Why do motor bearings get so hot, and what can be done about it? This article dives into the causes of motor bearing heat generation, from excessive loads and poor lubrication to environmental factors. You’ll learn how to identify signs of overheating and discover practical solutions to keep your motor running smoothly. By understanding these mechanisms, you can prevent costly failures and extend the life of your equipment.

Motor bearings are installed inside the motor. In fact, the motor body itself constitutes the working environment for the bearing. Therefore, it’s beneficial to understand and analyze motor overheating before delving into the specifics of motor bearing overheating.

A motor, being a device for electromechanical energy conversion, primarily operates through electromagnetic and mechanical processes. Regardless of whether it’s the electromagnetic or mechanical process, there are losses, which are ultimately dissipated in the form of heat. This results in an observable state of overheating.

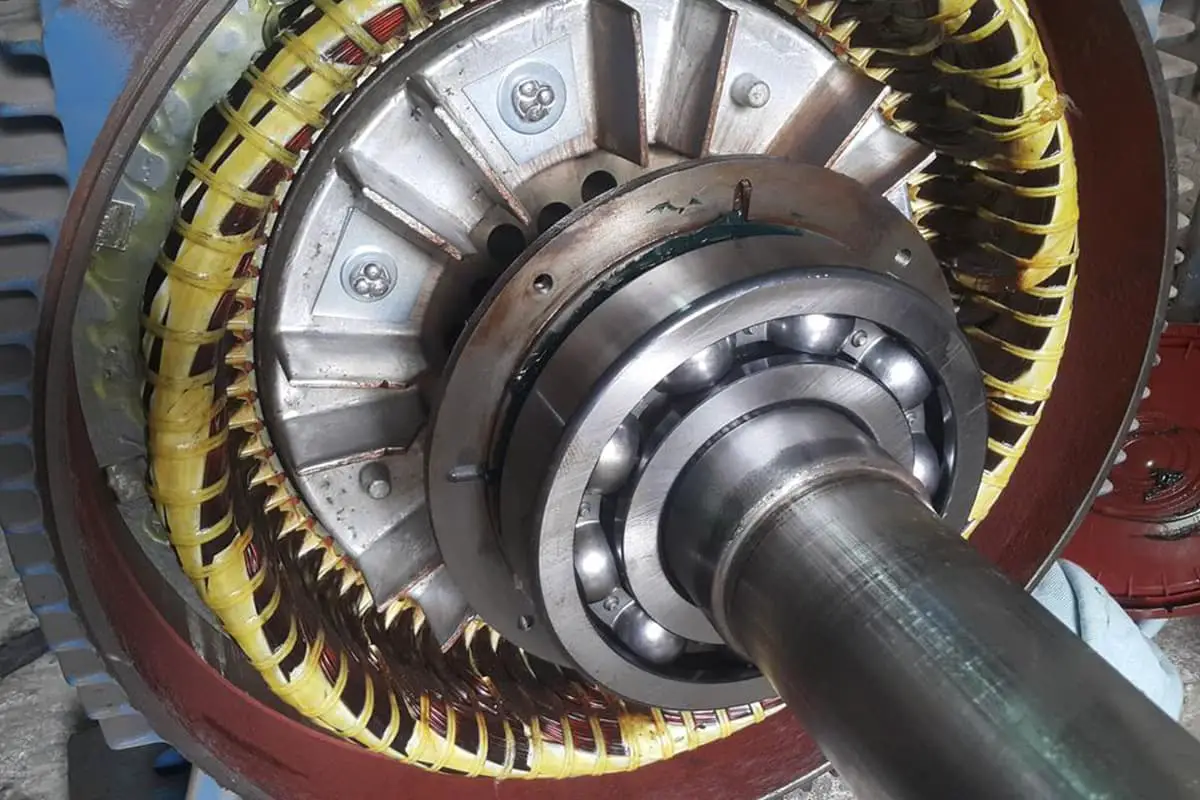

The most intuitive method to analyze motor overheating is to categorize it according to the external macro-components of the motor. Broadly speaking, a motor’s structural body includes the stator frame, rotor, sealing system, bearing system, and so on.

From an external measurement perspective, it can be categorized into frame overheating, rotor overheating, bearing overheating, and seal overheating, among others.

We understand that the exterior heating of the motor base is influenced by the winding heat.

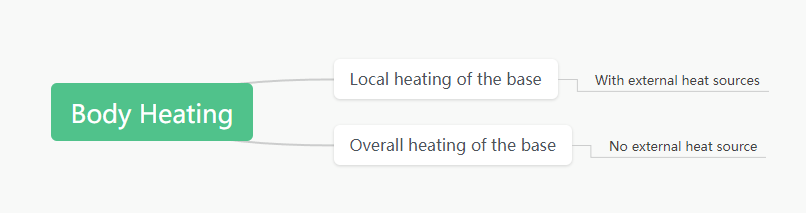

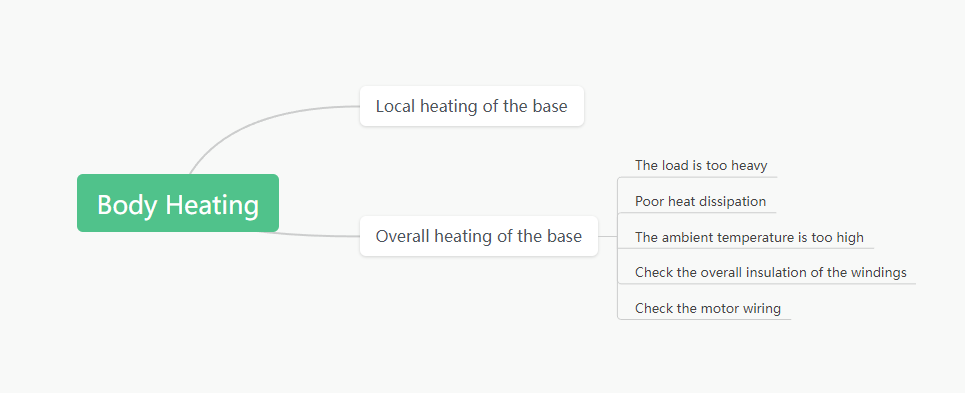

From the heating phenomenon of the base, we can distinguish between overall temperature increase and changes in the temperature distribution of the base.

Local temperature increase of the motor base

When the motor operates under “normal” conditions, the internal temperature of the motor base exhibits a certain distribution. This distribution is related to the heat source distribution and heat quantity within the motor during operation. Generally, there is a certain electrical and mechanical connection between the different heat sources, hence their heating relationships also have a certain correlation.

Therefore, under normal operating conditions, the temperature distribution inside the motor should show a certain stable trend. Please note that what is mentioned here is “temperature distribution” and “trend”, rather than absolute constancy.

The so-called abnormal motor heating refers to inconsistencies in temperature distribution compared to the “normal” state. (“Abnormal” refers to states deviating from “normal”.) This “abnormality” may indicate a malfunction, or it may not. This requires our subsequent fault diagnosis and analysis.

When an “abnormal” local temperature of the motor base is detected, the basic approach to fault diagnosis is to first confirm the presence of external heat sources.

The determination of the heat source is the third layer of content in this diagram. The confirmation of whether there is an external heat source is actually used to determine whether the heat is actively emitted from the motor itself or is a passive change caused by external influences.

For local overheating due to an external heat source, motor engineers first need to determine whether the external heat source itself is normal. If the external heat source is normal and causes such a temperature rise, it is necessary to confirm the impact of this temperature increase caused by the external heat source on the motor body.

Specifically, in the bearing part discussed in this article, it is whether this local temperature rise will affect the bearing. If this temperature does not pose a serious threat to the bearing operation, and since there is no problem with the heat source itself, this “anomaly” can be defined as a “non-fault”, and only its changes need to be monitored, without the need to take immediate measures.

For local overheating without an external heat source, motor engineers need to check the motor itself. Confirm whether this overheating is caused by some internal faults. Common situations include local high temperatures of the windings and high temperatures of the relative movement interface between mechanical parts.

This high local temperature of the motor itself is actually a state of active heat change obtained by comparing with the “normal” temperature distribution. Usually, this state is more likely to be a “fault”.

For example, local winding insulation problems, local mechanical part interference, mutual friction, etc. Therefore, for the situation where the motor body is locally heated and there is no external heat source, the possibility of faults in the motor body structure and insulation increases.

When we say the overall temperature of the motor base has increased, we mean that the current temperature of the motor is higher than its “normal” operating temperature. Moreover, this temperature distribution across the entire structure of the motor is basically consistent with the “normal” state.

The possible causes of overall heating of the motor base include: excessive motor load; poor motor heat dissipation; excessively high operating environment temperature of the motor; issues with the overall winding; wiring problems, among many others. We will elaborate on these separately.

The motor’s torque load variations indeed result in fluctuations in the motor’s current. An increase in current subsequently causes greater heating of the motor body.

On the other hand, if the axial and radial loads on the motor shaft end increase, the bearings will heat up more. However, this load-induced temperature increase primarily manifests as a localized temperature increase in the motor bearings, not a rise in the overall temperature of the motor body.

From this, we can infer that an increase in the overall temperature of the motor is related to “abnormal” external loads. As previously mentioned, a “normal” load, from the perspective of the equipment, is its design set value or the operating conditions provided before design.

