How can manufacturers ensure precision and efficiency in sheet metal bending? Choosing between a press brake and a CNC folder is crucial. This article compares their working principles, bending accuracy, material handling, and operator skill requirements, helping you decide the best fit for your production needs. Discover which machine offers the precision and ease of use you need, and learn how each one can impact your manufacturing process.

CNC press brake is capable of fulfilling the requirements of various small-batch products, including thin plates such as car front walls, door lintels, car tops, bottoms, and frames, as well as thick plate products.

CNC Folder

The CNC folder is equipped to handle the demands of a range of small-batch products, including thin plates that require lifting, such as car walls, tops, bottoms, and frames, as well as medium-thick plate products.

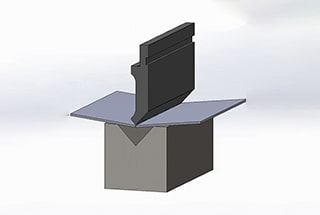

Fig.1 CNC Press Brake

Fig.2 CNC Folder

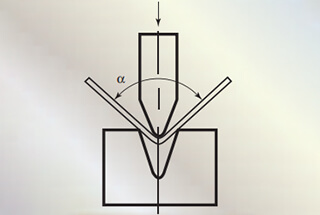

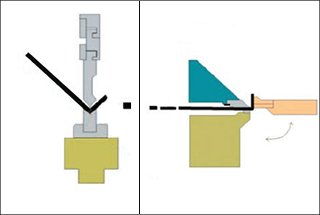

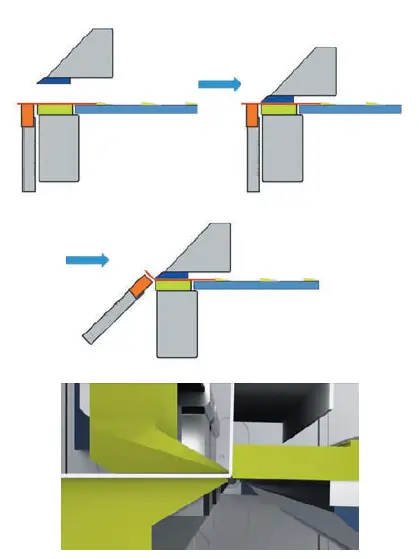

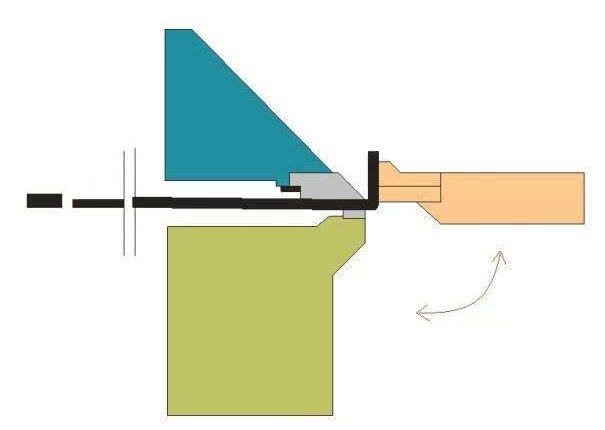

The press brake has its punch and die fixed on the upper and lower workable surfaces, respectively. It operates through the relative motion of the working table, which is powered by hydraulic pressure, and the interaction between the shape of the punch and die to achieve bending of sheet metal materials (refer to Figures 3 and 4).

Fig.3. Press brake bend forming diagram

Fig.4 Press brake bend car wall

The upper ram, powered by a motor, presses the metal sheet firmly. The folding beam rotates upward to create the bend in the sheet metal products (refer to Figures 5 and 6).

Fig.5 CNC folder bend forming diagram

Fig.6 CNC folder folding car wall

Comparison of press brake and CNC folder in sheet metal forming:

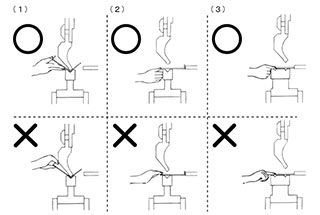

Press Brake: The angle of bend is controlled by adjusting the pressure of the punch. During the bending process, the short edge is on the inside, so operators must support most of the material from the outside. For bending heavy workpieces, the assistance of two or more workers may be necessary.

CNC Folder: The sheet metal is laid flat on the workbench, and the edge beam is pressed down to secure the plate. The bending beam moves up and down to perform edge folding operations. There is no need for manual intervention in positioning and auxiliary flanging during all folding operations on one edge.

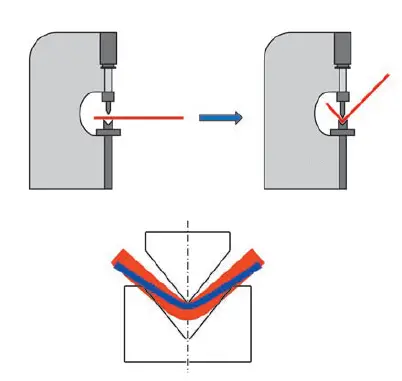

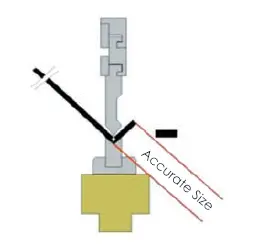

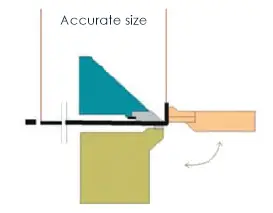

Press Brake: The control of the dimensional precision is based on the short side dimension precision of the backstop material positioning. After the bending process is finished, any final error will affect the size of the inner space. Additionally, since the bending angle is controlled by adjusting the pressure of the top punch, the angle is dependent on the thickness of the material (refer to Figure 7).

Fig.7 The press brake error accumulates to the inner space size

CNC Folder: The dimensional precision control takes the first edge as the reference for positioning after the first fold. The final size control is precisely the size of the inner space as specified by the customer. Additionally, the bending angle is directly controlled by the folding angle and is not dependent on the thickness of the material (refer to Figure 8).

Fig.8 CNC folder control inner space size

Press Brake: At work, the material undergoes relative motion in the lower die, resulting in indentations without surface protection. When bending a large workpiece, it is necessary to rotate the surface multiple times, leading to unavoidable scratches in the bending process.

CNC Folder: During operation, the edge-pressing beam tool and the folding beam tool remain stationary relative to the material, preventing any surface damage. When bending a large workpiece, all processing can be completed on one side of the plate at the same time as it is laid flat, thus avoiding any surface damage.

Press Brake: It requires highly skilled workers for bending operations.

CNC Folder: Programming can be performed visually with finger painting or by engineers using off-line software. The processing program can also be imported using USB or network connection. After programming is complete, workers’ main tasks are simplified to feeding and unloading, and there is no need for skilled bending workers.

Press Brake: Products with varying thicknesses and shapes require different top and bottom dies to accommodate their specific bending requirements. In some cases, such as arcs, it may be necessary to switch to a different tool or transfer the product to another machine, leading to increased transfer and temporary storage of semi-finished products.

CNC Folder: The rotatable edge beam and simultaneous installation of two sets of edge beam tools make it possible to complete all bending procedures in a single station. There is no need to switch tools for circular arc bending or other special bending requirements, only to modify the procedure.

Press Brake: Due to the relative motion of the workpiece between the punch and die, the tooling will experience wear and tear, which requires maintenance or replacement.

CNC Folder: By avoiding the relative motion between the material and tool, the tool can be used for a long time with minimal wear and tear, thus greatly extending its lifespan.

Press Brake: The hydraulic drive system requires more maintenance and is susceptible to environmental factors.

CNC Folder: The full electric drive design reduces maintenance and is unaffected by the environment, resulting in higher bending precision.

In recent years, 30% of sheet metal factories in Europe and the United States have expressed a willingness to invest in the use of folding machines instead of press brakes for bending fabrication. This is primarily due to the fact that the operation of folding machines is more convenient and they offer numerous advantages as a bending equipment.

While both types of equipment have their own unique characteristics, I will compare them based on their working principles for your reference.

Press Brake:

In the entire bending process, the operator must manually hold the sheet material and position it using the back gauge. This method is unsafe for operators handling large and heavy-duty sheets as the weight of the sheet can cause the bending angle to become larger. It is also difficult for a single operator to bend large workpieces.

The bending angle is determined by the depth of the upper die into the lower die, and even a small deviation in plate thickness can result in an inconsistent bending angle. Different plate thicknesses require different punch and die configurations.

The installation and commissioning of the machine require professional knowledge and a long startup time. Additionally, the cost of purchasing, replacing, and maintaining molds is high. The maximum bending width is limited by the upright.

Using a press brake can be more complex and requires trained, skilled workers. Each step in the process also requires a longer work cycle, and the repetition accuracy of the workpiece depends on the operator’s skill and technology.

Folding Machine:

| No. | Press Brake Features | Folding Machine Features |

| 1 | Large workpieces require multiple operators. | Large workpieces require only one or two operators. |

| 2 | Press braking can cause indentations. | Completely free of indentations and folding marks on surface-sensitive materials. |

| 3 | Bending size errors accumulate through the final bend. | The first fold corrects the sheet metal cutting size, ensuring precise internal dimensions. |

| 4 | Different tools are needed for various bending requirements. | A universal folding machine tool meets most bending needs. |

| 5 | Bending precision is related to material thickness. | Bending angle precision is independent of material thickness. |

| 6 | Bending quality depends on the operator’s skill level. | No skilled operators needed; the machine itself ensures bending precision. |

| 7 | Safety hazards exist when bending large and heavy workpieces. | Flat processing of large sheet metals eliminates the need for support and safety hazards. |

| 8 | Bending tools are prone to wear. | Folding and clamping beam tools with a lifespan of up to 20 years. |

| 9 | Parameter setting and adjustment are challenging, and it’s impossible to simulate bending effects. | Graphical Chinese control system for a complete simulation of folding effects, what you see is what you get. |

| 10 | Certain bending processes are difficult to complete with a press brake. | Some processes, such as arcs and bottom bending, are very simple for a folding machine. |

| 11 | Inaccurate material cutting sizes can lead to waste. | Tolerance of cutting size is shifted to less critical edges, compensating for cutting size deviations. |

| 12 | Insufficient bending precision increases subsequent welding and grinding workloads. | High precision bending reduces labor hours for subsequent welding and grinding. |

| 13 | Multiple press brakes are needed for different bending processes of a single workpiece. | Combined with flipping clamping beams and up-and-down bending functions, one machine can complete all bending processes. |

| 14 | Utilizing a hydraulic system increases maintenance work. | The folding machine uses a fully electric drive system, significantly reducing maintenance workload. |