Welding stainless steel demands precision to prevent defects like cracking and corrosion. Are you aware of the critical steps to ensure a flawless weld? This article highlights eight essential precautions, including selecting the right electrodes, managing heat treatment, and controlling welding current. By following these guidelines, you can maintain the integrity and performance of your stainless steel projects, avoiding common pitfalls and achieving professional results. Dive in to learn the vital techniques for mastering stainless steel welding.

Chromium stainless steel, renowned for its exceptional corrosion resistance, particularly against oxidizing acids, organic acids, and cavitation erosion, also exhibits superior heat resistance and wear resistance. These properties are primarily attributed to the formation of a passive chromium oxide layer on the steel’s surface, which provides a protective barrier against various corrosive environments.

This versatile alloy finds extensive applications in critical industrial sectors, including power generation plants, chemical processing facilities, petroleum refineries, and various high-performance equipment and materials. Its ability to withstand harsh operating conditions makes it indispensable in components such as heat exchangers, pressure vessels, and piping systems exposed to corrosive media or elevated temperatures.

However, chromium stainless steel presents challenges in fabrication, particularly in terms of weldability. The high chromium content, while beneficial for corrosion resistance, can lead to issues such as sensitization and hot cracking during welding. To mitigate these problems, it is crucial to implement precise welding procedures and carefully controlled heat treatment regimes. Key considerations include:

Chrome 13 stainless steel, also known as Type 410 or EN 1.4006, exhibits high hardenability after welding and is susceptible to cracking due to its martensitic microstructure. This material’s sensitivity to heat-affected zone (HAZ) hardening necessitates careful welding procedures to maintain structural integrity.

To mitigate cracking risks, the following welding practices are recommended:

Chromium 17 stainless steel, also known as Type 430 ferritic stainless steel, is enhanced through the strategic addition of stabilizing elements such as titanium (Ti), niobium (Nb), and molybdenum (Mo). These alloying elements significantly improve its corrosion resistance, particularly in chloride-containing environments, and enhance its weldability. The improved metallurgical structure offers superior performance compared to chromium 13 stainless steel, especially in terms of resistance to intergranular corrosion and stress corrosion cracking.

When welding Chrome 17 stainless steel using matching filler metals (such as ER430 or E430 electrodes, equivalent to G302 and G307), it is crucial to implement proper heat management techniques. Preheating to a minimum of 200°C (392°F) is strongly recommended to minimize the risk of cold cracking. Post-weld heat treatment (PWHT) should be performed at approximately 800°C (1472°F) for stress relief and to restore the desired microstructure. This tempering process helps to improve ductility and toughness while reducing residual stresses.

In situations where post-weld heat treatment is not feasible due to practical constraints or equipment limitations, an alternative approach is to utilize austenitic chromium-nickel stainless steel electrodes (such as ER308L or E308L, equivalent to A107, A207). This dissimilar metal welding technique can help mitigate the risk of cold cracking and improve the overall weld quality without the need for PWHT. However, it’s important to note that this method may result in a slight mismatch in corrosion resistance between the weld metal and the base material, which should be considered in the design and service conditions of the welded component.

When welding chromium-nickel stainless steel, repeated heating cycles can induce carbide precipitation at grain boundaries, a phenomenon known as sensitization. This process significantly compromises the material’s corrosion resistance, particularly its resistance to intergranular corrosion, and can adversely affect mechanical properties such as ductility and toughness.

To mitigate these issues, several strategies can be employed:

Chromium nickel stainless steel electrodes are renowned for their exceptional resistance to corrosion and oxidation, making them indispensable in various high-demand industrial applications. These electrodes typically contain 18-20% chromium and 8-12% nickel, which forms a passive oxide layer on the surface, providing superior protection against aggressive environments.

Their widespread use spans across multiple sectors:

These electrodes exhibit excellent weldability and maintain their mechanical properties at elevated temperatures, typically up to 800°C (1472°F). They also offer good ductility and impact strength, even at cryogenic temperatures.

Chromium nickel stainless steel coatings are typically applied using two main types of welding electrodes: titanium-stabilized and low-hydrogen. The titanium-stabilized electrodes are versatile, compatible with both AC and DC power sources. However, when using AC welding, it’s important to note that penetration depth is limited, and there’s an increased risk of hot cracking. For optimal results, DC welding is strongly recommended, particularly DC+ (reverse polarity), as it provides deeper penetration and better arc stability.

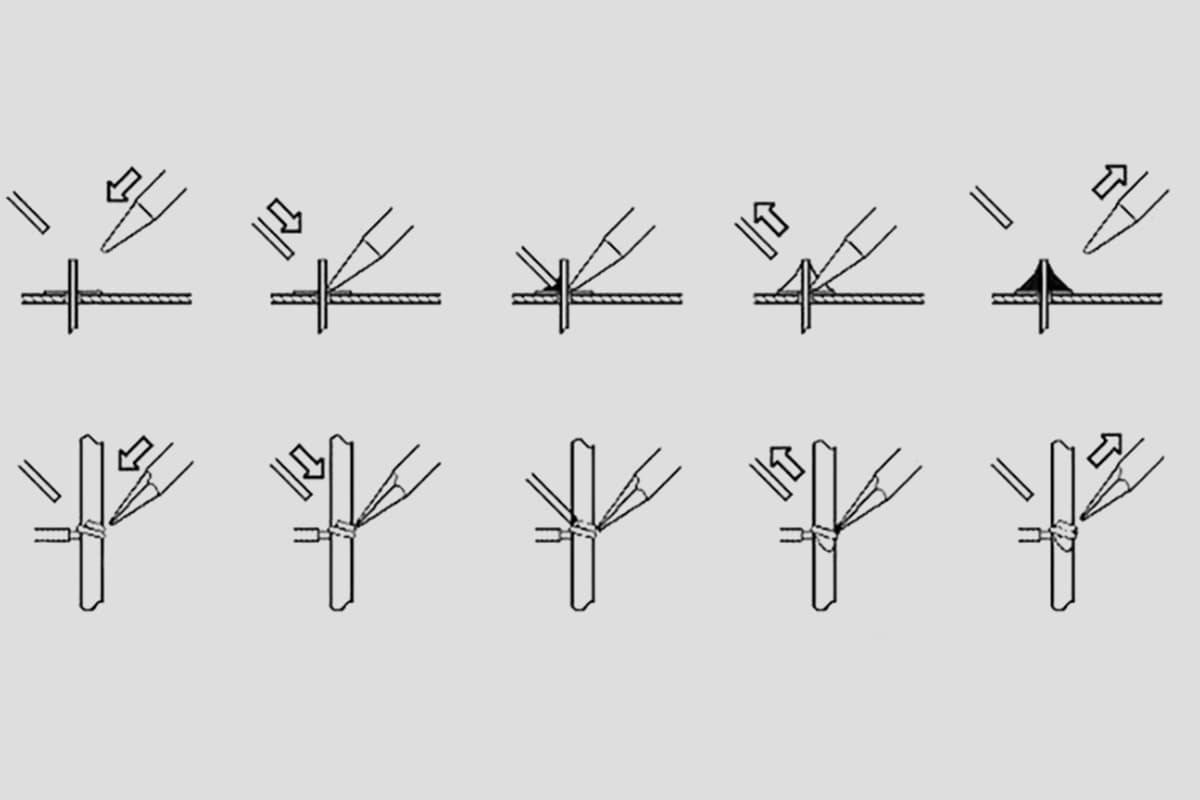

Electrode selection depends on the welding position and joint configuration. Electrodes with diameters of 4.0mm or smaller are suitable for all-position welding, offering excellent flexibility for complex geometries and out-of-position work. For flat and horizontal fillet welds, larger diameter electrodes (5.0mm and above) are preferred, as they allow for higher deposition rates and improved efficiency.

When applying chrome nickel stainless steel coatings, it’s crucial to maintain proper interpass temperature (typically below 150°C) to preserve the material’s corrosion resistance and mechanical properties. Additionally, using proper shielding gas (such as Ar/2-3% N2 for GTAW) can enhance weld quality and minimize chromium oxidation.

Proper electrode handling and preparation are crucial for ensuring high-quality welds. Maintaining electrode dryness during use is paramount to prevent weld defects and ensure optimal performance.

Different electrode types require specific drying procedures:

It’s essential to note that repeated drying cycles are not recommended, as they can lead to coating deterioration, including cracking and peeling. This degradation can compromise the electrode’s integrity and welding performance.

The primary purpose of proper electrode storage and drying is to prevent moisture absorption and contamination. Exposure to oil, dirt, or other contaminants can adversely affect the electrode coating. These impurities can introduce undesirable elements into the weld pool, potentially increasing the carbon content of the weld metal. Elevated carbon levels can negatively impact the mechanical properties and overall quality of the weldment, leading to issues such as reduced ductility, increased hardness, and susceptibility to cracking.

To maintain electrode quality and ensure consistent welding results, implement the following best practices:

When welding stainless steel, precise control of the welding current is crucial to prevent material degradation and ensure optimal weld quality. To mitigate the risk of chromium carbide precipitation and subsequent intergranular corrosion, it is essential to use a welding current approximately 20% lower than that typically employed for carbon steel electrodes. This reduction in current helps minimize heat input and limits the time spent in the sensitization temperature range (450-850°C).

Maintaining a short arc length is equally important, as it contributes to better heat concentration and reduces the heat-affected zone (HAZ). This practice not only improves weld penetration but also helps control distortion and residual stresses.

Rapid cooling of the interlayer is critical in stainless steel welding. This can be achieved through:

For optimal results, a narrow weld bead is preferred. This approach offers several advantages: