How can you precisely control the flow of liquids or gases in your machinery? The answer lies in the needle valve, a small yet essential component in many industrial applications. This article explores the functionality, types, and installation of needle valves, highlighting their importance in systems requiring fine adjustments. Discover how these valves ensure optimal performance and learn practical tips for their selection and maintenance. Dive in to understand how needle valves can enhance the efficiency and safety of your equipment.

Needle valves are a type of valve that can be precisely adjusted, widely used for various purposes, such as the cutting distance in flame cutting, the knob to adjust the flame temperature is a needle valve. Instrument needle valves are an important part of the instrument measurement pipeline system, mainly including globe valves and ball valves, whose function is to open or cut off the pipeline path. The valve core of a needle valve is a very sharp cone, like a needle inserted into the valve seat, hence the name.

Compared to other types of valves, needle valves can withstand higher pressures and have better sealing performance, so they are generally used for sealing gas or liquid media with smaller flow rates and higher pressures. Needle valves are most suitable for use with pressure gauges, and the general shape of needle valves is made with threaded connections.

PN2.5 PN4 PN6.4 PN16 PN32Mpa

DN5~DN25

Oil, water, gas, and other non-corrosive or corrosive media

-20℃ to +440℃ -70℃ to -240℃ ≤540℃ ≤570℃ etc.

20#, 1Cr18Ni9Ti, 304, 316, 316L, 12Cr1Mov, etc.

GB ANSI JIS

1. The main materials selected for the valve body are stainless steel and carbon steel. The difficulty in selecting valve body materials lies not only in considering corrosion issues but also in considering pressure and temperature resistance capabilities, whether it is economically reasonable, and whether it is easy to purchase, among other factors.

2. Adopt lining measures, such as lining with lead, aluminum, engineering plastics, natural rubber, and various synthetic rubbers. If the medium conditions allow, this is indeed a cost-saving method.

3. Under conditions of low pressure and temperature, using non-metallic materials for the valve body can often be very effective in preventing corrosion.

4. In addition, the outer surface of the needle valve body is also subject to atmospheric corrosion, and general steel materials are protected by painting.

1. The installation position, height, and inlet and outlet directions must comply with the design requirements, paying attention to the direction of medium flow should be consistent with the arrow direction marked on the valve body, and the connection should be firm and tight.

2. Before installing the valve, an external inspection must be carried out, and the valve’s nameplate should comply with the current national standard “General Valve Markings” GB12220.

3. For valves with a working pressure greater than 1.0MPa and that act as shut-off valves on the main pipeline, a strength and tightness performance test should be conducted before installation, and they can only be used after passing the test. During the strength test, the test pressure is 1.5 times the nominal pressure, lasting no less than 5min, and the valve body and packing should have no leakage to be considered qualified. During the tightness test, the test pressure is 1.1 times the nominal pressure; the test duration meets the requirements of GB50243.

1. For piping systems and devices with low-temperature media, it is advisable to use low-temperature needle valves with bonnets.

2. For the piping systems of catalytic cracking units in refining devices, lifting rod type needle valves can be used.

3. In devices and piping systems with corrosive media such as acids and alkalis in chemical systems, it is advisable to use all stainless steel needle valves made of austenitic stainless steel with polytetrafluoroethylene as the valve seat sealing ring.

4. In metallurgical systems, power systems, petrochemical devices, and urban heating systems with high-temperature media, metal-to-metal seal needle valves can be used.

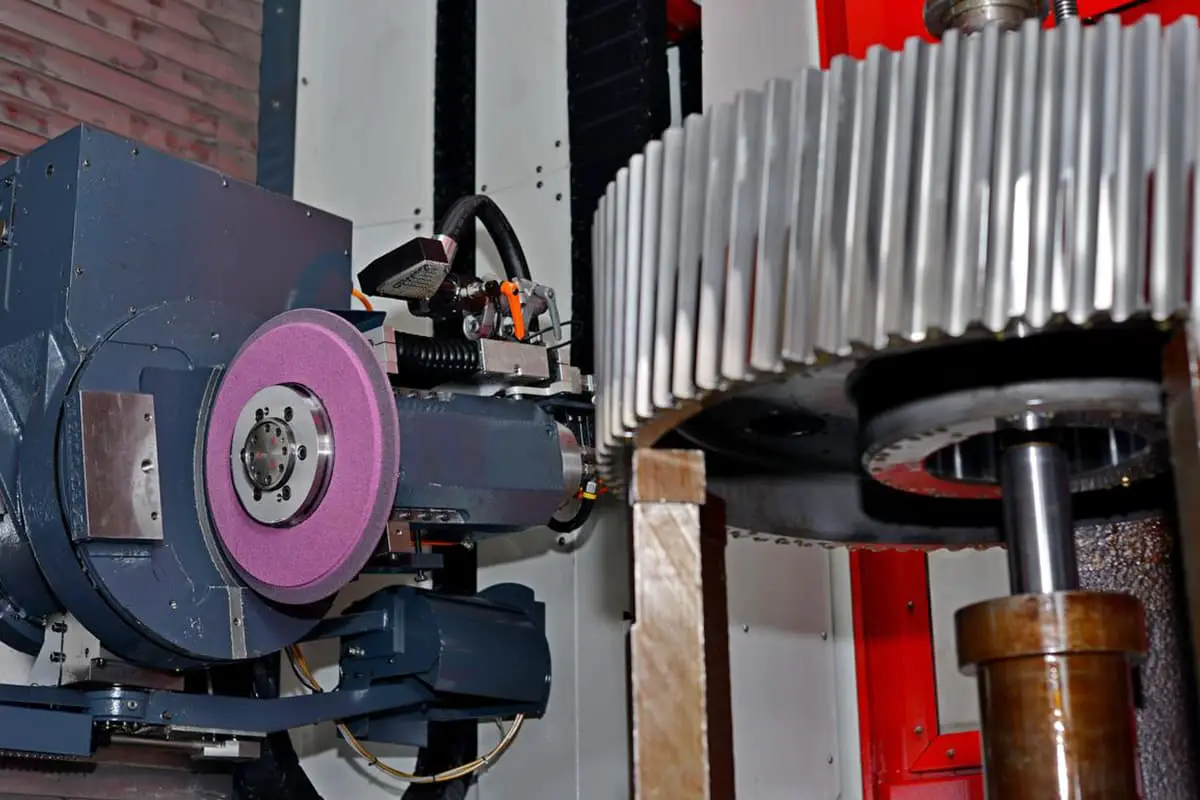

5. For flow regulation, needle valves with V-shaped openings, driven by worm gears and operated pneumatically or electrically, can be used.

6. For the main pipelines of oil and natural gas transportation that need to be cleaned and buried underground, full bore, fully welded needle valves are used; for those buried above ground, full bore welded or flanged ball valves are chosen.

7. For the transportation pipelines and purchasing and storage equipment of finished oil, flanged needle valves are chosen.

8. For urban gas and natural gas pipelines, flanged and internal threaded needle valves are chosen.

9. In the oxygen pipeline systems of metallurgical systems, needle valves with flange connections that have been strictly degreased are advisable.