Why do laser welds sometimes develop pores, compromising their integrity? This article explores the causes behind these tiny cavities and offers practical methods to prevent them. By understanding how factors like laser power, welding speed, and gas dynamics influence pore formation, you can optimize your welding process for stronger, defect-free results. Dive in to learn actionable strategies that will enhance the quality and reliability of your laser welds.

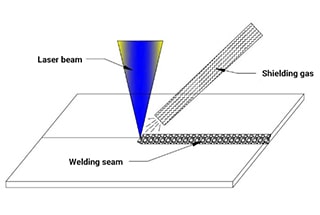

Laser welding has become a cornerstone technology in modern manufacturing, prized across industries for its ability to deliver highly concentrated energy, exceptional precision, and superior weld quality. This advanced joining technique offers numerous advantages, including minimal heat-affected zones, high welding speeds, and the capability to join dissimilar materials.

However, the sophisticated nature of laser welding systems introduces potential complexities that require careful consideration. Improper operation, suboptimal process parameters, or inadequate material preparation can lead to weld defects, with porosity being a particularly common and challenging issue.

Porosity in laser welds manifests as small voids or cavities within the weld bead, potentially compromising the joint’s structural integrity, corrosion resistance, and overall performance. To effectively mitigate this problem, a systematic approach is essential. This involves a thorough root cause analysis to identify the specific factors contributing to porosity formation, followed by the implementation of targeted solutions.

Porosity in laser welding is caused by the entrapment of gas during the solidification process of the weld metal. The cooling rate of the weld metal in laser welding is significantly faster compared to conventional welding, making it difficult for gas to escape and leading to the formation of pores.

There are two main causes of porosity in laser welding:

Weld formation process

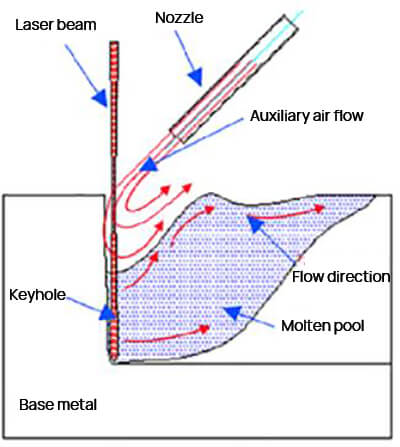

There is a correlation between the number of pores in a weld and the size of the laser power used. An increase in laser power is associated with an increase in the number of pores.

It is believed that the high heat generated by increased laser power causes the molten metal to reach extremely high temperatures, resulting in metal vapor production, making the liquid metal in the molten pool unstable, and causing turbulence.

To reduce the formation of pores, it is recommended to lower the laser power and increase the welding speed. This will reduce the production of metal vapor and minimize the formation of pores.

The formation of pores in laser welding can be minimized through a combination of metallurgical principles and advanced welding techniques. One effective approach involves introducing an active gas that either dissolves in the weld pool or reacts with the molten metal to form stable compounds. This process helps to reduce the nucleation and growth of gas bubbles that lead to porosity.

Pulse laser welding is another sophisticated technique employed to control the behavior of small holes and reduce the influx of shielding gas. By modulating the laser power, pulse welding creates a series of overlapping spot welds, allowing for better control of the heat input and molten pool dynamics.

While these methods significantly reduce porosity, complete elimination remains challenging. For deep penetration laser welding, the beam swing method has proven particularly effective in minimizing or eliminating pores. This technique involves the controlled oscillation of the laser beam across the weld seam.

The reciprocating movement of the beam over the weld serves multiple purposes:

To complement these welding techniques, implementing stringent quality control measures is crucial. Utilizing advanced inspection tools such as surface cleanliness meters and RFU (Residual Flux Units) analyzers allows for rapid and accurate assessment of part cleanliness. This data-driven approach eliminates the subjectivity inherent in manual inspection processes, enabling optimization of cleaning procedures for greater efficiency.

By integrating these advanced welding methods with precise cleanliness control, manufacturers can significantly reduce the occurrence of air holes in laser-welded joints. This comprehensive approach not only improves weld quality but also minimizes rework, reduces production costs, and enhances overall manufacturing efficiency.