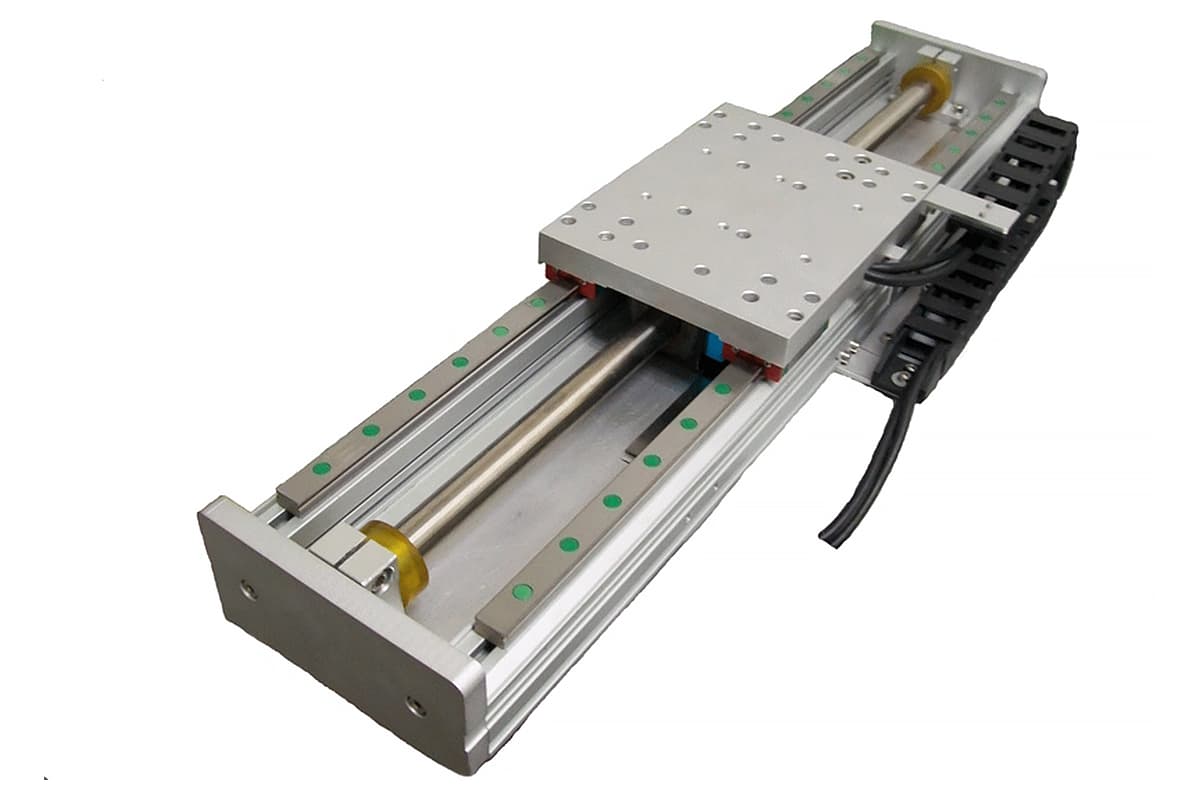

What’s the difference between positioning accuracy and repeatability in CNC machines? This blog explores these essential concepts, explaining how they impact the precision and reliability of mechanical systems. You’ll learn how positional accuracy measures the deviation from a target position in a single motion, while repeatability gauges the system’s ability to consistently reach the same position over multiple attempts. Dive into the details to understand how these metrics affect your machining processes and ensure optimal performance.

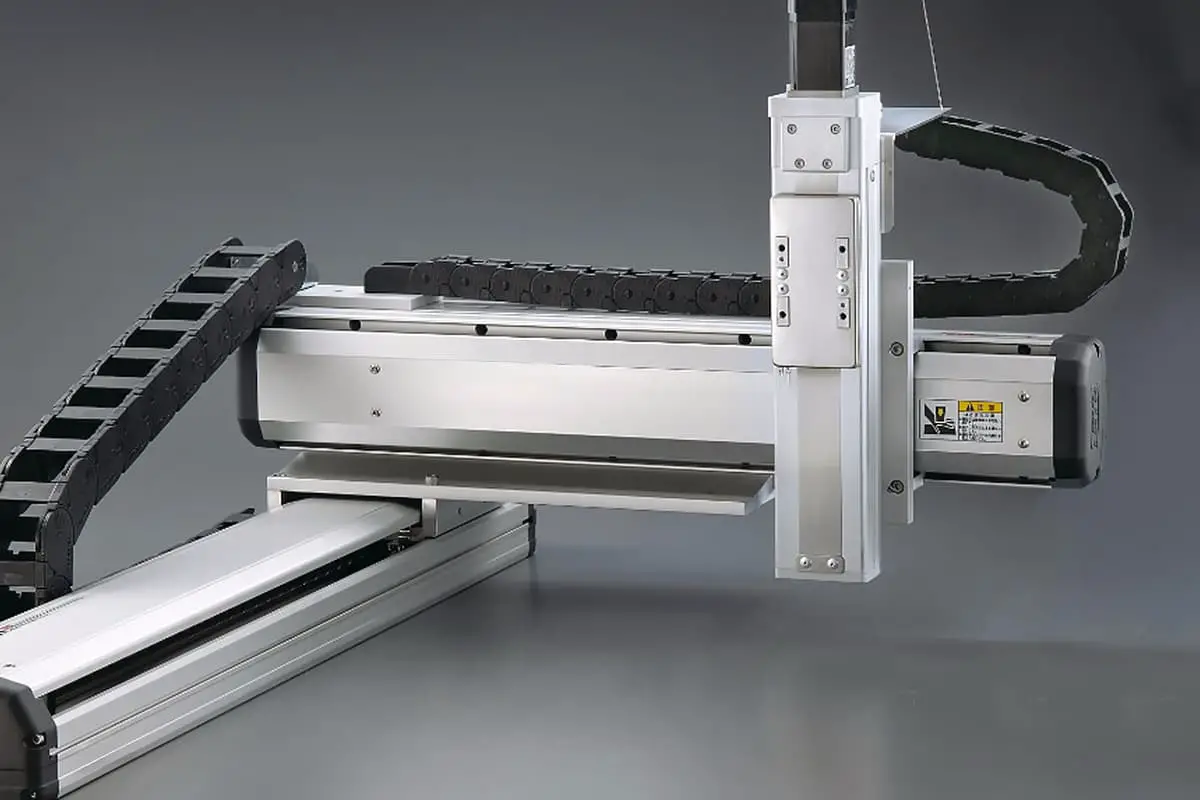

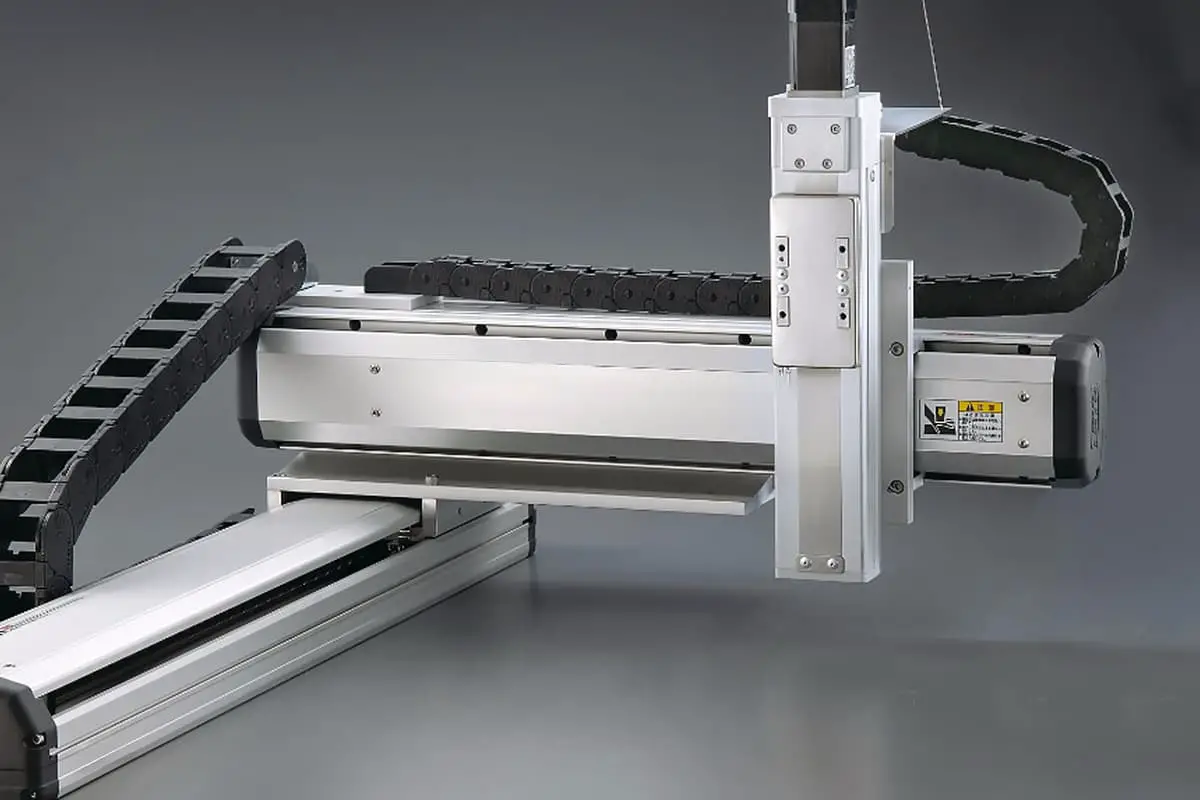

Positional accuracy and repeatability are two distinct concepts often used to describe the performance of mechanical systems in the industrial sector.

Repeatability is generally higher than positional accuracy.

Positional accuracy is a specific value, not a range, indicating the degree of deviation between the target position a mechanical system aims to reach in a single motion and its actual position.

It reflects the system’s accuracy in achieving the target position in a single movement.

In simple terms, it refers to the deviation between the actual position a piece of equipment stops at and the position it was supposed to reach.

Positional accuracy is a definite value (e.g., 0.01mm) rather than a range (e.g., ±0.02mm).

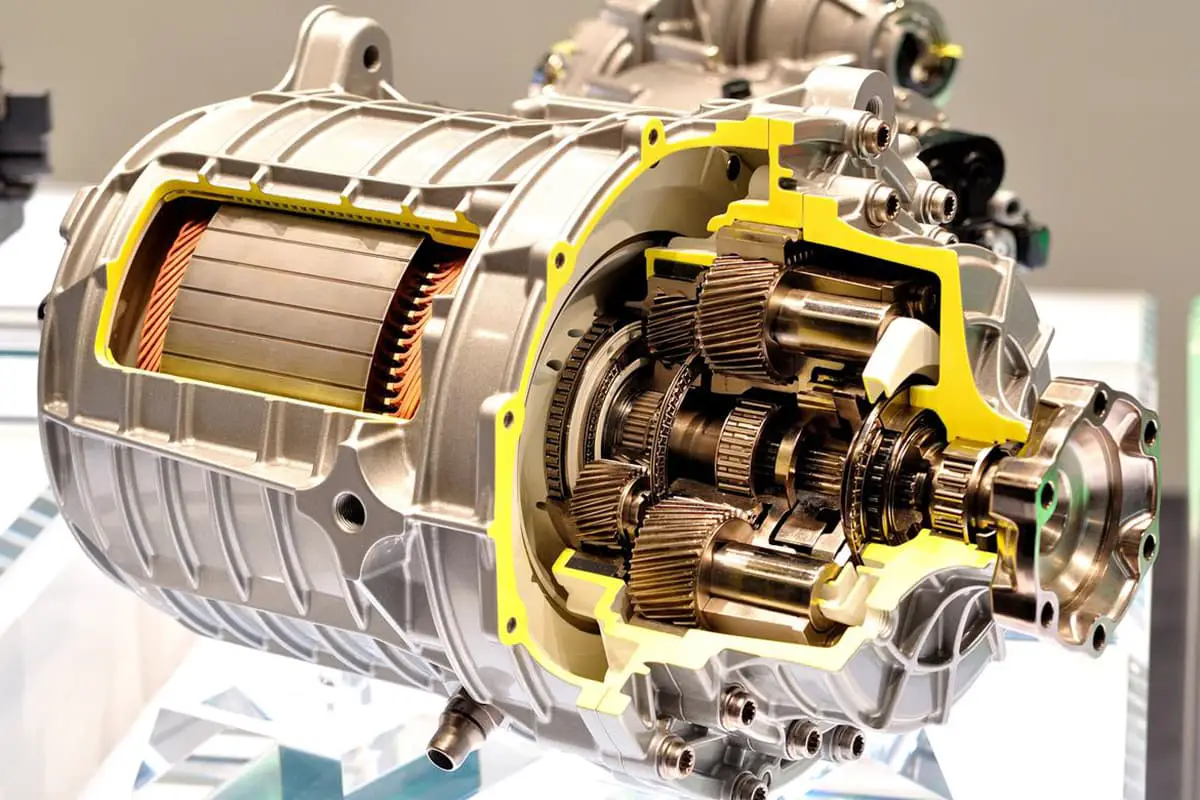

The error in positional accuracy depends on the manufacturing inaccuracies of the transmission components.

For example, if a shaft is meant to move 100mm but actually moves 100.01mm, the 0.01mm difference represents the positional accuracy. If a lead screw is set to move 100mm and the actual movement ranges from 99.99mm to 100.01mm, its positional accuracy is 0.02mm (100.01 – 99.99 = 0.02).

Repeatability refers to the precision with which a mechanical system can repeatedly reach the same target position over multiple movements. It demonstrates the system’s consistency and repeatability in achieving the same target position across multiple movements, which is crucial for applications requiring repetitive motion.

In layman’s terms, it is the error produced when positioning to the same location multiple times. Repeatability is expressed as a range (e.g., ±0.02).

The error in repeatability is related to the clearance in transmission components. Additionally, repeatability is influenced not only by the accuracy and resolution of the grating scale (displacement sensor) but also by errors in the mechanical system, such as the guidance system, transmission system, and structural rigidity.

These factors can reduce positional accuracy and, to some extent, affect repeatability.

For instance, if a shaft is required to move 100 mm, it might actually move 100.01mm on the first attempt and 99.99mm on a repeated attempt. The error between these two measurements, 100.01 – 99.99 = 0.02mm, represents the repeatability. Repeatability is expressed as ±x, with the above error represented as ±0.01mm, or ±(0.02/2).

For example, if a lead screw is set to move 100mm and over 100 movements the actual distance ranges from 99.988mm to 99.992mm, its repeatability is ±0.002mm.