metal.

MIG/MAG Welding:

Alloy loss caused by evaporation.

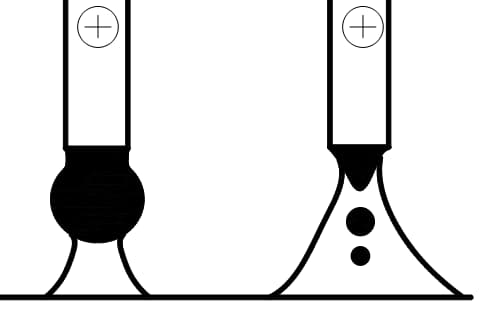

The main forms of droplet transition in MIG/MAG welding are: short-circuit transition, droplet transition, spray transition, and hyper-jet transition.

The form of droplet transition mainly depends on parameters such as current, arc length, polarity, gas medium, welding wire material, diameter, stick-out length, etc.

(1) The effect of arc length:

Under the same low current conditions, droplet transition may be particle transition or short-circuit transition. Particle transition requires a longer arc length, while short-circuit transition requires a shorter arc length.

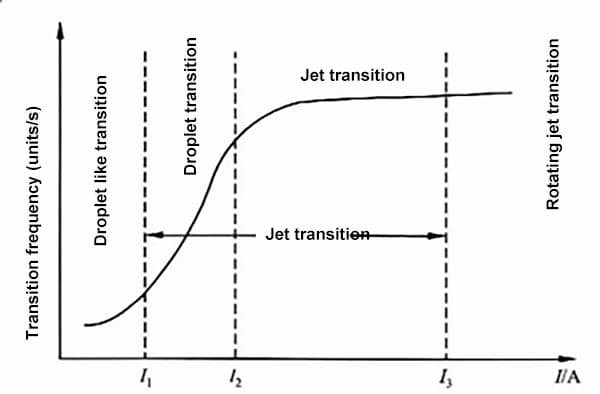

(2) The effect of current:

When the current is smaller than the critical current I1, particle transition occurs with a low transition frequency. When the current is higher than the critical current I1, spray transition occurs with a high transition frequency.

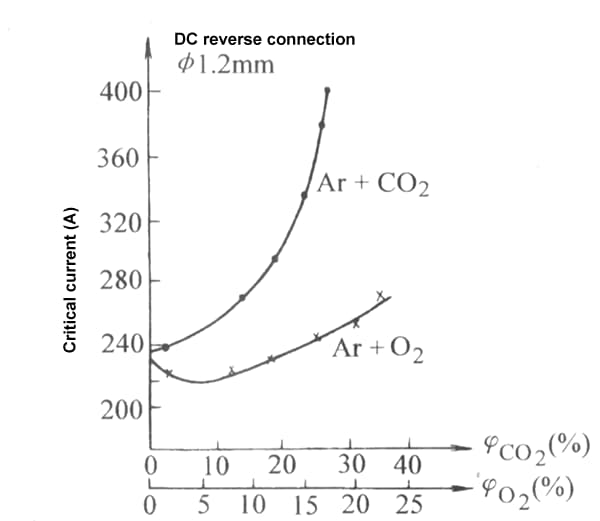

Gas medium:

Adding a small amount of O2 to Ar reduces surface tension, decreases the resistance of droplet transition, and reduces the critical current for spray transition. However, too much O2 can cause arc constriction due to O2 ionization, leading to an increase in the critical current.

Adding CO2 increases the critical current for spray transition.

Critical current: The minimum current that causes arc jumping.

Factors affecting critical current.

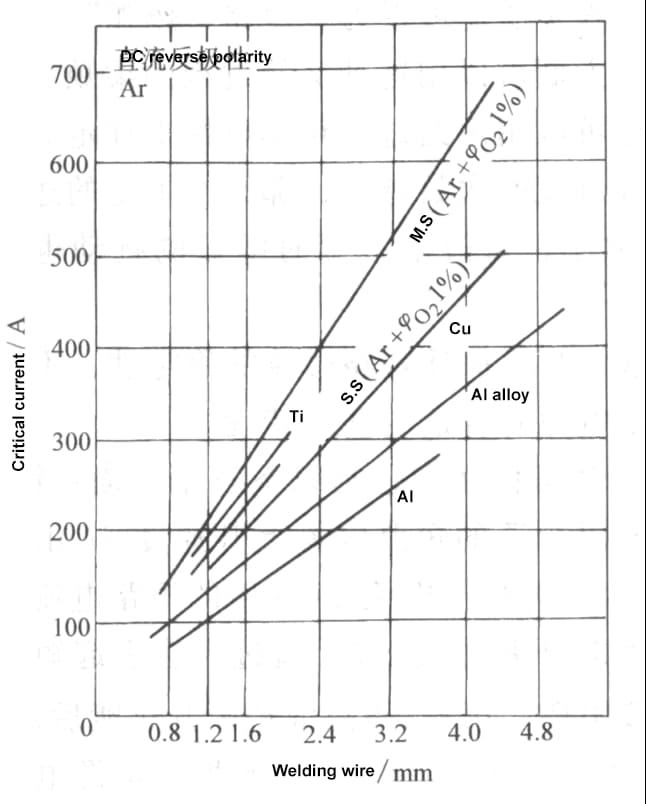

Welding wire material:

Under the same conditions, the critical current for steel welding wire is higher than that of aluminum welding wire. Aluminum welding wire is more likely to transition from droplet transition to spray transition, while steel welding wire is more likely to transition from droplet transition to hyper-jet transition.

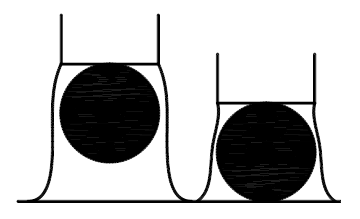

Wire diameter:

The smaller the wire diameter, the lower the critical current.

Stick-out length:

Increasing the stick-out length increases the resistance heat, which is beneficial for droplet transition.

(3) The effect of current polarity

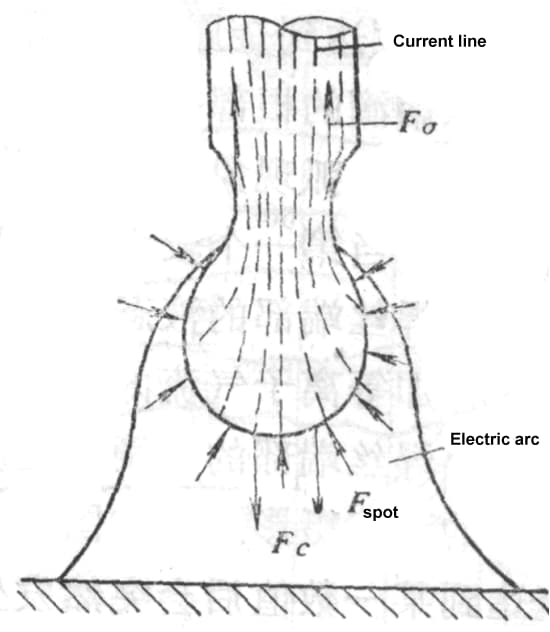

Principle: During hyper-jet transition, the arc forms a bell-shaped structure with a large arc root area that surrounds the entire droplet. The surface tension not only acts on the bottom of the droplet but also on the top, pushing the droplet through the transition.

As the current is divergent, the electromagnetic pinch force generates a strong thrust, and the only resistance to droplet transition is surface tension.

Therefore, the acceleration of droplet transition is greater than the gravitational acceleration of large-droplet transition.

Characteristics:

The arc forms a bell-shaped structure.

Spot forces and plasma flow forces promote droplet transition.

Small droplets with a high transition frequency.

The current must reach the critical current for hyper-jet transition.

Steel welding wire is used for MIG welding.

Hyper-jet transition has high penetration capability, which may result in finger-like penetration.

Formation conditions:

Hyper-jet transition occurs during MIG welding with steel wire, using direct current reverse polarity, high arc voltage (long arc), and a welding current greater than a certain critical value.

Problem of wrinkling in the weld seam:

Aluminum and other non-ferrous metals and their alloys are prone to this issue. It occurs when welding current is much greater than the critical current for hyper-jet transition, and there is poor protection in the welding area. Cathode spots move to the bottom of the arc crater and remain stable.

As a result, the bottom of the arc crater is subjected to strong arc force and is violently “digged out”, resulting in serious oxidation and nitridation. These metal droplets fall on the near-weld area and surface, causing poor fusion of the weld metal and rough wrinkling on the surface. A layer of black powder covers it, which is the phenomenon of weld wrinkling.

Preventive measures for weld seam wrinkling:

Formation conditions: During MIG welding with steel wire, if the stick-out length is relatively long, or the welding current is much greater than the critical current for spray transition, the length of liquid metal increases. High-speed ejection of fine droplets during spray transition generates a large reaction force. Once it deviates from the axis, rotational hyper-jet transition occurs.

Characteristics:

Used for MIG welding with steel wire.

Occurs when stick-out length is relatively long or welding current is much greater than the critical current for spray transition.

Results in uneven weld seam, unstable arc, and large spatter.

Applied to welding of steel structures, overcoming defects such as poor fusion of sidewalls during narrow-gap welding and corner welding.

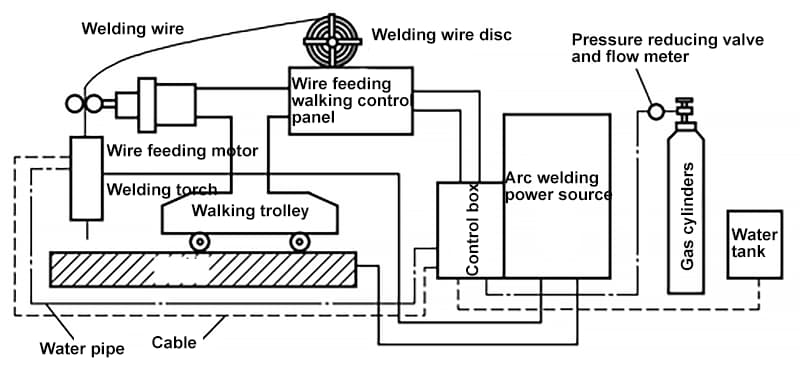

According to the level of mechanization, there are two types: automatic welding and semi-automatic welding. Semi-automatic welding equipment does not include a walking trolley, and the movement of the welding gun is manually operated. The welding gun of automatic welding equipment is fixed on the walking trolley for welding.

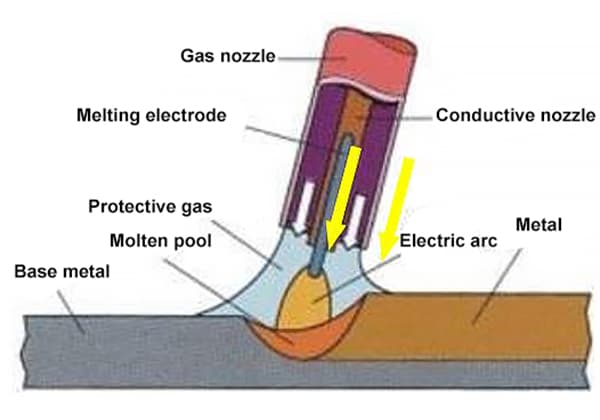

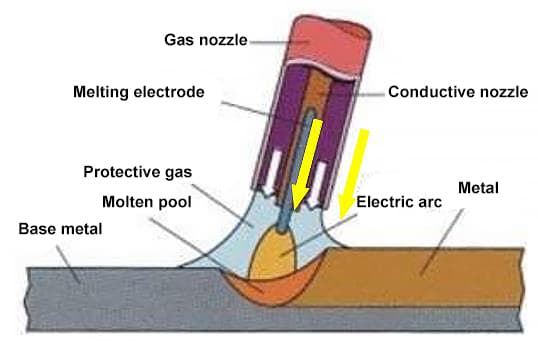

It mainly consists of an arc welding power source, wire feeding system, welding gun, walking trolley (for automatic welding), gas supply system, water cooling system, control system, etc.

Welding Power Source:

When welding aluminum, it is difficult to achieve subtransient droplet transition smoothly with a common constant speed wire feeding system and constant current source.

Therefore, it is necessary to have a welding machine with synchronous control (or automatic optimization) of welding current and wire feeding speed functions.

Gas Supply Device: Gas cylinder, hose, regulator, etc.

Wire Feeding Mechanisms: (pull-type, push-type, and push-pull type mechanisms)

Welding Gun:

Welding guns hold the electrode and direct the welding arc. They come in two types: water-cooled and air-cooled.