A qualified motor should perform according to design expectations when operating under design conditions, which is verified during the motor’s design and factory inspection. However, if the motor’s load state exceeds the initial design expectations during operation, the motor’s heating condition will become “abnormal.” If this temperature exceeds control standards, it should be addressed promptly.

A motor typically encounters “abnormal loads” that do not match its rated duty cycle or its rated workload.

To make an analogy for load conditions that exceed the rated duty cycle, consider a worker on an 8-hour shift being asked to work overtime continuously, thereby increasing their fatigue level. The same applies to a motor.

For load conditions that exceed the rated workload, it’s like asking a worker, who normally produces ten items under regular conditions, to produce twenty, which will also increase their fatigue level.

Of course, these are rough comparisons. When designing a motor, a certain overload capacity is considered; this is the design margin. If the motor operates under overload conditions, it could cause a generalized increase in heating.

Additionally, certain installation issues can also cause changes in the motor’s internal load. For example, loose motor footings or poor motor alignment, etc. These faults not only impose extra load on the motor’s mechanical system and bearings, generating more heat, but also result in additional torque in the motor itself, causing further heating.

Changes in the motor’s working environment include changes in its cooling conditions and environmental temperature. If we regard the variations in the motor’s overall heating caused by load changes as the root cause of overall temperature changes, then changes in the motor’s working environment affect the motor’s cooling conditions.

The motor’s design includes given (or rated) working environment temperatures and cooling conditions. When the motor’s cooling conditions change or the environmental temperature changes, the respective cooling environment after the motor’s normal heating also changes accordingly.

The motor sealing referred to here primarily denotes the seal between the motor shaft and the motor stator. These seals are mostly used to isolate the motor bearing chamber from the environment, preventing contamination of the bearings. (Of course, there are corresponding sealing components in actual applications such as fluid cooling pipelines, but these are not within the scope of this discussion).

The seals used to isolate the bearing chamber from the external environment can also be referred to as bearing seals. Typically, the seal is fixed on one side, while the other side has a lip responsible for sealing.

The following reasons mainly cause heating of the bearing seal: wear of the sealing lip; damage to the part of the sealing lip, etc.

For non-contact seals, since the sealing lip does not contact other components, such relative motion will not generate extra friction, nor will it cause heating. A common labyrinth seal belongs to this category.

For contact seals, there is a mutual contact force between the sealing lip and the sealed component. When the motor rotates, there is relative friction between the contact surfaces, which can cause some heating. Usually, this heat generation is stable within a certain range. If there is an additional temperature rise, the cause needs to be investigated.

Uniform Wear of the Sealing Lip

If additional heat is generated in the sealed part, the wear condition of the sealing lip can be checked. If the sealing lip shows uniform wear, it indicates that uniform friction has occurred between the lip and the sealed component.

Dimensional Tolerance Exceeded in Related Components

The primary cause of uniform seal lip wear in bearings is due to the size deviation of related components.

For non-contact seals, such friction should not occur. Should wear appear on the lip of non-contact seals, it must be addressed.

When the seal lip experiences uniform friction, if the contact force on the seal lip is greater than designed, or if the relative speed is higher, the wear will be more severe.

At this point, the shaft dimensions should be checked. If the size of the shaft is too large, it can cause excessive contact force between the seal lip and the shaft, resulting in excessive friction and heat.

In addition, the surface roughness of the shaft should be checked. If the shaft surface is too rough, the wear between the lip and the shaft will be more severe, thereby generating additional heat.

If the roundness of the motor shaft exceeds the tolerance, it may also result in excessive contact force between the shaft and the seal lip in certain areas of the shaft. This can lead to uniform wear on the seal lip, with the degree of wear exceeding normal levels.

Inappropriate Seal Selection

When the motor seal exhibits heat, inspect the seal. If the seal lip is uniformly worn, it’s also necessary to check the seal selection.

Firstly, if the actual rotational speed of the motor exceeds the maximum speed allowed by the seal, this could result in uniform excessive wear on the seal lip, leading to heat.

If there are substances in the actual working conditions that react chemically with the seal, this could cause degradation of the bearing seal, potentially leading to changes in the overall size of the seal, resulting in excessive contact force and additional heat.

If the actual operating temperature exceeds the maximum temperature limit that the seal can withstand, this could cause softening of the seal lip, thereby increasing wear and potentially leading to heat.

Uniform wear of the seal lip can also be caused by improper seal installation and maintenance.

Improper Installation and Maintenance of Seals

Upon observing uniform wear on the seal lip during its heat cycle, one should not only review the content from the previous article but also inspect the installation and maintenance of the seal.

If the bearing seal isn’t installed properly, resulting in the seal lip being positioned improperly, it may cause excessive friction between the lip and the shaft, leading to heat generation.

During routine maintenance of the motor, it’s vital to inspect the wear condition of the seal. Based on the seal’s wear, one should consider replacing the motor bearing seal to prevent improper friction and the resultant heat.

Non-uniform Wear of the Seal Lip

If significant heat is detected in the motor bearing seal section and upon inspecting the seal lip, one might find not only uniform wear but also instances of non-uniform wear.

Non-uniform wear of the seal lip is mainly related to the seal components and the installation and maintenance of the seal.

Issues with Seal-Related Components

Non-uniform wear implies that while some areas around the seal lip have worn, others have not. This uneven wear can be attributed to the shape, positional tolerance, or relative position of the seal-related components.

If the motor shaft is misaligned with the bearing chamber, one side of the seal lip may experience greater contact pressure, resulting in additional wear and increased heat. Consequently, upon noticing such seal lip wear characteristics, one should check for parallel misalignment between the motor shaft and the bearing chamber.

When the motor shaft and the bearing chamber are angularly misaligned, excessive friction between the motor shaft and seal lip occurs in the direction of misalignment and its opposite. The places at 90 degrees to this misalignment will experience lesser wear. However, the areas facing excessive friction will generate additional heat and exhibit non-uniform wear around the seal lip.

Such misalignment between the motor shaft and bearing chamber could be due to misalignment of the shaft or the bearing chamber (mainly the seal installation part). When the bearing chamber is misaligned, either parallel or angular, it’s likely for the seal lip to exhibit non-uniform wear around its circumference, thus generating extra heat.

Improper Installation of Seals

When the motor bearing seals heat up, the uneven wear around the circumference might be related to the installation and maintenance of the seals themselves.

If there was a deviation in the installation position of the motor bearing seals, causing the seals not to be aligned with the shaft, it would result in misalignment between the seal axis and the base axis, including both parallel and angular misalignment.

This could lead to additional seal wear and corresponding heat generation, similar to the problems of misalignment of the motor shaft and bearing housing.

Additionally, if the seal lip was damaged during the installation of the motor bearing seals, it could potentially cause deformation of the lip, leading to poor local contact. This might result in excessive local friction and subsequent heating.

Damage to Motor Bearing Seals

When the motor bearing seals are damaged or deformed, the lip contact friction might increase, causing heat generation.

Therefore, if local overheating occurs in the motor bearing seal section, it would be advisable to check whether the seals themselves are damaged or deformed.

The causes of damage and deformation to the bearing seals include the following:

Improper Installation and Maintenance

During the installation and maintenance of the motor bearing seals, if the seal frame was damaged, it could cause deformation of the entire seal or a part of it. This deformation would alter the lip’s contact with the sealed surface.

Too little contact would reduce the sealing effect, while too much contact would increase friction, leading to extra heat generation. Therefore, when extra heating caused by friction occurs in part of the seal, it’s important to inspect the seal’s condition to eliminate any installation or maintenance errors and positioning discrepancies during seal installation.

Apart from installation and maintenance issues, damage to seals may also be associated with interference between the seals and surrounding components.

Interference with Surrounding Components

For non-contact seals, when the motor is running, the seals should not interfere with the stationary components. If interference occurs, the interfering parts will be damaged, generating heat and causing the seals to overheat.

Therefore, at this point, the dimensional relationship between the seals and surrounding components should be checked. Based on the location of the seal interference, one can find the location of the corresponding parts and inspect components related to that location. Simultaneously, corresponding wear marks can be found on these parts to confirm wear and make corrections.

For contact seals, besides the seal lips, the seals should also not interfere with other moving components. The wear condition of the contact seal lips can be judged based on the previously introduced uniform and non-uniform wear. Additionally, interference marks appearing on the seals should be traced to corresponding marks on other parts in the same location to confirm and eliminate them.

Seal Rotation

Under working conditions, the seal should be fixed as a whole to either the stator or rotor of the equipment. The friction during operation should occur at the seal lips. Meanwhile, the seal and its fixed part should be relatively stationary. If some parts of the seal exhibit abnormal heating, and there is a relative position change in the fixed part of the seal, it may indicate a seal rotation issue.

Seal rotation can cause localized heating and decrease sealing efficiency. This should be corrected immediately. The problem may stem from a tolerance issue between the seal and the fixed part, or from an over tolerance issue with the seal itself.

Sometimes, changes in material hardness due to heating can alter the fitting tightness between the seal and matching parts, leading to the risk of rotation. When seal rotation occurs, the root cause can be identified and eliminated by considering the dimensions and temperature effects.

So far, we have introduced 77 nodes related to motor heating and 56 nodes related to seals in the motor heating mind map. We will continue to explain the content of over four hundred other nodes in the future.

