Have you ever considered how a punch press evolved from manual labor to automated systems that shape metals with precision? This article dives into the development and applications of punch presses, highlighting their history and technological advancements. You’ll discover how these machines transformed metalworking, the various types of punch presses, and their specific uses in manufacturing. By the end, you’ll understand how punch presses contribute to efficient mass production and the intricacies of their operation.

1. Manual press:

2. Manpower press:

3. Power press:

4. Auto punch press:

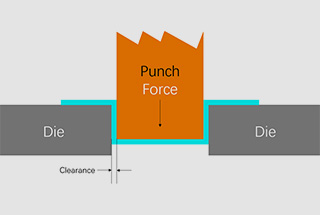

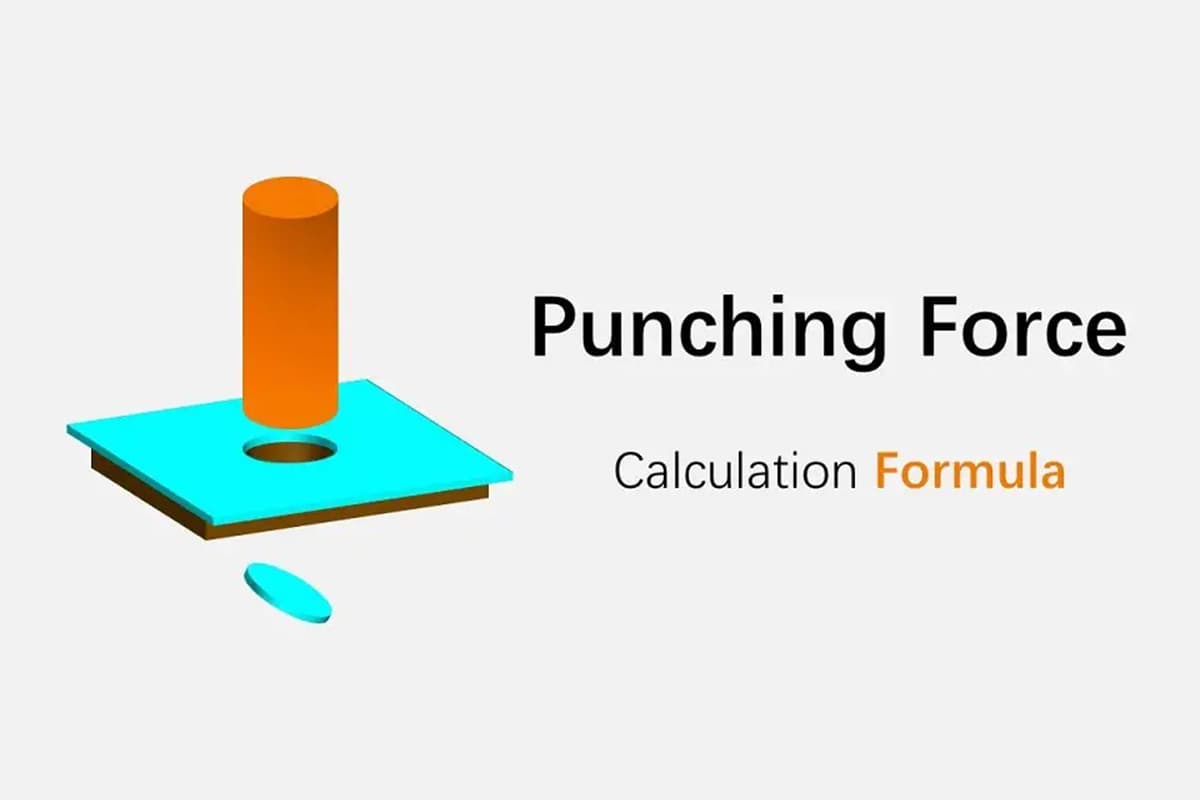

Applications: Used for punching, cutting, drawing, and compression forming of metal materials.

Exclusions: Not suitable for fabrication of fragile materials such as cast iron, wood, glass, and ceramics, or flammable materials such as magnesium alloys.

Features:

I. Basic knowledge of punch press

1.1 brief introduction to press function:

★ The essence of the punch press is translating the circular movement into a straight-line motion.

