Have you ever wondered how a flat sheet of metal is transformed into a complex shape? Press brakes are the unsung heroes of the manufacturing world, bending and shaping metal with incredible precision. In this article, we’ll dive into the fascinating world of press brakes, exploring their history, types, and key components. Get ready to discover how these powerful machines have revolutionized the metal fabrication industry!

A press brake is a sophisticated machine tool primarily utilized for bending sheet metal and plate material with high precision. This versatile equipment forms predetermined bends by clamping the workpiece between a matching punch and die, delivering accurate and repeatable fabrication results for various industries, including automotive, aerospace, and construction.

Operating through hydraulic, mechanical, or servo-electric power systems, press brakes exert controlled force to transform flat metal sheets into complex three-dimensional forms. The bending process involves positioning the workpiece on the lower die, then lowering the upper punch to create the desired bend angle. Modern press brakes often incorporate CNC (Computer Numerical Control) technology, allowing for programmable bend sequences and enhanced productivity.

Press brakes offer a wide range of bending capabilities, from simple 90-degree bends to complex multi-axis forming. They can handle various materials, including mild steel, stainless steel, aluminum, and even specialized alloys, with thicknesses ranging from thin gauge sheets to thick plates. The machine’s capacity is typically measured in tonnage, indicating the maximum force it can apply during the bending operation.

Is a brake press and a press brake the same thing? Indeed, the terms “brake press” and “press brake” are synonymous and used interchangeably within the metalworking industry. Both refer to the same machine designed for precision metal bending and forming operations. This linguistic equivalence underscores the equipment’s fundamental role in sheet metal fabrication processes.

For those seeking a more comprehensive understanding of press brakes, including their historical development, technological advancements, and the etymology of the term, please refer to the detailed article linked below. This resource provides valuable insights into the evolution of press brake technology and its significant impact on modern manufacturing practices.

This video may help you understand the process of bending sheet metal parts using a press brake.

Further reading:

Press brakes are indispensable machines in the metal fabrication industry, enabling precise bending and forming of sheet metal to create a wide range of structures and components. These versatile tools are classified into three main categories: mechanical, hydraulic, and electric press brakes. Each type offers distinct advantages and operational characteristics, making it crucial to understand their nuances when selecting the optimal press brake for specific manufacturing requirements.

Mechanical press brakes employ a flywheel-driven system to power the bending operation. The flywheel, energized by an electric motor, stores kinetic energy which is then transferred through a clutch mechanism to drive the press ram. This design offers a cost-effective solution for metal forming, particularly suited for smaller fabrication shops or operations with budget constraints.

The simplicity of the mechanical system contributes to lower initial costs and reduced maintenance requirements compared to hydraulic or electric alternatives. Mechanical press brakes excel in high-volume production of simple bends, where their consistent stroke and rapid cycling capabilities can boost productivity.

However, the fixed nature of the mechanical linkage system imposes certain limitations. Precision control of the ram position and bending force is generally less refined than in hydraulic or electric systems. This can affect the accuracy of complex bends or when working with more demanding materials that require precise force modulation.

Advantages:

Disadvantages:

While mechanical press brakes may lack the versatility of hydraulic or electric systems, they remain a viable option for specific applications. Their cost-effectiveness and reliability in high-volume, straightforward bending tasks make them an enduring presence in metal fabrication workshops.

Hydraulic press brakes employ a sophisticated hydraulic system to actuate the ram, enabling significantly enhanced pressure and force distribution during the bending process. This amplified power, typically ranging from 20 to 2000 tons, facilitates more precise bending and superior control compared to mechanical counterparts. The hydraulic system allows for infinitely variable stroke control, enabling operators to achieve complex bend angles with remarkable accuracy, often within ±0.1 degrees.

These machines excel in adaptability, easily accommodating various metal thicknesses and alloy compositions through programmable pressure settings. Modern hydraulic press brakes often incorporate CNC systems, allowing for automated multi-axis backgauge positioning and real-time bend angle monitoring. This integration results in exceptional repeatability and the ability to execute intricate, multi-step bending sequences with smooth, controlled motion.

While hydraulic press brakes generally command a higher initial investment, their versatility and performance often justify the cost in high-volume or precision-critical applications. They are particularly valued in industries such as aerospace, automotive, and custom fabrication, where material variability and complex part geometries are common.

Advantages:

Disadvantages:

Electric press brakes employ advanced servo-electric drive systems to control the ram’s movement, enabling high-speed, precise, and energy-efficient bending operations. These state-of-the-art machines utilize closed-loop control systems with ball screw or belt drive mechanisms, offering superior positioning accuracy and repeatability compared to hydraulic or mechanical alternatives. The servo motors provide dynamic force control throughout the bending cycle, allowing for complex part geometries and adaptive bending strategies.

Key advantages of electric press brakes include:

However, electric press brakes also have some limitations:

When selecting a press brake for your workshop, consider factors such as typical part geometries, material thicknesses, production volume, and energy costs. Electric press brakes excel in applications requiring high precision, frequent tool changes, and varied batch sizes. They are particularly well-suited for thin to medium-gauge materials and complex forming operations in industries like aerospace, medical devices, and precision sheet metal fabrication.

For workshops dealing primarily with heavy-gauge materials or requiring extremely high tonnage, hydraulic press brakes may still be the preferred choice. However, the ongoing advancements in electric drive technology continue to expand the capabilities and application range of electric press brakes, making them an increasingly versatile and efficient option for modern metal forming operations.

Frame and Bed

The frame and bed form the critical foundation of a press brake, engineered from high-strength alloy steel to withstand extreme forces during bending operations. The bed, typically constructed with a precision-ground surface, provides a stable horizontal platform for workpiece placement. The frame, designed with finite element analysis (FEA) for optimal stress distribution, supports the ram, hydraulic system, and auxiliary components while maintaining rigidity to ensure bending accuracy.

