Have you ever wondered how industrial machines achieve precision cutting of thick steel plates? This article delves into the fascinating world of guillotine shears, exploring their purpose and unique characteristics. Discover how these machines handle materials of varying strengths and sizes, and learn about the innovative technologies that enhance their efficiency and accuracy. Whether you’re in manufacturing or simply curious, this guide offers valuable insights into the mechanics behind these powerful tools.

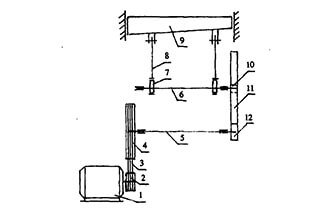

The machine is suitable for shearing a thickness of 1-8mm (with a tensile strength of the material to be sheared ≤ 450MPa) and a width of ≤3050mm steel plate.

If the strength of the sheared material is high, the thickness of the material to be sheared should be reduced accordingly, and a blade made of better material should be selected.

The machine is widely used in machinery manufacturing, automobile, shipbuilding, container manufacturing, metal structures, boiler containers, household appliances, and light industry.