How can a bending machine revolutionize sheet metal processing? This article explores three innovative techniques for sheet metal panel benders: flattening, rounding, and shaped bending. By understanding these methods, readers can learn how to enhance efficiency, reduce costs, and achieve superior results in metal fabrication. Whether you’re a seasoned professional or new to the field, this guide provides valuable insights into optimizing sheet metal bending processes with advanced machinery.

In Europe and North America, companies have long grappled with significant labor costs, particularly acute in Northern European nations. This economic pressure has been a driving force behind the industry’s push towards automation and intelligent manufacturing solutions.

To address these challenges, enterprises across these regions have consistently prioritized strategies aimed at enhancing production efficiency while reducing labor requirements. This focus has catalyzed a wave of automation and smart manufacturing initiatives, with an increasing number of companies investing in advanced equipment and exploring fully automated, unmanned production lines.

A pivotal moment in this technological evolution occurred in 1977 when Salvagnini introduced the world’s first P4 panel bender. This innovation marked a significant milestone in sheet metal forming technology. The Salvagnini P4 panel bender revolutionized the industry with its groundbreaking features:

In the four decades since its introduction, the P4 panel bender has continually evolved, incorporating advancements in materials science, control systems, and digital manufacturing. This ongoing development has kept the technology at the forefront of flexible, automated sheet metal forming, enabling manufacturers to meet the ever-increasing demands for precision, speed, and customization in modern industrial production.

The impact of Salvagnini’s innovation extends beyond the realm of bending technology. It has played a crucial role in shaping the broader landscape of smart manufacturing, influencing the development of integrated production systems and contributing to the realization of Industry 4.0 concepts in sheet metal fabrication.

P1 Lean panel benders

The P1 Lean panel bender (Fig. 1) is the smallest model in the family of Salvagnini Panel Benders, with a large forming length of 1250mm, full servo drive, fast speed, and an average power consumption of only 3 kWh per hour.

The small size of the machine allows for the production of small parts, making it very cost-effective.

P2L-21 compact panel bender

The P2L-21 Compact panel bender (Fig.2) is the main machine used in the commercial kitchen industry, with a forming length of 2180mm.

The new generation P2L adopts servo motor direct drive, which can meet most of the processing requirements of panel products, covering an area of 6m×3m. The cylinder hybrid drive ensures the long-term stability of the equipment and reduces the maintenance workload, with an average power consumption as low as 5 kWh per hour.

P4-2116 HPT standard panel bender

The P4-2116 HPT is a standard panel bender with semi-automatic loading and unloading (Figure 3), which can be used during machine production. The loading and unloading operations can be carried out without interrupting production, resulting in a significant increase in machine availability.

As a standard panel bender, the P4 can be loaded with additional options to expand production capacity, making it the ideal machine for several major refrigerator manufacturers.

S4+P4 flexible manufacturing system

S4+P4 FMS can accommodate the production of more variety and smaller quantities of products that are not yet available.

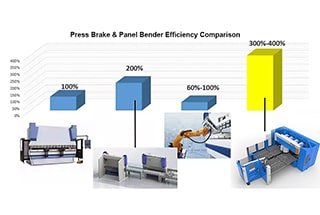

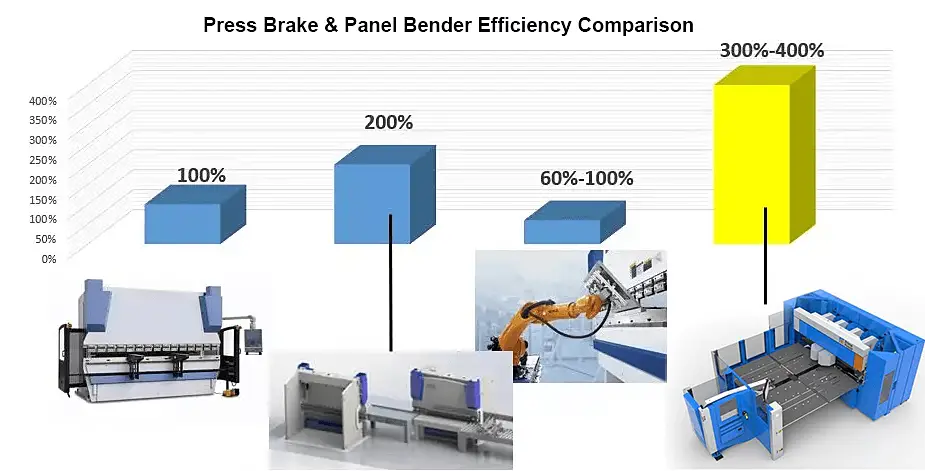

Previously, panel forming was done on dedicated production lines or manually operated pressure-bending machines. Panel benders have natural advantages over press brake machines for panel processing, including labor-saving and speed, as well as good repeatability and consistency of the workpiece.

With the arrival of the Salvagnini panel bender, sheet metal forming has entered the era of complete automation for the first time.

There are three main types of conventional sheet metal bending and forming:

However, despite the increasing level of automation, the efficiency bottleneck has not been eliminated.

In a panel bender, there is no need to change the die, the working stroke is short, the feeding is fast, and only one operator is needed to “put in” and “take out” the sheet.

A single machine can smoothly complete the positioning of the sheet in a single pass for four-sided bending… order, efficiency, and intelligence can be so simple.

The combined efficiency of the panel bender is 3 to 4 times that of a manually operated bending machine.

Panel benders can meet all user bending needs with their lean, fast, and energy-efficient capabilities.

The highly intelligent operating control system enables efficient bending of different workpieces, making the panel bender a revolutionary alternative to traditional press bending machines.

However, due to the high one-time investment cost, it has not been widely adopted by the majority of sheet metal processing users.

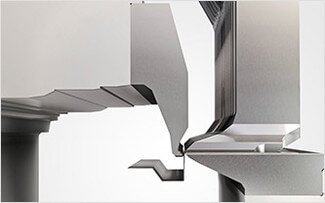

The panel bender has a new design concept, which involves downward bending with the upper knife and upward bending with the lower knife, with no limit on the number of bending times.

