Have you ever wondered how different types of motors impact performance and efficiency in machines? This article dives into the core differences between DC and AC motors, synchronous and asynchronous motors, and the nuances of variable frequency motors. By exploring these distinctions, you’ll gain valuable insights into motor selection, maintenance, and optimizing their use in various applications. Get ready to enhance your understanding of the mechanical world and make informed decisions for your projects!

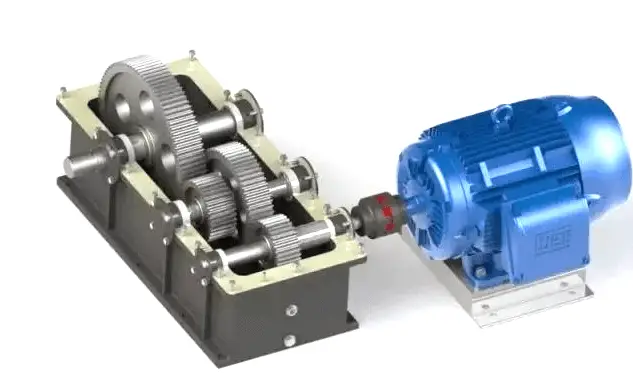

Schematic diagram of DC motor

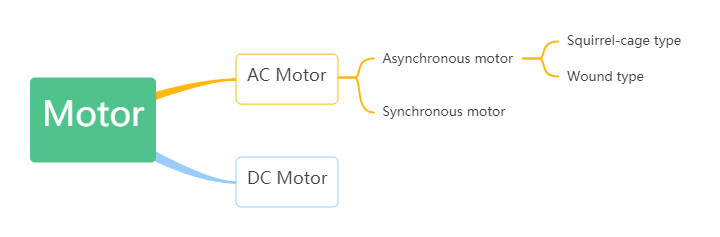

Schematic diagram of AC motor

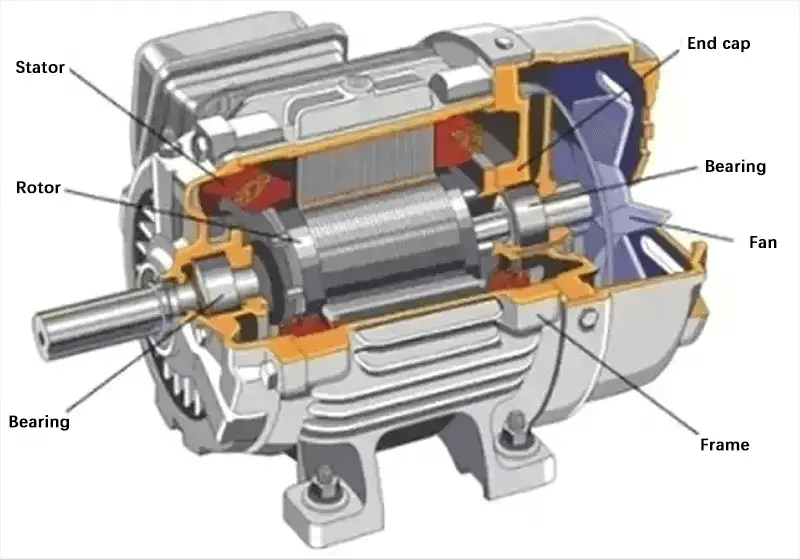

Just as its name implies, a DC motor uses direct current (DC) as its power source, while an AC motor uses alternating current (AC) as its power source.

In terms of structure, the principle of a DC motor is relatively straightforward, but its structure is complex and challenging to maintain. On the other hand, the principle of an AC motor is complex, but its structure is relatively simple and easier to maintain compared to a DC motor.

In terms of price, DC motors with the same power are typically more expensive than AC motors. Additionally, the cost of a DC motor is higher if you include a speed regulating device to control its speed.

In terms of performance, the speed of a DC motor is stable and the speed control is accurate, which cannot be achieved by an AC motor. However, DC motors are only used as a replacement for AC motors under strict speed requirements.

Although the speed regulation of an AC motor is more complex, it is widely used due to the widespread use of AC power in chemical plants.

A synchronous motor is a type of motor where the rotation speed of the rotor is the same as that of the stator. On the other hand, an asynchronous motor is a type of motor where the rotation speed of the rotor is not the same as that of the stator.

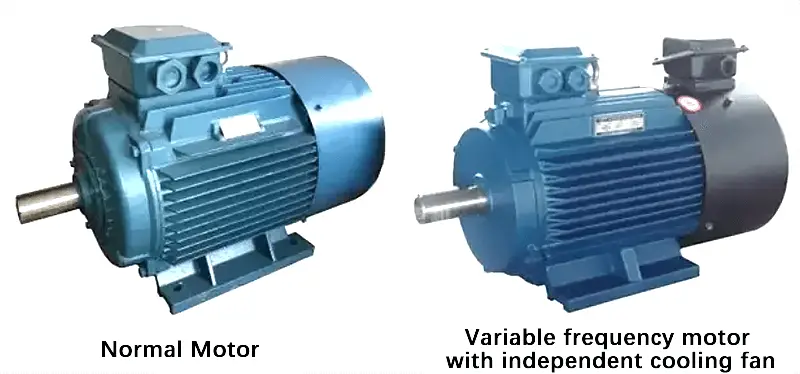

It is evident that regular motors cannot be utilized as variable frequency motors. This is because regular motors are designed to operate at constant frequency and constant voltage, which does not fully meet the requirements of frequency regulation for speed control. Hence, it cannot be used as a frequency conversion motor.

The impact of the frequency converter on the motor primarily affects its efficiency and temperature rise. The frequency converter generates various degrees of harmonic voltage and current during operation, causing the motor to operate under non-sinusoidal voltage and current. This leads to an increase in stator and rotor copper consumption, iron consumption, and additional losses in the motor.

Of all the impacts, the most significant one is the rotor copper consumption, which causes the motor to generate more heat and reduces its efficiency and output power. As a result, the temperature rise of regular motors generally increases by 10% to 20%.

The frequency range of the frequency converter ranges from several kilohertz to over ten kilohertz, which results in a high voltage rise rate in the stator winding of the motor. This is equivalent to applying a steep impulse voltage to the motor, putting the turn-to-turn insulation of the motor to a severe test.

When a motor is powered by a frequency converter, the vibration and noise generated by electromagnetic, mechanical, ventilation, and other factors become more complex.

The harmonics present in the variable frequency power supply interact with the inherent space harmonics of the electromagnetic part of the motor, resulting in various electromagnetic excitation forces and increased noise.

The wide working frequency range and large speed variation range of the motor make it difficult to avoid the natural vibration frequency of each structural part, resulting in a frequency of various electromagnetic force waves.

At low power frequency, the loss caused by higher harmonics in the power supply is substantial. Additionally, as the speed of the variable motor decreases, the cooling air volume decreases proportionally to the cube of the rotating speed, leading to a sharp increase in motor temperature and difficulty in achieving constant torque output.

So how to distinguish between ordinary motor and variable frequency motor?

Typically, variable frequency motors have an insulation rating of F or higher. To enhance the insulation strength, it is important to improve the ground insulation and wire turn insulation, particularly its capacity to resist impulse voltage.

For variable frequency motors, it is important to fully consider the rigidity of both the motor components and the entire motor. Efforts should be made to improve the natural frequency of the motor to avoid resonance with any force waves.

The variable frequency motor typically uses forced ventilation for cooling, which means that the cooling fan of the main motor is powered by a separate motor.

For variable frequency motors with a capacity exceeding 160 kW, measures to insulate the bearings should be implemented.

This is due to the likelihood of magnetic circuit asymmetry and shaft current generation. When high-frequency currents generated by other components combine, it can significantly increase the shaft current, leading to damage to the bearings. To prevent this, insulation measures are generally necessary.

For constant power variable frequency motor

When the rotation speed surpasses 3000 revolutions per minute, it is important to use a special grease with high-temperature resistance to counteract the rise in temperature of the bearing.

The cooling fan of the variable frequency motor is powered by a separate power source to guarantee its continuous cooling ability.

The basic contents required for motor selection:

Load type, rated power, rated voltage, rated speed and other conditions driven.

This should be approached from the characteristics of motors, which can be simply categorized into direct current (DC) motors and alternating current (AC) motors, with AC further divided into synchronous and asynchronous motors.

(1) DC Motors

The advantage of DC motors is the convenience of speed regulation through voltage adjustments, combined with the ability to provide considerable torque. They are suitable for loads that require frequent speed adjustments, such as rolling mills in steel factories and elevators in mines.

However, with the advancement of frequency conversion technology, AC motors can also adjust the speed by changing the frequency. Even though the cost of a variable frequency motor is not much more than regular motors, the price of the inverter constitutes a significant part of the overall equipment cost. Thus, another advantage of DC motors is their cost-effectiveness.

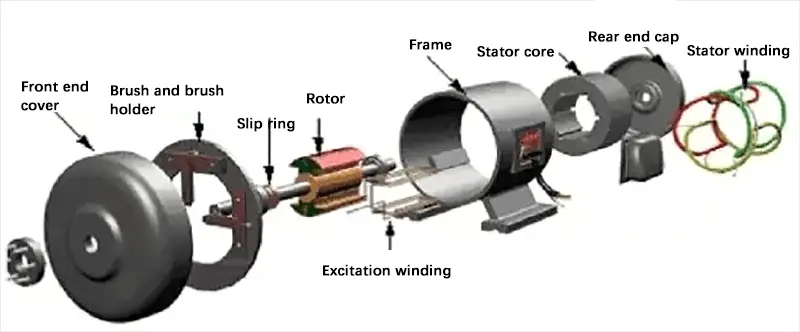

A disadvantage of DC motors is their complex structure, which inevitably leads to increased failure rates. DC motors, compared to AC motors, not only have more complex windings (excitation, commutating, compensating, and armature windings) but also include additional components like slip rings, brushes, and commutators.

These requirements not only demand high manufacturing precision but also result in higher maintenance costs in the long run.

Therefore, DC motors are in an awkward position in industrial applications, gradually losing popularity but still useful during the transition phase. If the user has sufficient funds, it is recommended to choose an AC motor with an inverter, given the many benefits that inverters offer.

(2) Asynchronous Motors

The advantages of asynchronous motors lie in their simple structure, stable performance, easy maintenance, and low cost. They also have the simplest manufacturing process. As an old workshop technician once said, the labor hours spent assembling a DC motor could complete roughly two synchronous motors or four asynchronous motors of similar power. This speaks volumes about the widespread use of asynchronous motors in the industry.

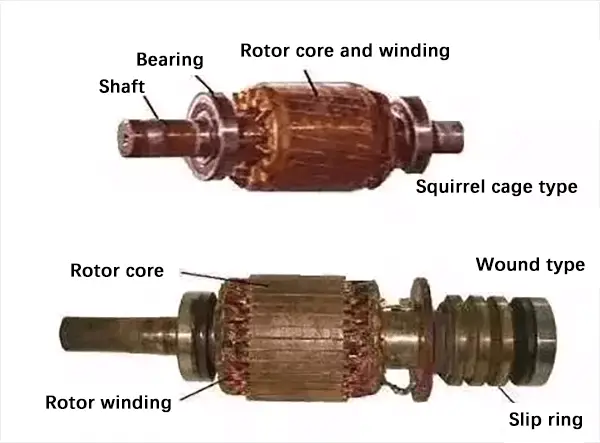

Asynchronous motors are further divided into squirrel cage and wound rotor types, differentiated by their rotors. The rotor of a squirrel cage motor is made of metal bars, either copper or aluminum.

Aluminum is cheaper, and since China is rich in bauxite, it is extensively used where requirements are not high.

However, the mechanical and electrical properties of copper are superior to those of aluminum, and most of the rotors I have encountered are made of copper. Squirrel cage motors, once the issue of broken bars is addressed, demonstrate significantly greater reliability than those with wound rotors.

A drawback, however, is that the torque generated by a metal rotor cutting magnetic lines in a rotating stator field is relatively small, and the starting current is large, making it difficult to handle loads that require high starting torque.

Although increasing the length of the motor core can yield more torque, the effect is quite limited. Wound rotor motors, on the other hand, energize the rotor winding through slip rings at startup, creating a rotor magnetic field. The resulting relative motion with the rotating stator field produces higher torque.

During startup, the starting current is reduced by the use of water resistors, the resistance of which is controlled by a mature electronic control device that changes its value during the startup process. This is suitable for loads such as rolling mills and elevators.

However, because wound rotor asynchronous motors add components like slip rings and water resistors, the overall equipment cost is somewhat higher. Compared to DC motors, they have a narrower speed adjustment range and relatively smaller torque, hence their value is lower.

Nevertheless, because asynchronous motors establish a rotating magnetic field by energizing the stator winding, which is an inductive component that doesn’t perform work, they draw reactive power from the grid, creating a significant impact.