The contact tip of a welding gun must have good conductivity, wear resistance and heat resistance. It is generally made of copper alloy and has a diameter that is equal to the welding wire diameter plus 0.2mm.

It is important to regularly check and replace the contact tip to ensure smooth and consistent welding performance.

Welding Process Parameters:

Standard Welding Process Parameters:

The standard welding process parameters may vary depending on the welding process, material being welded, and the desired weld quality. However, some general guidelines for setting welding process parameters.

MAG welding can be used for low carbon steel and low alloy steel, with Ar+ (5-20)% CO2 mixture gas used as shielding gas and sometimes a small amount of O2 added.

The droplet transfer mode can be short circuit transition, spray transition or pulsed transition in MAG welding.

(1) Short Circuit Transition MAG Welding:

Compared to CO2 welding, short circuit transition MAG welding has a more stable arc and less spatter. It can use thinner welding wire and lower welding current, resulting in shallower weld penetration and slower welding speed. This makes it suitable for welding thin plates.

(2) Spray Transition MAG Welding:

Spray transition is the most common droplet transfer mode in MAG welding. Generally, the welding current is set 30-50A higher than the spray transition critical current. When the plate thickness is greater than or equal to 3.2mm, the welding arc is very stable, resulting in a flat surface and good weld formation with minimal spatter.

Short-circuiting transition, jet transition, and pulse transition can be used.

(1) Short-circuiting transition for stainless steel MIG welding.

The diameter of the welding wire is 0.8-1.2mm, and the shielding gas used is Ar+(1~5%)O2 or Ar+(5~20%)CO2. The welding current is less than the critical current of the jet transition and is mainly used for single-layer welding of thin plates with a thickness of less than 3.0mm.

(2) Jet transition for stainless steel MIG welding.

The welding wire used has a diameter of 0.8, 1.0, 1.2, 1.6mm, and the shielding gas used is Ar+(1~2%)O2 or Ar+(5~10%)CO2. The welding current is greater than the critical current of the jet transition and is mainly used for welding steel plates with a thickness of more than 3.2mm.

Copper and copper alloys have very strong thermal conductivity, which can easily cause poor melting, so preheating is required before welding. Due to the need for a large welding current, the molten droplets exhibit jet transition.

The characteristic of the welding parameters for welding purple copper is a high preheating temperature and a large welding current (up to 600A). When using pure argon gas protection, the arc power is small. Using Ar+(50-75%)He protection can increase the arc power and reduce the preheating temperature.

When MIG welding aluminum alloys, it is necessary to use the cathodic cleaning effect to remove the oxide film. Aluminum alloys have fast thermal conductivity and require sufficient arc power to melt the base material and form the weld. Pure argon gas is usually used as the shielding gas for thin plate welding. When welding large and thick materials, Ar+He mixed gas protection is used, and the proportion of He is often around 25%. Short-circuiting transition or spray transition can be used.

Note:

When reversing the polarity of direct current, that is to say, using the welding wire as the positive electrode and the workpiece as the negative electrode, the molten welding wire droplets usually enter the weld pool in very fine granular “spatter transition” with a relatively large current used, resulting in high productivity. For aluminum plates with a thickness of more than 8mm, to stabilize the arc, the melting electrode argon arc welding typically adopts reverse polarity DC, which has a “cathode fragmentation” effect on welding aluminum workpieces.

(1) Short-circuiting MIG welding

This method uses pure argon gas as a shielding gas and typically uses a wire diameter of 0.8-1.0mm, with a small 0.5kg wire spool and a special feeding gun, for welding thicknesses of 1-2mm. Thinner aluminum alloy wires can be difficult to feed.

(2) Spray transition and subsonic MIG welding

This method also uses pure argon gas as a shielding gas and typically uses a wire diameter of 1.2-2.4mm.

(3) High-current MIG welding

Thick aluminum alloy plates can be welded using thick wires (diameter of 3.2-5.6mm) and high-current MIG welding, with welding currents reaching 500-1000 A and resulting in high productivity. A 50% Ar + 50% He shielding gas mixture is used in the inner nozzle to enhance arc power, while the outer nozzle is filled with Ar gas to further strengthen the protective effect.