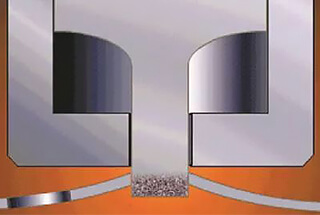

★ Function: Utilizes a transmission structure to generate the appropriate pressure and kinetic energy near the bottom dead center, in combination with a mold, causing the workpiece to undergo plastic deformation and produce the desired final product.

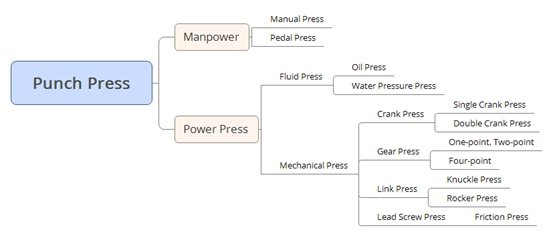

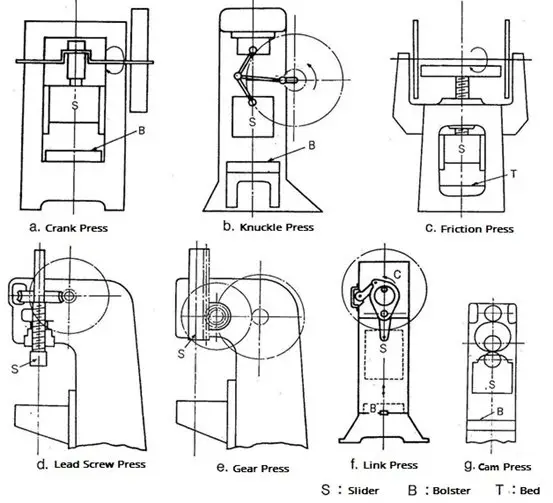

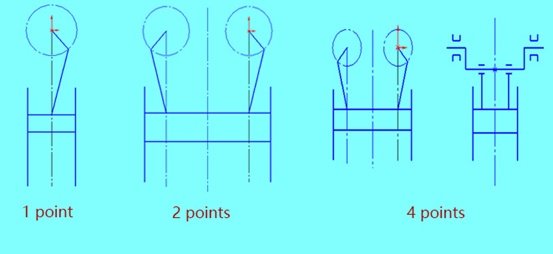

Punch press classification as per the slider movement:

II. Structure

Identification of punch points:

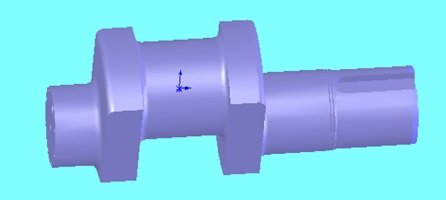

Crankshaft and eccentric gear

Crankshaft:

★ use when stroking < 400

★ low cost

Eccentric gear:

★ use when stroke > 400

★ high cost

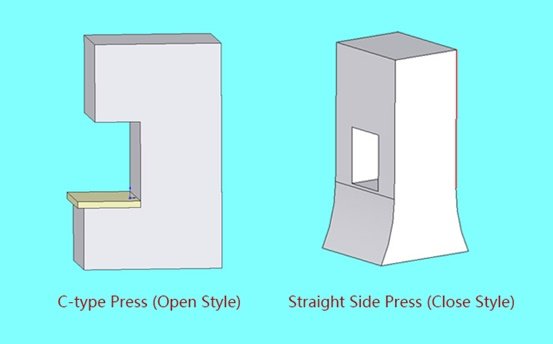

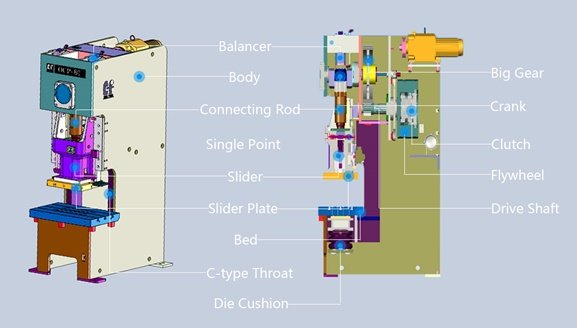

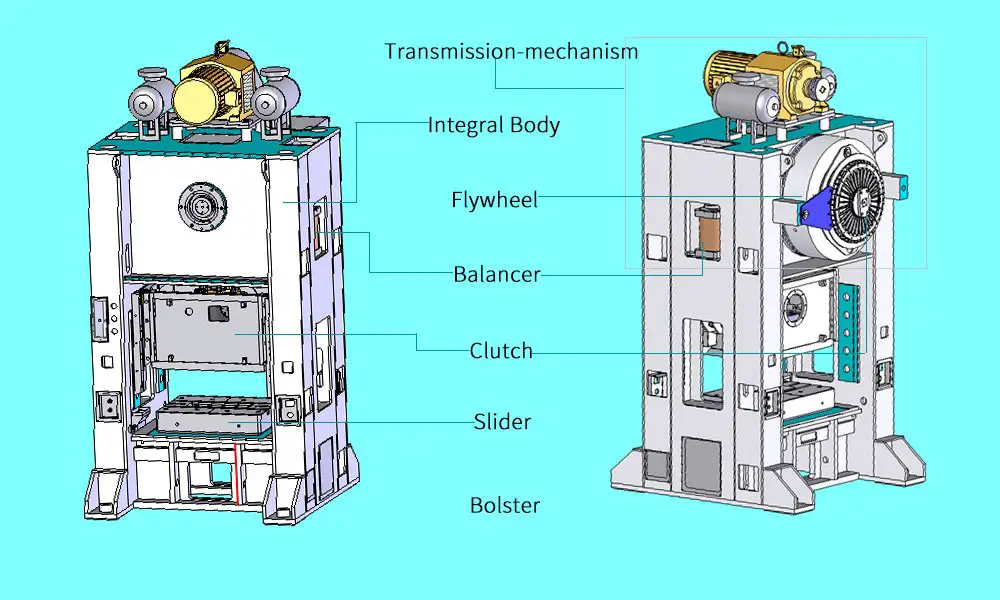

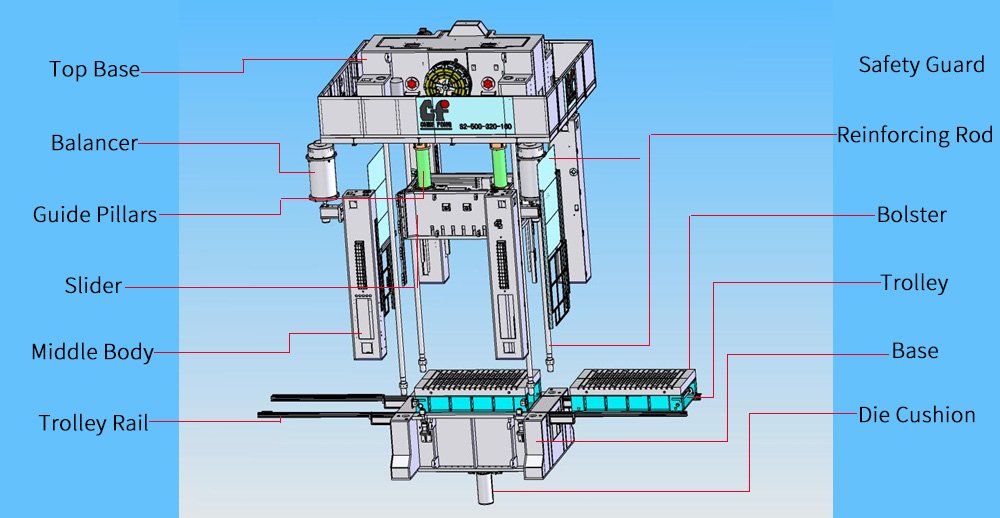

2.1 C-type press structure introduction (crank single point)

C frame press component:

