Have you ever wondered about the unsung hero of modern construction? Steel pipes, the backbone of our buildings and infrastructure, play a crucial role in shaping our world. In this article, we’ll dive into the fascinating world of steel pipes, exploring their types, applications, and the science behind calculating their weight. Get ready to discover how these seemingly simple structures make a big impact in our lives.

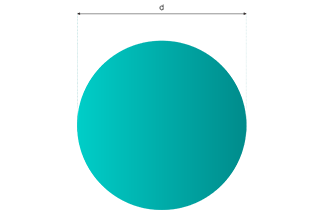

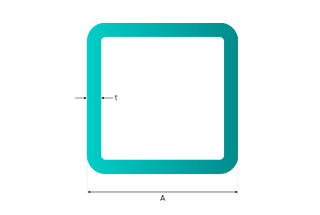

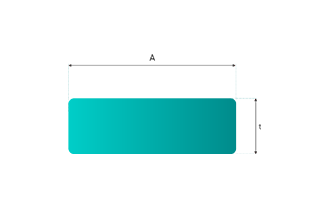

A pipe is a steel structure characterized by a hollow section where the length is significantly greater than its diameter or circumference. This structural form allows pipes to be used in a wide range of applications, from fluid conveyance to structural support.

Steel pipes can be classified based on several criteria, including section shape, material, purpose, and production process. Below is a detailed breakdown of these classifications:

Steel pipes are versatile and find use in various industries due to their strength, durability, and adaptability. Some common applications include:

Calculating the weight of a pipe is crucial for various engineering applications, including structural design, transportation, and cost estimation. The formula provided for calculating the weight of a pipe is accurate and commonly used in the industry. Here’s a detailed explanation and step-by-step guide to help you understand and apply this formula effectively.

The weight of a pipe per unit length can be calculated using the following formula:𝑊 (kg m)=0.02466×wall thickness×(outer diameter−wall thickness)W(kg m)=0.02466×wall thickness×(outer diameter−wall thickness)Where:

This formula is derived based on the density of steel (7.85 g/cm³) and the geometric properties of the pipe.

Step-by-Step Calculation

Example Calculation

Suppose you have a pipe with an outer diameter of 100 mm and a wall thickness of 5 mm.

Using the formula:𝑊=0.02466×5×(100−5)W=0.02466×5×(100−5)

𝑊=0.02466×5×95W=0.02466×5×95

𝑊=0.02466×475W=0.02466×475

𝑊=11.7015 kg mW=11.7015kg mSo, the weight of the pipe is approximately 11.7015 kg per meter.

According to the standards GB/T 21835-2008 and GB/T 17395-2008, the theoretical weight calculation method for circular steel pipes, including both welded and seamless pipes, is consistent.

Density Considerations

3. Practical Application

In practice, steel pipes can be delivered based on either theoretical weight or actual weight:

For convenience, you can use online steel pipe weight calculators. These tools allow you to input the outer diameter, wall thickness, and length of the pipe to automatically compute the weight. This can save time and reduce the risk of manual calculation errors.

Related Tool: Steel Weight Calculator

| Pipes | No. | Nominal diameter | O.D. | Thickness | Weight |

| JDG pipe | 1 | 16 | 15.7 | 1.2 | 0.43 |

| 2 | 20 | 19.7 | 1.2 | 0.55 | |

| 3 | 25 | 24.7 | 1.2 | 0.70 | |

| 4 | 32 | 31.6 | 1.2 | 0.90 | |

| 5 | 40 | 39.6 | 1.2 | 1.14 | |

| 6 | 50 | 49.6 | 1.2 | 1.43 | |

| 7 | 16 | 15.7 | 1.6 | 0.56 | |

| 8 | 20 | 19.7 | 1.6 | 0.71 | |

| 9 | 25 | 24.7 | 1.6 | 0.91 | |

| 10 | 32 | 31.6 | 1.6 | 1.18 | |

| 11 | 40 | 39.6 | 1.6 | 1.50 | |

| 12 | 50 | 49.6 | 1.6 | 1.89 | |

| KBG pipe | 1 | 16 | 15.7 | 1.2 | 0.43 |

| 2 | 20 | 19.7 | 1.2 | 0.55 | |

| 3 | 25 | 24.7 | 1.2 | 0.70 | |

| 4 | 32 | 31.6 | 1.2 | 0.90 | |

| Conduit TC | 1 | 16 | 15.87 | 1.6 | 0.56 |

| 2 | 20 | 19.05 | 1.6 | 0.69 | |

| 3 | 25 | 25.4 | 1.6 | 0.94 | |

| 4 | 32 | 31.75 | 1.6 | 1.19 | |

| 5 | 40 | 38.1 | 1.6 | 1.44 | |

| 6 | 50 | 50.8 | 1.6 | 1.94 | |

| Welded steel pipe | 1 | 16 | 20.75 | 2.5 | 1.13 |

| 2 | 20 | 26.25 | 2.5 | 1.46 | |

| 3 | 25 | 32 | 2.5 | 1.82 | |

| 4 | 32 | 40.75 | 2.5 | 2.36 | |

| 5 | 40 | 46 | 2.5 | 2.68 | |

| 6 | 50 | 58 | 2.5 | 3.42 | |

| 7 | 70 | 74 | 3 | 5.25 | |

| 8 | 80 | 86.5 | 3 | 6.18 | |

| 9 | 100 | 112 | 3 | 8.06 | |

| Water gas steel pipe | 1 | 16 | 21.25 | 2.75 | 1.25 |

| 2 | 20 | 26.75 | 2.75 | 1.63 | |

| 3 | 25 | 33.5 | 3.25 | 2.42 | |

| 4 | 32 | 42.25 | 3.25 | 3.13 | |

| 5 | 40 | 48 | 3.5 | 3.84 | |

| 6 | 50 | 60 | 3.5 | 4.88 | |

| 7 | 70 | 75.5 | 3.75 | 6.64 | |

| 8 | 80 | 88.5 | 4 | 8.34 | |

| 9 | 100 | 114 | 4 | 10.85 | |

| 10 | 125 | 140 | 4.5 | 15.04 | |

| 11 | 150 | 165 | 4.5 | 17.81 | |

| Galvanized steel pipe | 1 | 15 | 2.75 | 1.33 | |

| 2 | 20 | 2.75 | 1.73 | ||

| 3 | 25 | 3.25 | 2.57 | ||

| 4 | 32 | 3.25 | 3.32 | ||

| 5 | 40 | 3.50 | 4.07 | ||

| 6 | 50 | 3.50 | 5.17 | ||

| 7 | 70 | 3.75 | 7.04 | ||

| 8 | 80 | 4.00 | 8.84 | ||

| 9 | 100 | 4.00 | 11.50 | ||

| 10 | 125 | 4.50 | 16.85 | ||

| 11 | 150 | 4.50 | 22.29 | ||

| Galvanized round steel | 1 | 6 | 0.222 | ||

| 2 | 8 | 0.395 | |||

| 3 | 10 | 0.617 | |||

| 4 | 12 | 0.888 | |||

| Galvanized flat steel | 1 | 40*4 | 1.26 | ||

| 1 | 25*4 | 0.79 | |||

Calculating the weight of a pipe accurately is essential for various engineering and logistical purposes. By understanding and applying the provided formula, you can determine the weight of steel pipes efficiently. Always refer to relevant standards for specific density values and ensure measurements are precise for accurate results.