Have you ever wondered how a press brake’s hydraulic system works? In this article, we’ll dive deep into the intricacies of this essential component. Our expert mechanical engineer will guide you through the system’s key elements, explaining their functions and interactions. By the end, you’ll have a comprehensive understanding of how hydraulics power these impressive machines.

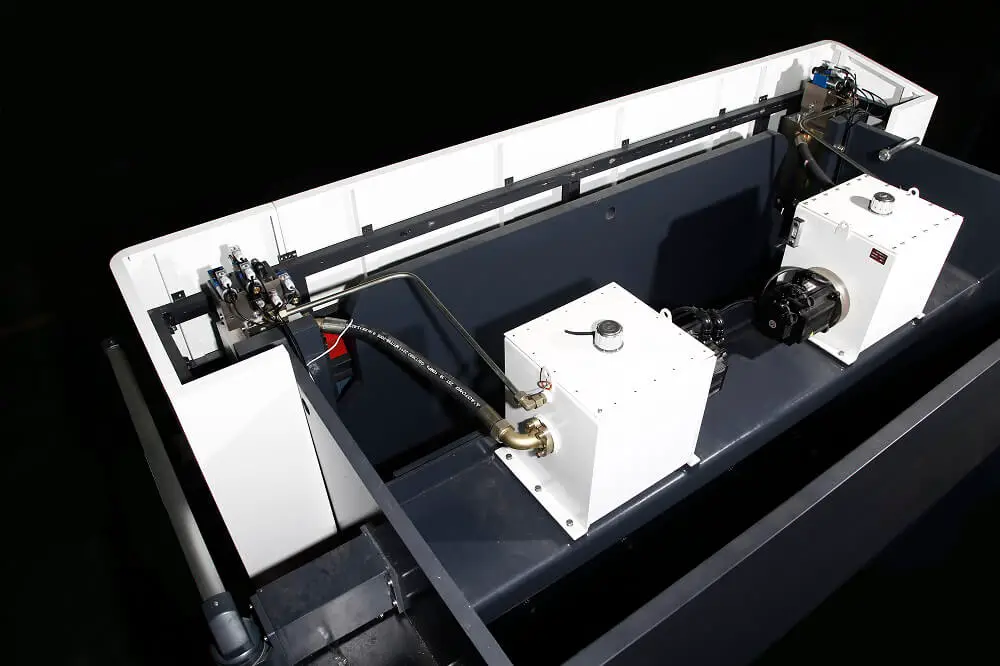

Powerplant

Hydraulic Pump: Converts mechanical energy from the prime mover into fluid pressure energy, serving as the system’s primary power source. Modern press brakes often utilize variable displacement pumps for improved energy efficiency and precise control.

Actuator

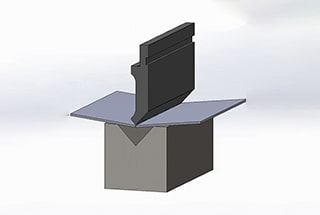

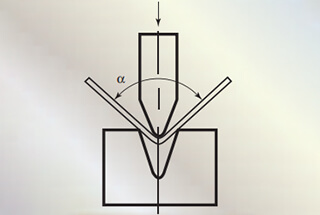

Hydraulic Cylinders: Transform fluid pressure energy into linear mechanical motion, applying force to the press brake ram. High-precision cylinders with integrated position sensors ensure accurate bending angles and depths.

Control devices

Hydraulic Control Valves: Regulate fluid direction, pressure, and flow to achieve precise control over the actuator’s movement. Key components include:

Advanced systems may incorporate servo-hydraulic valves for enhanced responsiveness and accuracy.

Auxiliary equipment

Working medium

Hydraulic Oil: Serves as the power transmission medium, typically a high-quality mineral or synthetic oil with specific viscosity, anti-wear, and anti-foaming properties. Modern formulations often include additives for improved performance and longevity.

Control and Integration

Programmable Logic Controller (PLC) or Computerized Numerical Control (CNC): Coordinates the hydraulic system components with the press brake’s overall operation, enabling precise control, automated sequences, and integration with production management systems.

The fuel tank, more accurately termed as the hydraulic oil reservoir in hydraulic systems, serves multiple critical functions:

Key design considerations for hydraulic reservoirs include:

Sizing:

The effective volume should be 6-12 times the total flow rate of the system’s hydraulic pump(s).

Design features:

Additional considerations:

Optimizing the hydraulic reservoir design ensures efficient system operation, extends fluid life, and enhances overall hydraulic system reliability and performance.

Hydraulic oil plays a critical role in ensuring optimal performance, operational reliability, longevity, and cost-effectiveness of hydraulic systems. Its multifaceted functions include:

Key concepts for optimal hydraulic oil management:

To maximize hydraulic system efficiency and lifespan, regular oil analysis, proper filtration, and timely oil changes are crucial. These practices help maintain oil quality, prevent system failures, and optimize overall performance.