For example, when a large inductive appliance is connected to the grid, the grid voltage drops and the brightness of electric lights decreases abruptly.

Therefore, power companies may restrict the use of asynchronous motors, which many factories must take into account. Some large electricity consumers, such as steel and aluminum factories, opt to establish their own power plants, forming independent grids, to alleviate these usage restrictions.

Thus, if an asynchronous motor is to meet the needs of high-power loads, it must be equipped with a reactive power compensation device. In contrast, synchronous motors can provide reactive power to the grid through excitation devices. The larger the power, the more evident the advantages of synchronous motors, hence creating a stage for their use.

(3) Synchronous Motors

In addition to compensating for reactive power in an over-excited state, the advantages of synchronous motors also include:

1) The speed of the synchronous motor strictly follows n=60f/p, allowing for precise speed control.

2) They offer high operational stability; in the event of a sudden drop in grid voltage, the excitation system typically enforces excitation to ensure stable operation, whereas the torque of an induction motor (proportional to the square of the voltage) would significantly decrease.

3) The overload capacity is larger than that of a comparable induction motor.

4) They boast high operational efficiency, especially in the case of low-speed synchronous motors.

Synchronous motors cannot start directly; they require either induction or frequency-conversion start-up. Induction start-up refers to the process where a start-up winding similar to the squirrel cage winding of an induction motor is installed on the rotor of the synchronous motor.

A supplementary resistor with a resistance value about ten times that of the excitation winding is connected in series in the excitation circuit to form a closed circuit, allowing the stator of the synchronous motor to be connected directly to the grid.

The motor then starts like an induction motor, and when the speed reaches the sub-synchronous speed (95%), the additional resistor is disconnected. Frequency-conversion start-up is not elaborated here. Hence, one of the drawbacks of synchronous motors is the need for additional equipment for start-up.

A synchronous motor operates on excitation current. Without excitation, the motor is asynchronous. Excitation is a direct current system applied to the rotor, with a rotation speed and polarity consistent with the stator.

If there are issues with excitation, the motor will lose synchrony, fail to adjust, and trigger a protection mechanism causing the motor to trip due to “excitation failure”. Therefore, another disadvantage of synchronous motors is the need for an added excitation device.

Formerly, this was supplied directly by a DC motor, but now it is mostly supplied by thyristor rectification. As the saying goes, the more complex the structure and the more equipment, the more potential points of failure, hence a higher fault rate.

Based on the performance characteristics of synchronous motors, their applications are primarily found in hoists, grinders, fans, compressors, rolling mills, water pumps, and other loads.

In summary, the principle for selecting a motor is that, provided the motor’s performance meets the requirements of the production machinery, priority should be given to motors with simpler structures, lower prices, reliable operation, and convenient maintenance.

In this respect, AC motors are superior to DC motors, AC induction motors are superior to AC synchronous motors, and squirrel cage induction motors are superior to wound rotor induction motors.

For production machinery running continuously with steady loads and no special requirements for starting or braking, it’s preferable to use a standard squirrel cage induction motor, which is widely used in machinery, water pumps, fans, and more.

Production machinery that requires frequent starts and stops, and demands high starting and braking torque, such as bridge cranes, mine hoists, air compressors, and irreversible rolling mills, should use a wound rotor induction motor.

In cases where there is no need for speed adjustment, and constant speed is necessary or power factor improvement is required, synchronous motors should be used. These are suitable for medium and large capacity water pumps, air compressors, hoists, grinding machines, and more.

For production machinery requiring a speed adjustment range of over 1:3 and needing smooth, stable speed regulation, it’s recommended to use separately excited DC motors or squirrel cage induction motors or synchronous motors with frequency speed control. These are suitable for large precision machine tools, gantry planers, rolling mills, hoists, and more.

Production machinery requiring high starting torque and having soft mechanical properties should utilize series or compound excited DC motors. These are optimal for electric vehicles, electric locomotives, heavy duty cranes, and more.

The rated power of an electric motor refers to its output power, also known as shaft power or capacity, which is a signature parameter of the motor. When people inquire about the size of the motor, they usually refer to the rated power, not the physical dimensions.

The rated power is the most important metric when quantifying the load-carrying capacity of the motor and is a necessary parameter when selecting a motor.