Bending forces are distributed transversely and generated by oscillating components, namely the bending knives.

The binding reaction force is generated by two components that are strongly locked to the sheet.

Downward bending (negative bending)

Upward bending (positive bending)

The bending length can be adjusted automatically, making it easy to realize unmanned production, which is shown schematically in Figure 8.

With the increasing demand for highly flexible automatic processing, there is a growing need for an easy and time-saving bending process.

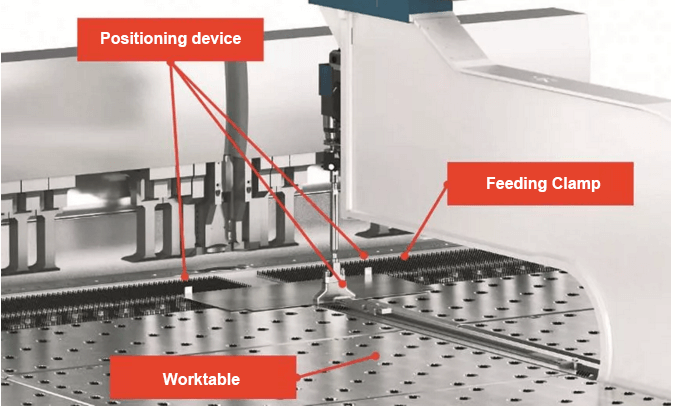

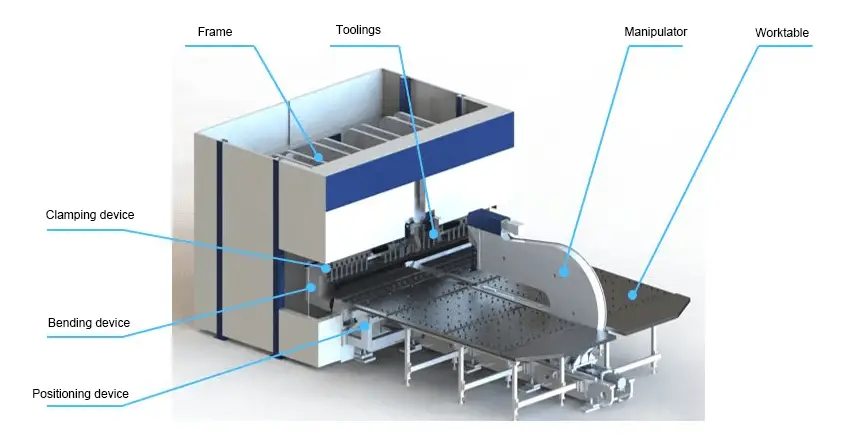

The CNC sheet bending machine features a unique two-way bending mechanism that keeps the sheet material horizontal during the bending process, avoiding space flip. It includes functional components like a positioning device, automatic die change, and operator, making it possible to achieve fast, highly flexible, and automatic processing.

Compared to the press brake processing method, the CNC panel bender (as shown in Figure 1) doesn’t require a die change, has a short working stroke, a fast feed rate, higher overall efficiency, and facilitates flexible production.

Figure 1 CNC panel bending machine

The successful development and promotion of products has brought to light the challenge of meeting the diverse process needs of various workpieces. This challenge is now a key issue in the development of bending machine technology.

Thanks to its free bending characteristics, the bending machine offers a lot of flexibility in the development of the process. It does not require mold changes or adjustments. By combining the upper and lower bending die with the compression die, a variety of bending processes can be achieved, resulting in superior process performance.

In this article, we will explore the features of panel bender process realization using typical workpieces from various industries.

The flattening process, also referred to as edge hemming, is a common technique used in sheet metal bending. It enhances the strength of the sheet metal edge while simultaneously making it smooth without the need for polishing.

To achieve the flattening of a press brake machine, two bending processes are required. Firstly, a 30° acute punch with an inserted deep V-slot is utilized to bend 30° to 45°. Then, the flattening die is employed to press the material.

On the other hand, when the panel bender machine executes the flattening process, there is no need to alter the mold. The bending beam and the pressing beam collaborate to produce a variety of flattening effects, including the bottom flattening process of hemming.

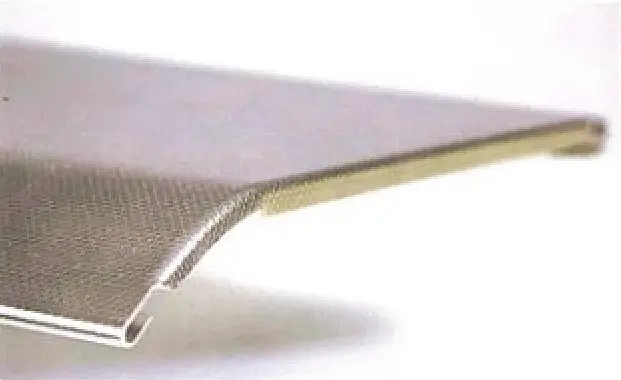

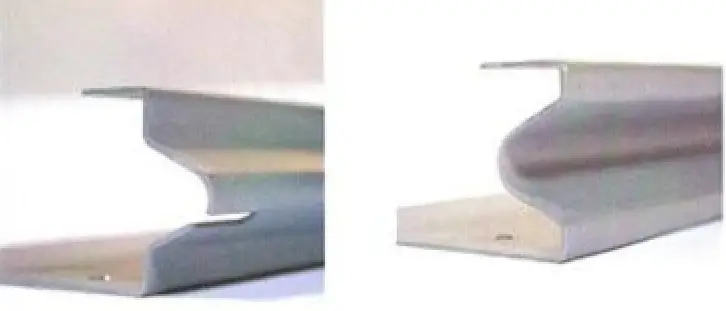

For both forward and reverse flattening on the panel bender machine, there is no need to flip the sheet. Instead, it is laid flat on the table surface and bent at an angle of 30° to 45° using the conventional bending process. The formed bending corner is then transferred to the lower die table and flattened using the pressing die. The entire process takes only a few seconds, as shown in Figure 2.

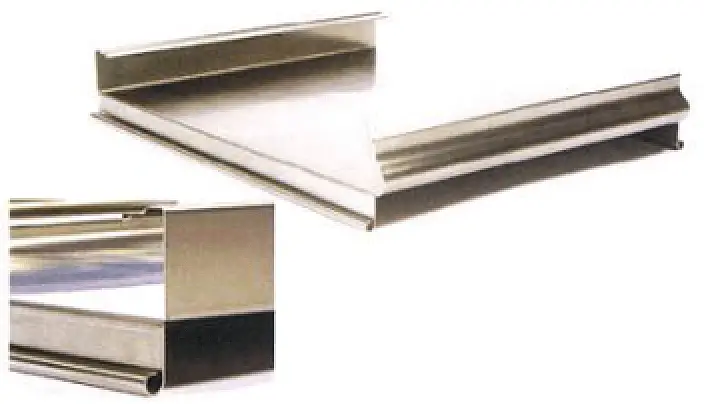

If bending is required after flattening (Fig. 3), the panel bending machine can handle the task directly.

Fig. 2 Bottoming and flattening process

Figure 3 Bending process after flattening

The switchgear and elevator industries sometimes require a specific type of flattening called “opening flattening” (as shown in Figure 4) to improve the strength and feel of the door edge.

To achieve this, panel benders can work in combination with a bending beam and a compression beam to easily create a variety of bending sizes and angles in the first pass, and then quickly achieve the desired final flattening effect.

Figure 4 Flattening process with openings

The rounding process (as shown in Figure 5) is now a necessary step for most manufacturers when producing their workpieces. To achieve this process, specific molds are required. However, different angles and radii of the arc need different molds, which can be expensive and time-consuming to produce.

In contrast, a bending machine only requires an additional bending process to achieve the rounding effect. With its efficient and continuous automatic bending capability, the arc can be formed by combining multiple small-angle bends. This method not only produces perfect results, but also doesn’t interrupt the continuous processing of the workpiece.

Figure 5 Panel bender for arc bending

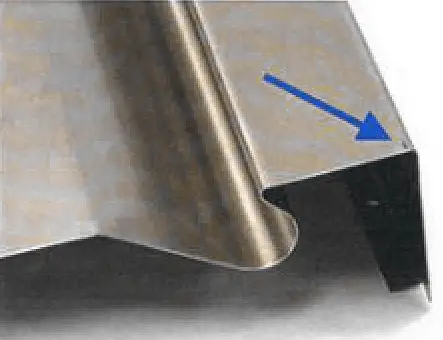

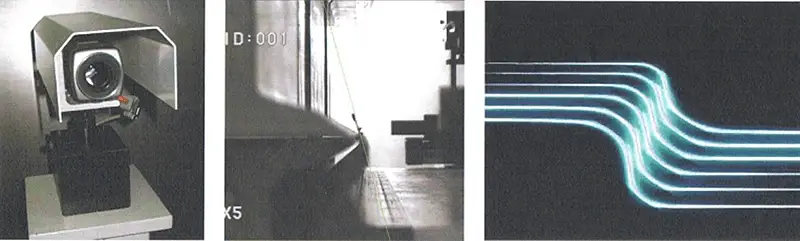

Using the conventional bending method, even if more segments are used, there will eventually be creases on the outside of the arc formed by continuous bending. This is due to the processing mechanism of the panel bender, which cannot meet the process requirements of some industry workpieces.

As a senior sheet metal equipment supplier with many years of research and development experience, we have continuously tested and finally developed a new set of arc process realization scheme. Through the mutual cooperation of the folding die and ram processing and forming, the crease now appears on the inner side of the arc, ensuring that it does not affect the surface smoothness.

This has improved the forming efficiency, and we can provide a suitable arc process scheme according to different sizes of arc and accuracy requirements, saving time and improving efficiency while meeting process requirements.

The advantage of the panel bender processing technique is not only to save time and money, but also to process workpieces that conventional bending machines cannot handle. For example, the side mounting plate shown in Figure 6 requires only two processes on one side – a 90 ° forming and a 1/4 arc forming.

If processed with a bending machine, first folding the 90 ° forming would prevent the arc from being processed, and folding the 1/4 arc forming first and then processing the 90 ° straight edge would certainly affect the already processed arc surface. However, this can be easily achieved with a panel bending machine, efficiently and with high precision.

Figure 6 Side mounting plate

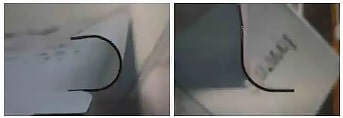

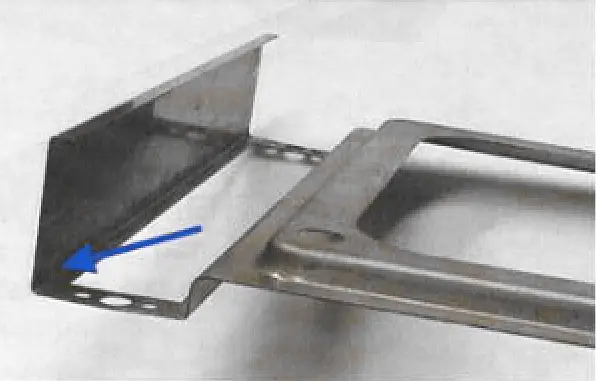

Shaped bending is a broad term that refers to the process of achieving various smaller size shapes by utilizing a panel bending machine’s free bending path and die combination.

For instance, U-shaped bending with an opening of less than 6mm, small Z-shaped bending with a 1mm step difference, N-shaped bending of various small sizes, and so on. Refer to Figure 7 for examples.

Figure 7 Common shaped bending parts

Although these formed shapes can eventually be processed by the press brake machine, they can be processed in one go using the panel bender.

The entire process does not require changing the mold or turning the surface, especially for larger workpieces. This results in low labor requirements and higher and more consistent machining accuracy.

The panel bender uses a universal, adjustable tooling with upper and lower bending knives, eliminating the need for a large number of bending tools based on the shape and size of the workpiece. This significantly reduces the cost and manufacturing time of molds and tools, as well as the preparation time of upper and lower molds and tools.

It also reduces the mold and tool stock, which facilitates production management. Furthermore, the absence of the need to design and manufacture special molds and tools for each product reduces the development cycle of new products, improving the competitiveness of enterprises in today’s increasingly competitive market.

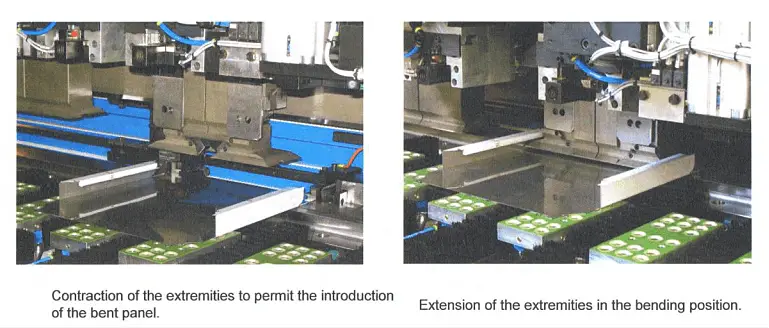

When folding box-shaped parts, you need to adjust the length of the mold according to the length of the inner edge of the workpiece. There are three methods of adjustment.

The first one is manual adjustment and takes 3 minutes.

The second type is semi-automatic adjustment and takes 90 seconds.

The third type is Automatic Adjustment (ALA), which coincides with the other work steps, so no adjustment time is required.

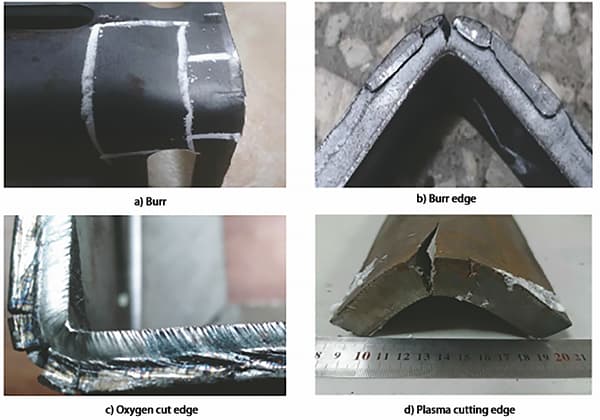

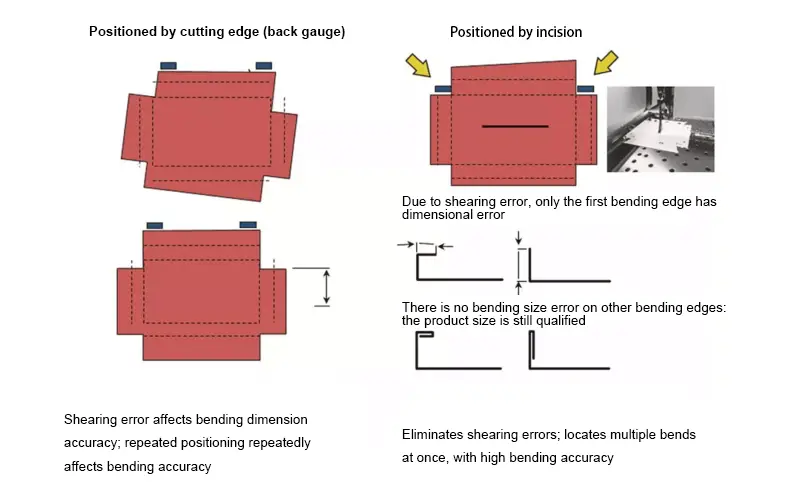

Before bending, positioning is carried out by the two cutting corners of the sheet instead of the edges of the sheet, which completely avoids the positioning error caused by the shearing of the sheet and improves positioning accuracy.

The sheet only needs to be positioned once in the process of panel bending, avoiding the cumulative error caused by repeated positioning of the sheet.

This greatly improves the final accuracy of the finished product.

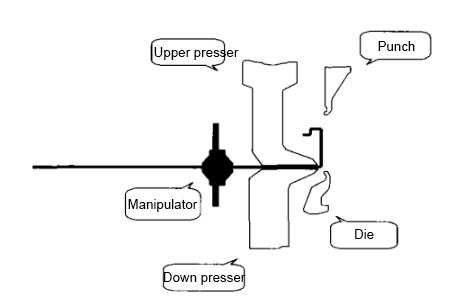

The manipulator can move the sheet forward and backward, as well as make discontinuous rotations of 90°, 180°, or 270° during multilateral bending. When the user needs a special angle of rotation, it can also be equipped with a CNC rotary device.

As shown in Figure 3, the panel bender clamps the workpiece with a rotating manipulator, which then clamps the workpiece to the upper and lower presses of the sheet. Between the upper and lower bending knives, the upper and lower bending knives act on the part of the sheet to be bent, making the necessary movements to obtain the bend angle and radius of the arc required by the program.

When one side is bent, the robot automatically rotates the sheet 180° so that the opposite side is bent, followed by the other two sides. When all four sides of the sheet have been bent, the manipulator exits. The panel is released and can be removed by the operator.

If equipped with an automatic loading and unloading system, the panel bending machine can also automatically bend the sheet placed in the designated location, which is after punching and shearing. After the bending is completed, the workpieces will be automatically taken down and stacked neatly. This can realize the automation of the bending process, reduce the labor intensity of the workers, and also avoid the quality accidents that occur due to workers.

The accuracy of the bending parts largely depends on the movement of the manipulator. Therefore, the manipulator of the panel bender has a high degree of positioning accuracy to ensure the accuracy of the bending parts.

The CNC systems of panel benders are based on Windows NT, with a user-friendly interface and an intuitive, easy-to-use human-machine dialogue. They offer powerful simulation, intervention, and documentation functions, as well as self-diagnosis and remote service functions.

In addition to providing fault codes, they can also be displayed graphically. The remote service function allows software engineers to access the customer’s control system remotely and intervene, diagnose, or modify programs. In most cases, the system can be returned to normal operation, eliminating the need for a repair service visit, or basic normal operation can be maintained until a service technician arrives.

To meet the requirements of different users and products, panel benders are available in a variety of models and configurations. For example:

a) They can be manually loaded or unloaded.

b) They can be equipped with an automatic loading and unloading system, allowing for unmanned operation.

c) They can be connected with the punching and shearing system, to become a punching, shearing, and folding integrated FMS (flexible manufacturing system).

Advantages:

(1) There is no need to change molds, upper and lower tools, which saves running costs, manufacturing costs, and management costs, and greatly improves production efficiency.

(2) Due to the advanced design structure and dynamic compensation of the bending knife, it has very good bending accuracy. Its angular accuracy is ±0.5°, and the parallelism of the two opposite sides after bending is ±0.1mm/m.

(3) Since its bending mechanism is different from other similar machines, it can perform bending processes that other bending centers cannot do. Therefore, it can greatly simplify and rationalize product structure. For example, a box-shaped part that originally required 8 plates to bend after welding can be made from 1 plate using P4 panel bender, thus reducing the weight of parts and processing time. It also reduces product design time, manufacturing costs, and improves product market competitiveness.

(4) It has the function of bending from the bottom to the top, which can avoid the indentation phenomenon that occurs when bending some workpieces with very high surface requirements (such as mirror stainless steel) and long lengths, and when the two ends are machined, greatly improving the appearance of the bent workpiece.

(5) In the machining process, the sheet feed and rotation are continuous and automatic, so its machining time is much shorter than other bending centers, especially for folding box-shaped parts, greatly improving efficiency.

(6) It has strong software functions for the automatic adjustment of the sheet compactor and the automatic generation of the bending program, thus reducing the preparation time considerably.

(7) It is extremely advantageous not only for small-batch production of many varieties but also for mass production of a single piece, and is suitable for production applications in sheet metal processing enterprises.

Disadvantages:

From what I understand, the biggest and only downside of this sheet metal panel bending machine is that it is expensive. The one-time investment is too large for some businesses.

Panel benders are characterized by the following:

(1) For companies whose parts require foam processing (such as refrigerators, rice steamers, etc.), the consistency of the parts provided eliminates the need to clean up leaks, resulting in significant improvements in processing efficiency and product quality.

(2) By using the corner-cut positioning method, it is possible to maintain the exact size of the exterior reference surface and ensure a high degree of consistency of the exterior part.

High accuracy can be maintained even if the sheet edge straightness deviates after unloading.

For workpieces with limited working envelopes that need to be refolded with a conventional bending machine, the size of the workpieces remains under control due to the exact outside dimensions.

Fig.10 Comparison of positioning methods

(3) For thin stainless steel plates (0.8mm thickness or less), manual bending can result in inconsistent offset bending due to operators prioritizing efficiency and synchronization.

The panel bender does not require lifting the plate during the bending process for larger panels, which eliminates the issue of offset bending caused by the plate not being lifted into place.

Compared to a press brake machine, the panel bender greatly improves surface quality and production efficiency, with an average increase of over 40%.

(4) The highly flexible processing capabilities of the panel bender allow for small batch and multi-mix production.

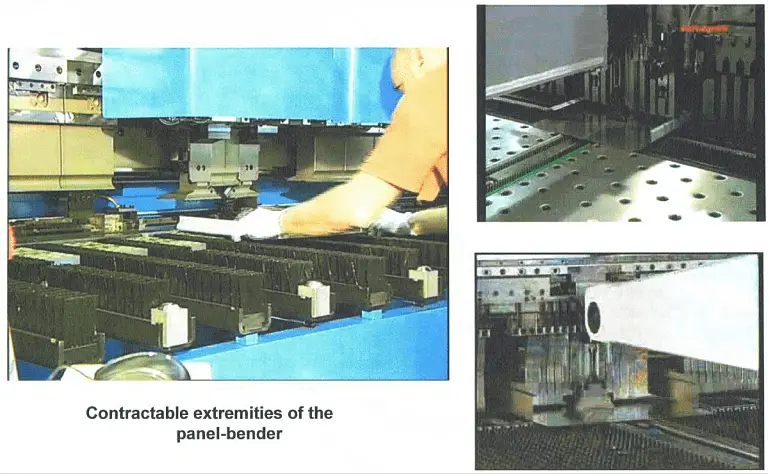

The unique ABA technology of the panel bender enables quick press length adjustments, even during robot edge changes.

As a result, it only takes an extra 2 to 3 seconds to complete the process of folding the long edge first and then the short edge (short wrap long).

The panel bender is also capable of processing products that require frequent press length adjustments.

(5) The panel bender offers advanced technology to develop new products and can complete most processes that are not possible with a press brake machine.

Compared to conventional bending machines, the panel bender has a relatively powerful processing capacity.

For example, Figure 11 illustrates the contoured shape of a refrigerator door handle developed for a customer.

Two different shapes were designed for the customer to choose and evaluate.

Previously, the customer was producing a similar product on an assembly line with five press brake machines and no quality control.

By using the P4 panel bender, the product’s quality was controlled, and the processing time was reduced to one minute.

