Imagine transforming flat metal plates into precise cylinders or intricate shapes with just one machine. Welcome to the world of the plate roll bending machine! This powerful tool, essential in industries like shipbuilding and aviation, bends metal sheets into various forms, enhancing efficiency and accuracy. Whether you’re curious about its mechanics or its types, this article unpacks everything you need to know, offering insights into its operation, classifications, and applications. Get ready to explore the marvels of metal shaping technology.

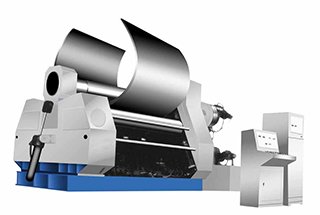

A plate roll bending machine, also known as a plate rolling machine or plate bender, is a sophisticated metalworking tool designed for the continuous and precise bending of metal plates into various curved profiles. This versatile equipment is essential in industries such as manufacturing, construction, and heavy engineering for producing cylindrical, conical, and multi-radius shapes.

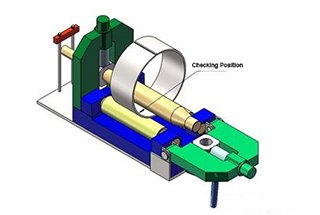

The machine typically consists of three or four rollers arranged in a pyramid or parallel configuration. These rollers work in concert to apply controlled pressure and movement to the metal plate, gradually deforming it into the desired curvature. Plate roll benders are available in two primary types:

Modern plate roll bending machines can produce a wide array of shapes, including:

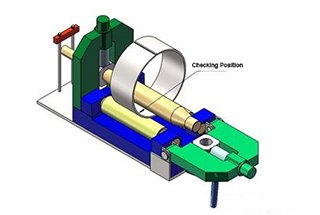

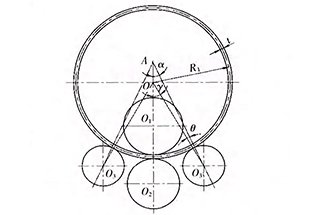

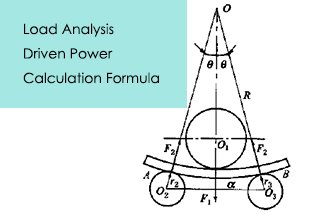

The symmetrical three-roll plate rolling machine operates on a principle of controlled deformation. The upper roller, positioned centrally between two lower rollers, moves vertically through hydraulic actuation. This movement is facilitated by hydraulic oil in the cylinder exerting force on a piston. The rotational motion is then transmitted to the two lower rollers via the final reduction stage of the main gearbox, generating the necessary torque for plate rolling.

As the metal sheet passes through the three work rolls, it undergoes a complex deformation process. The upper roller applies pressure while the lower rollers rotate, inducing a continuous bending action. This results in a three-zone deformation pattern:

This combination of forces leads to permanent plastic deformation, allowing the metal sheet to be formed into various shapes such as cylinders or cones.

One limitation of hydraulic three-roller bending machines is the need for pre-bending the plate ends, typically requiring auxiliary equipment. This step is crucial for achieving uniform curvature along the entire length of the workpiece.

This type of plate rolling machine is particularly well-suited for heavy-duty applications, capable of handling plates with thicknesses of 50mm or greater. To enhance precision and overall machine performance, the bottom section of the lower rollers is equipped with a series of fixed support rollers. This design feature effectively reduces the unsupported span between the two main lower rollers, minimizing deflection and improving workpiece accuracy.

Advanced models may incorporate CNC controls, variable speed drives, and real-time monitoring systems to optimize the bending process, ensure consistent quality, and accommodate a wide range of materials and geometries.

Roll bending machines are categorized based on their configuration and application across various industries. The primary classification is determined by the number of rollers: three-roller and four-roller bending machines.

Three-roller bending machines are further subdivided into:

Additionally, roll bending machines can be classified by their drive mechanism as either mechanical or hydraulic systems.

In terms of technological advancement, the hierarchy is as follows:

The evolution of these machines reflects improvements in precision, efficiency, and versatility in metal forming processes. Modern CNC-controlled hydraulic systems offer enhanced accuracy and repeatability, catering to the increasing demands of advanced manufacturing industries.

Four-roller bending machines, while not elaborated upon in the original text, offer additional advantages in terms of pre-bending capabilities and reduced material handling, making them particularly suitable for large-diameter or thick-walled pipe production.

