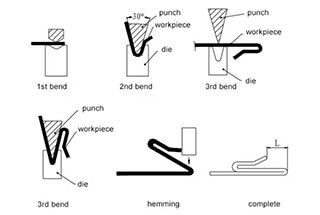

What makes the E21 and E200P press brake controllers distinct, and which one suits your needs? In this article, we compare these two controllers, both from Estun, by analyzing their screen types, axis control mechanisms, positioning accuracy, speed, and additional features. Whether you prioritize precision, speed, or ease of maintenance, this guide will help you understand the key differences and decide which controller aligns best with your manufacturing requirements.

The E21 and E200P press brake controllers are both products of Estun, a company based in China. The following are the differences between these two controllers:

| Comparison Parameter | E21 | E200P |

|---|---|---|

| Display Screen | Monocolor | Multicolour |

| X, Y Axis Positioning | Manual | Auto |

| X, Y Axis Control | 1. Ordinary Motor, poor positioning accuracy; | 1. Servo motor, the high positioning accuracy of 0.05mm; |

| 2. Positioning accuracy: 0.1mm at most; | 2. Repositioning accuracy: 0.02mm | |

| 3. Repositioning accuracy: 0.1mm; | ||

| X-axis Transmission | Round chrome-coated rod | Precise linear guide rail with more stable motion |

| X-axis Positioning Speed | 1. Ordinary Motor; | 1. Servo motor; |

| 2. Max speed: 40mm/s; | 2. Max speed: 200mm/s; | |

| Y-axis Positioning Speed | 1. Step Motor; | 1. Servo motor |

| 2. Max rotating speed: 500r/min | 2. Max speed: 1500r/min | |

| Wiring Assembly Function | None | 1. Built-in PLC to change the motion of valve in time; |

| 2. Setting of pressure-adding, pressure-holding & off-load time; | ||

| 3. Convenient for maintenance; | ||

| Stroke Return Distance Adjustment | None | 1. Adjustable return stroke height, no need back to the up dead point every time; |

| 2. Improve the efficiency |