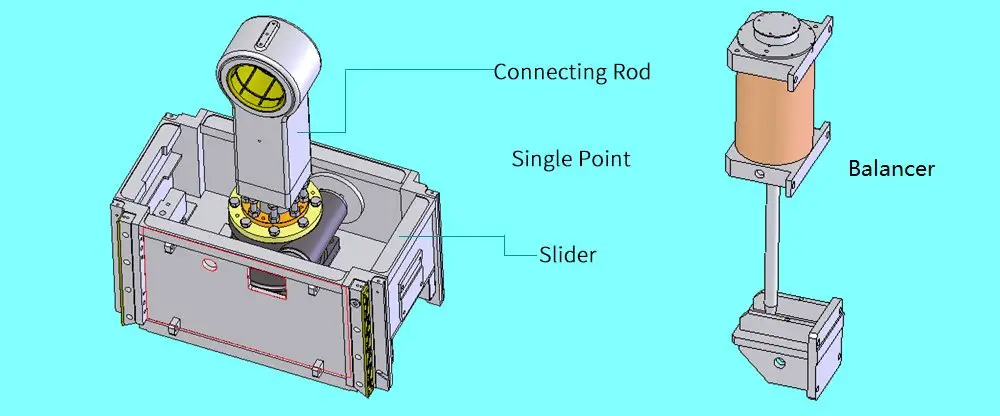

A1: Slider Component

A2: Balancer

A3: Die Cushion

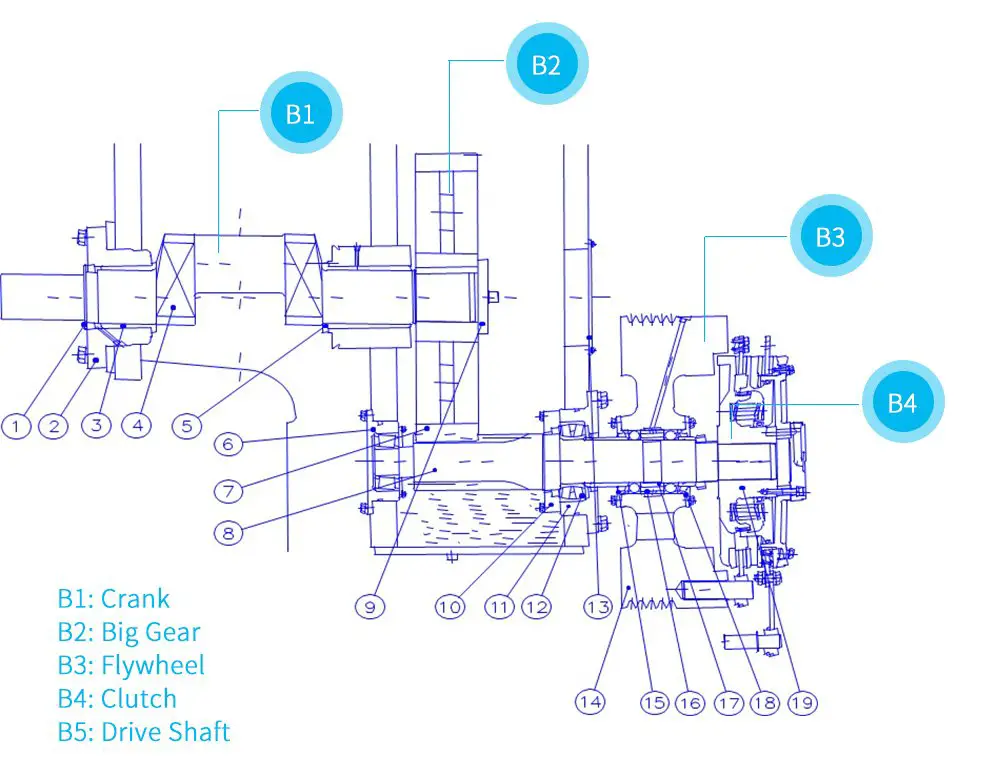

Punch drive structure plan:

2.2 C-frame press (crankshaft double point) structure:

Teach you how to judge the crank punch:

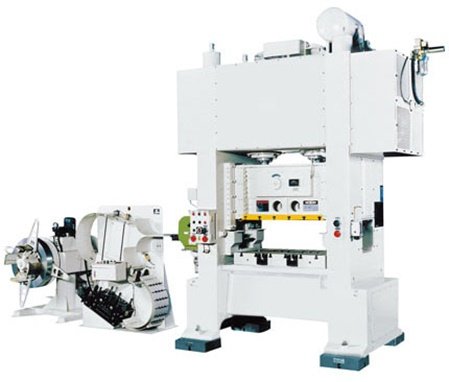

2.3 Closed (crankshaft single point) press structure:

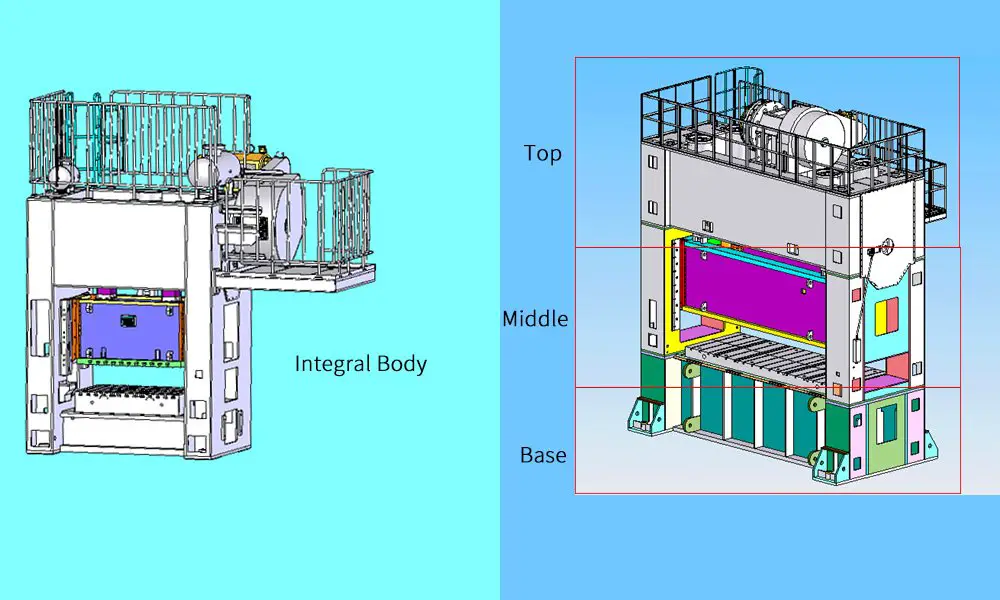

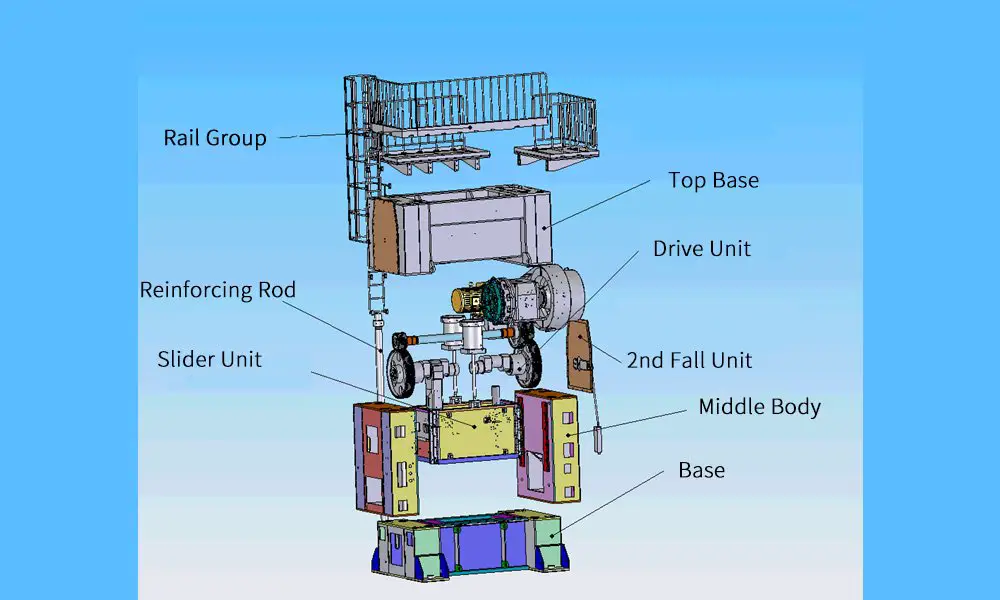

2.4 Closed (crankshaft double point) press structure:

★ Integrated body & three split body

— Applicable table is relatively small, tonnage is relatively small;

— Tablet generally ≤ 2300 * 1250, tonnage ≤ 260T

— Applicable table is relatively big, tonnage is relatively big;

— Tablet generally ≥2500*1400, tonnage ≥300T

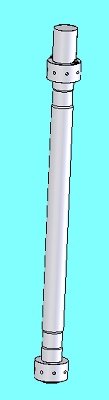

Three split bodies: use 4 reinforcing rod to connect the upper, middle and lower sides to a whole.

Three split body punch press:

2.5 Closed (eccentric gear single point) press structure:

2.6 Closed (eccentric gear double point) press structure:

2.7 High-speed punch press

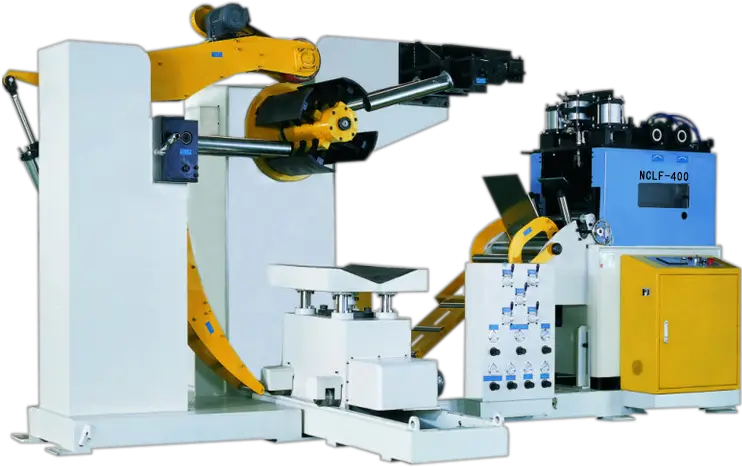

III. Punch press peripheral equipment

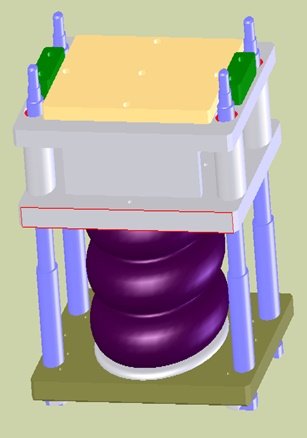

Quick mold changing device: including the upper clamp die, the lower clamp dies, die lifter, die arm, hydraulic power units, etc.

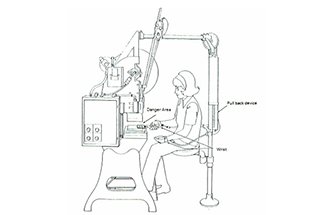

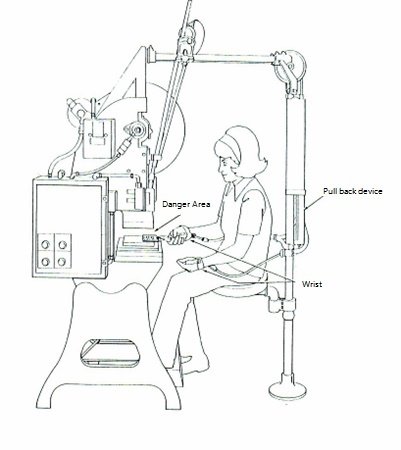

IV. Punch press safety

For Personnel Safety:

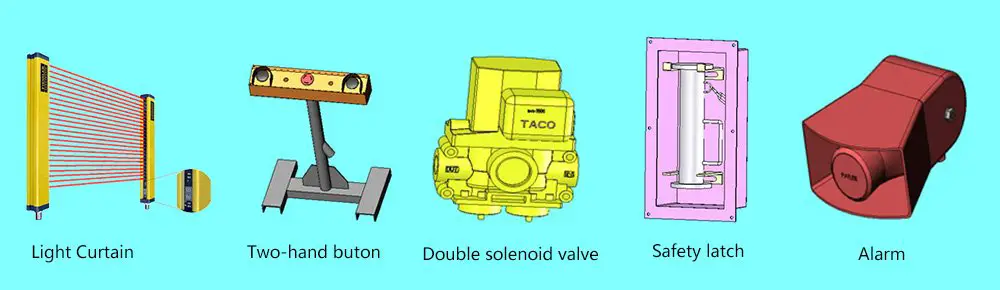

(1) Machine Safety Design: Equipped with safety devices such as a two-hand operation device, emergency stop device, re-start prevention device, double solenoid valve, and chain devices.

(2) Safe Operation: Includes safety fencing, photoelectric safety devices, safety plugs and stops, alarms, and more.

For Machine Safety:

(1) Overload Protection: In the event of exceeding the machine’s capacity, an overload protection device will stop to protect the machine.

(2) Thermal Relay Protection: Prevents damage to the motor due to excessive current.