Ever wondered how to keep your CNC press brake in top condition? Maintaining your machine involves more than just occasional cleaning; it’s about ensuring every part, from the hydraulic system to electrical components, operates smoothly. This guide will walk you through essential maintenance steps, helping you avoid costly downtime and extend your machine’s lifespan. Expect to learn practical tips and detailed procedures for keeping your CNC press brake efficient and reliable. Dive in to discover how proper upkeep can make a significant difference in your workshop’s productivity.

Lubrication part:

Check the lubrication of guide rail, bearing, screw, chain and all moving and transmission parts to ensure that they are clean, rust free and adequately lubricated (replace the lubricating oil if necessary).

Fill lubricating oil according to the specified brand, check and dredge the lubricating nozzle and pipeline to ensure their normal operation.

Mechanical part:

Check whether the transmission parts operate normally and wear, and the bolt fastening of key parts.

Hydraulic part:

Clean or replace the filter, dredge the hydraulic pipeline, clean the oil tank, check the state of the oil, filter or replace the appropriate hydraulic oil if necessary, check the hydraulic pipeline, tighten the pipe joint to prevent oil leakage.

Electrical part:

(Turn off the power supply) clean the electrical cabinet, wipe the motor surface, tidy the wires and trunking in the cabinet, ensure that they are neat and beautiful, there are no sundries in the cabinet, and remove the dust in the cabinet.

Check the working status of the exhaust fan and motor fan to ensure their good operation.

Replace damaged switches, buttons, indicator lights and instruments, and tighten the main circuit terminal of electrical appliances above 5kW in the electrical cabinet.

Machine surface:

Scrub the external surface of the machine, such as guide rail, column, protective cover, etc.

Safety devices:

Various safety devices of the equipment are effective without missing, such as photoelectric protection switch, emergency stop button, etc.

Press brake maintenance table

▲Spot check ■Cleaning ●Supplement ★Replace

| Position | No. | Item | Recommended cycle | ||||

| Daily | Weekly | Monthly | Quartely | Yearly | |||

| Lubrication part | 1 | Check the lubrication of ram guide rail, chain and lead screw | ▲ | ■ | Quarterly | ||

| Mechanical part | 1 | Check the looseness of bolts (e.g. hydraulic valves, oil circuit pipe joints, motors / pumps, etc.) | ▲ | ||||

| 2 | Check the cleanliness of the guide rail and lead screw for pulling, grinding and bumping | ▲ | |||||

| 3 | Check whether the geometric accuracy of the equipment meets the requirements | ▲ | |||||

| Hydraulic part | 1 | Clean the hydraulic station | ■ | ||||

| 2 | Check the oil level of the hydraulic oil tank and replenish it if necessary | ▲ | ● | ||||

| 3 | Check whether each pressure value of the hydraulic unit is normal | ▲ | |||||

| 4 | Check the temperature rise of hydraulic oil tank or hydraulic oil cooling system | ▲ | |||||

| 5 | Check and clean various filters and replace them if necessary | ▲■ | |||||

| 6 | Check the cleanliness of hydraulic oil, filter or replace appropriate hydraulic oil if necessary | ▲● | ★ | ||||

| 7 | Check whether the hydraulic pipeline is unobstructed, free of damage and leakage | ▲ | |||||

| Electric part | 1 | Check whether the cooling fan of the electrical cabinet works well | ▲ | ||||

| 2 | Clean the dust screen of the electrical cabinet | ■ | |||||

| 3 | Clean the interior of the electrical cabinet, and there shall be no sundries and dust in the cabinet | ■ | |||||

| 4 | Tighten the main circuit terminal of electrical appliances above 5kW in the electrical cabinet | ▲ | |||||

| 5 | Check the temperature rise of each motor and whether the motor fan works well | ▲ | |||||

| 6 | Clean each heat sink of the motor to ensure that there is no scale | ■ | |||||

| 7 | Check all emergency stop switches, buttons and limiters | ▲ | ▲ | ||||

| Cooling part | 1 | Check whether the oil cooling device works normally | ▲ | ||||

| Machine cleaning | 1 | Clean the external surface of the equipment | ■ | ||||

| 2 | Clean the surrounding environment of the equipment to ensure that there are no iron filings and sundries | ■ | |||||

| Safety device | 1 | Check whether various safety devices on the equipment are effective without missing. For example: photoelectric protection switch, emergency stop button, etc | ▲ | ||||

Hydraulic oil

1) Filling method of hydraulic oil

2) The following hydraulic oils are recommended for press brake

| Manufacturer | Hydraulic oil |

| CALTEX | 46# |

| ESSO | NUTO H46 |

| SHELL | TELLUS 46 |

| GULF | HARMONY 46 AW |

| BP | HLP46 |

| TBXACO | RANDO OIL 46 |

| MOBIL OIL | MOBIL DTE 25 |

| TOTAL | AZOLLA ZS46 |

Note: do not mix hydraulic oils of different brands.

3) Some precautions

The oil level must be checked every quarter.

When the ram is at the top dead center position, the oil level can be seen by observing the scale line of liquid level and liquid temperature agent.

If necessary, fill hydraulic oil through the air filter at the oil tank filler.

When the ram is at the top dead center position, the oil level must reach the upper scribed line of the liquid temperature agent (visible from the rear of the oil tank).

After working for 200 hours, the filter element must be cleaned and checked every 6 months or 1000 working hours.

The oil temperature in the oil tank works within the range of 10 ℃ ~ 60 ℃. If it exceeds this range, temperature rise or drop measures shall be taken.

The hydraulic oil must be replaced every 2 years or 4000 working hours, and the first time should be after 2000 working hours of machine operation. 500 working hours for the first time change and 2000 working hours for the future use will be a good option.

Oil filter

Regularly clean the oil filter in the system with solvent (gasoline, trichloroethylene, etc.).

The CNC press brake shall be cleaned for the first time one month after commissioning, and then regularly every two months.

Air filter

The air filter is installed on the oil tank cover.

It shall be cleaned for the first time two months after the commissioning of the machine.

After washing in solvent (gasoline, trichloroethylene, etc.), it shall be cleaned regularly every four months.

In case of leakage, tighten the pipe joint. If this is not helpful, replace the joint.

Sometimes, the high-pressure oil pipe in the hydraulic oil circuit must be replaced.

When installing the ferrule type pipe joint on the high-pressure pipe, the following provisions must be observed:

If the valve block leaks, please replace the corresponding O-ring or combined seal ring in time.

If the oil cylinder leaks, please replace the sealing ring of the oil cylinder in time.

Regularly check the fasteners of all mechanical parts for looseness and lubrication and wear of sliding block guide rail.

If any abnormality is found, it must be corrected in time before it can be used again.

Good lubrication is an important condition to ensure the normal operation and prolong the service life of the press brake.

The machine should be lubricated weekly (or every 40 working hours). No. 3 calcium base grease is selected and injected into each lubrication point with a grease gun.

Even if there is no lubrication point on the sliding surface of exposed parts and rolling bearings, it should also be lubricated once a week.

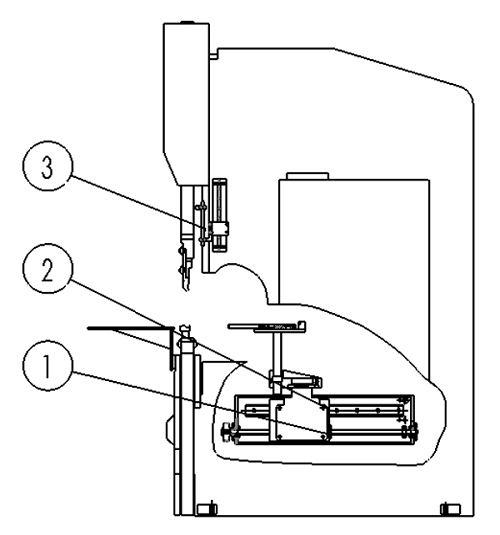

The location and name of each lubrication point are shown in the figure below:

| Lubrication point | Name | Oil quantity | Refueling clearance time | Type and brand of lubricating oil |

| 1 | Left and right lead screws | Middle | 40 hours | No. 3 calcium base grease |

| 2 | Left and right guide rails | Middle | 40 hours | No. 3 calcium base grease |

| 3 | Ram left and right | Middle | 40 hours | No. 3 calcium base grease |

The adjustment of the main relief valve is very important for the operation of the machine. The normal setting value is equal to the maximum allowable pressure.

When operating or overhauling the press brake, please follow the following specifications to ensure safety.

1. When energizing the machine, confirm the safety of the surrounding environment.

2. Stop the machine and cut off the power supply before replacing components, checking and repairing.

3. Do not wear loose clothes, gloves and ties to operate the machine.

4. When operating the machine, the electric cabinet door must be closed, and the external power supply must be cut off during maintenance in the electric cabinet.

5. At the beginning of the operation, it is necessary to check whether there are obstacles within the movement range of each axis.

6. Do not unplug electrical components, cable plugs and wiring when the machine is powered on and operating.

7. In order to ensure safety, the machine must operate in a bright, clean and orderly environment.

8. When entering the dangerous area of the machine, make sure whether the emergency stop button on the operation panel is pressed.