(Where Pn refers to rated power, Un refers to rated voltage, In refers to rated current, cosθ is the power factor, and η is the efficiency)

The principle of choosing the right motor capacity should be based on the premise that the motor can meet the load requirements of the production machinery, and to decide the power of the motor in the most economical and reasonable way.

If the power is chosen too high, it will result in an increase in equipment investment and waste, and the motor will often run underloaded, resulting in low efficiency and power factor. Conversely, if the power is chosen too low, the motor will run overloaded, leading to premature damage.

There are three main factors that determine the power of a motor:

1) The heating and temperature rise of the motor, which is the most crucial factor in determining the motor’s power;

2) The motor’s short-term overload capability;

3) For asynchronous squirrel cage motors, starting capacity must also be considered.

Firstly, the specific production machinery, based on its heating, temperature rise, and load requirements, calculates and selects the load power. The motor then preliminarily selects the rated power based on the load power, duty cycle, and overload requirements.

After the rated power of the motor has been pre-selected, it needs to undergo checks for heating, overload capacity, and, when necessary, starting capacity. If any of these checks fail, the motor must be reselected and rechecked until all parameters pass.

Therefore, the duty cycle is also a necessary requirement to provide. If there is no requirement, it will be processed according to the most common S1 duty cycle; motors with overload requirements also need to provide the overload multiples and corresponding operating time; asynchronous squirrel cage motors driving high-inertia loads such as fans also need to provide the load’s moment of inertia and the starting torque curve for starting capacity checks.

All the above-mentioned selections of rated power are conducted under the premise of a standard ambient temperature of 40°C. If the ambient temperature where the motor operates changes, the rated power of the motor must be revised.

Based on theoretical calculations and practice, at different ambient temperatures, the power of the motor can roughly increase or decrease according to the table below.

Hence, in areas with harsh climates, the ambient temperature must also be provided. For instance, in India, the ambient temperature needs to be checked at 50°C.

In addition, high altitude can also affect the power of the motor; the higher the altitude, the greater the temperature rise of the motor, and the smaller the output power. Motors used at high altitudes also need to consider the effects of corona discharge.

As for the current market range of motor power, I provide the following data from my company’s performance table for reference:

The rated voltage of a motor refers to the line voltage under its rated operating conditions. The choice of the motor’s rated voltage depends on the supply voltage of the power system to the facility and the capacity of the motor.

The voltage rating selection for AC motors mainly depends on the supply voltage level at the place of use. The common low voltage network is 380V, hence the rated voltage is typically 380V (Y or Δ connection), 220/380V (Δ/Y connection), or 380/660V (Δ/Y connection).

When the power of low voltage motors reaches a certain level (such as 300KW/380V), it becomes difficult or too costly to increase the current due to the limitation of the wire’s capacity.

In such cases, it is necessary to achieve high power output by increasing the voltage. The usual supply voltage for the high voltage network is 6000V or 10000V, but in foreign countries, there are also voltage levels of 3300V, 6600V, and 11000V.

High voltage motors have the advantage of high power and strong shock resistance. However, they also have the downside of high inertia, making them difficult to start and brake.

The rated voltage of a DC motor also needs to match the source voltage. It’s generally 110V, 220V, or 440V. The commonly used voltage level is 220V, but for high power motors, it can be increased to 600–1000V.

When the AC power source is 380V, and a three-phase bridge controllable silicon rectification circuit is used for power supply, the rated voltage of the DC motor should be set at 440V. If it is powered by a three-phase half-wave controllable silicon rectification source, the rated voltage of the DC motor should be 220V.

The rated speed of an electric motor refers to its speed under designated operational conditions.

Both the electric motor and the machinery it drives have their own rated speeds. When choosing the speed of an electric motor, one should consider that a too low speed is not desirable. This is because the lower the rated speed of an electric motor, the more stages it has, resulting in a larger size and higher cost.

Simultaneously, the speed of the electric motor should not be too high, as this would complicate the transmission mechanism and make it difficult to maintain.

Moreover, at a fixed power, the torque of the motor is inversely proportional to the speed.

For those with low startup and braking requirements, a comprehensive comparison can be made from the perspectives of initial investment, space occupation, and maintenance costs by considering several different rated speeds, and then the final rated speed can be determined.

For those who frequently start, brake, and reverse, but the transition time has little impact on productivity, the speed ratio and rated speed of the electric motor are mainly chosen to minimize transition process losses, in addition to considering the initial investment. For instance, elevator motors, which require frequent reversals and have high torque, have low speed. This results in a large motor size and high cost.

