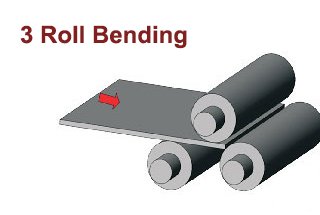

What is plate roll bending machine?

The plate roll bending machine is a tool for continuously bending plates into various shapes, such as O-type, U-shape, and multi-segment R. It comes in both mechanical and hydraulic versions. The machine is also known as a plate rolling machine or plate bending machine.

The working principle of the roll bending machine:

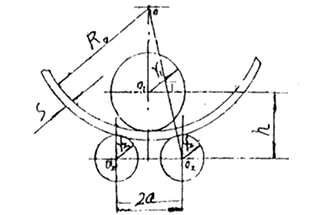

The upper roller of the symmetrical plate rolling machine moves vertically at the center of the two lower rollers through the hydraulic oil in the cylinder acting on the piston. This motion is then transferred to the two lower rollers through the final reduction gear of the main reducer, providing torque for the rolling plate.

The metal sheet is passed through the three work rolls (two lower rollers and one upper roll) of the machine, where the upper roller’s press and the lower roller’s rotation result in continuous bending (inner layer compression deformation, middle remains unchanged, outer stretch deformation), leading to permanent plastic deformation. The metal sheet is then rolled into the desired shape, such as a cylinder or cone.

One disadvantage of the hydraulic three-roller bending machine is that the end of the plate needs to be pre-bent with the help of additional equipment.

This plate rolling machine is suitable for large roll bending machines with a thickness of 50mm or more. The bottom part of the lower roller is fitted with a row of fixed rollers to shorten the span of the two rollers, improving the precision of the workpiece and enhancing the overall performance of the machine.

Classification of the roll bending machine

Roll bending machines can be categorized based on their use in various industries. They are primarily divided into two types based on the number of rollers: three-roller bending machines and four-roller bending machines.

Three roller bending machine is divided into:

- symmetrical 3-roll bending machine

- level down three rollers bending machine

- arc down the rolling machine

- upper roller universal three-roll bending machine

- hydraulic CNC roll bending machine

The roll bending machine can be divided into mechanical and hydraulic types. In terms of development, the three-roll bending machine with the upper roller being universal is considered the most outdated, while the level-down three-roll bending machine is slightly more advanced. The most advanced type is the arc-down rolling machine.

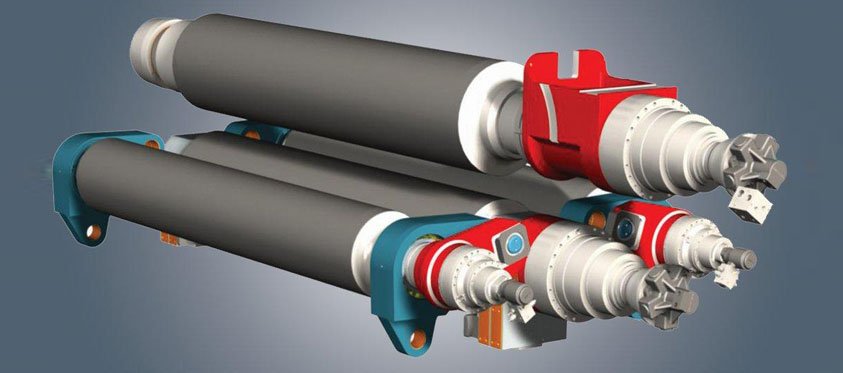

Three rolls bending machine

Three roll plate rolling machine include:

- Mechanical

- Hydraulic

The mechanical three-roll bending machine is divided into symmetrical and asymmetrical.

Mechanical three roller symmetrical

The structure of the machine is three-roller symmetrical.

The upper roller is positioned at the center between the two lower rollers in a symmetrical manner to facilitate vertical movements. This is achieved through the screw that drives the worm gear. The two lower rollers provide rotary motion, which is transmitted through the reduction gear output and meshing with the lower roller gear to generate torque for rolling the plate.

However, the machine has a limitation in that it requires additional equipment to pre-bend the end of the plate.

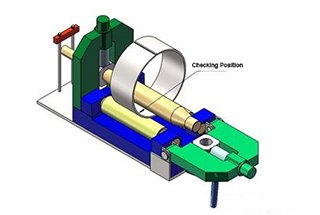

Mechanical three rollers asymmetrical

The machine structure is a three-roll asymmetrical design.

The upper roller serves as the primary drive, while the lower roller is responsible for vertical movement.

The plate is clamped through the meshing of the gears on the lower and upper rollers.

The side roller performs vertical movement and has the additional functions of pre-bending and round rolling.

It boasts a compact structure and is known for its ease of operation and maintenance.

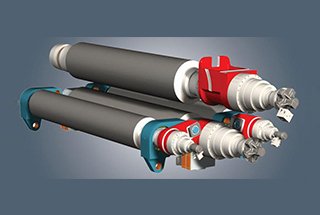

Hydraulic plate rolling machine

Features of the Hydraulic Three-Roller Symmetrical Bending Machine:

- The machine is equipped with a hydraulic oil cylinder that drives the piston rod, enabling vertical movement.

- The lower roller provides torque for the rolling plate through a reducer output gear meshing mechanism, which drives its rotation.

- The bottom part of the roller is equipped with an adjustable carrier roller.

- The upper roller is drum-shaped and helps improve the straightness of the finished product, making it suitable for tanks with long sizes and various cross-shapes.

- The up-adjust symmetrical three-roll bending machine has the ability to roll metal plates into circular, curved, and tapered shapes within a certain range.

- The lower roller is the driving roller, while the upper roller is the driven roller.

- It is widely used in industries such as shipbuilding, boilers, aviation, hydropower, chemicals, metal structures, and machinery manufacturing.