Have you ever wondered how to ensure a successful metal stamping project? In this blog post, we’ll dive into the critical factors that can make or break your stamping process. As an experienced mechanical engineer, I’ll share insights on calculating stamping forces and selecting optimal punch and die clearances. By the end, you’ll have a solid understanding of how to plan your stamping project for the best results.

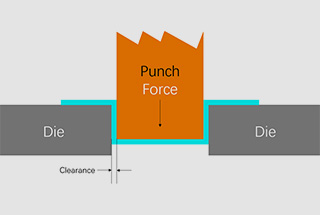

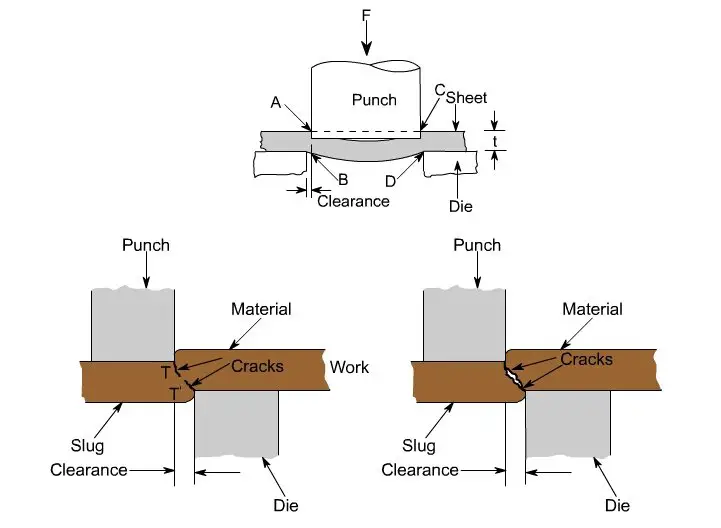

Punch force is the amount of force required to shear a hole in a workpiece using a punch and die setup. It is influenced by several factors including the material properties, thickness of the workpiece, and the geometry of the hole being punched.

Shear strength is a measure of a material’s ability to resist shear forces. It varies with different materials and is typically provided in material specifications. For example, aluminum has a shear strength of about 250 N/mm², while stainless steel ranges from 400 to 700 N/mm². Shear strength can also be estimated from tensile strength, where it is approximately 50-70% of the tensile strength.

The thickness ((t)) of the material being punched directly impacts the required force. Thicker materials require more force to be punched through.

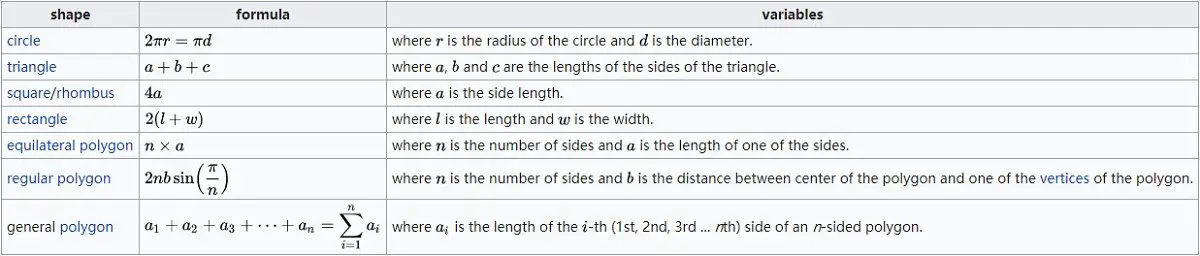

The perimeter ((L)) of the hole, determined by the shape and size of the hole, is crucial in calculating the punching force. The perimeter is the total length of the edge being cut.

When planning a metal stamping project, one of the most critical factors to consider is the stamping force required. Calculating the correct stamping force ensures you select a press with adequate tonnage and design tooling that can withstand the forces involved.

There are several methods for calculating stamping force depending on the specific stamping process and type of force. Here we’ll cover some of the most common formulas and provide a handy stamping force calculator.

Several methods exist for calculating stamping force, and which one to use depends on the specific stamping process and the type of stamping force that needs to be calculated. Here are some common methods for calculating stamping force:

A basic formula breaks down total stamping force into the sum of several parts:

The specific components involved will depend on your particular stamping operation.