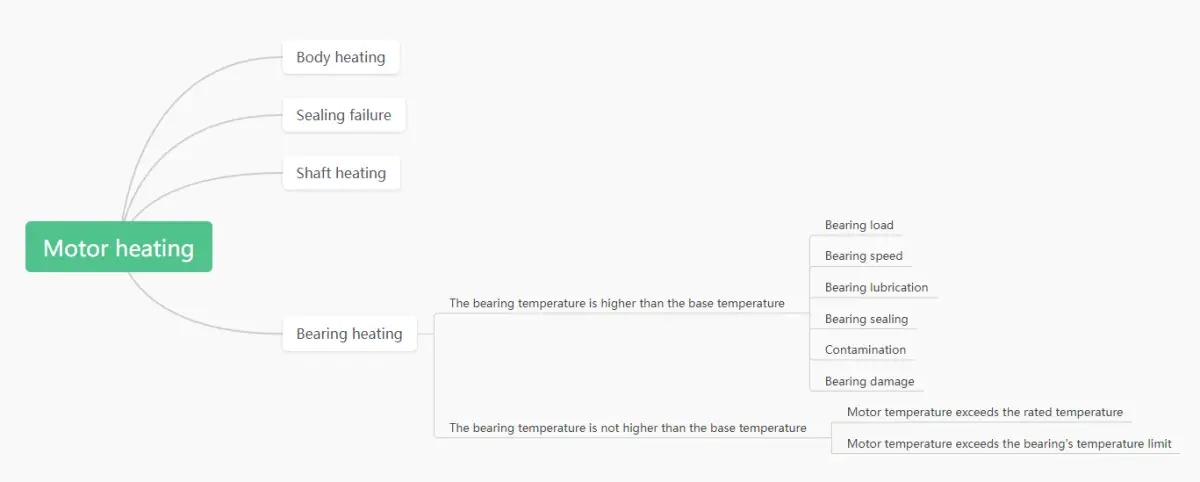

The prior discussion addressed the issues concerning heat generation in the motor, including the heat conditions related to the motor body and motor seals. From here, the focus shifts to discussing the components of motor overheating pertaining to bearings.

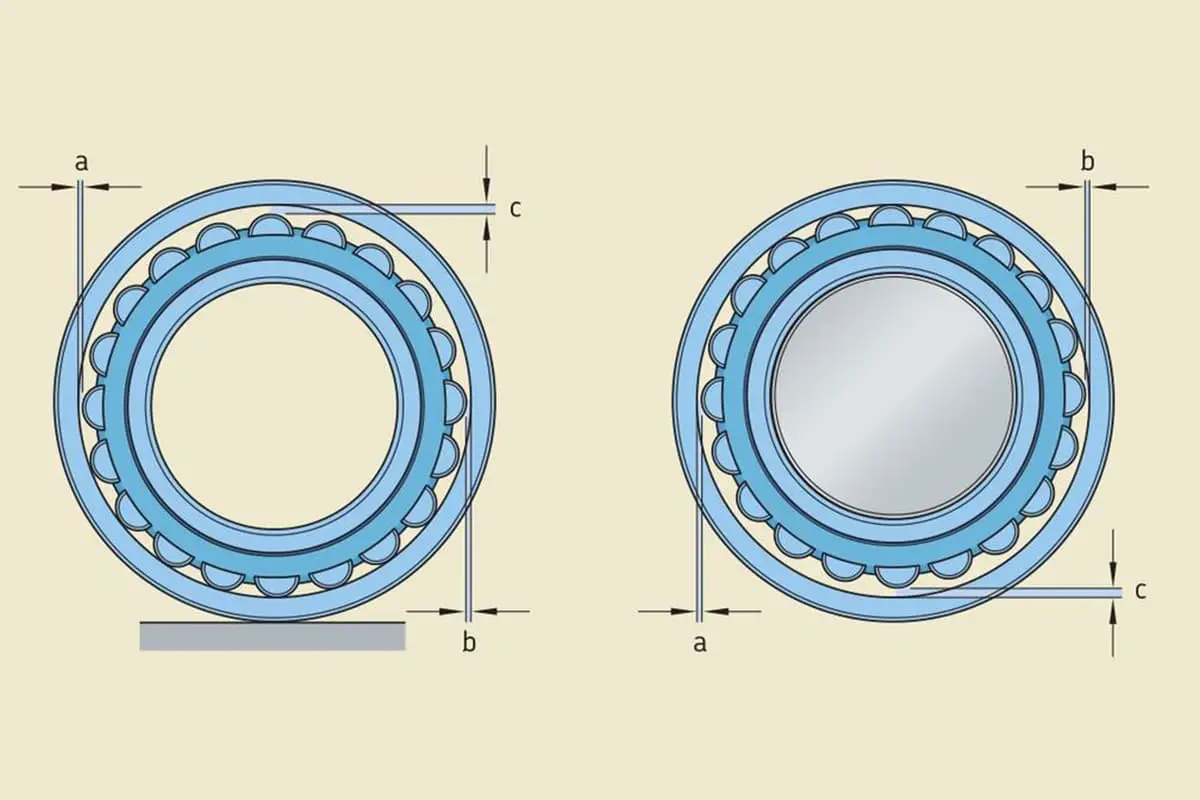

As previously mentioned, the temperature of motor bearings should not only be evaluated based on the absolute value but also in consideration of the distribution of temperature within the bearing components.

Regarding the temperature warning values for motor bearing overheating, these are documented in many international and national standards, which will not be reiterated here.

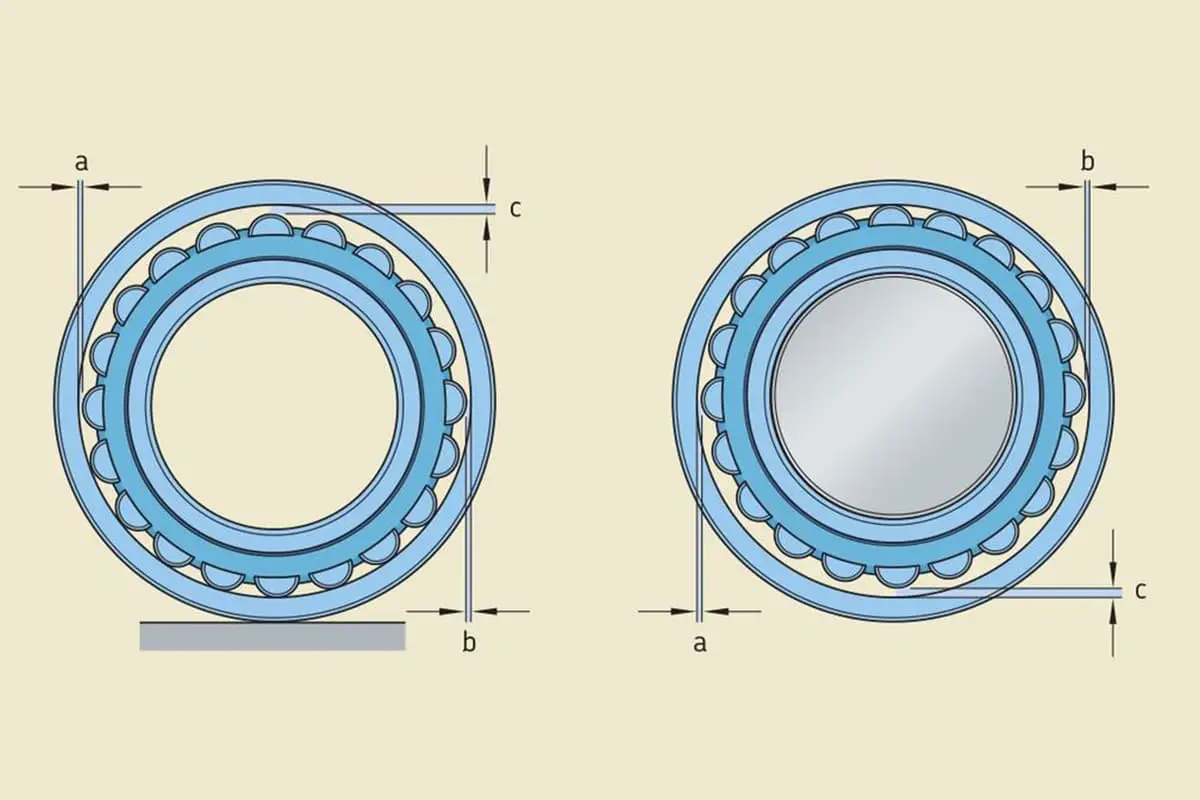

Following is a mind map addressing motor overheating issues. This diagram unfolds the topic of heat related to motor bearings in two directions: firstly, situations where there is no significant temperature difference between the bearing components and the motor housing, and secondly, scenarios where there is a considerable temperature disparity between the bearing components and the motor housing.

The determination of whether the motor bearing temperature is higher than the seat temperature or not is essentially an evaluation of temperature distribution. This determination is made based on the identification of the expected heating state of the bearing itself.

During operation, the bearing itself generates heat, but the heat generated by the bearing itself should not be the main part of the motor’s heating. In the matter of heating, the bearing primarily plays a role of passive absorption.

Based on the above conclusions, it is appropriate to use the temperature distribution between the self-heating of the motor bearing and the overall temperature of the motor seat as the starting point for fault diagnosis analysis.

From the previous introduction, it can be understood that when the temperature of the motor bearing is not higher than the seat temperature, or slightly and stably higher than the seat temperature (note, “not higher than” here refers to a small gradient that does not continuously increase), it is a normal performance of the motor bearing.

In other words, at this time, the internal operation of the motor bearing should not differ significantly from the normal state. Generally speaking, the chance of suspecting an internal fault in the motor bearing is reduced at this time.

When the motor bearing temperature is “not” higher than the motor seat temperature, there are two situations: the motor temperature is higher than the alarm temperature; the motor bearing temperature is higher than the bearing can withstand.

The premise of the motor temperature being higher than the alarm temperature discussed here is that the motor bearing temperature is “not” higher than the motor seat temperature. At this time, the self-heating situation of the motor seat should be checked first. A detailed investigation should be conducted based on the content discussed in the previous five articles.

If any problems causing the overall temperature of the motor to rise are found during the investigation of the overall motor heating, they should be eliminated.

If after investigation, there is no fault with the motor as a whole, or if these different working conditions would cause the motor temperature to exceed the warning, it may not be a fault of the motor or bearing, but rather the expected temperature of the motor working under different conditions. When this temperature exceeds certain standard alarm limits, the alarm limit needs to be adjusted.

The adjustment of the temperature alarm value can refer to relevant standards, but more importantly, it should be determined based on actual working conditions. Usually, the alarm temperature for working conditions can be determined using historical records or estimated heating under different loads. The setting of this alarm limit is somewhat like the enterprise standard based on the national standard.

On the other hand, this adjustment of the motor bearing temperature alarm value should not exceed the temperature limit that the bearing can withstand.

The temperature of the motor bearing exceeds the temperature limit that the motor bearing can withstand.

Changes in the temperature of the motor bearing can affect the performance of the motor’s lubrication and the motor’s bearing cage. When the temperature reaches a certain limit, it can even affect properties like the performance of the bearing steel.

In general, there is a basic limit to the temperature at which a motor bearing can work. When the temperature of the motor bearing exceeds this limit, the bearing cannot achieve its expected performance. (Please note that our current discussion is premised on the motor bearing temperature not exceeding the motor housing temperature, which implies that the motor bearing is most likely not in a failure state. Discussions about the bearing in a failure state will be covered in the subsequent failure tree.)

In the above situations, the first consideration is to adjust the motor. If there are any heat-generating issues with the motor body, they can be dealt with. If the motor is overheating due to operational reasons, or if the environmental temperature in which the motor works is causing the motor to overheat, then adjusting the motor will not reduce the temperature.

The necessary action would then be to adjust the bearing. In other words, we need to adjust the bearing selection so that the new bearing can perform as expected at this temperature.

So far, we’ve discussed scenarios where the temperature of the motor bearing “does not” exceed the temperature of the motor housing. This situation often prompts field engineers to look for faults outside the bearing.

In fact, it is not advisable for engineers to apply the above conclusion in an overly rigid manner. The judgment made above that there is no fault is only a probability and does not rule out issues with the bearing application in some cases. Here are a few possible scenarios:

Firstly, the motor bearing temperature does not exceed the housing temperature, but it is higher than the temperature of other bearings of the same model. In this case, there may be differences in the motion state within the motor bearing compared to other bearings of the same model and working conditions. This anomaly identified through lateral comparison also needs attention.

Even though the temperature does not exceed the housing temperature and sometimes remains within the allowable range for bearing operation, it could be an early stage of a fault. Therefore, the situation on site can be determined through the above lateral comparison method.

Secondly, consider the trend of the temperature. In some faults, the motor bearing temperature rises, but initially, the motor bearing temperature reaches higher than the housing temperature. As the fault progresses further, the temperature will exceed the housing temperature, indicating that the motor bearing is generating heat.

Therefore, the previous “not higher than the housing temperature” is only a temporary situation. At this point, the motor engineer should make a longitudinal comparison on the timeline. If the motor bearing temperature is stable, it indicates that the situation is normal. However, if the condition is deteriorating and the temperature is continuously rising, it indicates that there may still be some potential faults.

In conclusion, when diagnosing motor bearing faults, one needs to apply theoretical knowledge flexibly, and make horizontal and vertical comparisons of equipment status. This will greatly benefit the accuracy of fault diagnosis.

When the motor bearing temperature is not significantly higher than the motor base temperature, the overall heat generation from the motor bearing is not a major component of the motor’s heat. The temperature distribution at this time aligns with the expected normal distribution. Hence, from the perspective of temperature distribution, the likelihood of bearing failure can be somewhat downplayed.

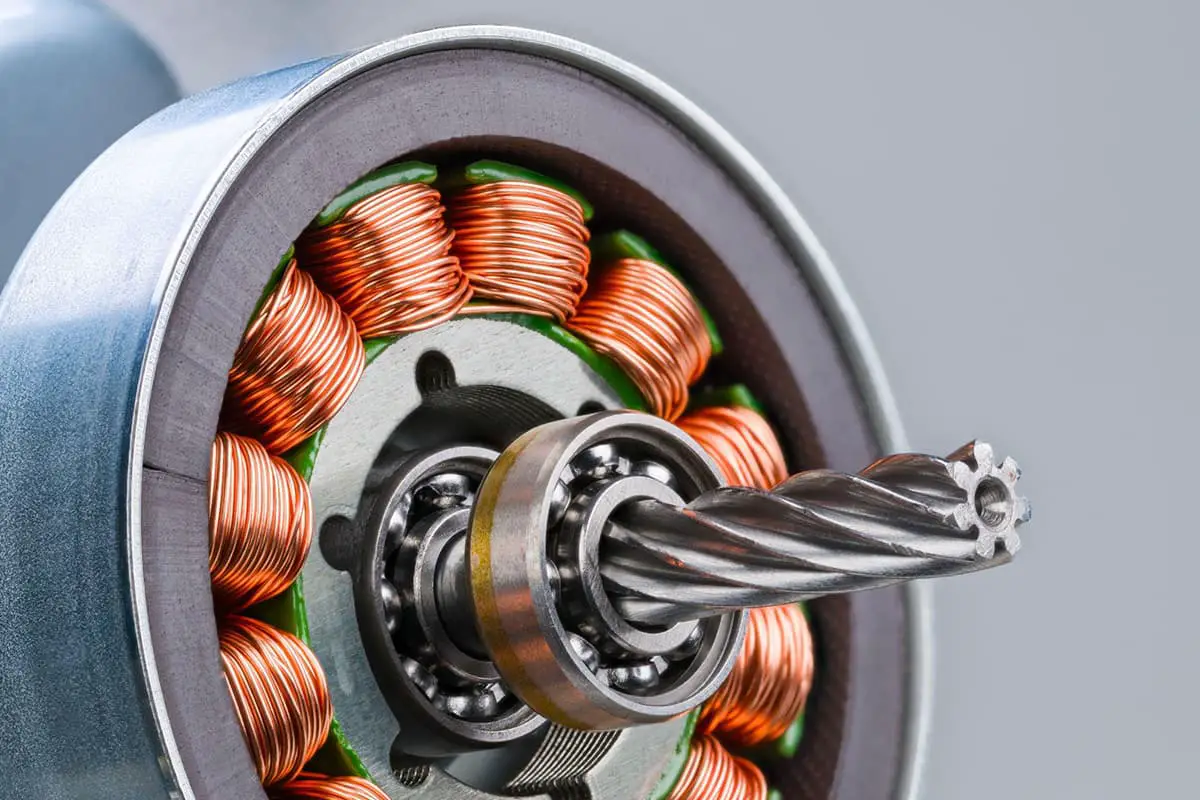

However, when the motor bearing temperature is significantly higher than the surrounding motor end cap and base temperature, the bearing, as a major source of heat, significantly affects the overall temperature distribution of the motor. This deviation from the expected temperature distribution between the motor bearing and the base gives reason to suspect potential bearing failure.

As previously mentioned, when the motor bearing temperature is noticeably higher than the base temperature, the heat sources for the bearing include both internal and external components. External heat comes from adjacent components such as the shaft and bearing chamber. Internal heat originates from various frictions within the bearing.

When the bearing temperature exceeds the base temperature, it implies that the internal friction of the motor bearing dominates the heat generation, becoming a major factor in the temperature increase.

The primary factors causing motor bearing heat include:

Let’s analyze these one by one.

Motor Bearing Load

One cause of motor bearing heat is a load issue. When selecting motor bearings, the life of the bearing is checked according to the set operating conditions. The essence of this check is to verify the chosen motor bearing’s load capacity. When the motor bearing heats up, the following scenarios require a check on the motor bearing load:

In this case, if heating occurs in the bearing and no other abnormalities are apparent, a comparison should be made between the design conformity and the actual load on the motor bearing. This is done to identify any discrepancies.

Firstly, when comparing the design conformity and the actual load of the motor bearing, check the actual load against the life difference. And based on the actual load, recheck the load of the motor bearing. If the bearing life checked under the actual load is less than the design check result or less than the life result required by the operating conditions, then the bearing selection is insufficient.

If this problem occurs during the design test phase, the bearing selection must be adjusted according to the actual load conditions.

If this problem occurs during the use of the motor, it means that the load at the motor shaft end is greater than the given design, and the motor operating load needs to be adjusted.

Apart from leaving a design margin for the electrical performance of the motor during general motor design, sometimes, if the application scenario of the motor varies greatly, it might also be necessary to leave a certain design margin for the selection of motor bearings. Usually, within this design margin, normal heating of motor bearings should not be a problem.

Note that this design margin must be reasonable. If the design margin is small, the load on the motor bearing will be large, which may cause problems such as heating. On the other hand, if the design margin is too large, there may be a situation where the minimum load on the motor bearing is insufficient, which will also cause abnormal heating of the bearing. (Related content will be introduced later.)

In addition to checking whether the due load on the bearing is too large for the heating problem caused by the motor bearing load, other aspects of the load on the motor bearing should also be checked. Sometimes these aspects are not discovered through the life check of the motor bearing.

When motor bearings overheat, one should compare the load that the motor bearings should bear with the actual load borne by the motor to determine whether the selection of the motor bearings is inappropriate or the load given at the time of motor application is improper. Simultaneously, a general description of the load selection margin issue for motor bearings to avoid such overheating situations must be provided.

In addition to checking the “expected load” borne by the motor bearings, sometimes other situations need to be investigated.

For instance, whether the motor bearings have assumed load components that their bearing capacity does not possess.

Several common situations in motors are as follows:

Firstly, motor bearings are equipped with floating-end and non-floating-end structures as well as cross-located structures. In motors with positioning end and non-positioning end structures, the axial load is borne by the positioning end bearing, and the non-positioning end bearing should not bear axial load. Therefore, axial load is generally not considered when selecting bearings.

At this time, if the floating-end bearing bears axial load, it can cause problems such as bearing overheating. In such cases, it is necessary to check the motor structure arrangement to ensure the floating-end bearing is appropriate.

In the above situations, the objective of the investigation is to identify the source of axial force on the floating-end bearing and eliminate it.

In the positioning end or cross-located structure of the motor bearing system, if the direction of the load borne by the bearing exceeds the design expectation, it can also lead to bearing overheating. A typical example is when the motor uses single-direction bearing capacity bearings such as angular contact ball bearings.

If reverse axial force occurs, the bearing may disengage, causing the motor bearing to overheat or even burn out. At this time, the source of the reverse axial force should be identified and eliminated. If it cannot be eliminated (or if the operating condition is just so), it is necessary to adjust the configuration of the motor bearing system.

Some bearings have a certain bearing load capacity, but their axial load capacity is limited. When the axial load exceeds the axial load capacity of this bearing, the bearing will overheat. For example, deep groove ball bearings, although they have a certain axial load capacity, if the axial force is too large, the bearing will overheat.

However, generally speaking, this situation can be detected in life calculations. The solution to this situation is to change the selection of motor bearings to accommodate large axial loads.

Another situation is difficult to perceive in conventional motor bearing load calculations. For example, the self-aligning roller bearing has a certain axial load capacity, but under a certain axial load, the unladen roller column is likely to have insufficient minimum load or disengagement and slippage. In this case, it will manifest as bearing overheating.

At this time, it is best to adjust the bearing selection. If it is impossible to adjust, there are some measures to alleviate it, but it cannot be cured. For example, methods such as reducing the viscosity of the lubricating grease within a reasonable range and appropriately tightening the bearing outer ring can help.

We’re discussing the issue of motor bearing overheating caused by the actual load the bearing supports not aligning with the designed or expected bearing load. Indeed, in the process of diagnosing and analyzing motor bearing failures, traces corresponding to such situations can be found on the surface of bearing rollers and raceways through bearing failure analysis.

Factors related to load in motor bearing overheating should be compared not only with the designed specifications but also with the bearing’s load capacity.

We’ve previously discussed the discrepancy that exists between the actual load a motor bearing experiences and its designed load, which may lead to the heating of the motor bearing. Essentially, this involves comparing the actual bearing load to the expected load during the design phase.

Motor bearing loads are primarily radial and axial. When diagnosing heating issues with motor bearings, it’s necessary to compare the different loads the bearing is subjected to, in order to identify the problem.

With respect to the radial load on a motor bearing, if the bearing is subjected to a radial load that is greater than what it can handle, it will not be able to reach its expected lifespan. This could be a result of the bearing being undersized.

In cases where the selected motor bearing is undersized, the bearing’s load capacity might be insufficient. If this is discovered during the design testing phase, consider adjusting the selection. If the bearing’s external radial size is limited and cannot be increased, select a bearing type with greater load capacity from among those with the same external diameter.

This could include:

If, during the design testing process, it’s discovered that the motor bearing’s load capacity is insufficient and the motor’s radial size can be increased, consider using a bearing with a larger diameter.

Whether changing the bearing type or increasing the size of the same type to improve its load capacity, it’s necessary to recalculate the bearing’s load capacity before making a selection, to ensure the correctness of the new selection.

In cases where the motor bearing is improperly configured:

If the radial load on the motor bearing is too large, it could be due to improper design during the bearing configuration of the shaft system, causing the bearing to bear a load it should not. Checking this usually requires comparing drawings and actual measurements.

Ensure that the actual assembly structure of the workpiece is reasonable and the bearing configuration is appropriate. If the bearing configuration is reasonable, the support structure of the shaft system should be adjusted. If this bearing configuration cannot be changed, the bearing selection should be changed to adapt to the operation of the bearing under this structural load.

In cases where the load on the motor shaft end is improper:

If the motor bearing is subjected to an excessive load and, after inspection, no issues are found with the internal bearing selection and structural arrangement of the motor, further inspection of the source of the radial load on the bearing is necessary. Common causes include excessive belt pulley tension and excessive radial force due to coupling weight.

In fact, a coupling generally will not be too heavy, but the distance between the action point of the coupling and the two bearings can affect the actual bearing load. The same radial force results in different bearing radial loads at different shaft end distances, which needs to be verified.

The above discussion pertains to the radial load factors related to motor bearing heat in the context of bearing load. In actual working conditions, bearing loads also include axial loads, and improper axial loads can also cause undesired heat production during the operation of the motor bearing.

As previously mentioned, motor bearings may also generate heat when subjected to excessive axial loads. Similar to the situation where a radial overload leads to bearing overheating, when an axial load is too large, considerations should include whether the bearing selection is appropriate, whether the bearing arrangement is proper, and whether the actual load on the bearing is correct.

In cases of undersized bearing selection:

The design of motor bearings takes into account the possible axial loads they may have to bear. However, if the actual axial load is greater than the designed axial load, this will cause the motor bearings to generate extra heat, leading to improper heating.

In this situation, adjustments to the selection of motor bearings are required. The adjustment methods are similar to those for insufficient radial load capacity, but the bearing type adjustments are different. These adjustments may include:

In addition to using different types of bearings to handle larger axial loads, the axial load capacity of the bearing can also be increased by using larger bearings.

Whether changing the bearing type or choosing a larger bearing, once the selection is confirmed, the bearing’s load capacity should be recalculated to ensure the correctness of the selection.

In cases of improper motor bearing arrangement:

Because of improper motor bearing arrangement, the bearing may endure an axial load it should not bear, or the axial load it bears may be too large, both of which can cause the motor bearing to overheat.

In such situations, if the arrangement of the motor bearing system can be adjusted, the configuration of the bearing system should be adjusted. If the arrangement of the motor bearing system cannot be adjusted, the bearing type needs to be adjusted, and a bearing type that can meet the load conditions based on the load borne by the bearing should be selected.

In cases of improper external load on the motor:

The external load of the motor is the direct cause of the load on the motor shaft system. If an axial load appears on a shaft system that should not bear an axial load, it is likely because of an improper external load.

For motors connected with pulleys, since the transmission method is through the pulleys, there should be no axial load on the motor shaft system. However, if there is misalignment of the pulleys, this type of connection can bring a certain axial force to the shaft system. This should be checked during fault diagnosis.

When the motor shaft end is connected with a coupling, misalignment of the coupling can cause axial load on the shaft system. Therefore, when an abnormal axial load appears on the motor shaft system, the coupling connection should also be checked.

We have discussed situations where the radial and axial loads borne by the motor bearings are greater than the loads the bearings should bear. At these times, the main diagnostic direction is to find the source of the load and develop reasonable adjustment plans or elimination measures based on the source.

In addition to the regular overload, there may be situations where the load inside the motor bearing is too small, or the load distribution is abnormal. Both of these situations can also lead to extra heat generation in the motor bearings.

Motor bearings may heat up when subjected to a load larger than they should ideally carry. Does this mean that the load on the motor bearing should be as small as possible? The answer is no.

If the load on a motor bearing is less than the minimum required for its operation, pure rolling cannot be formed within the bearing during operation. This leads to relative sliding between the rolling elements and the raceway inside the bearing, causing extra heat, which can result in overheating of the bearing.

When overheating occurs in motor bearings, the relationship between the load on the bearing and the minimum load can be checked using the method of calculating the bearing load. Evidence can also be found from the failure marks of the failed bearing.

If the bearing selection can be adjusted when overheating occurs, an attempt can be made to replace it with a bearing with a lower load capacity. For instance, ball bearings can replace roller bearings, single-row bearings can replace double-row bearings, or smaller bearings can replace larger bearings.

Before deciding to replace the bearing due to inadequate minimum load causing heating, a verification calculation must be performed on the bearing’s actual load, minimum load, and bearing life to ensure the success and efficacy of the bearing replacement.

