Have you ever thought about the hidden dangers lurking behind every welding spark? Welding, while essential, poses numerous risks, including electrical accidents, fires, toxic fumes, and physical injuries. This article explores various hazards in welding and provides crucial safety measures to protect welders. By understanding these risks and implementing preventive strategies, you can ensure a safer work environment and prevent potential accidents. Dive in to learn how to safeguard your welding operations and protect yourself and your colleagues from harm.

Welding, also known as arc welding, is a process that uses the thermal effect of welding equipment to heat and melt the cross-section of the welded metal, so that the originally separated metals are joined together to form a strong and non-removable joint.

According to different welding processes, arc welding can be divided into automatic welding, semi-automatic welding, and manual welding. Automatic and semi-automatic welding are mainly used in the manufacture of large-scale machinery and equipment, with equipment installed in factories and relatively fixed workspaces.

Manual welding, on the other hand, is more flexible and can be used in outdoor construction. Due to the differences in workspaces, welding operations involve various hazards, including electrical, optical, thermal, and open flame hazards.

a) During the welding process, the welder often needs to change welding rods and adjust welding currents, which requires direct contact with the electrodes and electrode plates.

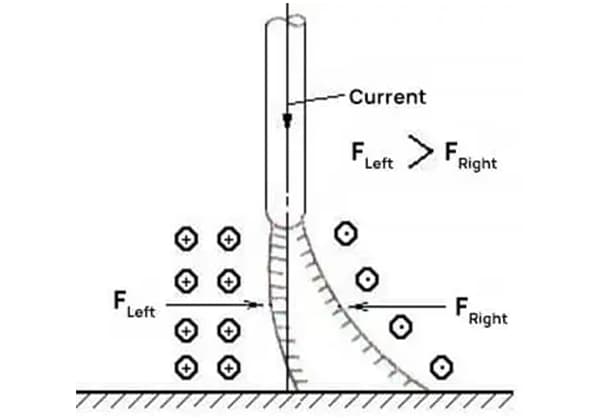

The welding power supply is usually 220V/380V, and electrical accidents can occur if electrical safety devices are faulty, labor protection equipment is not up to standard, or operators engage in unauthorized operations. The risk of electrical accidents is even greater when welding in metal containers, pipelines, or damp areas.

b) When the welding machine is in an idle state, the secondary winding voltage is generally between 60-90V. Although the voltage is not high, it can still pose a certain risk as it exceeds the regulated safety voltage of 36V.

For example, if the idle voltage of the welding machine is 70V and a person is working in a high temperature and humid environment, with a body resistance of approximately 1600Ω, the current passing through the person’s body would be: I=V/R=70/1600=44mA. At this current, the welder’s hand may experience spasms, leading to the risk of electrical accidents.

c) Since most welding operations take place outdoors, the welding machine, welding cables, and power cables are often exposed to high temperatures, humidity (construction sites), and dust.

In addition, the welding machine often operates under overload conditions, which can lead to insulation aging and reduced insulation performance of power and electrical lines, increasing the risk of electric leakage accidents.

During the welding process, the arc or open flame produced can easily cause fires when working in places with flammable materials. This risk is even greater when welding in areas with flammable and explosive devices (including pits, ditches, etc.) or when welding on containers, towers, tanks, and pipelines containing flammable and explosive substances.

There have been many cases of accidents in this regard, such as the “12.25” major fire accident in Luoyang in 2000, which was caused by illegal welding operations in a shopping mall and poor management, resulting in the ignition of surrounding flammable materials and causing 309 deaths.

On May 26, 2003, during welding operations on the axle nut of a train tank car containing methyl methacrylate at a Beijing Oriental Chemical Plant, an explosion occurred due to the lack of cleaning and replacement of the tank car and the failure to analyze the flammable gas inside the tank car. The explosion blew off the manhole cover, hitting the welder and causing death.

During the welding process, arcs and molten metal slag are generated. If welders do not wear specialized protective clothing, gloves, and shoes, especially when welding at heights where sparks from welding can fly, it can cause burns to the welder or workers below the work surface.

Intense visible light and invisible ultraviolet rays are generated during welding, which can cause strong irritation and damage to the eyes.

Prolonged direct exposure can cause eye pain, photophobia, tearing, and sensitivity to wind, leading to conjunctivitis and keratitis (commonly known as welding flash burns).

Welding arcs emit infrared, ultraviolet, and visible light, which can have a radiating effect on the human body.

Infrared radiation has a thermal radiation effect and can cause heatstroke in high-temperature environments during welding.

Ultraviolet radiation has a photochemical effect and can harm the skin. Prolonged exposure to visible light can cause a decrease in vision.

The arc temperature during welding can reach over 4200℃, causing the welding rod core, flux, and metal to undergo gasification, evaporation, and condensation, resulting in the production of a large amount of manganese chromium oxide and harmful smoke dust.

Additionally, the high temperature and intense radiation of the arc light can cause the surrounding air to produce toxic gases such as ozone and nitrogen oxides.

Engaging in welding operations for a long time in poorly ventilated conditions can lead to the inhalation of these toxic gases and smoke dust, which can have an impact on human health.

Due to construction requirements, welders often need to perform welding operations at heights.

If fall protection measures are not properly implemented, scaffolding is not properly erected and inspected before use, or personal protective equipment such as safety helmets and harnesses are not worn during high-level operations, accidents such as falls from heights can occur.

Welders often need to enter enclosed or semi-enclosed places such as metal containers, equipment, pipelines, towers, and tanks for welding.

If toxic and harmful substances or inert gases are stored or produced during transportation, improper work management and inadequate protective measures can easily lead to poisoning or asphyxiation of workers, especially in oil refining and chemical enterprises.

To prevent electrical accidents, insulation, shielding, isolation, leakage protection, and personal protective measures should be taken to avoid direct contact with live parts. Specific methods include:

a) Improve the insulation performance of welding equipment and circuits. The welding equipment and power cables used must be qualified products, and their electrical insulation performance should be suitable for the voltage level, surrounding environment, and operating conditions. Welding machines should be regularly maintained and protected from exposure to sunlight and rain to prevent degradation of their electrical insulation performance.

b) When a welding machine malfunctions, needs to be repaired, the work location needs to be changed, or the joints need to be replaced or the fuses need to be replaced, the power supply must be disconnected before operation.

c) When installing the power supply for the welding machine, do not forget to install a residual current device to ensure that the power will be automatically cut off if a person comes into contact with live parts. When welding in damp or metallic containers, equipment, or components, a residual current device with a rated operating current not exceeding 15mA and a rated operating time less than 0.1 second should be used.

d) Good protective grounding or zero grounding measures should be taken for the welding machine’s casing and the leads of the secondary winding. When the power supply is a three-phase three-wire system or a single-phase system, a protective grounding wire with a resistance value not exceeding 4Ω should be installed. When the power supply is a three-phase four-wire system with a grounded neutral point, a protective neutral wire should be installed.

e) Strengthen the education of workers on electrical safety knowledge and self-protection awareness. Welders must wear insulated shoes and special insulated gloves during work. Welding in the rain is prohibited. When welding in particularly humid environments, workers must stand on dry wooden boards or rubber insulation pads.

f) It is prohibited to use metal structures, pipelines, tracks, and other metal connections as conductors. When welding in metal containers or particularly humid places, the power supply for lighting fixtures must use a safe voltage below 12V.

a) When welding in flammable and explosive places, a permit for hot work must be obtained in accordance with regulations before welding. Approval from relevant departments is required before work can begin, and the principle of “no fire” must be strictly followed.

b) Before welding, check whether there are flammable and explosive substances below and around the work area, and handle flammable paints or anticorrosive substances properly if present. For welding operations near operating production units and oil tank areas, firewalls must be built. If welding is performed at heights, asbestos boards or iron plates should be used for isolation to prevent sparks from flying.

c) When welding on containers, equipment, or pipelines used for the production and transportation of flammable and explosive substances, it is necessary to check whether the connected equipment and pipelines are closed or blocked with blind plates, and carry out blowing, cleaning, replacement, and sampling for analysis according to regulations. Welding can only be performed after the analysis results are qualified.

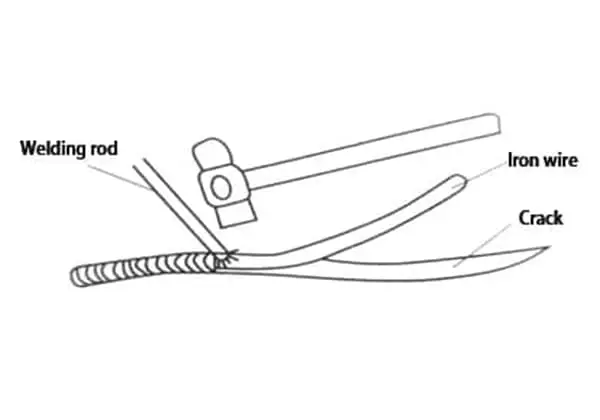

a) Welders must wear appropriate protective clothing, insulated gloves, and insulated shoes during welding. When using high currents for welding, welding tongs should be equipped with protective covers.

b) Newly welded areas should be covered with asbestos boards or other materials in a timely manner to prevent direct contact and burns to the feet and body.

c) Welding rod heads that are replaced during high-level welding should be piled up in a centralized manner to avoid burning workers below.

d) Protective goggles should be worn when cleaning welding slag. When performing overhead or horizontal welding at heights, isolation measures should be taken due to excessive sparks.

According to the intensity of the welding current, suitable face shields with special protective lenses and colored protective eyewear should be used.

Other personnel involved in welding assistance and those near the welding site should also take protective measures and wear appropriate protective eyewear.

Welders and surrounding workers should wear appropriate personal protective equipment. It is prohibited to observe the arc light directly without wearing welding masks and tinted goggles.

Skin exposure should be minimized, and in the summer, welding operations should not be carried out in shorts and short-sleeved shirts. If possible, UV protection cream should be applied to exposed skin.

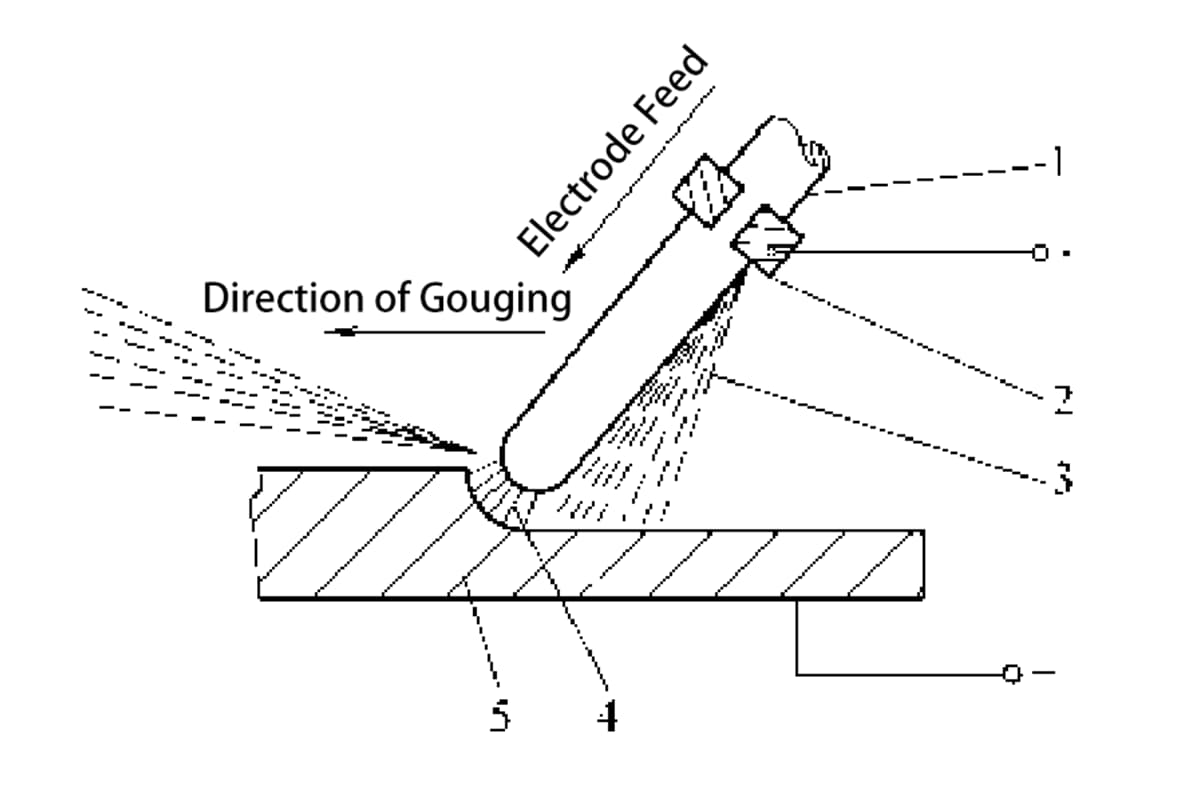

a) Design the welding process reasonably, and try to use single-side welding and double-side forming process to reduce the amount of welding inside metal containers.

b) For welding operations in small or enclosed spaces, forced ventilation measures must be taken to reduce the concentration of harmful gases and dust in the work area.

c) Whenever possible, automatic or semi-automatic welding should be used instead of manual welding to reduce the exposure of welding personnel to harmful gases and dust.

d) Use low-dust and low-toxicity welding electrodes to reduce the content of harmful smoke and dust in the work area.

e) During welding, welders and other personnel in the vicinity should wear dust and toxic gas masks to minimize inhalation of smoke and dust.

Welders must undergo regular medical examinations. Individuals with a history of hypertension, heart disease, epilepsy, etc. are prohibited from performing high-altitude welding. When working at heights, welders must properly fasten safety belts and wear safety helmets.

Prior to welding, the work area and its surroundings should be inspected to ensure the stability and integrity of the footholds, as well as the compliance of scaffolding and other safety protection facilities with safety requirements.

If necessary, safety nets should be installed below and around the work area. Isolation measures should be taken for operations involving up and down movements.

a) Before welding in enclosed or semi-enclosed areas such as containers, equipment, pipelines, towers, and tanks containing toxic or hazardous substances, all connected process equipment must be disconnected.

Cleaning, purging, and replacement should be carried out, and a work permit for entry into the equipment should be obtained in accordance with regulations. Sampling and analysis should be conducted, and only after passing the inspection can work commence.

b) Under normal circumstances, sampling and analysis should be conducted every 4 hours, and if conditions change, sampling and analysis should be done promptly. Adequate amounts of respiratory equipment (oxygen) should also be available on-site for emergency use.

c) Safety monitoring by designated personnel should be carried out during the operation, and welders should rotate their work on a regular basis.

For equipment with strong airtightness and prone to oxygen deficiency, oxygen replenishment should be done through forced ventilation (direct oxygen supply is prohibited) to prevent suffocation due to oxygen deficiency.

Welding, a specialty operation, involves significant occupational hazards including dust, toxic gases, high temperatures, arc light, and high-frequency electromagnetic fields. As society rapidly advances, welding becomes increasingly integral to nearly all industrial sectors.

The surge in the number of welders has led to an increase in occupational hazards associated with welding.

Given the variety and magnitude of hazards in welding operations, a series of effective protective measures must be implemented to reduce occupational risks to welders.

Improve Welding Technology, Processes, and Materials:

Enhancing welding technology to mechanize and automate operations can fundamentally eliminate the hazards of welding to human health.

Improving welding processes, such as designing containers for welding reasonably and adopting new techniques like single-side welding and double-side forming, can prevent welders from operating in poorly ventilated containers, significantly improving their working conditions.

Choosing non-toxic or low-toxicity welding rods by improving the material of welding rods is also an effective way to reduce welding hazards.

Improve Ventilation Conditions at Workplaces:

Ventilation can be natural or mechanical, with the latter relying on fans to provide air exchange, dust removal, and detoxification. In enclosed spaces with poor natural ventilation, mechanical ventilation measures are required.

Strengthen Personal Protective Measures:

Personal protective measures can prevent harm from toxic gases and dust produced during welding. Workers must use appropriate protective eyewear, face shields, masks, gloves, and wear white protective clothing and insulating shoes.

Bare arms are not permitted. If working in a poorly ventilated, enclosed container, a ventilated protective helmet must be worn.

Intensify Labor Protection Publicity, Education, and On-Site Monitoring:

Workers should receive necessary occupational safety and health knowledge education to increase their self-protection awareness and reduce the incidence of occupational diseases.

Additionally, it is crucial to strengthen the monitoring of dust and toxic hazards at welding sites and conduct regular physical examinations of welders to detect and solve problems promptly.

Personal protective measures for welding operations primarily involve safeguarding the head, face, eyes, ears, respiratory tract, hands, and body.

These measures primarily include dust protection, poison prevention, noise reduction, high-temperature radiation shielding, radioactivity protection, mechanical injury prevention, and general cleanliness.

In addition to wearing standard protective equipment (such as work clothes, gloves, glasses, masks), an air respirator may be worn in specific operational environments, such as during welding in enclosed containers or in situations where ventilation is difficult, to prevent the harm of smoke and dust.

In emergency welding repairs in highly toxic environments, an isolated oxygen respirator can be worn to prevent acute occupational poisoning.

To protect welders’ eyes from arc light damage, a face shield with special protective lenses should be used during welding. Lenses should be selected based on the intensity of the welding current, but consideration should also be given to the welder’s vision and the brightness of the work environment.

To prevent skin damage from the electric arc, welders should wear light-colored or white canvas work clothes. Sleeves should be tightly secured, collar buttoned, and no skin should be exposed.

For welding assistants and other personnel near the welding site, they should cooperate with each other to avoid arc light damage. Assistants should wear appropriately darkened filter glasses.

In multi-person operations or crossover work areas, protective measures should be taken, such as setting up protective screens, to prevent the arc light from injuring the eyes of welders and other workers.

Moreover, after handling thorium-tungsten rods, hands should be washed with running water and soap, and attention should be paid to regularly clean work clothes and gloves. Wearing noise-cancelling ear muffs or earplugs can protect against noise hazards. These are all effective personal protective measures.