Have you ever wondered how a massive steel plate is bent into shape? In this article, we explore the fascinating mechanics behind plate rolling machines, revealing the forces and calculations that make this complex process possible. Prepare to uncover the secrets of bending steel with precision and power!

The construction and installation company of Laiwu Iron and Steel Co., Ltd. has decided to select a motor for the plate rolling machine in support of the bidding for the reconstruction and expansion of the 750 m3 blast furnace at the Laiwu Iron and Steel General Plant (Lai Steel). The plate rolling machine, which has been inactive for many years, will be utilized to prepare for the production of the blast furnace body and is capable of rolling 40mm thick steel plates.

By referring to the working principle of a multi-roll straightening machine and considering force and energy parameters, the working principle and calculation formulas of force and energy parameters for the plate rolling machine have been logically deduced.

The results of the test run indicate that the selected motor has enough driving power to meet the design capacity requirements of the plate rolling machine.

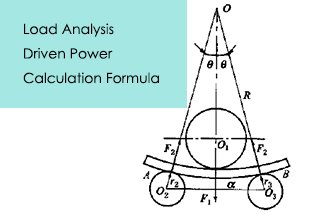

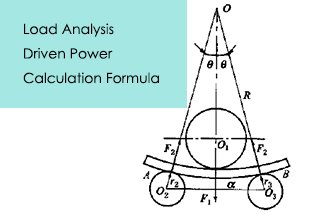

The bending deformation of a steel plate on a plate rolling machine is a transverse bending process. As illustrated in Figure 1, under the influence of the bending moment M under an external load, the longitudinal fibers above the neutral layer experience compression, while the longitudinal fibers below the neutral layer undergo tensile deformation.

Fig. 1 Bending deformation diagram of steel plate

According to the magnitude of the external load torque, when the maximum stress on the surface layer of the steel plate is below the yield limit of the steel plate material, the longitudinal fibers in each layer are in an elastic deformation state. As the bending moment under the external load increases, the deformation of each layer of steel fibers continues.

When the external load reaches a certain point, the stress on the longitudinal fibers on the surface of the steel plate surpasses the yield limit of the material and the fibers undergo plastic deformation. The greater the load, the deeper the plastic deformation zone extends from the surface layer to the neutral layer.

When the stress on all the longitudinal fibers in the cross-section of the steel plate exceeds the yield limit of the material, all the fibers enter a plastic deformation state and the bending process is concluded.

The plate rolling machine has two working parameters:

The selection of the reverse bending ratio is critical in determining if the steel plate can achieve the desired bending outcome. In a three-roller plate roll, the reverse bending ratio is achieved by pressing down on the reduction roll.

Different residual curvatures can be obtained by adjusting the reduction to produce different diameters of rolled pipes.

The force and energy parameters of the plate rolling machine refer to the pressure (bending force) exerted on the roller, the bending torque, and the driving power of the motor of the plate rolling machine.

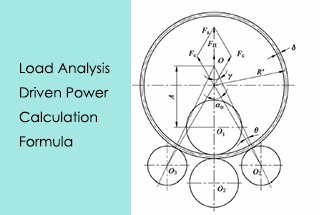

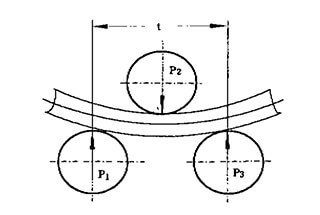

The pressure on the roller can be calculated based on the moment needed for bending the steel plate. In this case, the steel plate is considered a beam under a concentrated load. The load is the pressure exerted by each roller on the steel plate, as depicted in Figure 2.

Fig. 2 Pressure (bending force) acting on the roller

In the calculation, the bending moment of the steel plate under the second roll is assumed to be pure plastic bending moment Ms, that is, M2 = Ms (pure plastic bending moment M is the maximum bending moment that may be reached in elastic-plastic bending).

In the formula:

In this way, P1, P2, P3 can be calculated according to the balance condition of external force on the steel plate under the second roller:

Total pressure:

The bending torque MK acting on the roller can be determined according to the principle of equal function.

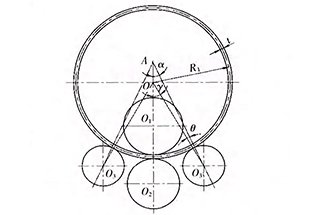

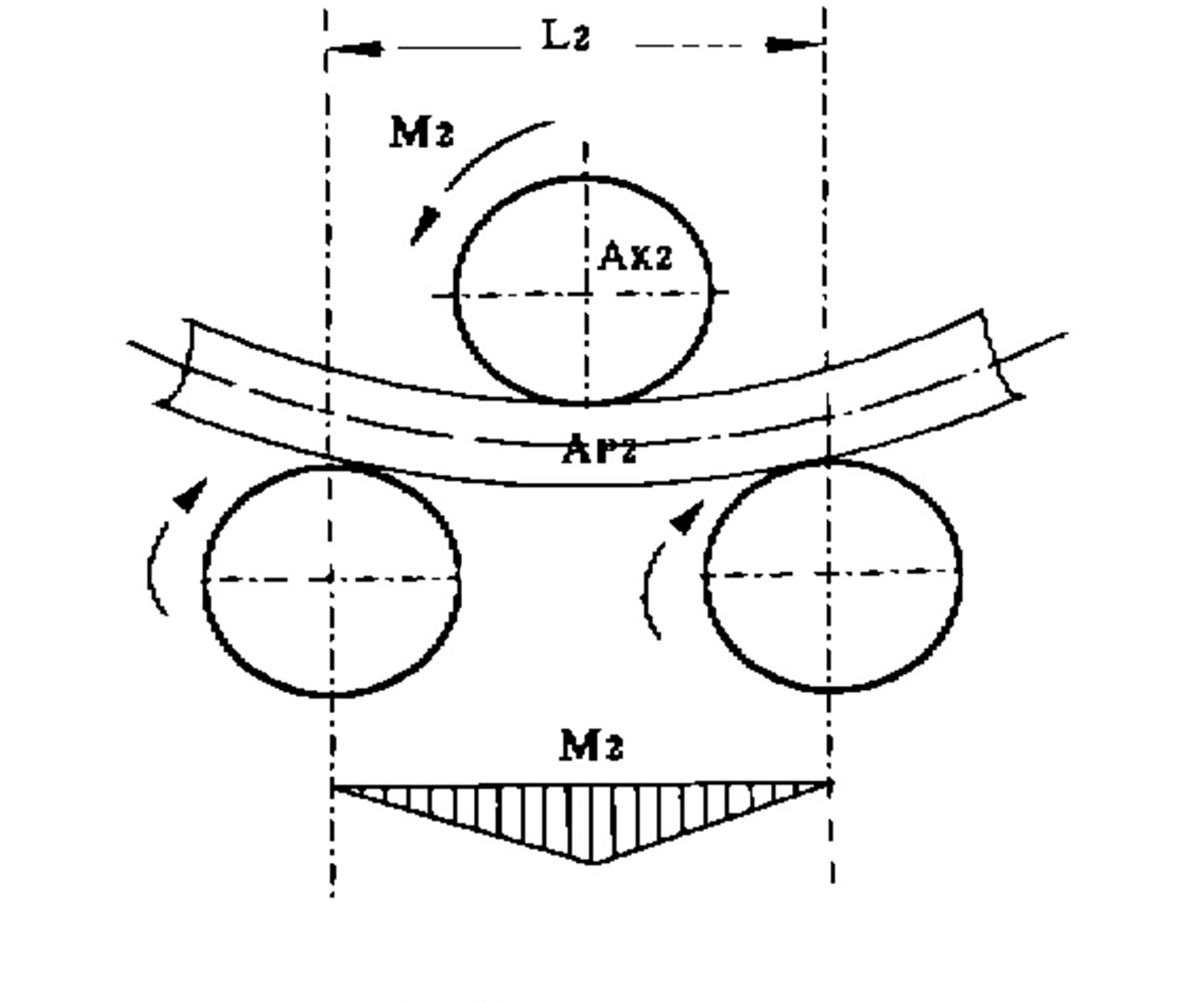

The bending work AK produced by bending torque on the roller shall be equal to the work AP for plastic deformation of steel plate, i.e. Ap = Ak (shown in Fig. 3).

Fig. 3 Variation of bending moment along plate length

The plastic deformation work Ap2 of the steel plate under the second roll is:

In the formula:

Bending work acting on the second roller:

Where D2 is the diameter of the work roll.

To make:

For the convenience of calculation, the following assumptions are made:

Then the formula is as follows:

The motor power can be calculated according to the following formula:

In the formula:

According to the above calculation formula, the motor driving power of 40 mm thick steel plate rolling machine is selected as follows:

It is known that: h = 40 mm, D = 420 mm, t = 900 mm, the maximum width of rolled steel plate b = 2500 mm, the minimum rolling diameter r = 1000 mm, d = 400 mm, v = 2 m/min.

Thus:

According to the above calculation, the motor driving power of the 40 mm steel plate rolling machine is selected as 25 kW.