For many stamping projects, shearing and punching forces make up the bulk of the stamping force. A common formula for calculating shearing or punching force is:

𝑃 = 𝑘 × 𝑙 × 𝑡 × Г

Where:

An alternative version of this formula is:

P = ltτ

Where:

For small parts stamped with a flat punch, the formula can be simplified to:

F = Ltτ

Where F is shearing force in newtons.

To calculate the force required to punch a round hole, use the diameter of the hole to find the perimeter:

Then apply the simplified formula:

For example, to punch a 3 mm diameter hole in 5 mm thick stainless steel with a shear strength of 400 MPa:

For a square hole, calculate the perimeter based on the side length of the square:

For example, to punch a 4 mm side length square hole in 5 mm thick aluminum with a shear strength of 250 N/mm²:

Using a safety factor ((K)) is essential to account for variables such as tool wear, material property variations, and other uncertainties. A typical safety factor is around 1.3.

Harder materials generally require greater punching forces. The state of the material, such as whether it is annealed or work-hardened, also affects the shear strength and, consequently, the required force.

The design of the punch and die can influence the required force. Beveling the punch can reduce the force but may distort the material. Proper die clearance and maintenance are also critical for efficient punching operations.

By considering these factors and using the appropriate formulas, you can accurately calculate the punching force needed for various metalworking operations, ensuring precision and efficiency in the manufacturing process.

To make calculating stamping force easier, here is an online calculator. Simply input your material, thickness, and part perimeter to get the required force in metric tons.

P.S: If you want to calculate hydraulic press tonnage, you can use our hydraulic press tonnage calculator.

Related calculator: V & U-shaped Bend Force Calculator

If you need to punch round, square, or any other type of hole through a given metal thickness, you’ll need to determine the punching force required to accomplish this task.

To calculate the required press tonnage, you can use the following punching force calculation formula, which is also applicable for blanking force calculation.

Press Tonnage (KN) = Perimeter (mm) * Plate Thickness (mm) * Shear Strength (kn / mm2)

Converted into metric tons: dividing the result of KN by 9.81

Common materials’ shear strength are as follows: unit: KN/mm2

| Aluminum | Brass | Low Carbon Steel | Stainless Steel |

| 0.1724 | 0.2413 | 0.3447 | 0.5171 |

For various shear strength table, you can check out the following post:

e.g: If punching one square hole in the 3mm thickness low-carbon steel plate, side length 20mm, you will get:

Punch Force (KN) = 80 x 3 x 0.3447 = 82.728 KN Convert into tonnage: 82.728 KN ÷ 9.81 = 8.43 Ton

For further information about shearing strength, including how to calculate it, you can refer to the Wikipedia article.

The formula mentioned can also be applied as the cutting force formula in press tooling or as the formula for determining the force required to punch a hole.

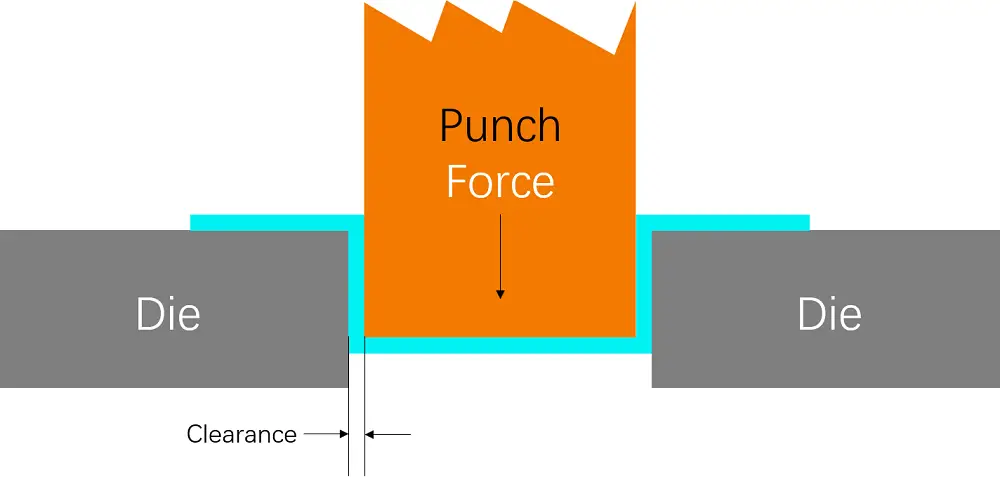

The clearance between the punch and dies is a critical factor in the punching process, and it is represented by the total difference.

For instance, suppose you are using an ø12 upper die and an ø12.25 lower die. In that case, the optimal clearance should be 0.25mm.

If the clearance is not proper, it can reduce the die’s service life, cause burrs, and lead to secondary cutting. An irregular opening can also increase the demounting force.

Moreover, the die clearance depends on the material and thickness, and for carbon steel plates, it is recommended to use a value between 12-18% of the thickness.

See also:

If there are no special requirements for the CNC punch, you can refer to the following table for selecting the die clearance.

In addition to stamping force, punch and die clearance is another key factor in successful stamping. Proper clearance, usually expressed as a percentage of material thickness, is critical to tool life, part quality and preventing secondary cutting.

Refer to this table for general clearance guidelines:

| Thickness | Mild Steel | Aluminum | Stainless Steel |

| 0.8-1.6 | 0.15-0.2 | 0.15-0.2 | 0.15-0.3 |

| 1.6-2.3 | 0.2-0.3 | 0.2-0.3 | 0.3-0.4 |

| 2.3-3.2 | 0.3-0.4 | 0.3-0.4 | 0.4-0.6 |

| 3.2-4.5 | 0.4-0.6 | 0.4-0.5 | 0.6-1.0 |

| 4.5-6.0 | 0.6-0.9 | 0.5-0.7 | / |

Calculating the punching force required for different materials involves understanding their unique properties, particularly shear strength. This chapter provides detailed calculations for various materials, taking into account their specific characteristics and common uses.

Shear strength is a measure of how much stress a material can withstand before failing in shear. It is a critical factor in punching force calculations because it directly affects the amount of force needed to punch through the material.

Aluminum is lightweight and has moderate shear strength, making it relatively easy to punch. It is commonly used in aerospace, automotive, and packaging industries.

Brass offers good machinability and corrosion resistance, with higher shear strength than aluminum. It is often used in plumbing, electrical applications, and musical instruments.

Carbon steel is commonly used in metalworking due to its high strength and durability. It is prevalent in construction, automotive, and manufacturing industries.

Stainless steel is known for its high corrosion resistance and strength, requiring significant force to punch. It is used in kitchenware, medical devices, and construction.

Mild steel, with its moderate strength and good ductility, is widely used in various industrial applications, including construction and machinery.

Copper is highly conductive and malleable, making it easier to punch than many other metals. It is extensively used in electrical wiring and plumbing.

Titanium offers an excellent strength-to-weight ratio and corrosion resistance, requiring substantial force to punch. It is commonly used in aerospace, medical implants, and military applications.

For non-circular holes, such as squares or rectangles, calculate the perimeter by summing the lengths of all edges.

By considering the specific properties of different materials and using the appropriate formulas, you can accurately calculate the punching force required for various metalworking applications.

Below are answers to some frequently asked questions:

The punching force in metalworking is influenced by several critical factors, which include material properties, geometric parameters, tool design and clearance, safety and coefficient factors, and additional forces.

Material properties play a significant role, with the shear strength of the material being particularly crucial. Shear strength is often derived from the material’s ultimate tensile strength (UTS), with specific percentages applied depending on the material type, such as 70-80% for mild steel, 50% for aluminum, and around 90% for stainless steel. Additionally, the tensile and yield strengths of the material must be considered as they can vary within the same material type.

Geometric parameters are also vital, particularly the perimeter length of the hole and the thickness of the material. The punching force is directly proportional to the total length of the perimeters involved and the material’s thickness, with thicker materials requiring higher forces.

The design of the punch and die, including the clearance between them, significantly affects the required punching force. Proper clearance ensures efficient punching and minimizes excessive force on the punch tip, reducing wear and breakage. Conversely, inadequate clearance can lead to poor edge quality and increased tool wear. The shape and size of the hole and the radius in the corners of the die also influence the punching force.

A safety factor is often included in calculations to account for variables such as tool wear, fluctuations in the gap between the punch and die, and lubrication conditions. This factor ensures that the calculated force is sufficient to handle these variations.

The basic formula for calculating the punching force (F) is

where ( K ) is the safety factor, ( L ) is the perimeter length, ( t ) is the material thickness, and ( τ ) is the material’s shear strength. Alternatively, tensile strength (( σb )) can be used when shear strength data is unavailable:

Additional forces such as unloading force, pushing force, and ejecting force must also be considered. These forces depend on the mechanical properties of the material, the shape and size of the workpiece, the clearance between molds, and lubrication conditions.

Lastly, the hardness and compressive strength of the punch material are important for tool longevity. The punch-point load should remain below 60% of the compressive strength of the punch material to prevent failure. Heat treatment and surface treatments like nitriding or PVD coating can enhance the tool’s hardness and wear resistance, although these treatments are not always necessary for maintaining tool life.

By taking these factors into account, engineers and metalworkers can accurately determine the punching force required, select suitable machinery, and design molds for efficient and reliable punching operations.

The type of material being punched greatly influences the punching force required due to variations in shear strength, tensile strength, and material properties. Shear strength is a primary factor, varying significantly across different materials. For instance, mild steel typically has a shear strength of 70-80% of its ultimate tensile strength (UTS), while aluminum’s shear strength is about 50% of its UTS. Stainless steel and copper alloys can have shear strengths ranging from 50% to as high as 90% of their UTS, depending on the specific alloy.

When precise shear strength data is unavailable, engineers may use the UTS as a proxy, though this often results in an overestimation of the required punching force. Additionally, the clearance between the punch and die, influenced by the material type, affects the punching force. Tighter clearances can increase the resistance and wear on the punch, while optimal clearances, tailored to the material’s thickness and tensile strength, help in reducing these issues.

The punching force (Fp) can be calculated using the formula:

where ( L ) is the punch-tip profile length, ( t ) is the material thickness, and ( st ) is the material’s shear strength.

The material type also affects punch tip pressure (Ft), calculated for a standard shoulder punch as:

Tool material selection is influenced by the material being punched, with different tool steels offering varying degrees of wear resistance, impact resistance, and toughness. Choosing the right tool material based on the punched material and processing conditions is crucial for preventing punch tip breakage and optimizing tool life. In summary, the material type impacts shear strength, tensile strength, and required clearances, all of which are essential for accurately calculating and managing the punching force.

Yes, a punching force calculator can be used for different materials, but it requires adjusting several key parameters specific to each material. The primary factor in the calculation is the material’s shear strength, which varies widely among different materials. For instance, mild steel, stainless steel, aluminum, and copper alloys all have different shear strengths, typically expressed as a percentage of their ultimate tensile strength (UTS).

The general formula for calculating the punching force is:

where ( F ) is the punching force, ( L ) is the perimeter of the hole to be punched, ( t ) is the material thickness, and ( \tau ) is the shear strength of the material.

To make the calculation easier, some calculators use material coefficients (K), which account for the specific characteristics of different materials. For example, the coefficient for mild steel might be 1, for stainless steel 1.5, and for aluminum, copper, and brass around 0.6.

Consider an example where you need to punch a 3 mm diameter hole in stainless steel with a shear strength of 400 MPa and a thickness of 5 mm. First, calculate the perimeter of the hole:

(π x3= 9.42)mm

Then, apply the formula:

While these calculations provide a useful estimate, real-world results can be influenced by factors such as punch sharpness, lubrication, and the condition of the punching machine. Therefore, it’s important to use the calculated values as a guide and complement them with practical experience and professional judgment, consulting an engineer if necessary.

The formula for calculating punching force in metalworking is derived from the relationship between the shear strength of the material, the thickness of the material, and the perimeter of the area to be punched. The primary formula is:

where:

If the shear strength is unknown, it can be approximated using the tensile strength ( T ) of the material, assuming that the shear strength is typically 50-70% of the tensile strength. In such cases, the formula becomes:

For example, to calculate the punching force for a rectangular hole measuring 1/2 x 5/8 inches in a sheet of steel with a thickness of 3/16 inches and a shear strength of 60,000 PSI:

Calculate the perimeter of the hole: P=2x(0.5+0.625)=2.25 inches

Calculate the punching force: F= P x t x S = 2.25 x 0.1875 x 60,000 = 25,312.5 1bs

Additional factors such as material type, clearance between punch and die, and lubrication can influence the actual punching force required. These can be adjusted using empirical formulas and specific coefficients for different materials and conditions.