Ram and Die

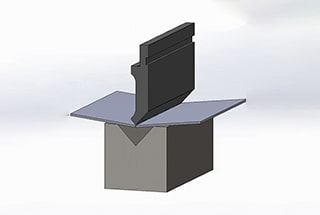

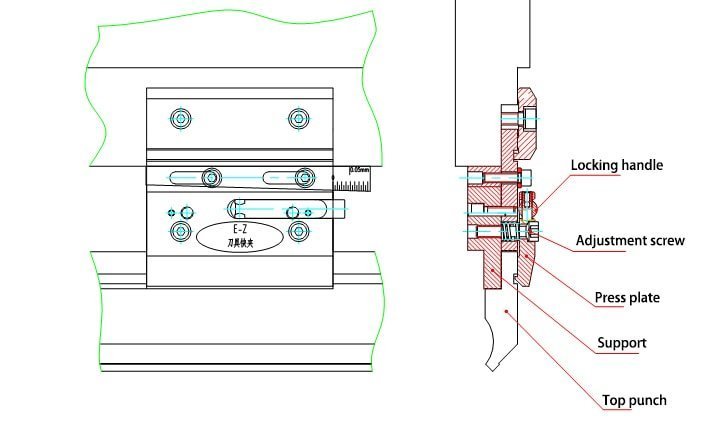

The ram and die are the core functional elements of a press brake. The ram, driven by hydraulic or servo-electric systems, applies precisely controlled force to the workpiece. Modern rams incorporate advanced position feedback systems for micron-level accuracy. The die, an interchangeable tooling component, defines the bend profile. Key die types include:

Advanced die materials like high-speed steel (HSS) or carbide-tipped variants offer extended tool life and precision in high-volume production environments.

Backgauge

The backgauge system is crucial for ensuring dimensional accuracy in bending operations. It consists of CNC-controlled fingers that precisely position the workpiece relative to the bending line. Modern backgauge systems feature:

These advanced features enable consistent bending results across diverse material types and thicknesses.

Controls

Press brake control systems have evolved significantly, ranging from basic manual interfaces to sophisticated CNC systems with Industry 4.0 capabilities. State-of-the-art control features include:

These advanced controls ensure precise, repeatable bending results while optimizing machine efficiency and reducing setup times.

Safety Features

Modern press brakes incorporate comprehensive safety systems to protect operators and maintain productivity. Key safety features include:

Additionally, many press brakes now feature augmented reality (AR) interfaces for operator guidance and remote diagnostic capabilities for enhanced maintenance and support.

This integrated system of advanced components and intelligent features ensures that modern press brakes deliver superior bending precision, operational efficiency, and workplace safety in metal fabrication processes.

Related reading: Parts And Functions Of Press Brake You Should Know

How many types of press brakes are there?

There are several types of press brakes, but the most commonly used are down-moving hydraulic press brakes and CNC press brakes, depending on the classification method used.

Let’s learn more about it through the following classification methods:

Press brakes can be categorized based on their force generation mechanism into four main types: Mechanical, Pneumatic, Hydraulic, and Servo-electric press brakes.

(1) Mechanical press brake

Mechanical press brakes utilize a crank mechanism driven by a flywheel to generate the vertical movement of the ram. This system offers high-speed operation and is suitable for high-volume production of simple parts. However, it has limited flexibility in stroke adjustment and force control.

(2) Pneumatic press brake

Pneumatic press brakes employ compressed air to actuate the ram movement. These machines are typically used for light-duty applications, offering quick cycling times and clean operation. While they provide consistent force throughout the stroke, their bending capacity is generally limited compared to other types.

Hydraulic press brakes use synchronized hydraulic cylinders to move the ram. This system offers superior force control, allowing for precise bending of thick materials and complex shapes. Hydraulic brakes provide flexibility in stroke length and speed adjustment, making them versatile for various bending operations.

(4) Servo-electric press brake

Servo-electric press brakes employ a servo-motor to drive a ball screw or belt mechanism, applying force to move the ram vertically. These machines offer high precision, energy efficiency, and rapid acceleration/deceleration capabilities. They excel in applications requiring precise control and repeatability, such as small batch production of complex parts.

Historically, mechanical press brakes dominated the global market prior to the 1950s. However, the landscape has shifted significantly with advancements in hydraulic technology and the integration of computer numerical controls (CNC). Today, hydraulic press brakes have become the most widely adopted option worldwide, offering a balance of versatility, power, and precision for a broad range of metal forming applications. The market has also seen a growing adoption of servo-electric models, particularly in industries demanding high precision and energy efficiency.

From another perspective, press brakes can be categorized into three main types: Manual press brakes, Hydraulic press brakes, and CNC press brakes.

(1) Manual press brake

Manual press brakes, also known as sheet metal brakes, are the most basic and traditional type of press brakes. They require manual adjustment of bending dimensions and angles during operation.

The key components of a manual press brake include:

Operating a manual press brake demands more skill and attention than other types. Operators must carefully set and verify bending parameters before initiating mass production. After completing a batch, readjustments to bending dimensions and angles are necessary for subsequent production runs.

(2) Hydraulic press brake

Hydraulic press brakes utilize hydraulic principles to generate substantial force for material manipulation. These machines offer several advantages over mechanical press brakes:

The core components of a hydraulic press brake include:

(3) CNC press brake

CNC (Computer Numerical Control) press brakes represent the most advanced category, offering high precision, efficiency, and automation. Key features include:

Major components of a CNC press brake:

Advanced features of modern CNC press brakes:

CNC press brakes significantly enhance productivity by automating the bending process, reducing operator intervention, and maintaining high accuracy across large production runs. The integration of advanced control systems and high-quality components from renowned manufacturers ensures exceptional performance and reliability in sheet metal fabrication.

Classified by synchronization, hydraulic press brakes can be categorized into three main types, each offering distinct advantages in precision, control, and efficiency:

1. Torsion Synchro Press Brake

This type utilizes a torsion bar system to maintain synchronization between the ram and the bed. The torsion bar mechanically links both sides of the machine, ensuring parallel movement and consistent bending force distribution. This design is particularly effective for longer machines and offers:

2. Electro-Hydraulic Synchro Press Brake

Employing advanced electronic controls and precision hydraulic systems, this type offers superior synchronization and adaptability. Key features include:

3. Hybrid Press Brake

Combining the best aspects of hydraulic and electric systems, hybrid press brakes offer:

Each type of synchronization system has its own merits, and the choice depends on factors such as required precision, production volume, energy efficiency considerations, and specific application demands. Modern CNC systems further enhance these machines’ capabilities, allowing for adaptive bending, real-time process monitoring, and integration with Industry 4.0 technologies.

Hydraulic press brakes can be categorized based on their primary movement direction during the bending operation:

1. Up-Acting Press Brake:

In this configuration, the lower beam (bed) remains stationary while the upper beam (ram) moves upward to perform the bending action. The workpiece is positioned on the lower die, and the upper die, attached to the ram, moves upward to create the bend. This design offers several advantages:

2. Down-Acting Press Brake:

This type features a fixed upper beam while the lower beam moves upward to execute the bending process. The workpiece is placed on the moving lower die, which rises to meet the stationary upper die. Key benefits include:

The choice between up-acting and down-acting press brakes depends on factors such as:

Modern hydraulic press brake designs may also incorporate hybrid systems that combine elements of both up-acting and down-acting movements to optimize performance for specific applications.

Further reading:

How does a hydraulic press brake work?

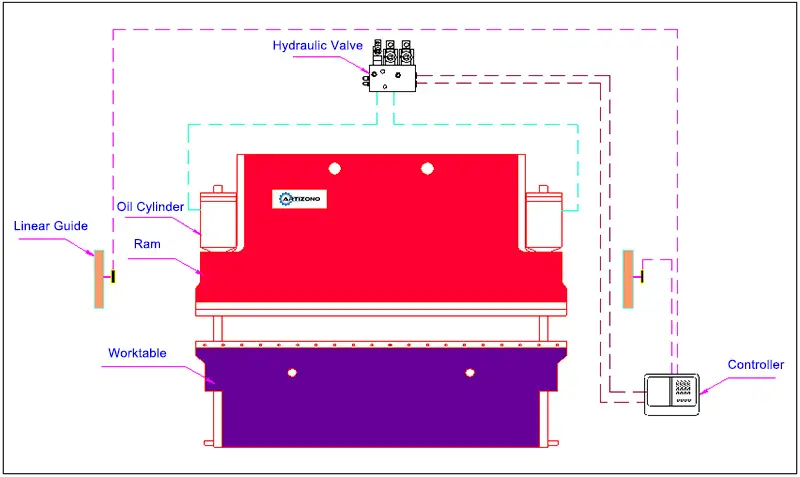

A hydraulic press brake operates by utilizing the synchronized motion of the punch and die, mounted on the upper and lower worktables respectively, to achieve precise sheet metal bending through a sophisticated hydraulic transmission system.

A more comprehensive explanation:

Modern hydraulic press brakes integrate advanced numerical control (CNC) technology, servo systems, and high-precision hydraulics to ensure accurate and repeatable bending operations.

The machine’s core functionality revolves around the controlled extension and retraction of left and right hydraulic cylinders. This movement is orchestrated by the CNC system, which regulates the action of proportional valves to drive the ram (upper beam) vertically with high precision.

To achieve synchronous ram movement, the system employs a closed-loop control mechanism. This involves real-time feedback from linear encoders or high-resolution grating scales, combined with precise flow control through servo-operated proportional valves. The CNC system continuously adjusts the hydraulic flow to maintain parallelism and achieve the desired bending angle.

The human-machine interface (HMI) of the CNC system provides a user-friendly touchscreen display for programming, monitoring, and simulating the bending process. This interface allows operators to input complex part geometries, visualize the bending sequence, and make real-time adjustments if necessary.

Each hydraulic cylinder is equipped with an independent control circuit, featuring a dedicated servo valve and a filling valve. This configuration allows for micro-adjustments of the ram position, ensuring optimal pressure distribution across the workpiece and compensating for any deflection in the machine structure.

The CNC controller generates digital signals that are converted into analog hydraulic commands via high-response servo valves. These valves modulate the oil flow with exceptional accuracy, allowing for precise control of the ram’s position, speed, and applied force throughout the bending cycle.

Advanced press brakes also incorporate adaptive bending technology. By continuously monitoring the bending angle in real-time using sensors or vision systems, the machine can automatically adjust the ram position to compensate for material springback, variations in sheet thickness, or changes in material properties.

This sophisticated control system enables the press brake to achieve complex, multi-angle bends in a single operation, significantly enhancing productivity and part quality. Furthermore, it allows for the integration of automated features such as dynamic crowning (automatic adjustment of the lower beam to compensate for deflection) and automated tool changing systems, further streamlining the bending process.

Hydraulic Press Brake Working Principle Diagram

Further reading:

Advantages of press brake

(1) Versatility for small batch and diverse production:

The press brake offers exceptional flexibility with a single set of punch and die, enabling the production of a wide range of materials and parts. This versatility makes it ideal for small-batch manufacturing and handling diverse product lines efficiently.

(2) Cost-effective and durable bending dies:

Press brake dies are remarkably cost-effective, with each set typically costing only a few thousand yuan. The straightforward manufacturing process eliminates the need for iterative trials, reducing initial tooling costs. Furthermore, the longevity of these dies, often exceeding 10 years, significantly lowers the overall cost of ownership and tooling replacement.

(3) Capability to produce complex “S” and “U” shaped parts:

While stamping processes struggle with “U” shaped parts due to material springback and punch-die fitting issues, the press brake excels in this area. By utilizing multiple bending operations, it can accurately form complex “S” and “U” shapes, overcoming the limitations of traditional stamping methods.

(4) Optimal for new product prototyping:

The press brake’s adaptability allows for the production of parts with varying shapes, sizes, and angles using a single set of tooling. This feature is invaluable for prototyping and small-scale production runs of new products, eliminating the need for costly dedicated tooling during the development phase.

(5) Precision forming of multi-bend polygon shapes:

Advanced press brake machines can produce intricate multi-bend parts with different edge heights by precisely controlling material positioning and bending angles. This capability enables the creation of complex polygon shapes with high accuracy and repeatability.

(6) Deflection compensation for long workpieces:

When bending long workpieces, traditional methods often result in inconsistent angles between the middle and edges due to beam deflection. Modern press brakes incorporate sophisticated deflection compensation systems that automatically adjust the bending angle along the workpiece length. This feature ensures straight, uniform bends, reduces manual adjustments, and significantly improves the quality and efficiency of long part production.

Disadvantages of press brake

(1) Material thickness limitations:

While press brakes can handle a wide range of material thicknesses, there are practical limits to consider. Generally, materials up to 50mm thick can be bent effectively, but thicknesses beyond this require substantial bending force. Most industrial press brakes have capacities ranging from 80t to 400t, which may be insufficient for extremely thick materials or high-strength alloys.

(2) Potential for material fracture:

The bending process can induce stress concentrations at edges and corners, particularly in materials with pre-existing burrs or oxide layers. These stress concentrations can lead to cracking or fracture during forming, potentially compromising product quality and increasing scrap rates. Proper material preparation and tooling selection are crucial to mitigate this risk.

(3) Surface indentation challenges:

Indentation is a common quality concern in press brake operations. Selecting inappropriate bending dies or using unsuitable die sets can result in unavoidable surface marks. In cases where surface finish is critical, additional post-processing such as grinding may be necessary. This not only adds to production time and cost but also requires careful monitoring of final part thickness to ensure dimensional accuracy.

(4) Material slippage during forming:

Certain materials, particularly those with irregular shapes or low friction coefficients, may be prone to slippage during the bending process. While square materials generally maintain stability, irregular workpieces can shift, resulting in out-of-specification bends. This issue necessitates careful fixturing and potentially the use of specialized anti-slip tooling to ensure consistent, high-quality results.

Further reading:

Preparation: Before operating the press brake, conduct a comprehensive pre-operation inspection. Ensure all safety systems, including light curtains and emergency stops, are functional. Verify that the hydraulic system is leak-free and at optimal pressure. Gather all necessary materials, tooling, and personal protective equipment (PPE). Inspect the machine for any signs of wear or damage, particularly on the ram, bed, and tooling surfaces.

Setup: Accurately adjust the back gauge system to achieve precise bend locations. Select and install the appropriate upper punch and lower die combination based on material thickness and desired bend radius. Set the ram stroke length and speed to match the workpiece requirements. Program the CNC control system with the correct bending sequence and parameters, if applicable.

Material Placement: Position the metal sheet onto the lower die, ensuring it’s flush against the back gauge fingers. For large or unwieldy pieces, use material handling aids to prevent operator strain. Align the bending line precisely with the die’s V-opening centerline. For complex parts, use bend markers or laser projection systems to guarantee accurate positioning.

Bending: Initiate the bending cycle, maintaining a controlled and steady pressure application. Monitor the bending angle progression using digital angle measurement systems or angle protractors for real-time adjustments. For air bending, account for material springback by overbending slightly. In bottom bending operations, ensure full contact between the punch and die surfaces to achieve consistent results.

Final Inspection: Carefully remove the bent component, avoiding any surface scratches or deformation. Conduct a thorough quality check, including bend angle verification using precision measurement tools. Assess the part for dimensional accuracy, bend consistency across its length, and absence of defects like cracking or excessive thinning at the bend radius. For critical components, perform non-destructive testing to ensure internal structural integrity.

Wear appropriate Personal Protective Equipment (PPE): Always use safety glasses with side shields, cut-resistant gloves, steel-toed safety shoes, and hearing protection. For high-noise operations, consider double hearing protection (earplugs and earmuffs).

Maintain a clean and organized workspace: Keep the area around the press brake free from debris, oil spills, and unnecessary tools. Implement a 5S system (Sort, Set in order, Shine, Standardize, Sustain) to ensure optimal organization and safety.

Never bypass or tamper with safety features: Press brakes are equipped with crucial safety mechanisms such as light curtains, two-hand controls, foot pedals with guards, and emergency stop buttons. Regularly test these features and immediately report any malfunctions. Disabling safety devices is strictly prohibited and can lead to severe injuries.

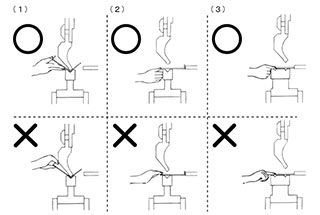

Be vigilant of pinch points and crush zones: Identify and mark all potential hazard areas. Keep hands, fingers, and limbs away from the die space, ram, and back gauge during operation. Use mechanical feeding devices or properly designed hand tools for small part manipulation when possible.

Implement a comprehensive maintenance program: Conduct daily visual inspections and follow a preventive maintenance schedule as per the manufacturer’s guidelines. Pay special attention to hydraulic systems, electrical components, and mechanical linkages. Document all maintenance activities and promptly address any irregularities.

Ensure proper training and certification: Only allow trained and authorized personnel to operate the press brake. Implement a structured training program covering machine operation, safety procedures, and emergency protocols. Regularly assess operator competence and provide refresher courses.

Use proper material handling techniques: Employ mechanical lifting devices for heavy or awkward workpieces. When manual handling is necessary, use correct lifting techniques and team lifting for larger parts. Consider ergonomic workstation design to reduce operator fatigue and strain.

Implement lockout/tagout procedures: Before any maintenance or die change, follow proper lockout/tagout procedures to isolate all energy sources. This includes electrical, hydraulic, pneumatic, and potential energy in springs or counterbalances.

Material Selection

Selecting the optimal material for press brake operations is critical for achieving desired outcomes. Consider key material properties such as yield strength, tensile strength, and elongation, as these directly impact formability and spring-back behavior. Evaluate the material’s K-factor and bend allowance to accurately calculate bend deductions. It’s crucial to match the material specifications with the press brake’s tonnage capacity and tooling limitations. For high-strength materials like advanced high-strength steels (AHSS), ensure your machine can generate sufficient force without compromising safety or accuracy.

Proper Setup and Maintenance

A meticulously maintained press brake is fundamental for consistent, high-quality bending. Implement a comprehensive preventive maintenance schedule, including regular inspection of hydraulic systems, ram parallelism, and tooling condition. Utilize precision alignment tools to ensure perfect tool alignment and minimize wear. Keep the machine’s CNC controller software updated to leverage the latest features and optimizations. When setting up, select appropriate punch and die combinations based on material thickness and desired bend radius. Verify back gauge accuracy using calibrated gauging blocks to maintain dimensional precision across production runs.

Best Practices for Bending

Employ these advanced techniques to elevate the quality and efficiency of press brake operations:

Understanding the bending process: Master various bending methods such as air bending, bottoming, coining, and hemming. Utilize finite element analysis (FEA) software to simulate complex bends and predict spring-back, especially for challenging materials or tight tolerances.

Programming bend sequences: Optimize bend sequences using advanced CAM software to minimize handling and maximize efficiency. Consider factors like part geometry, material properties, and tooling constraints when planning sequences. Implement nesting strategies for multi-part bending to reduce material waste and setup times.

Proper handling of material: Employ automated material handling systems or ergonomic lifting aids to ensure consistent positioning and reduce operator fatigue. Implement precise blank positioning techniques, such as using programmable stops or vision systems, to guarantee bend location accuracy. For large or unwieldy parts, utilize support arms or sheet followers to maintain material flatness and prevent distortion.

Use of process controls: Integrate real-time angle measurement systems, such as laser-based or tactile sensors, to provide closed-loop feedback for bend angle corrections. Implement advanced press brake controls with adaptive bending technology to compensate for material variations and tooling wear automatically. Utilize data logging and statistical process control (SPC) to track bend quality trends and identify opportunities for continuous improvement.

The specifications of a press brake machine encompass critical performance and dimensional parameters that directly influence its capabilities and suitability for specific metal forming tasks. Key aspects include:

1. Nominal Pressure: Expressed in tons or kN, this indicates the maximum bending force the machine can exert.

2. Workbench Dimensions: Length and height of the working surface, crucial for accommodating various workpiece sizes.

3. Ram Characteristics:

4. Structural Features:

5. Operational Parameters:

6. Machine Footprint: Overall dimensions for installation planning and workspace allocation.

7. Control System: Type and capabilities of the CNC or manual control interface.

8. Tooling Compatibility: Information on tool holding systems and compatible die sets.

It’s crucial to note that specifications can vary significantly between manufacturers and models. When selecting a press brake, a thorough comparison of these parameters is essential to ensure alignment with your specific bending requirements, material types, and production volumes. Additionally, consider factors such as accuracy tolerances, energy efficiency, and available safety features to make an informed decision that optimizes your metal forming operations.

Further reading:

Press brakes are indispensable tools in modern metal fabrication, finding widespread application across numerous industrial sectors. These versatile machines are extensively utilized in energy production, transportation systems, automotive manufacturing, general machinery construction, metallurgical processes, shipbuilding operations, aerospace engineering, defense equipment fabrication, agricultural machinery production, petroleum equipment manufacturing, and power generation industries.

In the energy sector, press brakes are crucial for forming components of wind turbine towers, solar panel frames, and hydraulic fracturing equipment. The transportation industry relies on press brakes to shape chassis components, body panels, and structural elements for trains, buses, and commercial vehicles. Automotive manufacturers employ these machines to produce precise body parts, reinforcement structures, and intricate brackets.

The machinery and metallurgy sectors utilize press brakes for creating various equipment housings, conveyor systems, and heavy-duty frames. In shipbuilding, press brakes are essential for forming hull plates, bulkheads, and deck structures. The aviation industry depends on these machines for shaping aircraft fuselage panels, wing components, and intricate aerospace parts that demand high precision and material integrity.

Military applications include the production of armored vehicle components, weapon system housings, and specialized equipment enclosures. In agricultural machinery, press brakes are used to form tractor body panels, implement frames, and harvester components. The petroleum industry employs these machines in the fabrication of storage tanks, pipeline fittings, and offshore platform structures. Power generation facilities rely on press brakes for manufacturing turbine housings, generator components, and switchgear enclosures.

The versatility of press brakes, combined with their ability to work with a wide range of materials and thicknesses, makes them indispensable in these diverse industries. Their capacity to produce complex bends, maintain tight tolerances, and adapt to various production scales contributes significantly to the efficiency and quality of modern industrial manufacturing processes.

Further reading:

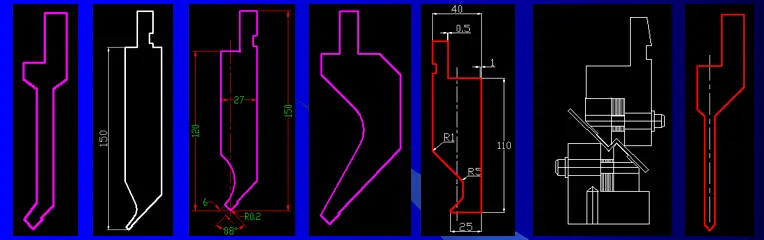

Press brake tooling is a critical component of press brake machines that ensures precision, quality, and repeatability in sheet metal bending operations. It comprises two primary elements: the punch (upper tool) and the die (lower tool), which work in tandem to shape metal sheets or plates into desired forms.

These tools are typically manufactured from high-strength materials such as tool steel, often heat-treated to achieve optimal hardness and wear resistance. Common materials include D2, M2, or premium tool steels like Toolox 44, selected for their ability to withstand high pressures, resist deformation, and maintain dimensional stability under repeated use.

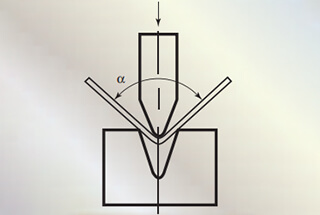

Press brake tooling comes in a wide array of profiles, sizes, and configurations to accommodate various bending applications, material thicknesses, and geometric requirements. Standard profiles include V-dies, gooseneck punches, acute angle tools, and hemming tools, among others. The die’s geometry plays a crucial role in determining the final bend angle, with V-openings ranging from 6° to 120° to suit different bending needs.

Key components of press brake tooling include:

Modern press brake tooling often incorporates advanced features like precision ground surfaces, nitride treatments for enhanced durability, and CNC-machined profiles for optimal performance. Some systems also utilize quick-change mechanisms to reduce setup times and increase productivity.

The selection of appropriate tooling is critical for achieving desired bend angles, maintaining part accuracy, and ensuring efficient press brake operations. Factors such as material properties, bend radius, flange length, and required tonnage must be carefully considered when choosing press brake tooling for specific applications.

Punches, also known as the upper tool or male die, are secured to the ram of the press brake. These precision-engineered components exert controlled force on the workpiece, driving it into the die to create the desired bend. Punches are available in a diverse array of geometries and dimensions, tailored to specific bending requirements and material properties. Key punch types include:

Straight Punches: Utilized for simple bends with larger radii, offering versatility across various applications.

Gooseneck Punches: Engineered for producing acute angle bends and U-shaped channels, featuring an extended nose for improved access and reduced interference.

Hemming Punches: Specialized tools designed for creating flat, folded edges by bending the sheet metal at a continuous angle, often used in automotive and appliance manufacturing.

Rotational Punches: Adjustable tools that can be rotated to different angles, allowing for multiple bend profiles with a single tool, enhancing flexibility and reducing setup time.

Dies, also referred to as the lower tool or female die, are positioned on the bed of the press brake. They provide a precisely shaped cavity or groove that complements the punch geometry and accommodates the material during the bending process. The interaction between punch and die is critical in achieving accurate and consistent bends. Common die configurations include:

V-shaped Dies: The most versatile option, suitable for a wide range of materials and thicknesses. Available in various angles (typically 30°, 60°, or 90°) to accommodate different bend requirements.

U-shaped Dies: Employed for forming channels, troughs, and flanged shapes. The radius of the U-bottom can be customized to achieve specific profile requirements.

Offset Dies: Engineered for creating complex Z-shaped bends or double bends in a single operation, improving efficiency in multi-bend parts production.

Adjustable V-Dies: Feature movable side plates that allow for altering the V-opening width, providing flexibility to accommodate various material thicknesses and bend angles with a single tool.

The selection of appropriate punch and die combinations is paramount to achieving optimal bending results. Factors influencing tooling choice include material composition and properties, sheet thickness, desired bend radius, required bend angle, press brake tonnage capacity, and production volume. Additionally, considerations such as tool wear resistance, surface finish requirements, and potential for springback must be evaluated.

Proper tool management, including regular inspection, maintenance, and precise alignment, is crucial for ensuring consistent bend quality, prolonging tool life, and maximizing production efficiency. Advanced tool storage systems and quick-change mechanisms can significantly reduce setup times and enhance overall press brake productivity.

Further reading:

When considering the acquisition of a press brake, identifying the most suitable manufacturer is crucial for ensuring optimal performance and reliability in your metal forming operations. The following ranking of press brake manufacturers is designed to guide you in selecting a provider that aligns with your specific manufacturing needs, production volume, and budget constraints.

Each manufacturer has its strengths, whether in technological innovation, precision, energy efficiency, or cost-effectiveness. When evaluating these options, consider factors such as:

In the near future, we plan to supplement this list with comprehensive reviews of each manufacturer’s press brake offerings. These reviews will provide in-depth analysis of performance metrics, user experiences, and value propositions to further assist you in making an informed decision.

Before performing maintenance or cleaning on the press brake machine, align the top punch with the bottom die, then power down and lock out the machine until work is completed.

If machine activation is necessary for troubleshooting or adjustments, utilize the jog mode and follow all safety protocols.

Hydraulic System

Conduct weekly inspections of oil levels in reservoirs. Replenish with specified hydraulic oil if level falls below sight glass.

Use only ISO HM46 or Mobil DTE25 hydraulic fluid, or equivalent as recommended by the manufacturer.

For new press brakes, perform initial oil change after 2000 operating hours. Subsequently, change oil every 4,000 to 6,000 hours or annually, whichever comes first. Clean the reservoir thoroughly during each oil change.

Maintain system oil temperature between 35°C and 60°C, not exceeding 70°C. Higher temperatures accelerate oil degradation and can damage hydraulic components.

Monitor oil condition. If oil appears cloudy, discolored, or contains visible particulates, consider early replacement.

Filtration

Replace or thoroughly clean filters during each oil change.

Replace filters immediately if experiencing related alarms, visible oil contamination, or unusual pressure drops across the filter.

Clean the reservoir air breather filter quarterly. Replace annually or more frequently in dusty environments.

Hydraulic Components

Perform monthly external cleaning of hydraulic components including manifolds, valves, motors, pumps, and hoses. Use lint-free cloths and avoid harsh solvents.

After one month of operation, inspect hoses for deformation or wear at bend points and connection points. Replace if necessary.

After two months, with the system fully depressurized and locked out, systematically check and torque all hydraulic connections to manufacturer specifications.

Regularly inspect cylinders, seals, and actuators for leaks or unusual operation.

Preventive Maintenance

Maintain detailed maintenance logs including oil analysis results, filter changes, and any observed issues.

Familiarize yourself with common press brake failure modes and their symptoms to aid in early problem detection and resolution.

Follow manufacturer-recommended maintenance schedules for additional tasks specific to your press brake model.

Ensure all maintenance personnel are properly trained in hydraulic system safety and maintenance procedures.

By adhering to this comprehensive maintenance regimen, press brake operators can significantly extend equipment life, minimize downtime, and maintain optimal performance and precision in metal forming operations.

Further reading:

Brief Description

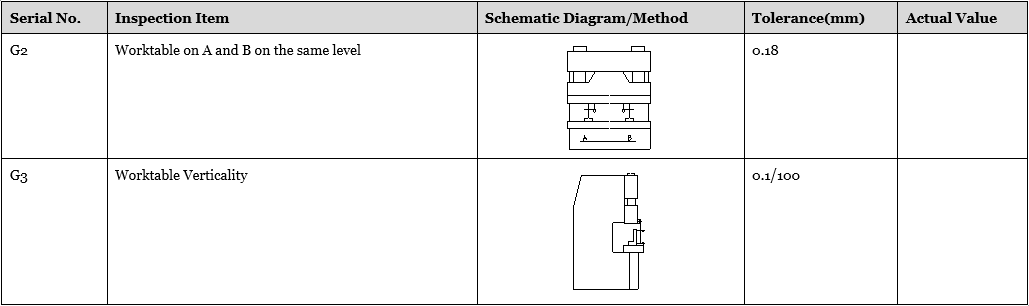

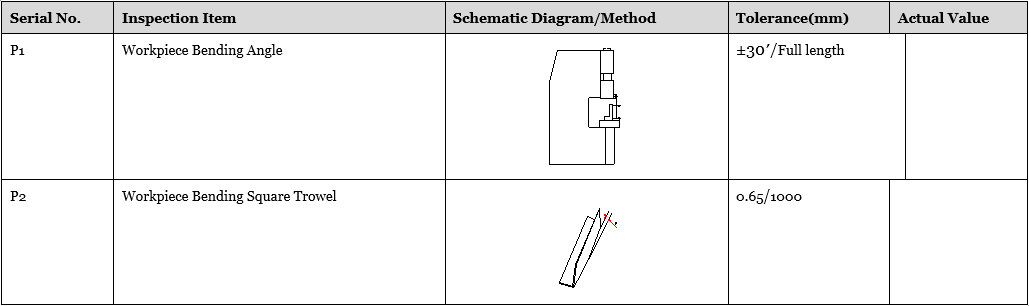

The standard test order is flexible and may be adjusted as needed; it does not necessarily represent the actual sequence of testing.

During the testing process, it is strictly prohibited to adjust any mechanisms or components that could potentially impact the machine’s precision.

Workpiece Precision Inspection Conditions:

Requirements for Workpiece:

The inspection method and accuracy range shall be based on GBT-14349-2011-Metal Press Brake- Precision

Note: the worktable is floated, inspection G2, G3 shall refer worktable vertical plate as a benchmark.

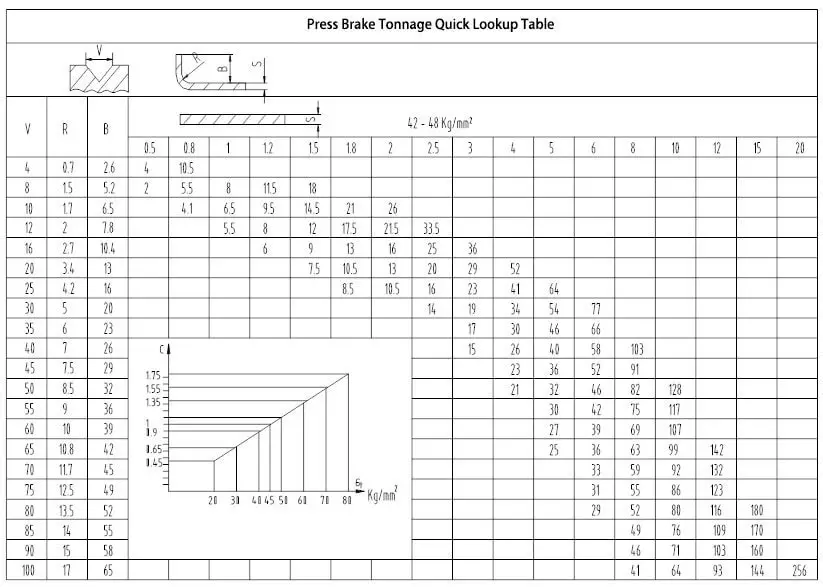

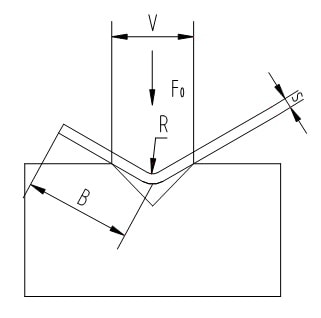

Determining the appropriate press brake size is crucial for efficient and precise metal forming operations. The calculation of press brake forming force, or tonnage, is a critical step in this process. This section outlines methods to accurately estimate the required press brake capacity for your specific bending applications.

For quick reference, consult the chart below. This chart provides a convenient way to estimate the required press brake capacity based on common parameters:

Press brake bending chart (metric)

The bending force values in the quick reference chart are based on the following standard conditions:

For materials with different tensile strengths, use the following formula to calculate the required bending force per meter:

F1 = F0 · (σ / 450) [T/m]

Where:

This formula allows for precise tonnage calculations across a wide range of material properties, ensuring optimal press brake selection for your specific application.

Additional Considerations:

See also:

There are two popular press brake controllers, namely the one from China’s Estun, which is the exclusive agent of DELEM control in China, and the other one is DELEM from the Netherlands.

See also:

The key factors for a press brake machine are divided into two parts: the machine itself, such as its quality and accuracy, and the control system.

You can download the installation and operation manual for press brake controllers in PDF form from the following link.

Operation Manual:

Installation Manual:

The operation and installation manuals for press brake controllers provide comprehensive guidance on programming and setup procedures. It is essential to thoroughly review these documents, which can be accessed via the provided link.

Instructions on Using a Hydraulic Press Brake:

The following outlines a basic procedure for operating a hydraulic press brake to fabricate Q235 mild steel:

By following these guidelines and referring to the manufacturer’s documentation, operators can ensure safe, efficient, and precise bending operations with the hydraulic press brake.

Here, we provide press brake operation manuals to guide you in operating the press brake.

Furthermore, by reading the articles in our bending category, you can gain knowledge about various aspects of press brake and sheet metal bending.

It is recommended to take your time to carefully read and learn from these articles.

Comprehensive training for press brake operation and programming is essential for optimal performance and safety. While manufacturer manuals provide valuable information, they should be complemented with hands-on experience and expert guidance.

Operator training typically covers:

While manuals available through the provided link offer a solid theoretical foundation, they should be used in conjunction with practical training. Many manufacturers and industry associations offer specialized courses, combining classroom instruction with hands-on machine time.

For continuous skill development, consider:

Remember, proficiency in press brake operation requires ongoing practice and staying updated with the latest advancements in bending technology and techniques.

Further reading:

For workshops with occasional bending requirements, investing in a commercial press brake may not be economically justifiable. In such cases, fabricating a custom DIY press brake can be a cost-effective solution for simple bending operations.

A homemade metal brake press, while limited in capacity and precision compared to industrial models, can effectively handle light to medium-gauge sheet metal for basic forming tasks. These DIY setups typically utilize hydraulic jacks or mechanical leverage systems to generate the necessary bending force.

Key considerations for building a DIY press brake include:

While a DIY press brake can be a valuable addition to a small workshop, it’s crucial to understand its limitations and adhere to safe operating practices. For more complex or high-precision bending tasks, professional equipment may still be necessary.

Here, I have collected some videos on building a home-made press brake. I hope that these tutorials will help you make one on your own.

Automation and Industry 4.0 Integration

The press brake industry is poised for a significant transformation through increased automation and Industry 4.0 integration. This evolution is driven by the imperative to enhance productivity, precision, and consistency in manufacturing processes. Companies are increasingly implementing advanced robotic systems and artificial intelligence (AI) into their press brake operations, enabling the execution of complex bending tasks with unprecedented ease and accuracy.

State-of-the-art automated press brakes not only boost efficiency but also mitigate the reliance on skilled labor, as they can operate with minimal human oversight. The integration of advanced sensors, machine learning algorithms, and smart controls ensures superior repeatability and product quality. Furthermore, the implementation of digital twin technology allows for real-time monitoring, predictive maintenance, and optimization of press brake operations.

Environmentally Sustainable Manufacturing

The future of the press brake industry is intrinsically linked to the development and adoption of environmentally sustainable technologies that minimize ecological impact. Manufacturers are intensifying their efforts to create eco-friendly materials and energy-efficient machinery, contributing to a more sustainable industry. Key advancements in this domain include:

Additive Manufacturing Integration

The convergence of press brake technology with additive manufacturing is emerging as a game-changing trend. Hybrid systems that combine traditional bending capabilities with 3D printing technologies are being developed, allowing for the creation of complex, customized parts with unique geometries that were previously unattainable through conventional methods alone.

These innovative trends signify that the press brake industry is continuously evolving, embracing cutting-edge technologies to meet the demands of modern manufacturing. As a result, it is anticipated that these advancements will lead to a more efficient, sustainable, and competitive industry, capable of meeting the challenges of Industry 4.0 and beyond.

How much does a press brake cost? Or what is the price of a press brake?

The cost of a press brake machine is primarily determined by its bending force, working length, and control system sophistication. These key factors directly influence the machine’s capabilities and performance, thus significantly impacting its market value.

Several other critical factors that influence the price include:

To provide a general idea of the price range for press brake machines, we have compiled a reference table for both NC (Numerical Control) and CNC (Computer Numerical Control) press brakes. It’s important to note that these figures are approximate and can vary based on the factors mentioned above and current market trends.

Press Brake Price Table (USD)

| Model | NC Press Brake | CNC Press Brake |

|---|---|---|

| 40T*2200 | 4800 | 19000 |

| 40T*2500 | 4850 | 20000 |

| 50T*2500 | 5200 | 20500 |

| 63T*2500 | 6300 | 21000 |

| 63T*3200 | 7300 | 22000 |

| 80T*2500 | 7900 | 23000 |

| 80T*3200 | 9200 | 24000 |

| 80T*4000 | 10500 | 23500 |

| 100T*2500 | 8800 | 24000 |

| 100T*3200 | 9900 | 25000 |

| 100T*4000 | 11500 | 26000 |

| 125T*2500 | 9500 | 25000 |

| 125T*3200 | 10800 | 26000 |

| 125T*4000 | 12500 | 27500 |

| 160T*2500 | 13000 | 27000 |

| 160T*3200 | 14500 | 29000 |

| 160T*4000 | 16000 | 32000 |

| 160T*5000 | 20500 | 36500 |

| 160T*6000 | 24000 | 43000 |

| 200T*3200 | 16000 | 32000 |

| 200T*4000 | 18500 | 36500 |

| 200T*5000 | 23000 | 45000 |

| 200T*6000 | 27000 | 48000 |

| 250T*3200 | 24000 | 38000 |

| 250T*4000 | 27000 | 43000 |

| 250T*5000 | 32000 | 49000 |

| 250T*6000 | 35000 | 55000 |

When considering the investment in a press brake, it’s crucial to evaluate not only the initial purchase price but also the total cost of ownership, including maintenance, energy consumption, and potential productivity gains. High-end CNC press brakes, while more expensive initially, often offer superior precision, efficiency, and versatility, which can lead to a better return on investment over time for high-volume or complex bending operations.

Selecting the optimal hydraulic press brake for your manufacturing needs is a critical decision that can significantly impact your production efficiency, quality, and overall operational success. This comprehensive guide provides essential insights into the complex world of press brakes, equipping you with the knowledge to make an informed choice.

We begin by defining the press brake and its fundamental role in sheet metal fabrication. The guide then delves into a detailed examination of the key components of a hydraulic press brake, including the frame, ram, bed, backgauge system, and control interface. Understanding these elements is crucial for evaluating machine capabilities and performance.

Our analysis covers the spectrum of press brake technologies, from traditional manual machines to advanced hydraulic systems and state-of-the-art NC/CNC models. We provide an in-depth comparison of NC (Numerical Control) and CNC (Computer Numerical Control) press brakes, weighing their respective advantages and limitations in terms of precision, programming flexibility, productivity, and cost-effectiveness.

The guide outlines critical factors to consider during the selection process, such as:

We provide actionable tips for evaluating these factors in the context of your specific manufacturing environment, production volume, and future growth projections. Additionally, we discuss the importance of considering total cost of ownership, including maintenance requirements, operator training, and long-term support.

This comprehensive resource is indispensable for fabricators, manufacturing engineers, and decision-makers involved in the acquisition of press brake technology. By thoroughly exploring the technical aspects, operational considerations, and strategic implications of press brake selection, this guide empowers you to make a well-informed investment that aligns with your production goals and enhances your competitive edge in the metal forming industry.

Related reading: Press Brake Buying Guide