Figure 11 Refrigerator door handle contouring

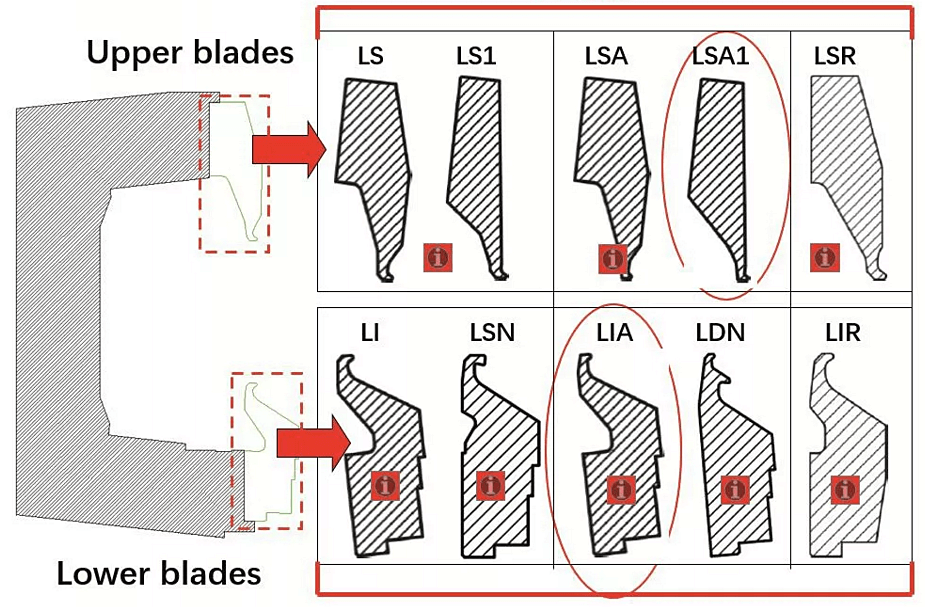

(6) The panel bender offers a wide range of bending tools for customers to choose from, and it is recommended that the thin red circle type bending tool be used for thin plates in general.

The configuration of the panel bender can be targeted to meet specific professional requirements.

Figure 12 Bending tool selection

(7) Industries that heavily utilize “201” chrome manganese series stainless steel often encounter difficulties due to the material’s high hardness and bending rebound.

Panel benders with new material property compensation technology as a standard feature have significantly improved product processability and first-piece success rates.

(8) Panel benders are available in various configurations based on customer requirements and investment size.

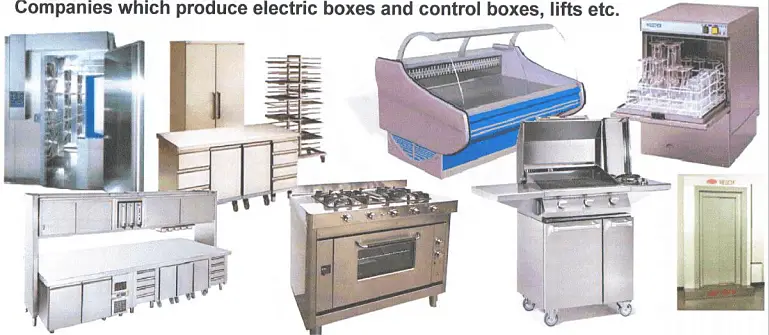

The panel bender is suitable for producing professional kitchenware for the catering and food industry, as well as ovens, cooking systems, cleaning systems (such as dishwashers and glassware washers), refrigerators, instant freezers, refrigerator counters and freezers, stainless steel furniture, and air handling systems (such as extractor hoods and exhaust fans).

Additionally, it is suitable for bending electrical industry cabinets, elevators, and lifts.

The panel bender has a standard tooling width of 160 mm and a minimum cross-section in the overall dimensions of 131 cm2, making it one of the best in the field of panel bending.

The machine is equipped with an independent locking system, which ensures flexibility during the bending process.

The structure, number, and handling of the bending tools in the panel bender enable the machine to bend even extremely sensitive material surfaces without scratches or indentations.

Moreover, the bending process ensures low wear of the bending tools.

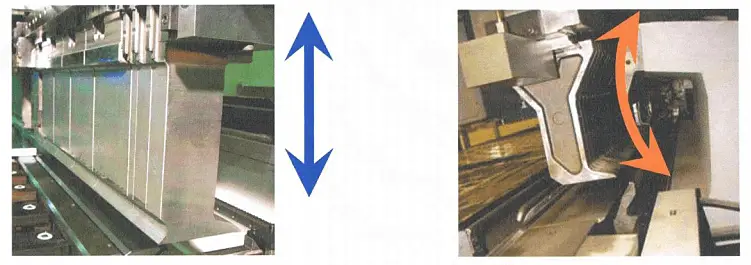

The panel bender moves vertically over a metal panel during the bending process.

Additionally, there are commercially available panel benders that move rotationally.

During the bending process, 80 tons of pressure are applied to the panel bender to ensure the flatness of the metal sheet and avoid bending indentations.

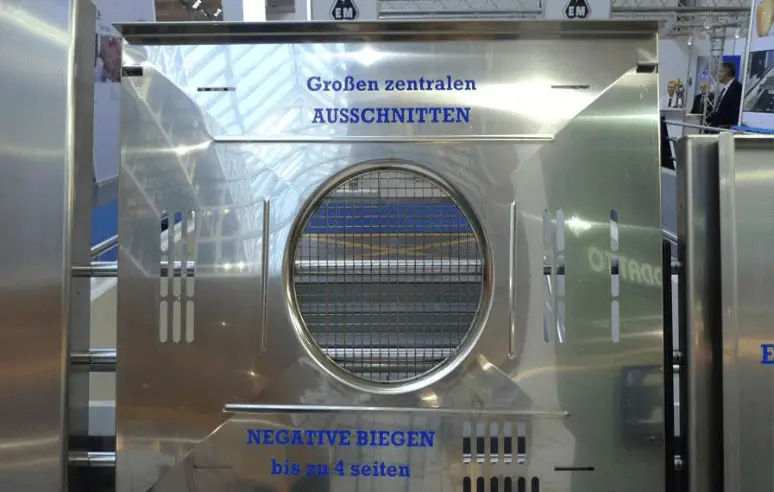

The bending system of the panel bender allows for front, reverse, wide, curved and right angle bending of the panel during the bending process!

As shown in the figure below.

DOOR WITH HANDLE

It is made out of only one piece.

It foresees the execution of 8 sides and the overturning of the panel during the cycle.

This last operation can be performed only by a semiautomatic machine.

For its production one needs to use the PSA with a toolset and two SA blades.

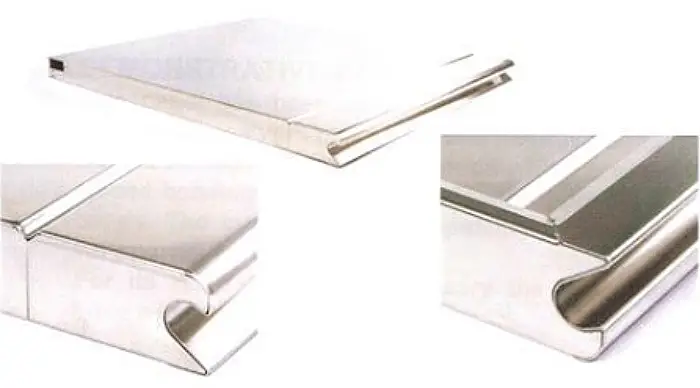

PLATING PANEL

This panel has radius bends of different dimensions completed with an edge without any containment.

Despite having a surface with an orange peel effect (and therefore being very fragile), it can be produced without the usage of a protective film, and there won’t be the smallest mark on the panel.

The panel has a length of 3000mm.

DEMONSTRATIVE PANEL

This panel has been created to demonstrate the ability to execute pieces with more than one negative bend, as well as the ability to perform bends that are tightly closed between themselves and with opposite radii bends.

The curl demonstrates the capability to work in a very precise manner.

To produce this panel, it is necessary to use a table with brushes.

WORK TABLE

The new frontier for creating working tables, especially for the catering field, is characterized by the absence of corners and weldings.

This panel also demonstrates the capacity to create radius corners, both positive and negative, without the need for containment.

They can be made for a length of up to 3000mm and a rise of up to 200mm.

To produce this panel, it is necessary to use the PSA option with the aid of a video camera and one SA blade.

BACK PANEL WITH A LARGE HOLE

The drawn hole was created before the bending process, and it demonstrates the critical situation of handling.

In fact, the panel should be handled with the drawing upward, while the bends must be executed downward.

At the end of the process, the panel will have four sides with downward bends.

FRONT FOR OVEN-FRIDGE

The characteristic manipulator composed of vacuum cups allows for the handling of panels with bends or central drawings.

To produce this panel, it needs to be overturned between the first and third sides, an operation that can only be done by a semi-automatic machine.

EXHAUST FAN

The panel is produced with a particular fixed end.

This solution allows for the elimination of the majority of welds, reducing production scrap in a drastic way.

Furthermore, welding the vertical corners no longer requires masking.

DOOR WITH HANDLE

The shown bend has been executed for last by using the PSA with two functions able to make the negative radius bend.

COMPRESSOR PROTECTION

Producing large radius bends for this panel is definitely not a problem, and special tools are not necessary.

Everything can be produced with standard tools.

The radius corner, even if it’s 7mm high, can be executed without the need for containment, and the result is without any deformation.

FRYER SURFACE

This particular panel has been executed using the vertical movement of the manipulator to control the downward encumbrance for the last shown bend.

To produce this panel, it was necessary to mount the PSA and sheet clamps on the panel bender.

MALE AND FEMALE SLIDING DOORS

These are interesting examples that demonstrate the ability to produce negative hidden bends.

To execute them, the PSA is necessary.

DOORPOST

Using the “cutting unit” option, it is possible to create very small shapes that are only bent on two sides and then cut with an appropriate blade.

Once the shape is cut, it is expelled into a bin located on the side of the machine.

The “cutting unit” is an option for the PSA.

PANEL

The characteristic of this panel concerns the lower central part.

In fact, it cannot be handled using the sheet clamps.

The operator can visualize what is happening to the metal sheet during the bending stage with the aid of a video camera and can actively intervene by modifying the bends that the machine is performing.

This solution is really important for executing panels for the first time or for the execution of bends on panels coming from different batches.

Once the desired result is achieved, the operator can save the applied process so that it can be executed on the next panels to be bent.

This is achievable not only through the usage of sophisticated algorithms, which require perfect knowledge of the material (type, thickness, length), but also through the simple movement of a joystick.

The aid of the video camera gives the possibility to control the different elastic returns and obtain the “first good piece.”

In traditional press brake operations, panel handling often necessitates multiple operators, particularly for panels exceeding 1500mm in length. The dynamic nature of the bending process makes single-operator manipulation challenging and potentially compromises precision and safety.

Panel benders, by contrast, streamline the handling process significantly. The operator’s role is reduced to three primary tasks: loading the panel onto the working table, rotating it for multi-side bending operations, and unloading the finished component. This simplification not only enhances efficiency but also minimizes the risk of handling errors.

Advanced panel bending systems further optimize the process. In these setups, the operator’s involvement is limited to unloading the completed part, as the machine autonomously manages panel loading and manipulation throughout the bending sequence.

Moreover, panel benders eliminate the cognitive load associated with traditional bending methods. Unlike press brakes, where operators must memorize and execute complex bend sequences, semi-automatic panel benders guide the process. The machine prompts the operator for necessary panel rotations, ensuring consistent, high-quality results regardless of operator experience level.

This technological evolution in bending processes not only improves productivity and part consistency but also enhances workplace ergonomics and safety. By reducing manual handling and simplifying operator tasks, panel benders represent a significant advancement in sheet metal fabrication technology.

Handling of a panel with the pess-brakes

Overturning of the panel on the ball table of a panel-bender

Press brakes demand highly skilled operators with specialized experience in sheet metal forming and the ability to meticulously control each stage of the bending process. These operators must possess a deep understanding of material behavior, tooling selection, and complex bend sequencing to achieve precise results.

In contrast, panel benders offer a significant advantage in terms of labor requirements. These advanced machines can be efficiently operated by a single person without extensive metalworking expertise. The panel bender’s sophisticated control system and automated bending sequence execution eliminate the need for manual adjustments and real-time decision-making during the forming process.

This automation translates to substantial benefits for manufacturers:

While the initial investment in a panel bender may be higher, the long-term savings in labor costs, increased productivity, and improved part consistency often justify the technology upgrade for many sheet metal fabricators.

The panel bender represents a significant advancement in automated sheet metal fabrication technology. Prior to October 2008, awareness of semi-automated panel benders was limited within the global metalworking industry. The technology’s debut at EuroBLECH, where only two companies showcased their semi-automatic panel bending machines, marked a pivotal moment in sheet metal processing innovation.

Extensive market research has revealed substantial untapped potential in the sheet metal bending sector. For decades, the bending process has been predominantly executed using manual press brake machines, highlighting a significant opportunity for technological advancement. This reliance on traditional methods stems from a lack of widely known alternatives to press brake technology, creating a latent demand for more efficient and automated solutions.

Despite various attempts to automate press brake operations, these efforts have yielded limited success in terms of widespread adoption or substantial productivity gains. This technological gap underscores the market’s readiness for innovative bending solutions that can address the limitations of conventional methods.

The panel bender emerges as a promising solution to meet these unaddressed needs in the sheet metal fabrication industry. By offering enhanced automation, improved precision, and increased productivity, panel benders have the potential to revolutionize bending processes across various manufacturing sectors, including HVAC, enclosure production, and custom metal fabrication.

As awareness of panel bending technology grows, its market potential is likely to expand significantly. Industries seeking to optimize their production processes, reduce labor costs, and improve product consistency are prime candidates for adopting this advanced bending technology. The panel bender’s ability to handle complex bends with minimal setup time positions it as a valuable asset for both high-volume production and flexible, small-batch manufacturing scenarios.

In the stainless steel sector, panel benders are extensively utilized for manufacturing a wide range of products, including:

Commercial kitchen equipment:

Food service and hospitality furnishings:

HVAC and air handling systems:

Specialized equipment:

For other metal sheet applications, panel benders demonstrate versatility in producing:

Transportation systems:

Security and fire safety products:

Architectural elements:

Industrial cabinets and enclosures:

The adaptability of panel benders allows for efficient production of both standardized and customized components across these diverse product areas, ensuring high precision, consistent quality, and reduced material waste.

Panel benders are particularly valuable for:

Enterprises specializing in stainless steel fabrication:

Quality-driven manufacturers:

Small-batch and custom production facilities:

Companies transitioning from traditional press brake operations:

Enterprises with complex product portfolios:

Sheet metal fabricators seeking automation and digitalization:

Panel benders offer significant advantages in precision, efficiency, and versatility, making them invaluable for manufacturers aiming to enhance their sheet metal forming capabilities and overall product quality.

The cost of a panel bender, like any advanced manufacturing equipment, varies significantly based on its technological sophistication, automation level, and production capabilities. However, focusing solely on the initial price overlooks the comprehensive value proposition of this specialized bending technology.

When evaluating a panel bender investment, it’s crucial to consider the total cost of ownership and potential return on investment. This assessment should include:

By conducting a comprehensive analysis that encompasses these factors, manufacturers can make an informed decision based on the overall value and potential competitive advantage offered by panel bending technology, rather than focusing solely on the initial purchase price. This holistic approach ensures that the investment aligns with long-term production goals and operational efficiency objectives.

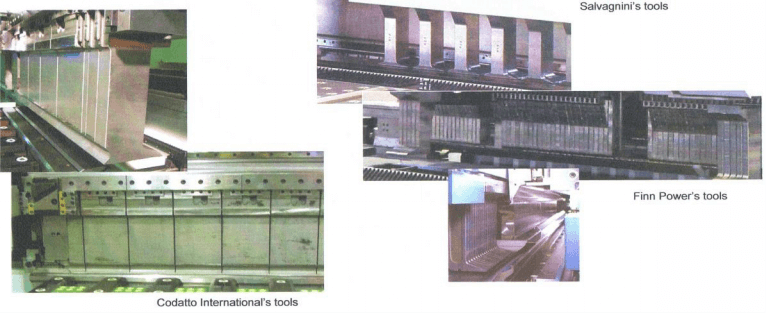

In the realm of advanced sheet metal fabrication, panel benders have revolutionized the folding process, offering unparalleled precision, flexibility, and efficiency. The following five manufacturers stand out as industry leaders, each contributing unique innovations to the field:

Each of these manufacturers continues to push the boundaries of panel bending technology, focusing on automation, precision, and integration with smart manufacturing systems to meet the evolving demands of modern sheet metal fabrication.

The panel bender represents a significant leap forward in metal forming technology, effectively decoupling product quality from operator skill level. This advanced bending machine ensures consistent, high-precision results across production runs, minimizing variability and defects inherent in manual processes.

Beyond quality assurance, the panel bender substantially reduces physical strain on operators, enhancing workplace ergonomics and safety. Its automated sequences and programmable controls allow for complex bending operations with minimal manual intervention, boosting productivity and reducing fatigue-related errors.

Furthermore, the panel bender’s versatility and precision open new avenues for product design and innovation. Design engineers can now explore more intricate geometries and tighter tolerances, previously challenging or impossible with conventional bending methods. This capability accelerates product development cycles and enables rapid prototyping of complex sheet metal components.

In the competitive landscape of modern manufacturing, the panel bender provides a strategic advantage. Its ability to swiftly adapt to changing product specifications allows companies to respond agilely to market demands, facilitating quick transitions between product lines and enabling cost-effective small-batch production. This flexibility, combined with its quality and efficiency benefits, positions enterprises to maintain a competitive edge in dynamic and demanding markets.