Have you ever considered the unseen dangers lurking in the machining industry? From deafening noise to hazardous dust, machinists face numerous occupational risks daily. This article delves into the top five hazards of machining, highlighting critical safety measures to protect workers. Learn about the specific dangers of forging, casting, heat treatment, general machining, and assembly, and discover effective strategies to mitigate these risks. Equip yourself with essential knowledge to ensure a safer working environment in the machinery manufacturing sector.

The machinery manufacturing industry encompasses a broad range of sectors, including transportation, machine tools, agricultural machinery, textile machinery, power machinery, and precision instruments. In general, the production process involves casting, forging, heat treatment, machining, and assembly workshops.

The basic production flow consists of casting, forging, heat treatment, machining, and assembly. In the machinery manufacturing process, metal parts are typically created through casting, forging, welding, stamping, and other methods, followed by cutting to produce qualified parts, and finally assembled into a machine.

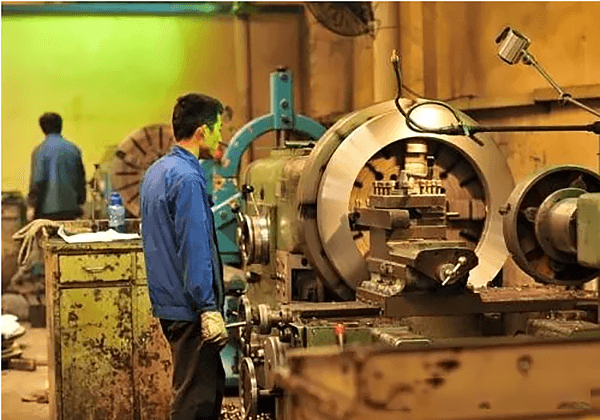

Machining is the use of various machine tools to perform operations such as turning, planing, drilling, grinding, milling, and other cold processing on metal parts.

Evaluation and detection of occupational hazards is crucial in the machinery industry, particularly in the machinery manufacturing sector. There are many potential hazards in this industry, and the following points highlight some of the factors that require attention.

Forging is a process in which an external force is applied to a blank, causing plastic deformation and resulting in a forging.

Physical Hazards:

Noise is the most damaging occupational hazard in the forging process. Forging hammers (air hammers and pressure hammers) can generate loud and intense noise and vibration, usually in the form of impulse noise, with an intensity exceeding 100dB (A). A noise detection conducted in a machinery factory’s forging workshop showed results ranging from 83-100, 2dB (A), with an average of 92.08dB (A). Punching machines and shearing machines can also produce high-intensity noise, but the intensity is typically lower than that of forging hammers.

The temperature in the heating furnace can reach as high as 1200℃, while the forging temperature is between 500-800℃. During production, high temperature and strong radiant heat can be produced in the workplace.

Dust and Poison Hazards:

Metal dust and coal dust can be generated during charging, discharging, and forging in the forging furnace and forging hammer, particularly in the furnaces of the fuel industry. Combustion furnaces can emit harmful gases such as carbon monoxide, sulfur dioxide, and nitrogen oxides.

Modeling can be divided into manual and mechanical molding. Manual molding involves completing sand tightening, mold stripping, trimming, and box closing manually. This process has high labor intensity and exposes workers directly to dust, chemical poisons, and physical factors, leading to significant occupational hazards. On the other hand, mechanical molding has high productivity, stable quality, low labor intensity for workers, and fewer chances of workers coming into contact with dust, chemical poisons, and physical factors, resulting in relatively small occupational hazards.

Dust Hazard:

A significant amount of sand dust is produced during molding, casting sand falling, and cleaning. The nature and harm of dust are primarily determined by the type of molding sand used. For instance, when quartz sand is used, it is most harmful due to its high content of free silica. A dust concentration detection conducted in a machinery factory’s molding workshop found results ranging from 27.5 to 62.3mg/m3, with an average of 39.5mg/m3.

Poisons and Physical Hazards:

The coal drying, melting, and pouring of sand mold and sand core result in high temperature and heat radiation. If coal or gas is used as fuel, it produces carbon monoxide, sulfur dioxide, and nitrogen oxides. If high-frequency induction furnaces or microwave ovens are used for heating, high-frequency electromagnetic fields and microwave radiation are produced.

