Ever noticed your welding arc wandering off track? This is likely due to magnetic blow, a common issue that disrupts weld quality. This article explores the causes of magnetic blow and provides practical solutions to mitigate its effects. From adjusting electrode angles to using AC welding, discover how to maintain a stable welding arc and ensure superior welds. Dive into the intricacies of this phenomenon and learn how to keep your welds precise and clean.

This article explains the causes of arc magnetic blow and the factors that affect the size of magnetic blow, and introduces the impact of magnetic blow on welding quality.

From the aspects of design and technology, measures are proposed to control the influence of magnetic blow on welding quality.

Arc rectitude refers to the property of the arc as a flexible conductor to resist external interference and strive to keep the welding current flowing along the axis of the electrode.

When the electrode is tilted, the direction of the arc also tilts, and the center line of the arc extends in the direction of the electrode’s tilt, which is called magnetic blow.

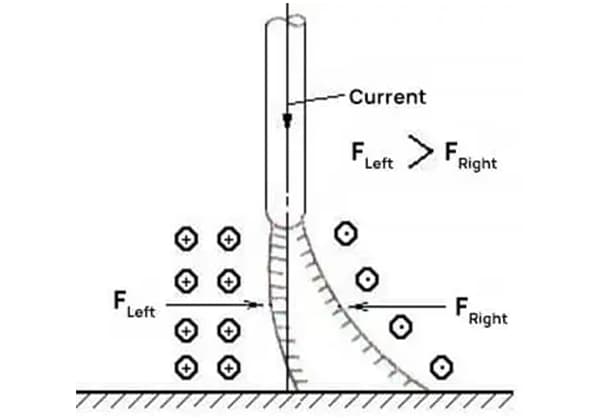

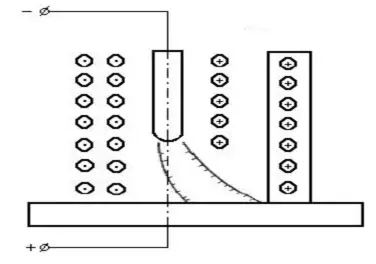

(1) Improper connection position causes magnetic blow.

The welding current generates a magnetic field in space. When the electrode is perpendicular to the workpiece, the magnetic field density on the left side of the arc is greater than that on the right side.

The uneven distribution of the magnetic field causes the denser side to exert thrust on the arc, making it deviate from the axis.

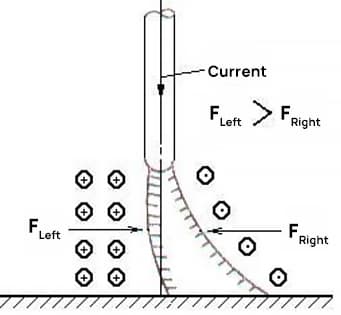

(2) Asymmetric ferromagnetic materials cause magnetic blow.

When welding, placing a steel plate (magnetic conductor) on one side of the arc, due to the much higher magnetic conductivity of ferromagnetic materials than air, most of the magnetic field lines on the ferromagnetic material side form closed curves, reducing the density of magnetic field lines between the arc and the ferromagnetic material, so under the action of electromagnetic force, the arc tends to blow towards the side with the ferromagnetic material.

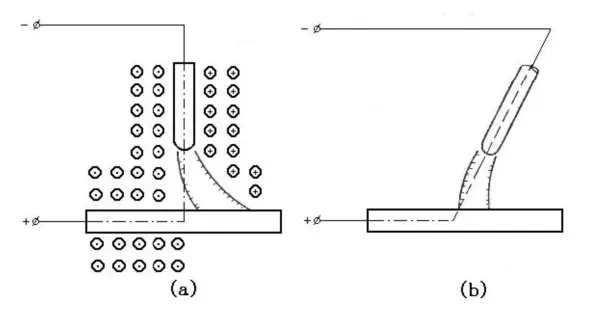

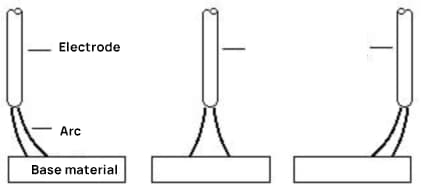

(3) Movement of the arc on the end of the steel plate causes magnetic blow, as shown in the figure below.

This is because when the arc reaches the end of the steel plate, the magnetic flux area changes, causing an increase in the density of spatial magnetic field lines near the edge of the workpiece.

Therefore, under the action of electromagnetic force, a magnetic blow pointing towards the inside of the workpiece is produced.

As shown in the following picture:

(1) Magnetic deflection caused by wire connection position

(2) Magnetic deflection caused by ferromagnetic material near the arc

(3) Magnetic deflection blowing generated when the arc is at the end of the workpiece

During the welding process, due to the interference of the gas flow, the eccentricity of the coating of the electrode and the magnetic force of the magnetic field, the phenomenon of deviation of the arc center from the axis of the electrode occurs.

That is, if some reason destroys the uniformity of the magnetic field distribution and the charge in the arc is unevenly stressed, it will cause the arc to deviate to one side.

In other words, the magnetic deflection blowing of the welding arc caused by the electromagnetic force generated by the welding circuit during DC arc welding is called the welding arc’s magnetic deflection blowing.

Magnetic deflection blowing not only makes the arc burn unstable, increases spatter, and loses protection when the molten droplets fall, but also seriously affects the forming of the weld.

According to the causes of magnetic deflection blowing, the following methods can be used in production and installation to overcome and eliminate the influence of magnetic deflection blowing on welding arc:

(1) Properly change the position of the ground wire on the weldment to make the magnetic field lines around the arc as evenly distributed as possible;

(2) Adjust the electrode inclination angle appropriately during operation, and tilt the electrode towards the direction of deflection blowing;

(3) The use of segmented back welding and short arc welding can also effectively overcome magnetic deflection blowing;

(4) Use AC welding instead of DC welding. When using AC welding, the changing magnetic field produces induced current in the conductor, and the magnetic field produced by the induced current weakens the magnetic field caused by the welding current, thus controlling the magnetic deflection blowing;

(5) Place ferromagnetic materials that generate symmetrical magnetic fields, and try to distribute the ferromagnetic materials around the arc uniformly;

(6) Reduce residual magnetism on the weldment.

The residual magnetism on the weldment is mainly caused by the orderly arrangement of atomic magnetic domains.

In order to disrupt the arrangement of magnetic domains on the weldment and reduce or prevent magnetic deflection blowing, local heating should be applied to the parts with residual magnetism on the weldment at a temperature of 250-300℃.

This method has good demagnetization effect in production and use.

In addition, a magnet can be added to balance the magnetic field at the residual magnetism part of the weldment.

(7) Use demagnetization method. That is, let the weldment produce a magnetic field opposite to the residual magnetism on the weldment to overcome and eliminate the influence of magnetic deflection blowing on the welding arc.

Taking pipeline welding as an example, the application of prevention of magnetic deflection blowing is introduced.

In the welding of pressure pipelines, magnetic deflection blowing is prone to occur in the butt welding process of thick-walled pipes, making it impossible to perform manual tungsten argon arc welding on the root pass.

According to the occurrence of magnetic deflection blowing, magnetic deflection blowing mainly occurs at the joint of thick-walled pipeline, and it occurs at several welds when the pipeline is about to be closed.

Thick-walled pipelines with ferromagnetic materials have residual magnetism during manufacturing and processing.

The longer the pipeline, the more residual magnetism accumulates, which manifests itself at the final closing joint, causing magnetic deflection blowing.

Specific measures: Use the welding cable to wind around both sides of the joint.

When the arc is struck, the welding current generates an induced magnetic field through the cable winding to counteract the residual magnetism and overcome the magnetic deflection blowing.

The effect of the welding can be adjusted by the following two methods:

1) When the welding current is constant, the induced magnetic field strength generated on the weldment can be adjusted by adjusting the number of cable windings to be equal in magnitude and opposite in direction to the residual magnetic field strength;

2) When the number of cable windings is constant, the welding current can be changed within the allowable range to adjust the induced magnetic field strength generated on the weldment to be equal in magnitude and opposite in direction to the residual magnetic field strength, thereby eliminating the residual magnetism at the joint and overcoming the influence of magnetic deflection blowing on the welding arc.

In actual welding environments, the causes of magnetic deflection blowing are not the same due to different welding environments.

Therefore, it is necessary to combine with the actual situation on site to find out the causes of magnetic deflection blowing and deal with them based on the above summary experience to ensure the welding quality in field welding.