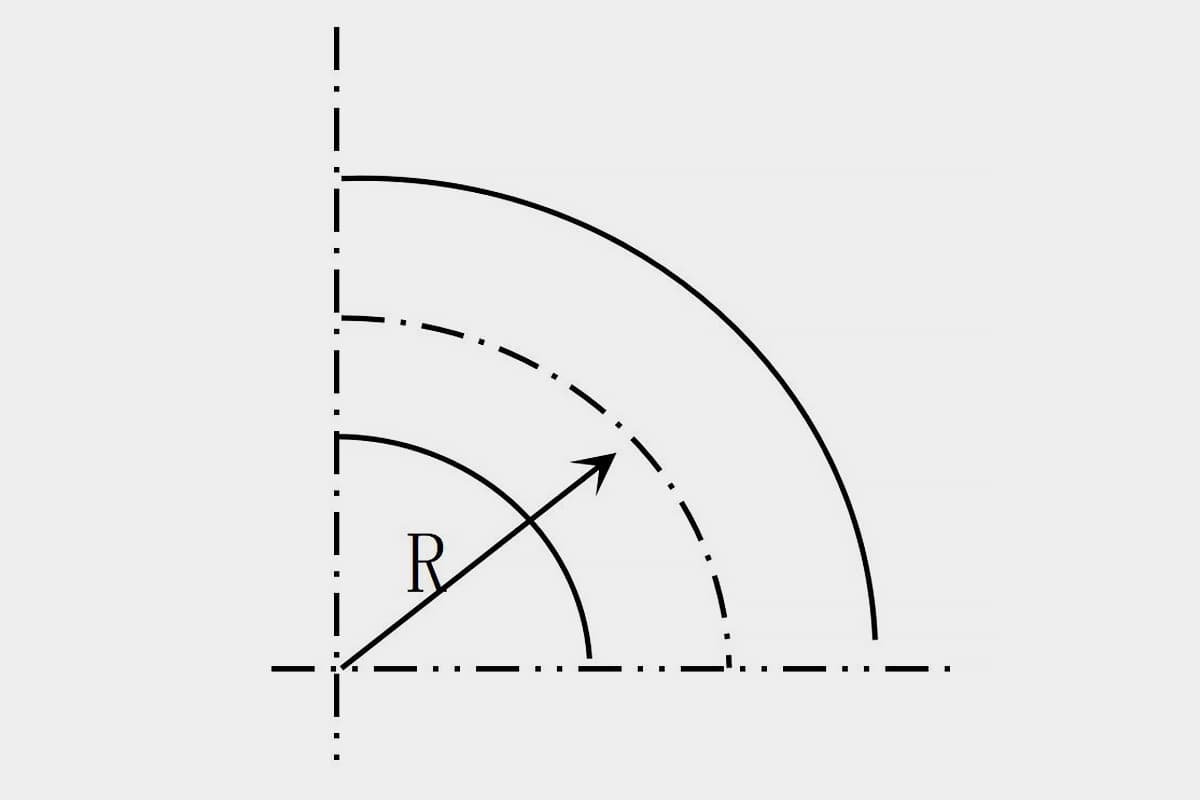

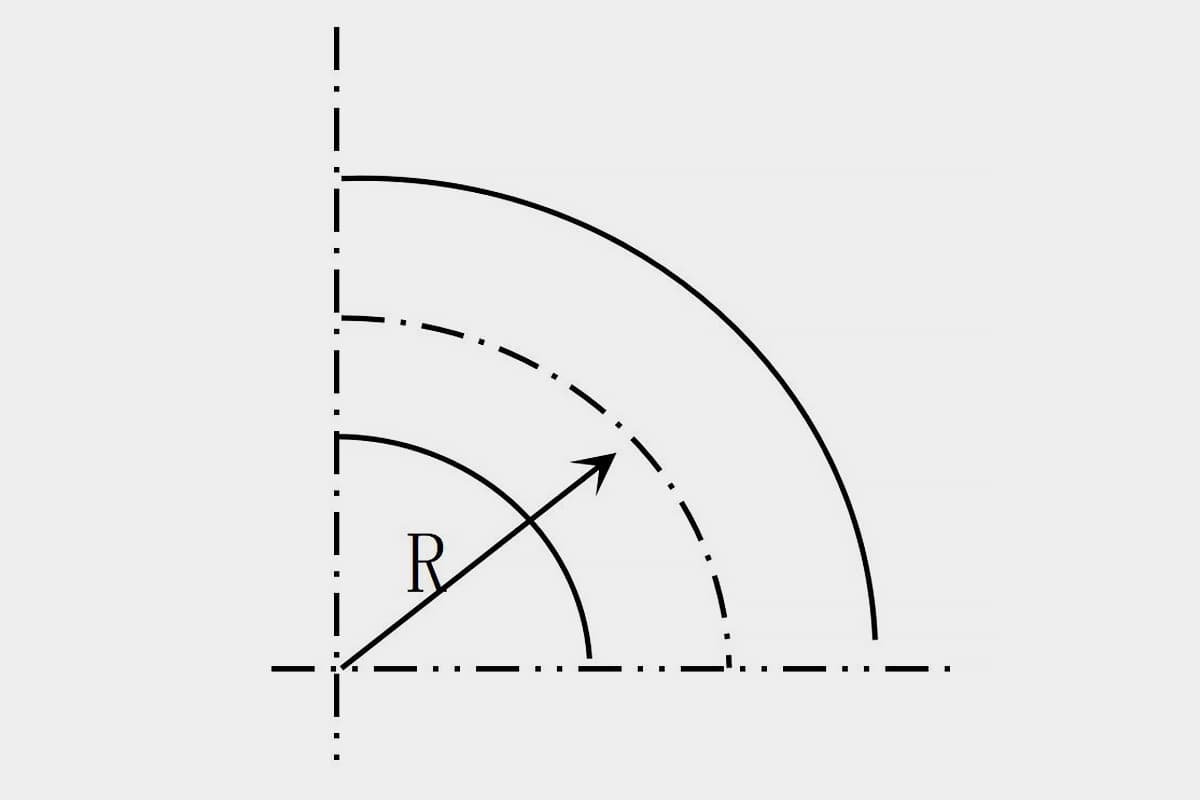

Ever wondered how to ensure precision in pipe bending? This article introduces a comprehensive table of minimum bending radii for various pipe specifications, focusing on carbon steel, low-alloy steel, and stainless steel. By understanding these critical measurements, you can enhance the accuracy and quality of your bending projects. Dive in to learn the essential guidelines and achieve optimal results in your metalworking endeavors.

| Carbon Steel, Low-Alloy Steel | Stainless Steel | ||

| Pipe Spec. | Min Bending Radius | Pipe Spec. | Min Bending Radius |

| Φ14*3 | 30 | Φ14*2 | 30 |

| Φ18*3 | 50 | Φ18*2 | 50 |

| Φ25*3 | 50 | Φ25*2 | 50 |

| Φ32*3.5 | 70 | Φ32*2.5 | 70 |

| Φ38*3.5 | 80 | Φ38*2.5 | 80 |

| Φ45*4 | 100 | Φ45*3 | 100 |

| Φ57*5 | 150 | Φ57*3 | 170 |

| Φ73*5 | 200 | Φ73*4 | 220 |

| Φ89*6 | 250 | Φ89*4.5 | 270 |

| Φ108*6 | 300 | Φ108*4.5 | 340 |

| Φ133*7 | 400 | Φ133*5 | 420 |

| Φ159*7 | 500 | Φ159*5 | 520 |

| Φ219*8 | 600 | Φ219*6.5 | 700 |

| Φ273*9 | 800 | ||

| Φ325*10 | 900 | ||

| Φ377*11 | 1000 | ||

| Φ462*11 | 1200 | ||

| Φ480*11 | 1500 | ||