When a motor bearing overheats because of insufficient minimum load, and it is impossible to replace it with a bearing with a lower load capacity, the viscosity of the motor bearing lubrication can be appropriately reduced. This method can help decrease the minimum load required for bearing operation to some extent, but it may not work for all motor bearing heat failures caused by insufficient minimum load.

Motor bearing heating failures due to load issues may not only be caused by excessive or insufficient loads, but also by incorrect load distribution. A typical example is the eccentricity problem of the motor bearing load.

The eccentricity problem of motor bearing load refers to a situation where there is an offset or misalignment between the load carried by the motor bearing and the axis of the center hole of the bearing. In this case, the rolling elements inside the bearing cannot operate in the middle of the load area, sometimes causing excessive local load, while being too light in other areas. This can lead to extra heat during operation of the motor bearing.

The eccentricity problem of the motor bearing may be caused by improper installation of the motor bearing or by inappropriate shape and position tolerances of the relevant parts of the motor bearing.

When an eccentric load occurs in the bearing, evidence can be found through failure analysis of the motor bearing, and corresponding features will also appear on the vibration spectrum of the motor bearing.

Usually, the shape and position tolerances of the motor shaft and bearing chamber are checked to rule out size issues with the related parts of the motor bearing. The installation process of the motor bearing is also examined to eliminate the possible causes of eccentric load on the motor bearing.

So far, we have discussed the heating problems of motor bearings caused by incorrect load and their basic countermeasures. The heating of motor bearings includes many factors besides load, such as speed, lubrication, sealing, bearing damage, and others.

As mentioned earlier, besides the bearing load’s impact on heat generation, many other factors influence motor bearing heat production, with speed being a significant factor that cannot be overlooked. When designing motors, engineers must ensure the actual bearing speed falls within the bearing’s tolerable range. Both excessively high and low speeds could lead to abnormal bearing heating.

Before discussing the implications of overly high and low speeds, we need a reference standard. In other words, what is considered too high or too low relative to what? Typically, a comprehensive bearing catalog will provide a rated speed value, including concepts like oil lubrication rated speed, grease lubrication rated speed, thermal reference speed, and ultimate speed.

Firstly, when the motor’s speed exceeds the bearing’s thermal reference speed, the motor bearing tends to heat up. Sometimes this heating disrupts the bearing’s thermal equilibrium, leading to bearing burnout. Other times, a new thermal equilibrium state forms, which may not directly cause bearing burnout but can affect factors like lubrication, thereby reducing bearing life.

When the actual operating speed of the motor exceeds the thermal reference speed of the bearing, the first step is to examine and adjust the bearing selection, provided conditions permit. Principles for adjusting bearings include:

Choose bearings with higher speed capabilities to replace the current overheating ones. As explained in articles introducing bearing speed performance, generally, ball bearings of the same inner and outer diameter have a higher speed capability overall than roller bearings; single-row bearings have higher speed capabilities than multi-row bearings. Therefore, adjustments can be made according to this principle when changing the type of bearings.

Within the same type of bearing, the diameter size of the bearing is also related to its speed capability. Therefore, among the bearings that can meet the motor bearing load requirements, the lack of speed capability can be improved by adjusting the size of the bearing.

Usually, light series bearings have higher speed capabilities than heavy series bearings, and small diameter bearings have higher speed capabilities than large diameter bearings. However, whether changing the light/heavy series of bearings or altering the bearing diameter, it should always be done to meet the bearing load capacity requirements. Therefore, in addition to checking speed, it is also necessary to re-check the bearing life.

In bearings of the same size and type, different internal designs also impact the bearing’s speed capability. Typically, bearings with nylon cages have higher speeds than those with steel and brass cages; bearings with steel cages have higher speeds than those with brass cages, and stamped steel cages have higher speeds than machined cages. This rule can also be applied to situations where the speed exceeds the mechanical limit speed.

This article expounds on the principles and measures to adjust the motor bearing when the working speed of the motor bearing exceeds its thermal reference speed. In fact, when the actual operating speed of the motor bearing exceeds its thermal reference speed, it can also be addressed by improving lubrication and heat dissipation methods.

The text discussed earlier that when the actual operating speed of the motor bearing is higher than the thermal reference speed of the motor bearing, the principles and ideas for handling are achieved by adjusting the selection and size of the bearing.

In fact, it’s not difficult to discover from the definition of the thermal reference speed of the motor bearing: when the speed of the motor bearing exceeds the thermal reference speed but is lower than the mechanical limit speed, adjustments can be made by improving lubrication and enhancing heat dissipation.

This prevents the bearing from failing prematurely. Adjustments to cooling and heat dissipation are primarily achieved by increasing the flow of the cooling medium and reducing the temperature of the cooling medium, such as the airflow of the motor cooling fan, or by enhancing the cooling medium’s heat dissipation to lower its temperature.

In this way, an increase in the temperature of the motor bearing is balanced by a decrease in the temperature of the cooling medium, transitioning from one thermal equilibrium state to another.

Adjustments to lubrication to address the heat generation problem caused by high rotation speed of the motor bearing can be made in the following ways:

Firstly, the viscosity of the lubricant can be adjusted. For commonly used motor grease, the thickness of the grease and the base oil can be reduced. This reduces drag loss caused by high speed, which is beneficial for high-speed lubrication.

Secondly, the issue of motor bearing heat due to high speed can be alleviated by adjusting the quantity of lubrication. Generally speaking, while satisfying the basis for lubrication, appropriately reducing the quantity of lubricant is beneficial for high-speed applications.

In addition to adjusting lubricant viscosity and quantity, the method of lubrication can be changed to meet high-speed requirements, if conditions allow. For example, using oil lubrication instead of grease lubrication, using spray oil lubrication instead of oil bath lubrication, using oil mist lubrication instead of spray oil lubrication, etc.

In summary, while adjusting lubrication to accommodate high-speed motor bearing operation and reduce bearing heat has a certain alleviating effect, there can sometimes be certain limitations.

For example, it is generally challenging to change the method of lubrication in actual working conditions. Furthermore, using the method of adjusting the viscosity of the lubricant can only alleviate the issue to a certain extent, and this adjustment also presents challenges for lubrication performance.

From the above discussion, we understand some approaches to handle situations when the actual operating speed of motor bearings exceeds their thermal reference speed. The heat generated by the motor bearings is a very apparent and direct indication of their thermal reference speed, offering some room for mitigation.

On the other hand, when the actual operating speed of the motor bearings exceeds their mechanical limit speed, heating may occur before or during bearing failure. At this point, characteristic signs should be identified from a failure analysis of the failed bearings, and a check of the motor bearing speed will reveal that it exceeds the mechanical limit speed.

Although the mechanical limit speed of motor bearings is not fundamentally indicated by their heat generation, it does have a relationship with heating. Moreover, bearing damage caused by speed exceeding the mechanical limit is essentially irreversible once it occurs.

Therefore, through bearing heat generation, and comparing bearing parameters or failure analysis, when a conclusion related to the motor bearing speed exceeding the mechanical limit speed is reached, measures should be sought from aspects such as bearing selection.

The previous text mentioned that when the actual operating speed of a motor bearing exceeds the mechanical limit speed of the bearing, it exhibits a state of heat generation before or during the bearing’s collapse.

From the connotation of this speed definition, it is not hard to deduce that once the motor bearing speed surpasses the mechanical limit speed, each component of the bearing undergoes a severe test under the influence of substantial centrifugal force.

If a particular component reaches its strength limit and fails, the entire bearing faces the risk of collapse. To accommodate such high speeds, the following measures can be considered:

Adjust the type of bearing, opting for one with a higher mechanical limit speed. Generally, components with smaller mass experience less centrifugal force during high-speed rotation, hence the following principles:

In the selection of cages, it isn’t just about size; for certain speeds, it may be necessary to balance strength and mass. For example, a nylon cage is lightweight but has low strength, while a machined brass cage is stronger but heavier.

On the other hand, not all bearings offer all types of cages due to material and manufacturing processes, so the choices for an electrical engineer can sometimes be limited.

In addition, the selection of a cage not only considers centrifugal force but also its relative position and guidance method inside the bearing, which can affect the internal friction conditions of the bearing and generate heat.

A common situation is the cylindrical roller bearing guided by the bearing ring (inner or outer), which, when the bearing’s speed ndm exceeds 250,000, is suitable for oil lubrication, not grease lubrication. Using grease lubrication can easily lead to overheating and the production of bronze powder.

These scenarios are prevalent in the actual production activities of motor factories, so initial bearing selection should be given adequate attention.

Up until now, we’ve discussed issues of bearing overheating due to excessive rotational speed. In reality, bearings can also heat up when their rotational speed is too low. This is because the formation of an oil film between the rolling elements and the raceway requires a certain relative speed.

When the bearing’s rotational speed is too low, it becomes difficult to form this oil film, thus a proper lubrication mechanism cannot be established, which may lead to bearing overheating.

When motor bearings rotate at very low speeds, the following adjustments can be made:

Adjust lubrication viscosity: Increasing the grease thickness and the base oil viscosity can help form a lubricating film at low speeds.

Adjust the amount of grease added: In low-speed conditions, the drag loss caused by the motor bearing stirring the grease is minimal. At this time, increasing the amount of grease added can help form an oil film without adding excessive drag loss.

Adjust the additives within the lubricant: When the bearing’s speed is insufficient to form an oil film, certain extreme pressure additives and anti-wear additives can be used. Adding extreme pressure additives can allow the bearing to still achieve separation of the rolling elements and raceway at low rotational speeds. Using anti-wear additives can prevent direct wear between the rolling elements and the raceway.

Of course, when the bearing’s rotational speed is too low, in addition to considering lubrication, more attention should also be paid to the bearing itself during verification. Besides the bearing’s fatigue life, the static load verification of the bearing becomes key, and adjustments should be made to the bearing based on the verification results.

The previous text discussed possible reasons for motor bearing heat generation at high and low speeds. In fact, when motor bearings operate at variable speeds, internal friction and collisions within the bearing are relatively severe, resulting in additional heat generation.

Variable motor speeds may be due to frequent start-ups, unidirectional speed changes, or changes in direction (referred to as reciprocating motion).

Two situations differ slightly. For unidirectional speed changes (including frequent startups), if motor bearing overheating occurs, it is advisable to check whether the selected bearing is suited for such conditions.

For variable speed situations, it’s recommended to choose bearings with a strong cage, and if possible, use a lightweight, soft material cage. This can reduce the collision between the cage and the bearing rollers during speed changes, and decrease the resulting additional damage and heat generation.

On the other hand, selecting a grease with anti-wear additives can reduce friction, heat, and wear caused by the sliding between individual components within the bearing during speed changes.

For reciprocating motion conditions, additional verification of the selected bearing is necessary, such as considering the bearing’s static load calculation, not just the bearing’s rated fatigue life calculation.

For bearings in reciprocating motion, it is important to select lubrication with extreme pressure additives to protect the friction surfaces during low speed directional changes.

Up to this point, we have elaborated on the content related to speed in the motor bearing heat generation fault tree.

Aside from the potential causes mentioned before, another significant factor for motor bearing heat generation is lubrication. The heat conditions caused by lubrication can sometimes progress rapidly, faults can develop swiftly, and sometimes, symptoms such as heat generation may appear even when there are minimal changes in vibration.

Consider the following facets when diagnosing excessive heating in improperly lubricated motor bearings:

1. Unsuitable lubricant selection,

2. Inappropriate lubrication methods,

3. Faulty design of the lubrication oil path.

These are the three major areas to investigate.

Motor bearing lubrication design encompasses the choice of lubrication method, lubricant viscosity, and the selection of lubricant additives.

The choice of lubrication method for motor bearings should be according to actual operational requirements. Different lubrication methods result in different levels of internal drag loss in the bearings and thus different heating conditions.

In ascending order of heat generation, the methods are: oil and gas lubrication, oil spray lubrication, oil bath lubrication, and grease lubrication. Oil and gas lubrication has a more precise lubrication position, and with properly controlled lubrication volume, it presents the least internal drag loss in the bearing. However, this system is relatively complex and requires certain control standards.

Oil spray lubrication uses a larger volume of lubricant than oil and gas lubrication, resulting in relatively less heating of the bearing, and the oil spray has a certain cooling function. Correspondingly, oil spray lubrication requires a specific oil path design and lubrication control capabilities. It is relatively complex and has higher costs.

The oil path structure and control structure of oil bath lubrication are simpler than oil spray lubrication, but the work involved in parts stirring lubrication is relatively high. The lubricating oil has a certain cooling effect, commonly used in gearboxes and large motors.

Grease lubrication is the most commonly used method of lubricating motor bearings. Its oil path design is simple and cost-effective. However, compared to the other two methods, the drag loss from bearing stirring lubrication is higher.

Different lubrication methods have certain applicable ranges, and within these ranges, adjusting the lubrication medium can help reduce corresponding friction and heating. However, if the operational conditions exceed this range, a change in lubrication method is necessary.

The previous section discussed some inspections and considerations when choosing lubrication methods for motor bearings during heating. Correspondingly, the choice of motor bearing lubricant has a significant impact on bearing heating.

Through this knowledge, we understand that the primary goal in choosing a motor bearing lubricant is its viscosity. Purely from the perspective of reducing heat generation in motor bearing lubrication, lowering the lubricant’s viscosity can help reduce drag losses during bearing operation. Therefore, a low-viscosity grease that meets lubrication requirements, as well as a low base oil viscosity lubricant, can be selected.

It should be emphasized here that reducing the viscosity of the lubricant must still meet the basic lubrication needs of the motor bearing. It should be reduced within this demand range. Otherwise, the motor may experience heating and bearing damage due to poor lubrication.

Furthermore, after choosing the appropriate viscosity for the lubricant, the selection of additives must be considered, especially in special speed scenarios. For low-speed situations, extreme pressure additives are necessary. Molybdenum disulfide is commonly used in general motors as an extreme pressure additive.

However, in situations where the motor bearing speed is high, molybdenum disulfide cannot continue to be used, as it may cause internal wear in the motor bearing and poor lubrication. This is because, under high speeds, molybdenum disulfide may act as an abrasive particle in abrasive wear.

When the internal lubrication method, lubricant viscosity, and additives for the motor bearing are all appropriately chosen, heating of the motor bearing will not occur. However, in addition to this, the application of lubrication will influence the heating of the motor bearing.

The application of lubrication includes the amount applied, the timing of application, and the method of application.

If excessive grease is added to the motor bearing, the bearing’s rotation will generate heat due to the stirring of the grease. Therefore, when the motor bearing exhibits heat, a check of the grease amount is necessary.

In addition to excessive grease causing bearing heat, insufficient lubrication can also cause internal bearing friction pairs to heat up through contact. In this case, firstly, the initial grease amount for the motor bearing should be checked to ensure lubrication needs are met.

If the initial grease amount is adequate but the residual grease inside the bearing is insufficient, there may be an oil leak during motor operation. The cause of the leak should be investigated. If the leakage is caused by the seals, these should be repaired.

For vertical motors, the risk of oil leakage is inevitably increased due to gravity. Apart from checking for leaks, it is also necessary to monitor and adjust the supplementary lubrication to ensure that the remaining grease inside the bearing meets lubrication needs.

Motor lubrication amounts should be monitored not only for the initial lubrication but also for supplementary lubrication. Insufficient supplementary lubrication can also lead to oil starvation inside the motor bearing.

Typically, the intervals and amounts for periodic supplementary lubrication should be adjusted based on lubrication validation calculations. For continuous lubrication systems, the continuous lubrication oil injection amount should be adjusted.

As mentioned above, one of the causes of motor bearing overheating is the issue of lubrication quantity. Both excessive and insufficient lubrication can lead to heating of motor bearings.

In fact, improper lubrication replenishment ends up causing either too much or too little lubrication within the bearings. The discussion of over or under-lubrication primarily pertains to the improper lubrication quantity during the initial installation. This section deals with the part about lubrication replenishment.

Firstly, let’s consider the timing of lubrication replenishment. Generally speaking, engineers will calculate and select the timing for motor bearing lubrication replenishment based on the type of bearing and its operating conditions.

The replenishment timing should meet the lubrication needs of the motor bearing’s operation. However, many special operating conditions require adjustments to the lubrication replenishment timing.

For instance, for vertical motors, the standard re-lubrication interval is typically halved; in vibrating environments, the standard re-lubrication interval should also be halved. The corresponding lubrication replenishment section in the manual discusses many situations that require adjustment of re-lubrication timing.

When onsite overheating of motor bearings occurs requiring a check on lubrication intervals, these factors should be paid attention to.

In addition to the issue of lubrication replenishment timing, the quantity of lubrication replenishment should also be considered during inspection. As for the quantity of lubrication replenishment, the corresponding calculation formula in the manual can be referred to, which will not be repeated here.

Maintenance personnel onsite should adhere to this quantity when replenishing lubrication to the motor bearings. Insufficient addition should be avoided.

If excessive lubrication is added onsite, the oil drain valve should be opened to let the surplus grease flow out, thus preventing the excessive grease inside the bearing from causing overheating. If a continuous oiling system is used for motor bearing lubrication and overheating occurs under the current lubrication conditions, the continuous oiling quantity can be appropriately adjusted.

When inspecting the lubrication replenishment of motor bearings, the method of lubrication replenishment should also be checked.

Generally speaking, lubrication should be added as much as possible when the equipment is operating at low speed. Compatibility of the added grease should be ensured during addition. The compatibility of incompatible greases should be checked before mixing to ensure grease performance.

On the other hand, when replenishing lubrication to the motor bearings, if the new grease and the temperature of the motor bearings differ significantly, the new grease should be appropriately heated, especially for high-speed running equipment.

This is because the viscosity of grease generally increases with a decrease in temperature, and greases with a significant temperature difference have a large disparity in viscosity. Such a mixture of cold grease trying to quickly reach operating state may lead to poor lubrication.

When replenishing lubrication to the motor, try to add lubrication when the motor is operating at a low speed. If the motor cannot be slowed down, lubrication should be replenished when the motor is stopped.

If the motor cannot be slowed down or stopped, lubrication should be added slowly on the premise that the temperature of the grease is the same. This approach minimizes the impact of the newly added grease.

Earlier, we discussed some issues concerning lubricant quantity in the lubrication part of motor bearing overheating problems. In fact, the overheating problem of motor bearings due to poor lubrication can sometimes be related to the lubrication oil circuit.

