Ever wondered how a press brake bends metal sheets with precision? In this article, we’ll explore the science behind calculating the punch’s penetration depth into the die. Learn how factors like bending angle, sheet thickness, and die opening influence the process. By the end, you’ll understand the key elements that ensure accurate and consistent bends.

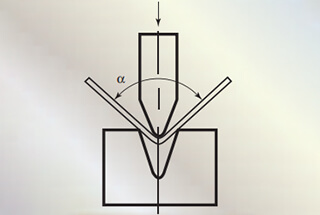

How to calculate the depth of the bend (or the penetration depth of the punch into the die) on a press brake with a given bending angle, measured angle, sheet thickness, and die opening?

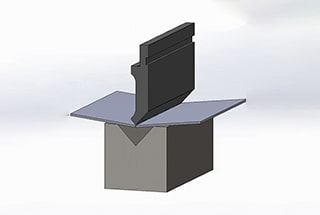

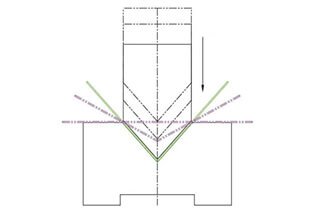

The penetration depth of the punch into the press brake die is calculated and controlled when the sheet is bent at a certain angle by air bending on the press brake machine.

This is to control the positioning value of the ram when moving up and down.

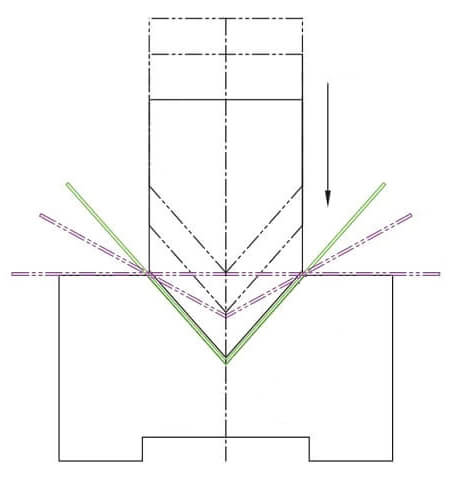

The upper die mounted on the ram will bend the sheet to a certain position exactly at the sum of the certain set angle and the rebound angle. In this way, the workpiece can spring back to the set angle after the ram returns.

However, in actual bending, many factors affect the bending angle of the sheet material. The measured angle of the first bend often does not match the set angle and needs correction. At this point, the angular error should be converted into the depth correction value.

To achieve this, the bend depth formula of the ram for air bending and the formula for correcting the depth of the ram in case of angular error are used. These formulas have been simplified into a practical formula that can be applied at the production site.

For your convenience, we have created an online calculator, which we hope will be useful to you.

Remarks: