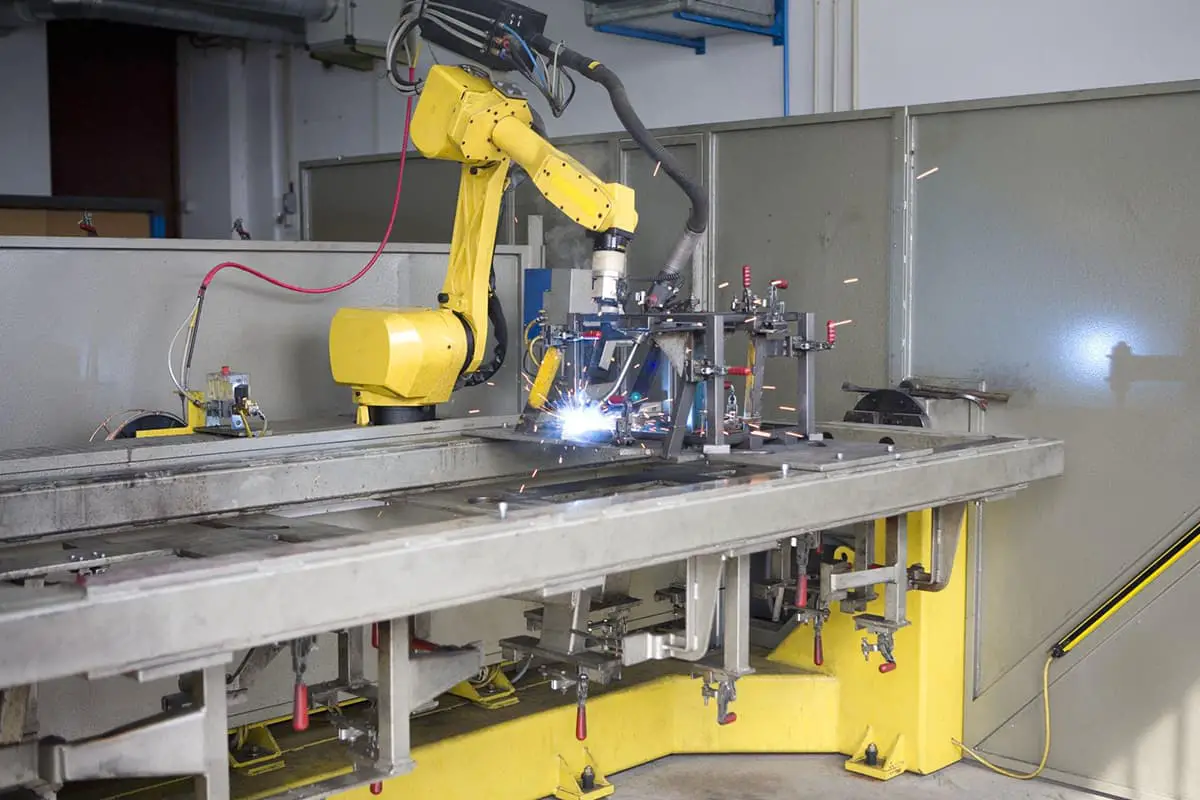

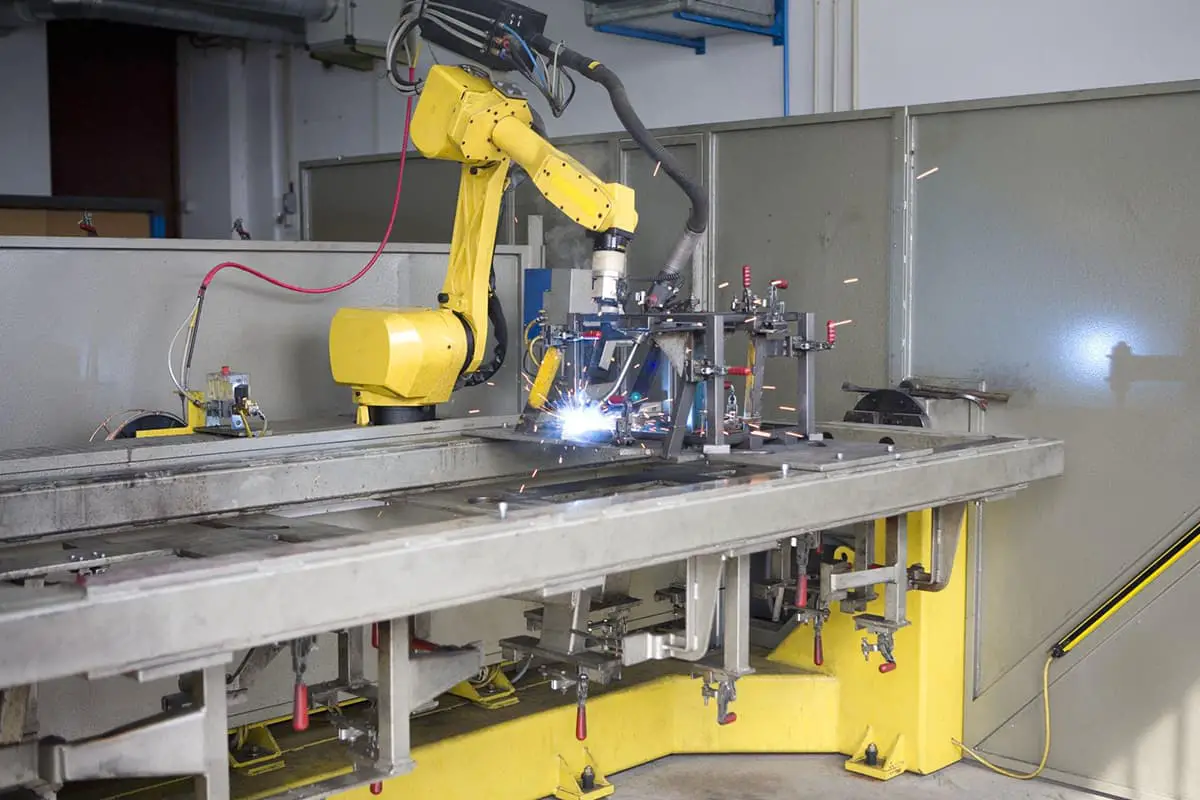

I. Inspection Content for the Welding Robot Body II. Inspection Content for the Welding Robot Control Box III. Inspection Content for the External Axis and Welding Clamp of the Welding Robot IV. Inspection Content for the Intelligent Welding Machine (Automated Welding Equipment) Recommended for you: Laser Cutting Parameters: Thickness, Speed, Gas, Focus, Pressure, Nozzle Aluminum […]