Three roll plate rolling machines are essential equipment in metal fabrication, primarily used for bending sheet metal and plates into cylindrical or conical shapes. These machines are categorized into two main types:

The mechanical three-roll bending machine is further subdivided into two configurations:

a. Symmetrical

b. Asymmetrical

Each type offers distinct advantages in terms of operation, precision, and application scope. Mechanical machines are known for their reliability and simplicity, while hydraulic systems provide greater force and control. The choice between symmetrical and asymmetrical configurations in mechanical machines depends on factors such as material thickness, desired bend radius, and production requirements.

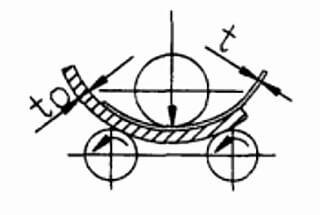

The machine employs a symmetrical three-roller configuration, optimized for efficient and precise metal forming operations.

The upper roller is strategically positioned at the midpoint between the two lower rollers, maintaining perfect symmetry to facilitate controlled vertical movements. This precise positioning is achieved through a robust screw-driven mechanism coupled with a worm gear, allowing for fine adjustments and consistent pressure application. The two lower rollers serve as the primary drive components, deriving their rotary motion from a high-torque reduction gear system. This motion is then transmitted through precision-engineered meshing with the lower roller gears, generating the substantial torque required for effective plate rolling.

This configuration offers several advantages:

However, it’s important to note that this design has an inherent limitation: it requires auxiliary equipment for pre-bending the plate ends. This pre-bending step is crucial for initiating the rolling process and achieving a uniform cylindrical shape throughout the entire length of the workpiece.

To mitigate this limitation, modern implementations often incorporate:

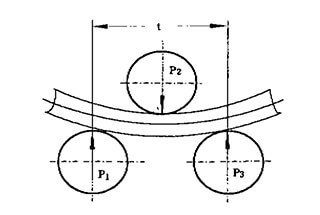

The machine employs a sophisticated three-roller asymmetrical configuration, optimizing the metal forming process. This design offers enhanced control and versatility in shaping operations.

The upper roller functions as the primary drive mechanism, delivering consistent power and rotational force to the workpiece. Simultaneously, the lower roller facilitates precise vertical movement, allowing for accurate thickness control and material feed.

Material engagement is achieved through the intricate meshing of precision-engineered gears on both the lower and upper rollers. This synchronized action ensures uniform clamping pressure distribution across the plate’s width, minimizing distortion and enhancing forming accuracy.

The side roller, capable of vertical adjustment, serves multiple critical functions. It excels in pre-bending operations, crucial for initiating the curvature in plate edges, and performs efficient round rolling for creating cylindrical shapes. This multifunctionality significantly reduces the need for separate pre-bending equipment.

The machine’s compact design optimizes floor space utilization while maintaining robust performance. Its user-friendly interface and accessible components contribute to streamlined operation and simplified maintenance procedures, reducing downtime and increasing overall productivity.

Features of the Hydraulic Three-Roller Symmetrical Bending Machine:

The machine incorporates a precision-engineered hydraulic system with a high-capacity oil cylinder that actuates a robust piston rod, enabling precise vertical movement and controlled bending force application.

The lower roller serves as the primary drive mechanism, transmitting torque to the workpiece through a sophisticated reducer output gear meshing system. This configuration ensures optimal power transfer and smooth, consistent plate rotation during the forming process.

An adjustable carrier roller is integrated into the bottom assembly, allowing for fine-tuning of plate support and feed control, which is crucial for achieving uniform bending results across various material thicknesses.

The upper roller features a specialized drum-shaped design, engineered to enhance the straightness and cylindricity of the finished product. This makes the machine particularly suitable for fabricating large-diameter tanks with extended lengths and complex cross-sectional profiles.

The symmetrical three-roll configuration, with its up-adjustable mechanism, offers versatile forming capabilities. It can efficiently roll metal plates into precise circular, curved, and conical shapes within specified dimensional ranges, accommodating a wide variety of industrial applications.

In this setup, the lower roller functions as the driving roller, providing the primary rotational force, while the upper roller acts as the driven roller, ensuring uniform pressure distribution and material flow during the bending process.

The machine finds extensive application across diverse industries, including shipbuilding, pressure vessel manufacturing, aerospace, hydroelectric power generation, chemical processing, structural steel fabrication, and general machinery production. Its versatility and precision make it an indispensable tool for creating high-quality cylindrical and curved metal components.