Have you ever wondered how intricate patterns on your car’s dashboard or smartphone case are created? This article delves into mold laser etching technology, explaining how lasers enhance mold surface quality and efficiency. By reading further, you’ll discover the principles behind this precise technique, its applications in various industries, and its potential to replace traditional methods due to its superior precision, speed, and environmental benefits. Explore how this innovative technology is transforming manufacturing processes and setting new standards in product design and quality.

Based on the principles of laser etching technology for molds, this paper explores its advantages and developmental trends in mold surface processing.

The use of laser beams to etch precise patterns and textures on mold surfaces has been proven to significantly enhance the surface quality and performance of products and increase production efficiency, while also offering environmental protection benefits.

Molds are an indispensable tool in industrial production, widely utilized in the manufacturing of household appliances, automobiles, electronic devices, and medical instruments. The texture and pattern on the surface of molds play a crucial role in the quality and appearance of products.

With the increase in consumer standards, traditional mold etching methods have limitations and cannot meet the requirements for the fineness and complexity of textures on high-end products. The emergence of laser etching technology for molds has introduced new possibilities for mold surface treatment.

Traditional etching heavily relies on manual techniques, resulting in low repeatability. Due to the complexity of the process, etching services typically only offer standard textures for clients to choose from, leading to a lack of product individuality.

Many textures are beyond their capability, and even with the use of appropriate photochemical films, wrinkles are hard to avoid, necessitating expensive and meticulous post-processing.

Moreover, the raw materials and waste generated by the etching process significantly pollute the environment.

Laser etching technology combines highly digitalized texture designs with precise five-axis laser machining equipment, making it possible to achieve appearances that conventional etching methods cannot.

From the digital design of textures on computers to the creation of machining programs, this technology ensures the accurate reproduction of any complex graphic texture, which is then transferred to high-precision laser equipment for ultra-fine processing, resulting in a distinctive product appearance.

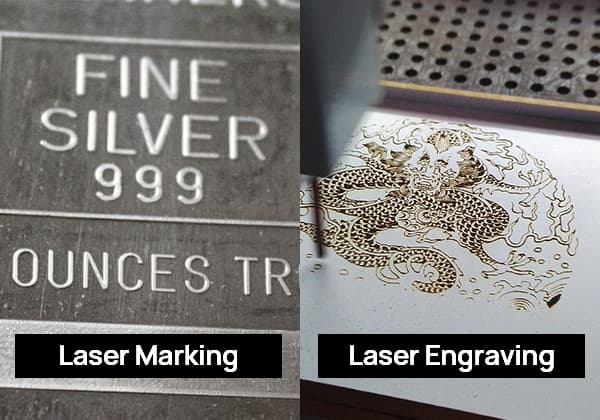

Laser etching is a relatively new processing technique that generates only metal dust, which can be vacuumed away, and does not produce liquid, sludge, or debris waste. It enables efficient and repeatable processing, engraving, and microstructuring, as well as complex two-dimensional or three-dimensional marking on objects.

As chemical etching can only process 3-5 levels of texture, while laser technology can handle more than 10, laser processing can create textures with multiple levels, better and more refined surface quality. The process of mold laser etching is shown in Figure 1.

Currently, the mold laser etching industry is rapidly developing. By using laser beams to etch precise patterns and textures onto mold surfaces, this technology adds greater value and aesthetic appeal to products.

With the continual advancement of the manufacturing industry and increasing demand for high-quality products, the scale of this industry is expanding yearly.

Mold laser etching technology is now extensively applied in various fields, including automobiles, electronic devices, medical instruments, and household products. Due to its precision, efficiency, and repeatability, laser etching is expected to gradually replace traditional mechanical engraving and chemical etching methods.

Modern laser etching equipment features higher levels of automation and intelligent capabilities, leading to improved production efficiency and quality. Furthermore, as laser technology continues to evolve and costs decrease, the mold laser etching industry is expected to keep growing.

Overall, the industry demonstrates significant development potential and broad market prospects. With technological advancements and market demands driving progress, the industry is poised for robust growth in the future.

3.1 Laser Emission

A laser generates a beam of high-intensity, high-energy light. These laser beams are typically produced using laser diodes, solid-state lasers, or gas lasers.

3.2 Laser Focusing

The laser beam is focused into a very fine point through an optical system, such as lenses or mirrors. The focused energy density determines the depth and precision of the etching.

3.3 Mold Surface Irradiation

The focused laser beam is irradiated onto specific areas of the mold surface. The interaction between the laser beam and the mold surface causes the material to melt, evaporate, or peel off, forming the desired patterns and textures.

3.4 Movement and Control

The mold is usually combined with CNC machine tools or laser etching machines, controlling the relative movement of the laser beam and the mold to achieve etching on the mold surface. These movements can include rotation, translation, or tilting of the mold.

3.5 Coordination and Control

Advanced computer control systems coordinate and control the laser source, optical system, and mold movement. This allows the laser etching process to be carried out with high precision and repeatability.

Mold laser etching technology utilizes the high energy of laser beams and precise control to achieve high-precision etching on mold surfaces, forming fine patterns and textures. This non-contact processing method offers advantages in efficiency, precision, and repeatability, gradually becoming an important technology in mold processing.

4.1 Automotive Industry

The automotive industry is one of the significant application areas for mold laser etching technology. It is used for surface texture processing on automotive interior components, steering wheels, dashboards, door panels, and seats.

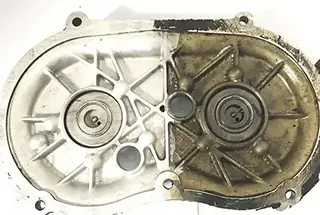

Laser etching creates various fine textures, enhancing the quality and aesthetics of car interiors, thereby improving the vehicle’s overall appearance and comfort. The effect of mold laser etching is shown in Figure 2.

4.2 Electronic Products

In high-end electronic products, mold laser etching technology is often used for pattern and texture processing on the exteriors of smartphones, displays, projectors, tablets, and laptops. These patterns and textures not only add visual appeal but also provide better grip and slip resistance.

The appearance textures of electronic products significantly enhance user experience.

Mold laser etching technology can create delicate, uniform textures on electronic product casings, buttons, and displays, enhancing the product’s visual and tactile quality and effectively boosting its competitiveness among numerous choices.

4.3 Medical Equipment

The surface texture of medical equipment significantly impacts product hygiene and usability. Mold laser etching technology can create micro-fine textures on the surfaces of medical equipment components during manufacturing.

This makes the equipment more comfortable to handle for medical professionals and easier to clean, while the delicate laser textures effectively enhance the product’s antibacterial properties.

4.4 Home Furnishings

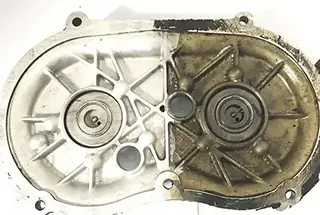

The application of mold laser etching technology in home furnishings is also gaining attention. For instance, applying textures to the surfaces of furniture, lighting fixtures, and kitchenware enhances their tactile quality and artistic value. The effect of jewelry laser etching is shown in Figure 3.

Overall, mold laser etching technology has a wide range of applications in high-end products, adding unique design elements and enhancing the products’ visual appeal and added value. With ongoing technological advancements and innovations, its applications in high-end product sectors will continue to expand.

Mold laser etching technology boasts several advantages:

In summary, mold laser etching technology, with its precision, flexibility, efficiency, reproducibility, non-contact nature, and eco-friendliness, is an ideal choice across numerous industries.

Mold laser etching technology is trending towards higher precision, multifunctionality, speed, intelligent control, and environmental friendliness.

With continuous technological advancements, mold laser etching technology is set to play an increasingly significant role in mold manufacturing.

(1) Technological Innovation:

As laser technology continues to evolve and innovate, mold laser etching technology will also be further improved and refined. In the future, more efficient, precise, and controllable laser etching techniques may emerge, leading to even more detailed and exquisite etching effects.

(2) Expanded Material Applications:

Currently, mold laser etching technology is primarily used on metal and plastic molds. However, with the advent of new materials like ceramics and composites, laser etching will gradually be applied in the creation of these new material molds, offering better surface treatment methods.

(3) Automated Production:

With the advancement of industrial automation, mold laser etching technology will also develop in an automated direction. By integrating with robots and automated equipment, automated etching processes for molds can be realized, thus enhancing production efficiency and quality.

(4) Expanded Application Fields:

Mold laser etching technology can be applied not only in the mold industry but also expanded to other fields. For example, it can be used for surface treatment of aerospace parts and surface processing of automotive components. As demand for surface treatment grows across various industries, mold laser etching technology will have a broader range of applications.

Mold laser etching technology is an innovative technique that uses the high energy density of lasers for mold surface treatment. Through laser irradiation, tiny laser ablations are produced on the mold surface, forming complex textures or patterns.

This technology offers high detail precision, rapid processing speed, good temperature control, excellent etching effects, and wide applicability. This article has introduced the principles, advantages, and development trends of mold laser etching technology.

Through application analysis and processing verification, it can significantly improve surface quality and production efficiency. This technology holds substantial value in the mold industry, enhancing mold-making precision and efficiency while making mold surfaces more aesthetically pleasing and artistic.

Mold laser etching technology, with its vast potential for development, innovation, and application expansion, is set to become an important surface treatment technique in the mold industry, bringing higher production efficiency and product quality to mold manufacturing and related sectors.