The poor lubrication of motor bearings related to the oil circuit mainly involves several aspects:

1. Inlet oil passages are not smooth.

2. Outlet oil passages are unobstructed.

3. The oil circuit design is unreasonable.

4. Problems with the oil flinger.

For motor bearings that need lubrication replenishing, the motor design should include some lubricating oil passages on the base. Usually, there are oil filling holes on the motor casing or end cover. The path from the oil filling hole to the bearing is the motor bearing lubrication replenishing oil circuit. Sometimes these oil circuits are composed of the end cover and the casing together, and it should be ensured that they are unobstructed after assembly and design.

During use, it should also be ensured that the lubrication added from the oil nozzle can regularly enter the bearing. Otherwise, all further lubrication cannot be applied, resulting in the inability to replenish motor bearing lubrication, leading to lubrication degradation and bearing overheating problems.

In addition to requiring a smooth inlet oil passage when the motor bearing is running, a smooth outlet oil passage is also needed. When designing a motor that needs lubrication replenishing, an oil outlet will be designed on the motor casing or end cover.

The oil path from the bearing to the oil outlet is the motor bearing’s oil drain path. The oil drain path needs to be unobstructed to ensure that the motor bearing can eliminate excess grease through the oil drain path.

It is not uncommon in actual work situations for motor bearings to overheat due to the inability to eliminate excess grease caused by improper design of the oil outlet and blockage of the oil drain path.

The rational design of the motor bearing oil circuit is also key to ensuring motor bearing lubrication. If the oil circuit design is improper, it may cause bearing overheating due to the inability of the replenished lubrication to enter the bearing.

Therefore, when checking for bearing overheating in newly designed motors, the rationality of the motor bearing oil circuit design should also be checked. The key factor here is to ensure that the lubrication oil circuit passes through the bearing, rather than being a “bypass” relationship with the bearing.

In some medium and large motors, an oil flinger is often designed when using grease for lubrication. Here, the oil flinger is also part of the motor bearing lubrication oil circuit. When checking the lubrication oil circuit of a motor bearing that is overheating, this should also be checked.

Common improper designs of the oil flinger include improper size of the oil flinger, improper distance between the oil flinger and the motor bearing, and improper size of the oil flinger outlet. These design factors all affect the operational effectiveness of the oil flinger.

The previous text discussed the impact of motor bearing lubrication on bearing heat generation. Another influential factor is the seal of the bearing. The primary purpose of the seal is to protect the bearing, preventing lubricant leakage, and the like. Seals include non-contact seals and contact seals.

The stronger the contact between the seal lip and the contact surface, the better the sealing effect.

However, the friction generated by contact force and relative motion will be greater, leading to higher heat generation. Conversely, the weaker the contact, the poorer the sealing effect, and the less friction and heat generated due to contact force and relative motion. The selection and application of seals often involve a balance between heat generation and sealing performance.

In general bearing applications, seals include both contact and non-contact types. Non-contact seals ensure sealing performance through lip design. As there’s no contact force, almost no heat is generated due to lip contact.

Light contact seals have better sealing performance than non-contact seals, but because the seal lip will contact and relatively rub against the sealing area, some heat is generated when the bearing operates.

Therefore, if the bearing temperature is significantly affected by the seal during motor operation, consider reducing the contact force while ensuring sealing performance, thereby reducing the heat generated by the seal lip.

Overall, the strategy involves using dust covers (non-contact seals) in place of light contact seals, using light contact seals instead of heavy contact seals, or adopting special seal structures.

Moreover, the installation of the seal can affect lip contact, influencing the sealing performance and heat generation of the seal. The largest impact on the seal comes from its eccentricity.

For bearings with seals, the eccentricity of the bearing is limited by the bearing’s own structure. When the bearing is eccentric, the heat generated by internal friction in the bearing is often high.

However, for self-aligning bearings, the structure of the bearing itself allows a certain degree of eccentricity, and the eccentricity within the structural allowance of the bearing may cause an eccentric state that the bearing seal cannot withstand. This situation often occurs in applications of self-aligning roller bearings with seals.

During failure diagnosis, if heat generation is found in the bearing seal part, the seal lip of the failed seal can be checked to find the wear location. Based on the wear condition, information about the bearing installation deviation can be obtained, thus deducing the cause of the failure and eliminating it.

Bearing contamination is another significant factor in motor bearing heat generation. We know that bearing seals are key components to protect the bearings from contamination. Therefore, when diagnosing bearing heat caused by bearing contamination, the condition of the bearing seal should also be checked first.

The situation where bearing heat is caused by contamination entering the bearing due to seal damage is closely related to the seal. Therefore, subsequent introductions will first explain the methods of diagnosing bearing heat failure when the seal is damaged.

Damage to the bearing seal includes uniform wear of the bearing seal lip, non-uniform wear of the bearing seal lip, and damage to the non-lip part of the bearing seal.

The text discussed that damage to bearing seals can expose the interior of the bearing to potential contamination. This damage includes wear of the bearing seal lip and other non-lip parts of the bearing seal.

Wear of the seal lip includes uniform and non-uniform wear.

Firstly, uniform wear of the bearing seal lip:

For contact seals, the lip of the bearing seal normally makes uniform contact with the sealing surface, causing friction and heat during bearing operation. A good seal design typically strikes a balance between sealing efficiency and heat generation.

Under normal circumstances, the heat generated during the operation of the seal should not be excessive. However, if there is severe heat generation and uniform wear of the seal, it may be due to the following reasons:

Deviation in the dimensions of related components. For instance, the size of the shaft or the inner ring of the bearing might exceed the tolerance, causing excessive contact force at the seal lip. In this case, the dimensions of the respective components should be adjusted.

Excessive surface roughness of related components, thereby increasing friction and wear at the seal lip, leading to additional heat generation.

Deviations in the shape and position size of related components. For example, out-of-roundness of the shaft causing wear of the seal lip.

These issues require the shaft and related components to be processed to eliminate the faults.

Additionally, improper selection of the seal can also lead to wear of the seal lip. The potential causes of uniform wear include: the rotational speed performance of the seal not meeting actual application requirements; the corrosion resistance of the seal not satisfying actual application needs; the temperature performance of the seal not fulfilling actual application requirements.

Typically, seals have a corresponding application speed requirement based on the friction relationship between their lips and the shaft. If the bearing speed exceeds this requirement, it can result in wear of the seal lip. When other factors of bearing sealing are normal, this wear appears as uniform lip wear.

Common bearing seals are generally made of rubber material. If the seal’s operating environment contains corrosive gases or liquids, it can cause the rubber material to deteriorate, sometimes softening or cracking. If softening occurs, similar uniform friction damage may appear at the lip.

On the other hand, bearing seals have a specific operating temperature range. When the actual application temperature exceeds this range, the seal may soften and uniform wear traces may appear on the lip during relative motion.

Aside from the impact of the seal’s operating environment, inappropriate practices during installation and use can also cause undesired wear on the seal, leading to overheating of the related bearing parts.

For example, if bearing maintenance is not timely and the bearing seal has already aged, damage to the seal can result in additional wear, heat, and oil leakage. Improper installation, causing additional seal wear, can also lead to excess heat generation among other issues.

The previous discussion dealt with the issue of motor bearing heat generation arising from uniform wear on the motor bearing seals. Now, let’s discuss the situation of non-uniform wear on the seal lips.

Non-uniform wear on motor bearing seals can cause lubricant leakage and facilitate the entry of contaminants, both of which can result in motor bearing overheating. Correspondingly, the unevenly worn frictional areas of the motor bearing seals can also generate additional heat, contributing to motor bearing overheating.

Non-uniform wear on motor bearing seals may primarily be caused by improper installation or maintenance of the seals themselves or by issues related to associated parts.

Firstly, during seal installation, if there is a parallel or angular eccentricity between the seal itself and the shaft axis, the seal lip will not align properly with the corresponding contact areas. This will result in a part of the lip exerting excessive contact pressure, while another part exerts very little. The high-pressure parts of the lip will wear down with the rotation of the shaft, generating significant heat in the process.

Under these circumstances, the contact pressure between the lip and the rotating component is greater than normal, leading to higher frictional heat generation. On the other hand, where the seal lip contact pressure is low (in the direction perpendicular to the misalignment), the seal lip may not contact the rotating component at all, or it may lightly touch it.

Here, the contact pressure is low, resulting in less frictional heat generation and, correspondingly, less wear. Therefore, after the bearing has run for a while, the bearing seal lip will exhibit non-uniform wear.

Another possibility for the seal misalignment with the shaft axis is due to issues in the part production process. These issues are mostly caused by poor form and positional tolerances of the corresponding parts. (Note that this is different from the case of uniform lip wear discussed above, where the part production issues are mostly due to dimensional tolerances).

Especially when these form and positional tolerances lead to eccentricity after assembly of the parts, the cause-effect relationship is very direct. The alignment of the shaft and the bearing housing after installation should be checked under these circumstances. Relevant dimensions include the bearing shoulder, the end cap stop, the concentricity of the bearing housing, and so on.

So far, we’ve discussed the inspection of seal wear when motor bearing temperatures are too high. In fact, apart from the lip, damage to the seal itself can also affect the bearings. This damage can occur outside the lip friction contact surface, possibly on the frame or lip area.