Imagine a simple yet powerful sealing solution that works seamlessly in both hydraulic and pneumatic systems. The O-ring, with its various shapes and properties, provides reliable sealing by compressing and responding to system pressure. This article explores the principles behind O-ring functionality, highlighting its advantages, potential pitfalls, and installation tips. Dive in to discover how this ubiquitous component can enhance the efficiency and reliability of your machinery, ensuring minimal leakage and optimal performance.

The O-ring is a circular rubber ring, which is the most widely used seal in hydraulic and pneumatic systems. O-rings can have circular, square, X-shaped, and Y-shaped cross-sections, each shape having different properties and applicability.

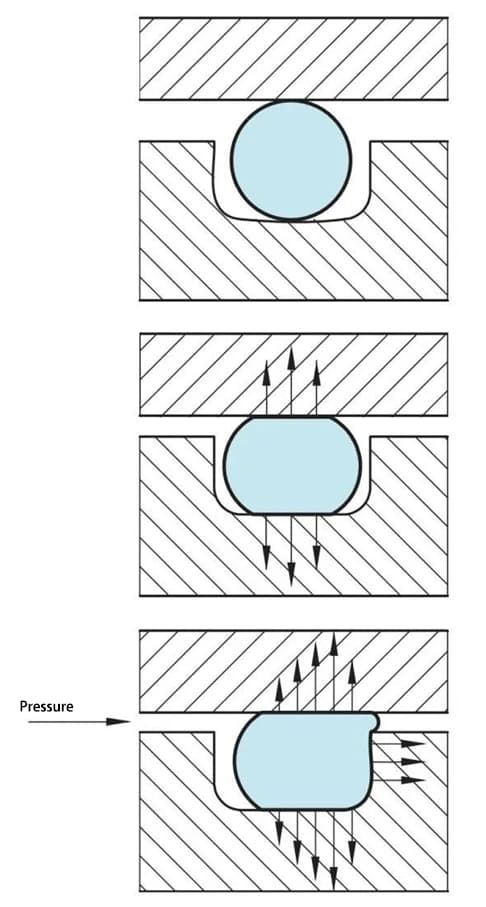

The O-ring is a bidirectional sealing element. When installed, the initial compression of the O-ring in the radial or axial direction determines its initial sealing capability. The force generated by the system pressure acting on the O-ring is its total sealing force; this sealing force increases as the system pressure rises.

Under pressure, the shape of the O-ring and the liquid with high surface tension are similar. The pressure is transmitted equally in all directions.

The self-sealing of the O-ring is limited. When the internal pressure is too high, the “rubber extrusion” phenomenon of the O-ring will occur. That is, due to the existence of a gap in the sealed part, the O-ring under high pressure will generate stress concentration at the gap.

When the stress reaches a level that the rubber material of the O-ring cannot bear, the rubber material will be squeezed out. At this time, although the O-ring can still temporarily maintain the seal, it has actually been damaged.

Therefore, it is necessary to strictly select the type.

1. Advantages of O-rings

2. Disadvantages of O-rings

1. Basic requirements for O-ring installation

Before installing the O-ring, check the following:

2. For manual installation, note the following:

3. When installing over threads, splines