When the motor speed is high, one should also consider the motor’s critical speed. Every motor rotor vibrates during operation, and the amplitude of the rotor increases with the speed.

At a certain speed, the amplitude reaches its maximum (also known as resonance), and beyond this speed, the amplitude gradually decreases with increasing speed and stabilizes within a certain range. This speed, where the rotor amplitude is at its maximum, is known as the critical speed of the rotor.

This speed equals the rotor’s natural frequency. As the speed continues to increase and approaches twice the natural frequency, the amplitude will increase again. The speed equal to twice the natural frequency is called the second-order critical speed. This continues with the third order, fourth order, and so on.

If the rotor operates at the critical speed, severe vibrations will occur, and the bending of the shaft will markedly increase, which, over time, can result in severe bending deformation or even breakage of the shaft. The first-order critical speed of a motor is generally above 1500 rpm, so the impact of critical speed is usually not considered for conventional low-speed motors.

Conversely, for 2-pole high-speed motors, with a rated speed close to 3000 rpm, the impact of this effect must be considered, and the motor should not be operated at the critical speed for an extended period.

Generally speaking, the type of load driven, the rated power, rated voltage, and rated speed of the motor can roughly determine the motor.

However, if you want to optimally meet the load requirements, these basic parameters are far from enough.

Additional parameters needed include frequency, duty cycle, overload requirements, insulation class, protection class, rotational inertia, load torque curve, installation method, ambient temperature, altitude, outdoor requirements, etc., provided according to specific circumstances.

In case of motor operation or malfunction, four methods can be utilized to prevent and rectify the issue in a timely manner, thus ensuring the safe operation of the motor.

Observe for any abnormalities during the motor operation, which are primarily indicated by the following scenarios:

1). If the stator winding experiences a short circuit, the motor may produce smoke.

2). If the motor operates under severe overload or phase loss, the speed will decrease and a loud “buzzing” sound will be heard.

3). If the motor’s maintenance network operates normally but suddenly stops, sparks may be observed at loose parts of the wiring. This could be due to a blown fuse or a stuck component.

4). If the motor vibrates excessively, it could be due to a stuck transmission device, poor fixation of the motor, or a loose foot bolt.

5). Discoloration, burn marks, and smoke marks at the internal contacts and connections of the motor may indicate local overheating, poor contact at conductor connections, or winding burnout.

The motor should emit a uniform and light “buzzing” sound during normal operation, without any additional noises or special sounds. If the noise level is too high, including electromagnetic, bearing, ventilation, mechanical friction, etc., it may indicate a potential problem or malfunction.

(1) For electromagnetic noise, if the motor produces a loud and heavy sound, the possible causes are:

(2) The sound of the bearings should be monitored regularly during motor operation. This can be done by pressing one end of a screwdriver against the bearing installation and holding the other end close to the ear to listen to the running sound.

If the bearing is operating normally, it should produce a continuous and small “rustling” sound, without any changes from high to low or metal friction sounds.

(3) If the transmission mechanism and driven mechanism produce a continuous, rather than uncertain, sound, it may be caused by the following:

Faults in a motor can be detected and prevented by using the sense of smell.

To check for faults, open the junction box and smell it for any burnt or unusual odors.

If there is a smell of paint, it could indicate that the internal temperature of the motor is too high.

If a strong, pungent smell or a burnt smell is present, it may indicate that the insulation or winding has been damaged.

Even if there is no noticeable odor, it is still important to measure the insulation resistance between the winding and the shell using a megger.

If the insulation resistance is lower than 0.5 trillion ohms, the motor should be dried. A resistance value of zero indicates that the motor has been damaged.

Touching the temperature of various parts of the motor can also help diagnose faults.

For safety reasons, it is best to use the back of the hand to touch the motor shell and parts near the bearing when checking the temperature.

If an abnormal temperature is detected, it could be due to several reasons such as:

If the temperature around the bearing is excessively high, it could be caused by bearing damage or a lack of lubrication oil.

According to regulations, the maximum temperature of rolling bearings must not exceed 95℃ and the maximum temperature of sliding bearings must not exceed 80℃, with a temperature rise not exceeding 55℃ (calculated as the difference between the bearing temperature and ambient temperature during testing).

Potential causes and solutions for excessive temperature rise in bearings include:

For the solution section, the following revisions should be made: