Ever struggled with press brake punch and die installation? This guide offers step-by-step instructions to ensure precise alignment and secure setup, minimizing errors and downtime. You’ll learn essential tips for preparing, adjusting, and operating your press brake efficiently. Master these techniques to enhance your metalworking precision and productivity. Dive in to simplify this complex process!

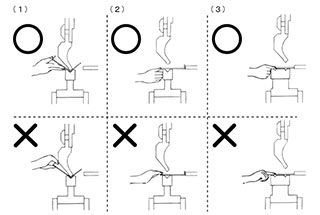

Do not start the press brake machine when installing the punch and die.

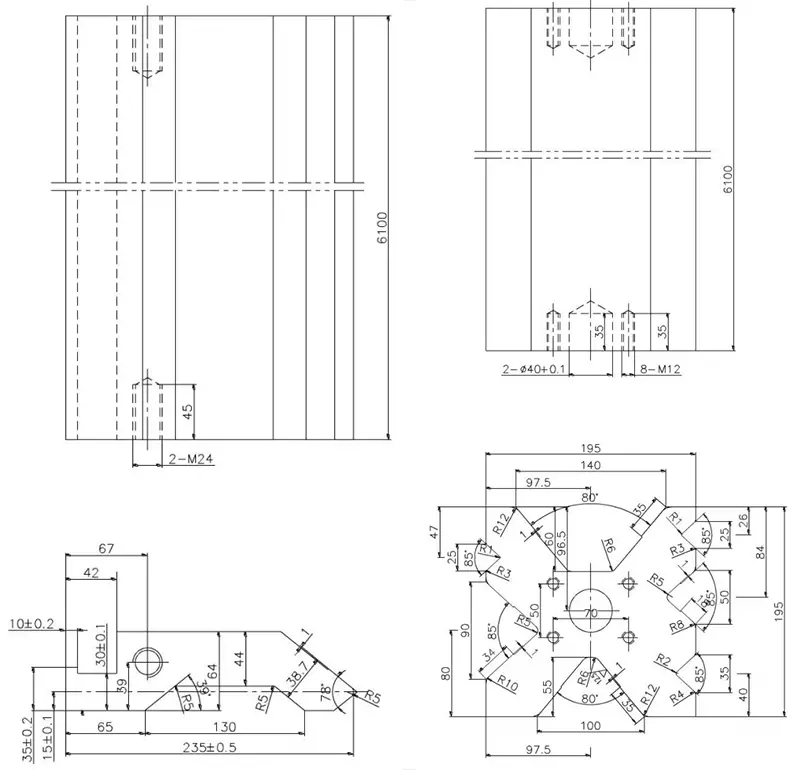

Remove any burrs, flash, or impurities from the die and the die mounting surface.

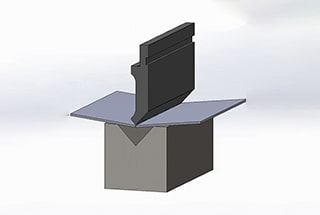

Adjust the top dead center position of the ram according to the selected die height, and install the upper and lower dies.

After the mold is installed, adjust the pressure of the hydraulic system to 3.5Mpa through computer programming.

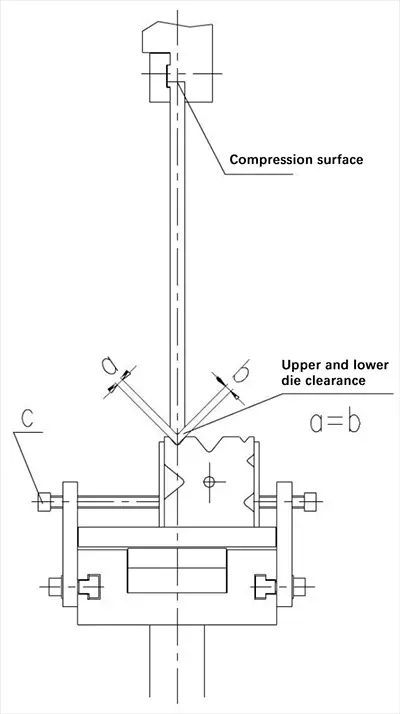

Start the press brake and press the switch (button) on the operation station to make the ram go down and control it at an appropriate position so that there is a certain gap between the punch and die. Then shut it down.

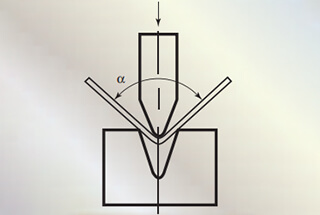

Check if the punch and die are aligned, meaning if the gaps a and b are equal along the entire length. If not, adjust the lower dies with screw c (see the figure below for details).

Tighten the screws c while pressing.

Start the machine and press the switch (button) on the operation station to make the ram go down, close and pressurize the punch and die (3.5Mpa). Check whether there is any gap between the ram and the top punch.

Press the return switch on the operation station to return the ram to the top dead center.

Use computer programming to adjust and restore the original pressure of the hydraulic system.

Attention:

Regularly check the fixing bolts of the mold. When replacing the mold, carefully place it on the shelf next to the machine to avoid damaging the mold.

When not in use at night or for an extended period, lower the ram onto the flat plate.

When bending, always remember the maximum allowable load of the machine and die, as well as the maximum allowable load per unit length!