The primary objective of the heat treatment process is to alter the physical properties of metal such as hardness, toughness, elasticity, conductivity, and others, while preserving the shape of the parts. This aims to meet the requirements of the process and enhance the product quality.

The heat treatment process encompasses normalizing, quenching, annealing, tempering, and carburizing.

Heat treatment can be further classified into three categories: general heat treatment, surface heat treatment (which includes surface quenching and chemical heat treatment), and special heat treatment.

Toxic gas

The heat treatment processes of mechanical parts, including normalizing, annealing, carburizing, quenching, and others, require a diverse range of auxiliary materials, such as acids, alkalis, metal salts, nitrates, and cyanides.

These ingredients are highly corrosive and toxic substances that can pose a significant threat to both the environment and human health.

For instance, when barium chloride is utilized as a heating medium, and the temperature reaches 1300°C, a large quantity of barium chloride evaporates, creating barium chloride dust that contaminates the workshop’s air.

The chlorination process also releases a substantial amount of ammonia into the workshop’s air.

Potassium ferrocyanide and other cyanides are utilized in the carburizing and carburizing processes, while nitrogen oxides are produced through the interaction of molten nitrate and oil stain with the workpiece in a salt bath furnace.

Furthermore, organic agents such as methanol, ethanol, propane, acetone, and gasoline are often employed in the heat treatment process.

Physical hazards

Normalizing and annealing of mechanical parts are heat treatment processes carried out at high temperatures. Heating furnaces, salt baths, and heated workpieces in the workshop are all sources of heat.

These heat sources can create a high-temperature environment with strong thermal radiation.

Additionally, various motors, fans, industrial pumps, and other mechanical equipment can generate noise and vibration. However, the noise level in most heat treatment workshops is low, and instances of noise exceeding standards are rare.

In the mechanical manufacturing process, metal parts are fabricated using casting, forging, welding, stamping, and other techniques. Then, various machine tools such as lathes, planers, drills, grinders, mills, and others are utilized to perform cold processing on the metal parts, including turning, planing, drilling, grinding, and milling. Finally, the qualified parts are cut and assembled into machinery.

General machining

The occupational hazards in the production process are minimal, primarily due to the use of cutting emulsions and the impact of cutting on workers.

The commonly used cutting emulsions consist of mineral oil, naphthenic acid or oleic acid, and alkali (caustic soda). The high-speed transfer of machine tools can cause emulsion splashes, which can easily pollute the skin and lead to skin diseases such as folliculitis or acne.

During the machining process, there is also a significant amount of metal and mineral dust generated from rough and fine grinding. Synthetic grinding stones are primarily composed of emery (alumina crystal), with a low content of silicon dioxide, while natural grinding stones contain a large amount of free silicon dioxide, which can result in aluminum pneumoconiosis and silicosis.

Most machine tools produce mechanical noise ranging between 65 dB (A) and 80 dB (A), and instances of excessive noise are rare.

Special machining

The occupational hazard factors in specialized machining are mainly related to the machining tools being used.

For example, EDM produces metal dust, laser processing generates high temperatures and ultraviolet radiation, electron beam X-ray generates metal dust, ion beam processing produces metal dust, ultraviolet radiation, and high-frequency electromagnetic radiation, and if a tungsten electrode is utilized, ionizing radiation can also be present.

On the other hand, electrochemical machining, liquid jet machining, and ultrasonic machining pose relatively lower hazards.

Moreover, the operation of the equipment can also create noise and vibration.

The occupational hazard factors in simple mechanical assembly processes are few and similar to those in general machining.

However, in complex assembly processes, the occupational hazards are mainly related to the specific assembly techniques being used.

For instance, the use of various welding techniques can result in welding-related occupational hazards, while the use of adhesives can result in adhesive-related occupational hazards. If a coating process is required, there can also be occupational hazards associated with the coating process.

The occupational hazards in the machinery manufacturing industry primarily include the hazards of silicon dust in casting production, organic solvents such as benzene and its derivatives in coating production, and welding (smoke) dust in welding operations. To address these hazards, the following measures should be taken: