Have you ever wondered how laser welding achieves such precision and efficiency? The principle behind this cutting-edge technology involves the careful management of heat transfer. By directing a high-energy laser beam, surfaces are heated and the energy spreads internally, creating seamless welds. In this article, you’ll discover the fascinating process of heat conduction welding and the role of parameters like laser pulse width and power density. Dive in to understand how this method revolutionizes material processing and enhances welding precision.

Laser welding is a highly efficient and precise welding technique that utilizes a high-energy density laser beam as the heat source. This method is a significant aspect of laser material processing technology.

Initially, in the 1970s, laser welding was mainly utilized for welding thin-walled materials and for low-speed welding operations. This process is a type of heat conduction welding, meaning the laser radiation heats the surface of the workpiece, and the heat transfers internally through conduction.

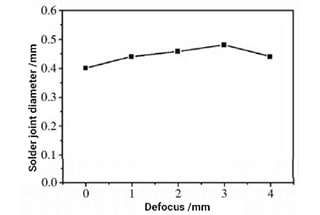

By carefully controlling parameters such as laser pulse width, energy, peak power, and repetition frequency, the workpiece is melted and a specific molten pool is formed.

Due to its unique advantages, laser welding has been successfully applied to the precision welding of micro and small parts.

Laser welding can be performed using either a continuous or pulsed laser beam. The principle of laser welding can be divided into two categories: heat conduction welding and laser deep penetration welding.

When the power density is less than 104 to 105 W/cm2, it is considered heat conduction welding. At this power density, the penetration is shallow and the welding speed is slower.

On the other hand, when the power density exceeds 105 to 107 W/cm2, the metal surface will be concave and form “holes” due to the heating effect, resulting in deep penetration welding. This type of welding is characterized by its fast welding speed and large depth-to-width ratio.

The principle of heat conduction laser welding is:

The surface to be processed is heated by laser radiation, with the heat diffusing internally through heat transfer. The workpiece is then melted to form a specific molten pool by controlling laser parameters such as laser pulse width, energy, peak power, and repetition frequency.

The laser welding machine used mainly for gear welding and metallurgical sheet welding relates to laser deep penetration welding, which typically employs a continuous laser beam to connect materials.

The metallurgical physical process of laser deep penetration welding is similar to that of electron beam welding, where energy conversion occurs through the formation of a “key hole” structure.

Under the high-power density laser irradiation, the material evaporates and forms small holes filled with steam. These holes act like blackbodies, absorbing nearly all the incident beam energy and reaching an equilibrium temperature of about 2500 degrees.

The heat is then transmitted from the outer wall of the high-temperature hole cavity to melt the surrounding metal, while the small hole is filled with high-temperature steam generated by the continuous evaporation of the wall material under light beam irradiation.

In most conventional welding processes and laser conduction welding, energy is deposited on the surface of the workpiece and then transmitted to the interior. However, in laser deep penetration welding, the four walls of the small hole are surrounded by molten metal, which is surrounded by solid materials.

The liquid flow and wall surface tension outside the hole wall are in dynamic equilibrium with the continuous steam pressure inside the hole cavity. The light beam continuously enters the small hole as the material outside flows continuously. With the movement of the light beam, the small hole is in a stable state of flow and moves forward at the speed of the leading beam. The molten metal fills the gap left by the small hole and condenses to form the weld.

All these processes happen at such a fast pace that the welding speed can easily reach several meters per minute.

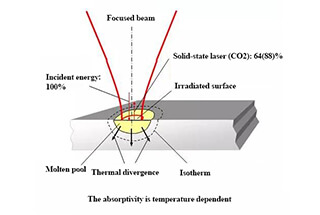

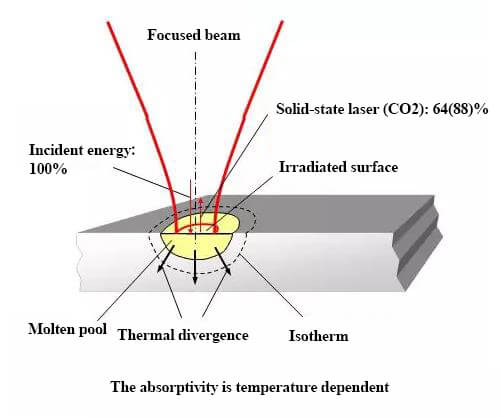

Heating material surface

The required surface heat power is greater than the sum of reflection and heat divergence.

Heat is conducted both on the surface and deeply.

The surface temperature reaches the melting point (TM, for steel it is 1490°C).

Absorptivity varies with temperature: for a semiconductor laser it changes from 38% at 20°C to 36% at 1500°C. For a CO2 laser it changes from 5% at 20°C to 12% at 1500°C, at which point a molten pool begins to form.

Weld seam

The feed movement shapes the weld.

The depth and width of the slit are linked to the power and speed.

Typical welding rate: 1-3 meters per minute.

The weld has a smooth surface and is free of any impurities.

The ratio of depth to width is less than 1.