Viscosity standard: Viscosity is a critical parameter in hydraulic systems, always referenced to a specific temperature. As temperature increases, viscosity decreases, while increased pressure results in higher viscosity. The ISO standard for hydraulic oil viscosity is measured at 40°C, categorizing oils into grades #10, #22, #32, #46, #68, and #100. This classification allows engineers to select the appropriate oil for specific operating conditions and system requirements.

Oil contamination standards: Two primary standards are used globally to quantify hydraulic oil cleanliness: the International ISO 4406 and the American NAS 1638. These standards provide a systematic approach to assessing and maintaining oil quality:

Maintaining proper oil cleanliness is crucial for system reliability, efficiency, and longevity. Regular oil analysis, coupled with appropriate filtration techniques, helps prevent contamination-related issues and ensures optimal hydraulic system performance.

Hydraulic valves are critical components in fluid power systems, controlling the direction, pressure, and flow rate of hydraulic fluid. They can be classified based on various criteria:

Each type of valve has specific applications and characteristics, influencing system design, performance, and efficiency in hydraulic circuits.

The primary function of a directional valve is to manage fluid flow paths within hydraulic systems. It facilitates the connection and isolation between different hydraulic circuits, and controls the direction of fluid flow to actuators (such as cylinders or motors) for precise starting, stopping, and movement control.

Classification of directional control valves

Divided by actuation method:

Divided by construction and mounting style:

Valves are further classified by the number of ports (e.g., 2-way, 3-way, 4-way) and positions (e.g., 2-position, 3-position), defining their flow control capabilities and complexity.

Features

The primary function of a relief valve is to regulate system pressure, safeguarding various components and pipelines against overload and potential rupture. This critical role has earned it alternative names such as pressure valve or safety valve.

When system pressure reaches the predetermined set point, the relief valve activates as a pressure limiter. The normally closed valve opens, allowing excess flow to return to the reservoir through the valve port. In this configuration, the relief valve is typically installed in a bypass arrangement.

It’s crucial to note that the power dissipation when flow Q passes through the relief valve at pressure P is calculated as P×Q/612 (assuming consistent units). This energy loss manifests as heat in the hydraulic system, leading to an increase in hydraulic fluid temperature. Proper thermal management is essential to maintain system efficiency and fluid properties.

Fundamental Principle

The relief valve operates on a force balance principle. Inlet pressure P acts upon the effective area A of the valve element, generating a hydraulic force. This force is continuously compared to the opposing spring force, which is adjustable to set the valve’s cracking pressure.

When the hydraulic force exceeds the preset spring force, the valve element compresses the spring, opening the valve port. This action creates a flow path between the valve inlet and outlet, allowing excess fluid to bypass the main circuit and return to the tank. The valve modulates its opening to maintain system pressure at or near the set point, providing continuous protection against pressure spikes and overloads.

The flow valve is a critical component in hydraulic systems, precisely regulating the speed of hydraulic actuators. It achieves this control by dynamically adjusting the cross-sectional area of its internal throttle, which directly influences the volume flow rate (Q) of hydraulic fluid to the actuator.

This mechanism allows for fine-tuning of actuator speed, essential in applications requiring precise motion control. Flow valves can be broadly categorized into two main types:

Both types play crucial roles in modern hydraulic systems, offering different levels of control precision and adaptability to suit various industrial applications, from manufacturing equipment to mobile hydraulic machinery.

The primary function of a check valve is to permit fluid flow in one direction while preventing backflow in the opposite direction. This unidirectional flow control is crucial in many hydraulic and pneumatic systems, as well as in various industrial processes.

Check valves utilize diverse sealing element designs, including:

Each design offers specific advantages in terms of flow characteristics, sealing efficiency, and suitability for different applications and media.

To allow flow in the intended direction, the sealing element must overcome a relatively low spring force. This spring tension is carefully calibrated to ensure the valve opens at the desired minimum pressure while still providing reliable closure when flow ceases or reverses.

The fundamental operating principles of check valves are succinctly represented in their standardized graphic symbols, which visually depict the valve’s unidirectional flow capability and basic internal structure.

In modern manufacturing, check valve design and selection have been further refined through computational fluid dynamics (CFD) analysis and advanced materials, optimizing performance for specific operating conditions and improving overall system efficiency.

The two-way cartridge valve is engineered with a compact plug-in design, optimized for integration into high-density hydraulic control circuits. This modular structure allows for efficient installation and maintenance while minimizing system footprint.

Typically, the cover plate serves a dual purpose: it acts as both a sealing element and a sophisticated interface between the main valve body and the pilot valve. This integrated design enhances system reliability and reduces potential leak points.

By pairing the main valve with an appropriate pilot valve, the cartridge assembly can perform a wide range of hydraulic functions. These include precise pressure control, rapid flow reversal, and fine throttling adjustments. Moreover, these functions can be combined to create complex control strategies tailored to specific application requirements.

The versatility of two-way cartridge valves enables them to execute critical hydraulic operations such as:

This adaptability makes two-way cartridge valves essential components in modern hydraulic systems across various industries, from mobile equipment to industrial machinery.

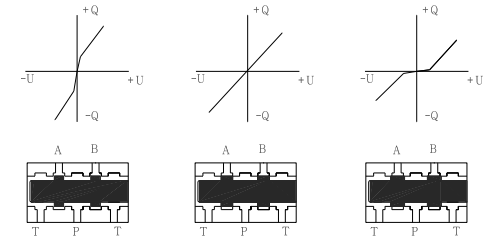

Proportional valves are advanced fluid control devices that offer precise and continuous control of flow, pressure, or direction in hydraulic and pneumatic systems. They are classified into two main categories:

Open-Loop Proportional Valves

These valves provide a proportional relationship between the input signal and the output flow or pressure without feedback. Types include:

Closed-Loop Proportional Valves (Proportional Servo Valves)

These valves incorporate feedback mechanisms for more precise control. They are further categorized by their amplifier configuration:

Key performance characteristics of high-end proportional servo valves include:

These advanced features make proportional valves ideal for applications requiring precise flow or pressure control, such as in industrial automation, mobile hydraulics, and high-performance machinery.

Open-loop control system:

An open-loop control system operates without feedback between the output and input. In this configuration, the system’s output does not influence its control parameters. This type of system is characterized by its unidirectional flow of control signals, from input to output, without any self-correction mechanism.

Closed-loop control system:

A closed-loop control system is an automatic control system that operates on the principle of feedback. This system continuously monitors its output and compares it to the desired setpoint, using the difference (error) to adjust its control actions. The feedback loop allows the system to self-regulate, maintaining the output close to the desired value despite disturbances or variations in system parameters.

Key components of a closed-loop system include:

The integration of these components forms a closed loop, hence the name “closed-loop control system.”

Comparison of open-loop and closed-loop systems:

Open-loop systems offer simplicity in design and are generally more cost-effective. However, they lack the ability to compensate for errors caused by external disturbances or internal system changes.

Closed-loop systems, while more complex, provide several advantages:

However, closed-loop systems require careful design to ensure stability. Improper gain selection in the feedback loop can lead to oscillations or instability.

Advanced control strategies:

To further enhance control accuracy, especially when disturbances are measurable, feedforward control is often combined with feedback control. This composite control system anticipates and compensates for known disturbances before they affect the output, while the feedback loop handles any remaining errors. This approach combines the proactive nature of feedforward control with the robustness of feedback control, resulting in superior overall system performance.

| Open-Loop Proportional Valve | Closed-loop servo valve |

| Frequency response: 15Hz | Frequency response: 120Hz |

| Hysteresis: 5% | Hysteresis: 0.1% |

| Reverse error: 1% | Reverse error: 0.05% |

| Repeat accuracy: 0.1 | Repeat accuracy: 0.01 |

| Median dead zone | Zero cover |

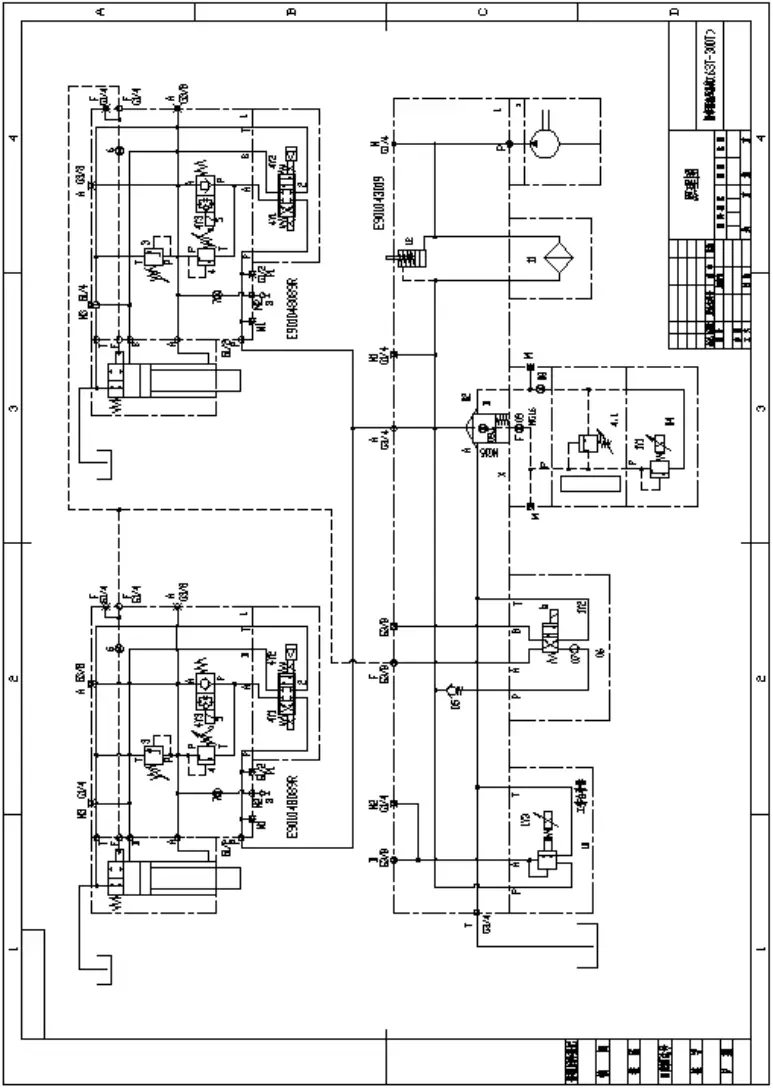

Principle of Electro-Hydraulic Synchronous Press Brake (System below 300 tons)

Pressure control

The system initiates with the oil pump motor start. The proportional pressure valve (4) regulates the two-way cartridge valve (2) to adjust the hydraulic system pressure, meeting the required bending force. A safety valve (4.1) limits the maximum system pressure.

Work cycle

The proportional pressure valve (4) receives 20-30% voltage (1Y1), while solenoid valve (6) 1Y2 is de-energized. Energizing solenoid valve (5) 4Y3 applies positive voltage to the proportional servo valve.

As the slider descends rapidly, oil is drawn into the cylinder’s upper cavity through the flow valve. Simultaneously, pump-discharged oil enters this cavity via the proportional servo valve (2).

Oil from the cylinder’s lower chamber returns to the tank through solenoid valve 5 (A-P) and proportional servo valve (2) (B → T).

The slider’s rapid descent speed is controlled by adjusting the proportional servo valve’s (4Y5) control voltage, altering its opening degree.

The proportional pressure valve (4) 1Y1 and electromagnetic reversing valve (6) 1Y2 are energized, closing the filling valve. Solenoid valve (5) 4Y3 is de-energized. Pressurized oil from the pump enters the cylinder’s upper cavity (rod-less side) through proportional servo valve (2).

During downward pressing, oil from the cylinder’s lower chamber returns to the tank via the backpressure valve (4) and proportional servo valve (2).

Working speed is regulated by adjusting the proportional servo valve’s control voltage (4Y5), which modifies its opening degree.

A safety valve (3) prevents excessive pressure in the cylinder’s lower cavity, set 10% higher than system pressure. The backpressure valve (4) is typically set to equilibrium pressure plus 30-50 bar.

When the ram reaches bottom dead center, the proportional servo valve 2 (4Y5) receives 0V, isolating the cylinder’s upper and lower chambers, maintaining the slider’s position.

Post pressure maintenance, the proportional pressure valve sustains pressure while the system applies a slight negative voltage to proportional servo valve 2 (4Y5), causing minimal opening (return direction).

The ram ascends slightly, with the distance determined by the unloading distance parameter. The process duration is set by the decompression speed parameter.

Pressure in the cylinder’s upper cavity releases through proportional servo valve (2).

Solenoid valve (6) 1Y2 de-energizes, proportional pressure valve (4) receives a specific voltage, solenoid valve (5) 4Y3 de-energizes, and proportional servo valve (4Y5) receives negative voltage.

Pressurized oil flows from the pump block through two synchronization blocks.

Hydraulic oil routes from the upper proportional servo valve (2) and electromagnetic reversing valve (5) (P-A) to the cylinder’s lower chamber (rod side). The upper chamber (rod-less side) drains to the tank via the filling valve.

The ram returns rapidly.

Return speed is controlled by adjusting proportional servo valve 4Y5’s control voltage, modifying its opening degree.

Worktable compensation

Worktable compensation is achieved by controlling the proportional pressure reducing valve (10) 1Y3.

Pressurized oil enters the compensation cylinder through this valve. Adjusting the valve’s voltage alters its pressure, creating a convex table shape to compensate for bending-induced deformation.

System without pressure

1. Inspect the proportional pressure valve (04):

2. Examine the two-way cartridge valve (02):

3. Assess the proportional pressure valve (04) for spool sticking

4. Evaluate the oil pump condition:

Ram down issues

1. Check for pressure decrease in back pressure and safety valves

2. Diagnose leakage:

3. Maintenance steps:

Slow or unsynchronized fast down movement

1. Check poppet valve on sync block:

2. Assess proportional servo valve:

3. Inspect sync block components:

4. Examine ram rail and cylinder for excessive tightness

Fast down without work progress

1. In diagnostic state, provide electrical signals to:

2. Close filling valve and adjust proportional servo valve opening

3. If both cylinders fail to drive:

4. If single cylinder fails:

Ram quick down with middle pause

Ram return issues

1. Verify system pressure in diagnostic state

2. Provide electrical signals to valves and adjust as in fast down troubleshooting

3. For overall return issues:

4. For single cylinder return problems:

5. Verify proportional servo valve signal and feedback consistency

Overheating and high pressure during dry run

1. Check fluid resistance (8) on Y port of pressure control cover for blockages

2. Inspect and replace oil filter element if rapid temperature rise occurs without pressure

3. Evaluate working cycle:

4. Review hydraulic system piping configuration for optimization

By implementing these structured troubleshooting steps, technicians can efficiently diagnose and resolve issues in the electro-hydraulic servo press brake system, ensuring optimal performance and minimizing downtime.

System purging

Fully open the safety valve (014) on the cylinder’s top valve assembly. Access the DELEM system diagnostic interface and offset the valve by approximately 40%. The corresponding motor speed should be around 700 RPM, with a torque setting of about 80DA. Run the system for 5-10 minutes, then close the safety valve.

Precautionary measures

When closing the safety valve, use a pressure gauge to adjust the lower chamber pressure to 20 MPa. If a gauge is unavailable, fully tighten the safety valve, then loosen it one turn. After purging, initial operations may produce noise, and the return stroke might not occur. Synchronization issues and slow return are typically caused by residual air in the hydraulic lines and cylinders.

Generally, normal operation is achieved after 5-8 cycles. If return motion is still not possible after purging, release the lower chamber safety valve and repeat the purging process as described above. Avoid repeated automatic parameter searches or forced return strokes to prevent pump damage.

During initial commissioning, limit the fast return stroke speed to 100 mm/s to protect the pump from damage due to incomplete air removal and high-speed operation.

Pressure adjustment

Lower cavity safety valve: Factory-set to 20 MPa, adjustment is typically unnecessary unless required.

Backpressure valve adjustment: First, observe the system’s static back pressure, usually around 4-5 MPa. Add 3-4 MPa to this value to determine the dynamic back pressure setting.

Fine-tune the backpressure valve based on the machine’s actual operating conditions.

Lowering the ram to bottom position

Enter the DELEM diagnostic interface, offset both valves by 20%, set the pressure valve (torque) DA value to approximately 80DA, then open the quick-release valve. The ram will descend slowly until it contacts the lower die.

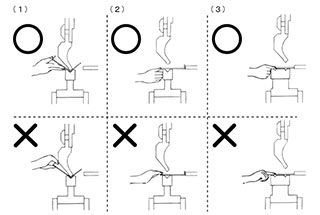

Precautions:

Ensure that the backpressure valve adjustments on both sides are closely matched. Significant discrepancies can lead to asynchronous operation.

When lowering the ram, always apply torque to prevent rapid descent that could damage the die or cylinder bottom, potentially causing severe safety hazards.

Energy efficiency: Achieves up to 70% reduction in energy consumption through optimized servo motor control and elimination of throttling losses.

Precision control: Pump control replaces conventional valve control, allowing dynamic adjustment of servo motor speed for precise oil distribution.

Reduced idle power consumption: Motor shuts off when flow or pressure is not required.

Environmental impact: Lower power consumption and CO2 emissions.

Compact design: Servo motors can be significantly overloaded for short durations, allowing for 50% reduction in installed power capacity.

Hydraulic system optimization: 50% reduction in oil tank volume and overall hydraulic oil usage.

Thermal management: Lower equilibrium temperature eliminates the need for cooling devices, extending hydraulic component lifespan.

Noise reduction: Significantly quieter operation during idle, fast down, pressure holding, and return phases, improving the work environment.

Enhanced safety: Faster braking of servo motors compared to conventional motors, allowing rapid pressure and flow cut-off in emergency situations.

Improved contamination tolerance: Reduced oil particle sensitivity from NS7 (proportional servo valve) to NS9 (plunger pump). Wider operating temperature range: servo motor 10°C – 80°C, plunger pump 20°C – 90°C, compared to proportional servo valve 20°C – 50°C.

Superior speed control:

Exceptional position control:

Scalability: The same valve group can be equipped with 6, 8, and 10 cc/rev pumps, covering press brakes from 30 to 300 tons capacity.

Overload protection: System-specific maximum torque control prevents overload due to human error or improper operation.

Pressure Control

Rapid Descent

Working Stroke

Load Removal

Return Stroke

Ram down issues

No fast down or slow down

No work progress at speed change point

Cannot return or slow return

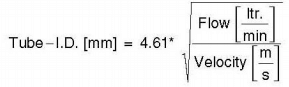

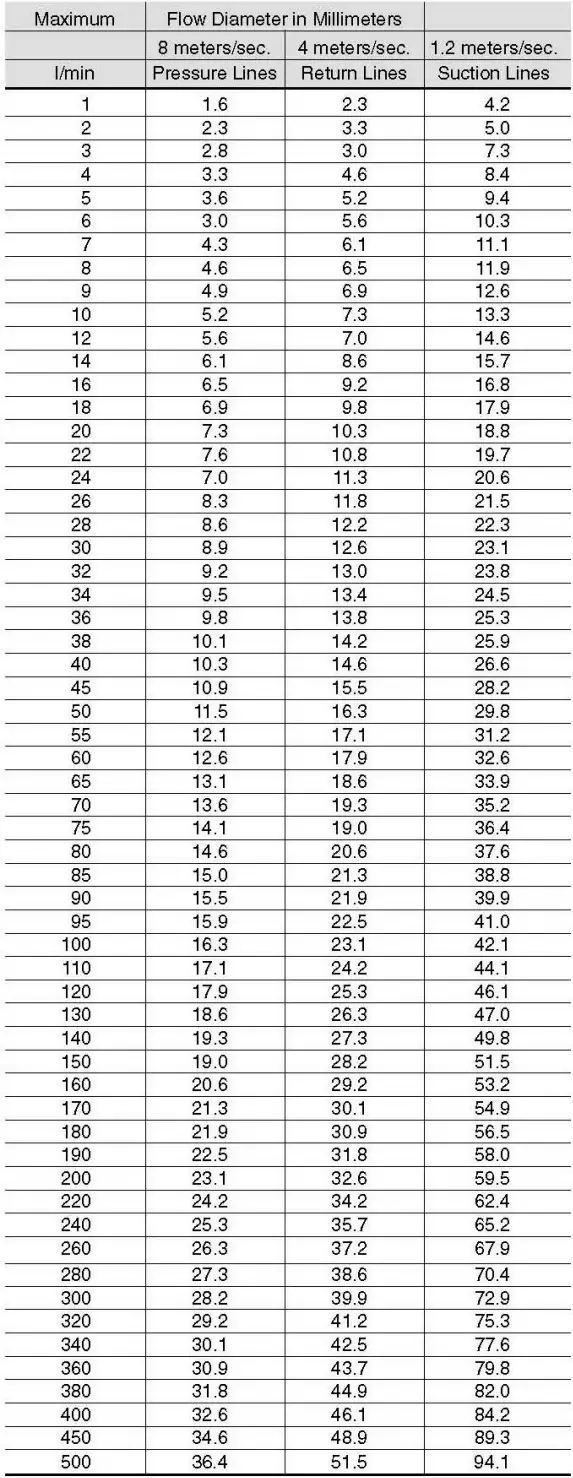

Attached Table 1: Selection of hydraulic pipe diameter

Flow Diameter

Determining Tube Size for Hydraulic Systems

Selecting the proper tube material, type, and size for a given application and fitting type is critical for ensuring efficient and trouble-free operation of the fluid system.

Choosing the right tube material and determining the optimal tube size (O.D. and wall thickness) are essential when selecting proper tubing.

Proper sizing of the tube for various parts of a hydraulic system results in an optimal combination of efficient and cost-effective performance.

A tube that is too small causes high fluid velocity, which can have many detrimental effects. In pressure lines, it causes high friction losses and turbulence, both of which result in high-pressure drops and heat generation.

High heat accelerates wear in moving parts and leads to the rapid aging of seals and hoses, ultimately resulting in reduced component life.

Excessive heat generation also means wasted energy and reduced efficiency.

Selecting an oversized tube increases system cost. Thus, optimum tube sizing is critical. The following is a simple procedure for sizing tubes:

Determine the Required Flow Diameter

Use a table to determine the recommended flow diameter for the required flow rate and type of line.

The table is based on the following recommended flow velocities:

If you desire to use different velocities than the above, use one of the following formula to determine the required flow diameter.

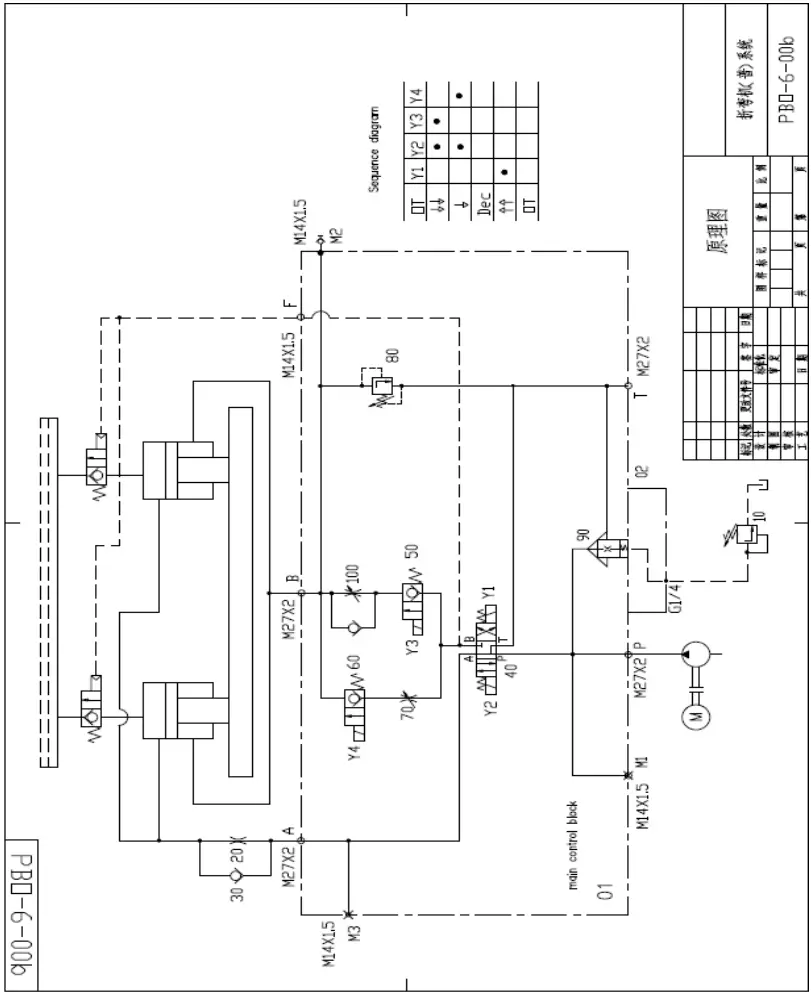

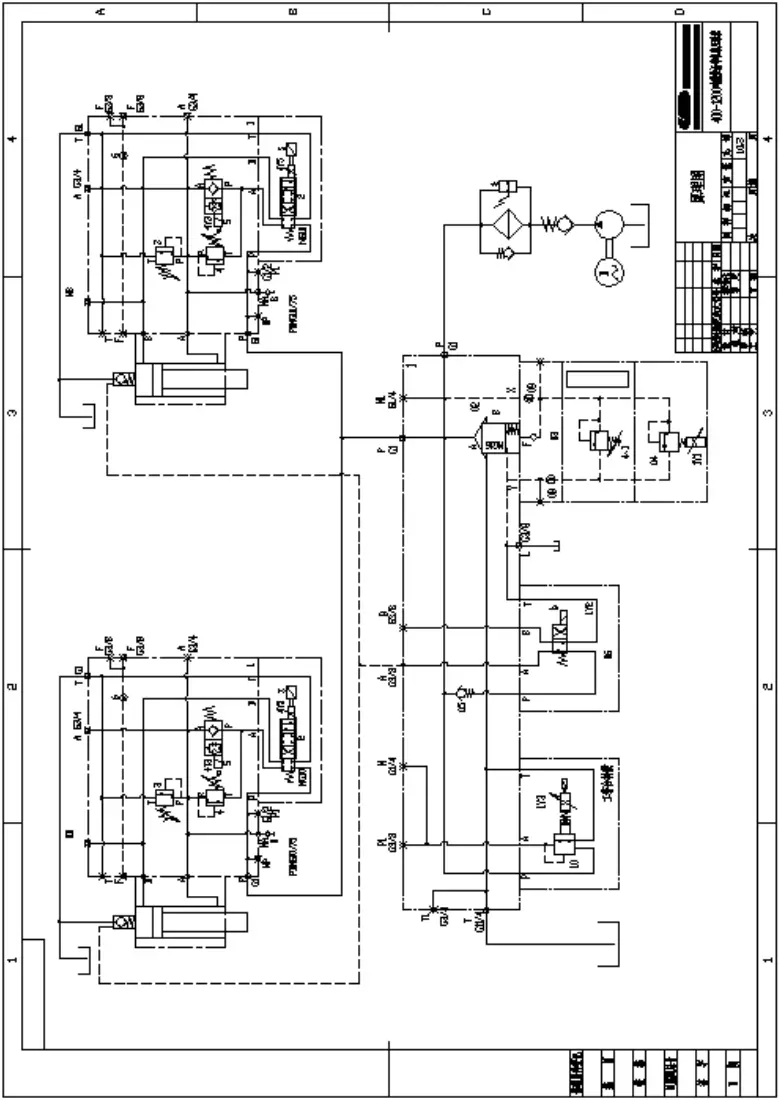

Appendix: Schematic Diagram Of Electro-Hydraulic Servo Press Brake Hydraulic System

Appendix: Schematic Diagram Of Electro-Hydraulic Servo Press Brake Hydraulic System (400-1200 tons)

Appendix: Schematic Diagram Of Electro-Hydraulic Servo Press Brake Hydraulic System (400-1200 tons)

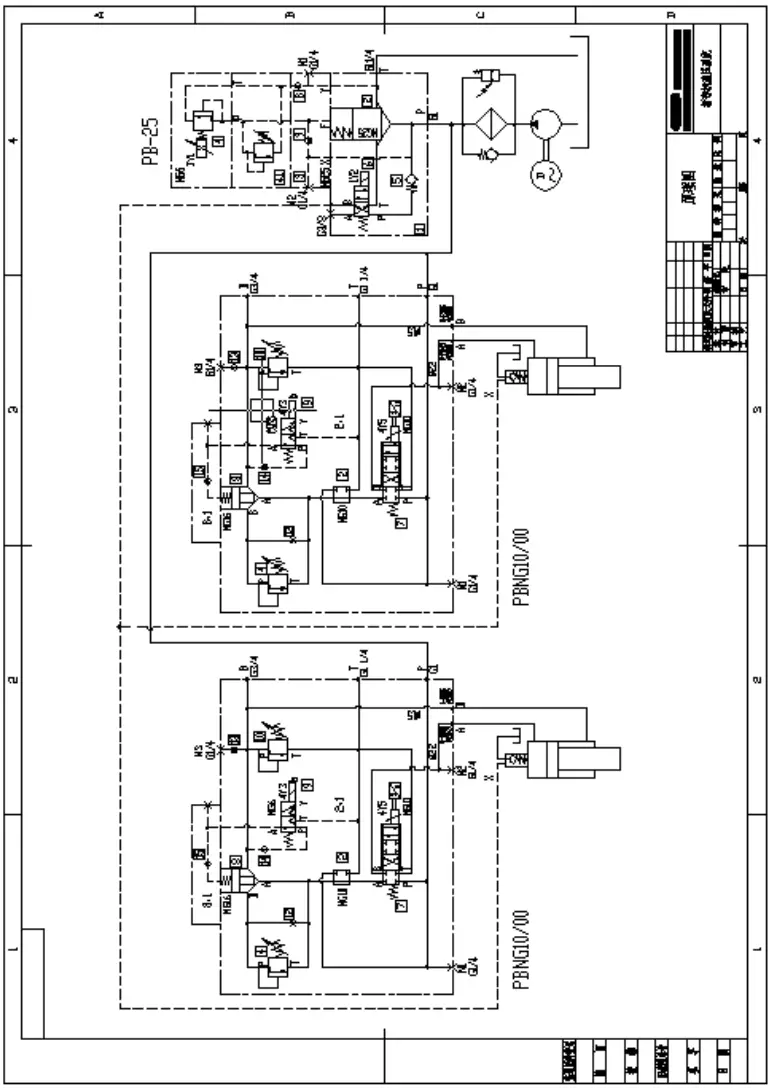

Appendix: Schematic Diagram Of Electro-Hydraulic Servo Press Brake Hydraulic System (1600-3000 tons)

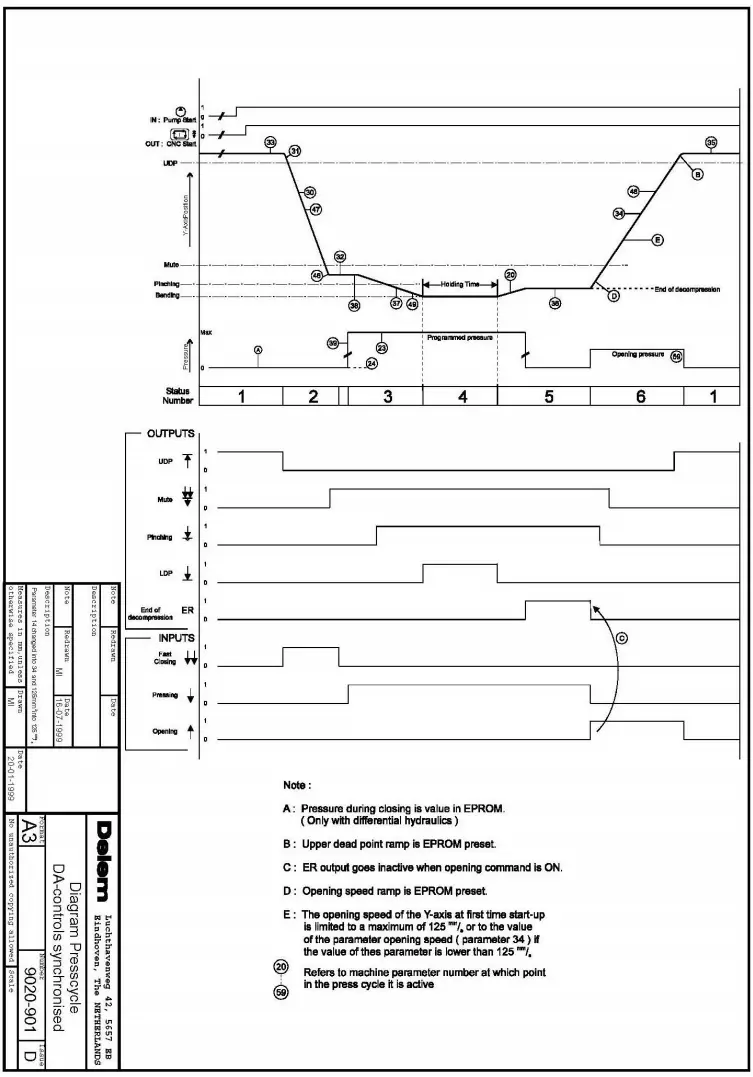

Appendix: Timing Chart Of Electro-Hydraulic Servo Press Brake

Appendix: Schematic Diagram Of Press Brake Action Sequence

Appendix: Principle Of Pump-Controlled Hydraulic System Of Electro-Hydraulic Servo Press Brake

Appendix: Schematic Diagram Of Hydraulic System For Torsion Bar Synchro Press Brake