Ever faced a misalignment while repairing threads on a CNC lathe? This article addresses common challenges like tool damage and misaligned threading, offering practical solutions to ensure precision. You’ll discover techniques for realigning tools, adjusting programs, and preventing errors in both small and large batch repairs. Dive in to learn how to maintain thread integrity and improve your CNC lathe operations.

During the process of thread cutting on a CNC lathe, the following issues often arise:

(1) The threading tool gets damaged in the middle of the process.

(2) There is a need to replace the threading tool for high-speed precision threading.

(3) After removing and measuring the thread, it is found that the depth is insufficient. We often feel helpless when encountering these problems because after changing the tool or re-clamping the workpiece, it is difficult to align the threading tool with the original spiral groove, and the starting position cannot be accurately located, leading to thread misalignment.

To solve these problems, we need to first understand the principle of thread cutting on a CNC lathe. To accomplish thread cutting, it is necessary to accurately ensure that for every revolution of the workpiece, the tool advances by one lead.

To achieve this, a spindle encoder is set up on the CNC lathe. Using its synchronous pulse as the control signal for the tool’s entry and exit points, a corresponding relationship is established between the number of pulses of the feed servo motor and the speed of the spindle.

However, since there is no direct mechanical connection between the rotation of the spindle and the feed movement on a CNC lathe, it is not easy to achieve the cutting of the tool tip along the original spiral groove after reinstallation of the tool or the workpiece.

Currently, most enterprises use a single clamping tool for thread cutting on CNC lathes. Both rough and fine cuts are made with the same tool at the same speed. If the tool breaks in the middle of the process, the tool rod is not removed, and the blade is directly replaced to prevent thread misalignment.

However, if separate tools are used for rough and fine cuts or if the workpiece is re-clamped, this can lead to thread misalignment.

If the tool gets damaged during thread cutting or if there is a need to replace it with a precision threading tool, the new tool can be installed and simply realigned. During realignment, it is relatively easy to adjust in the X direction.

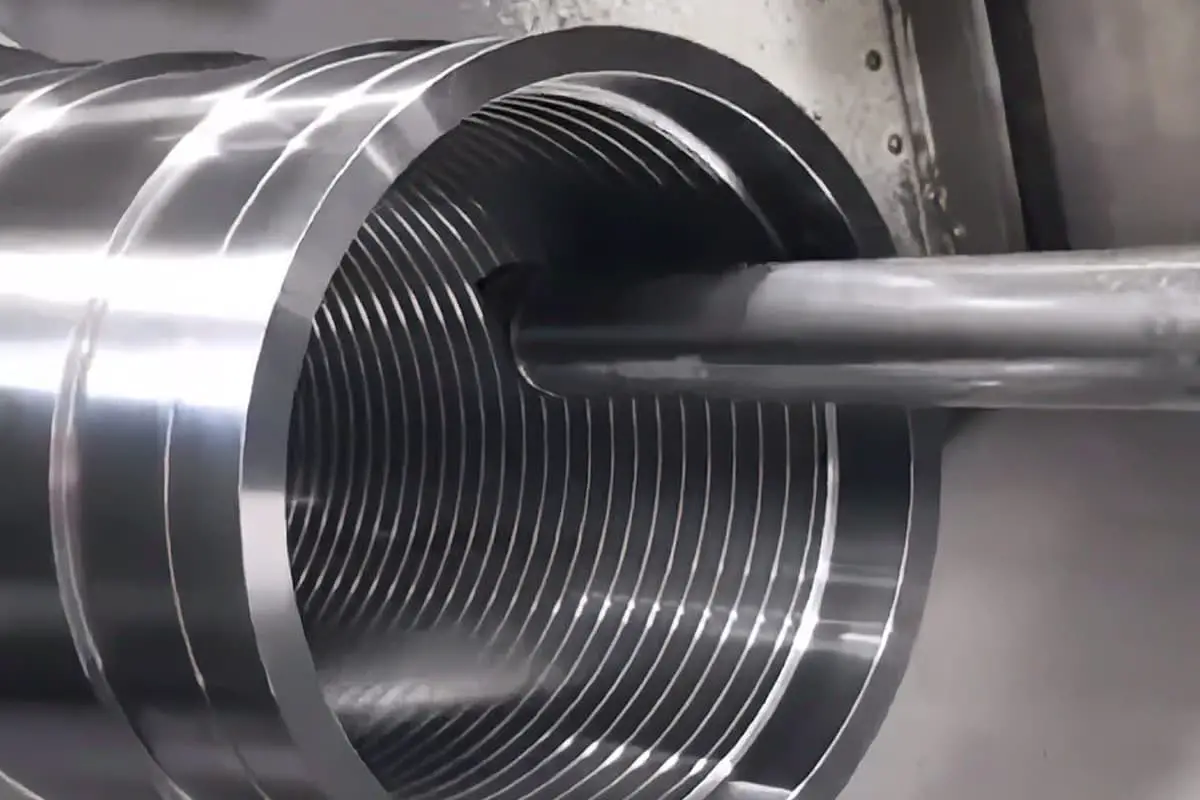

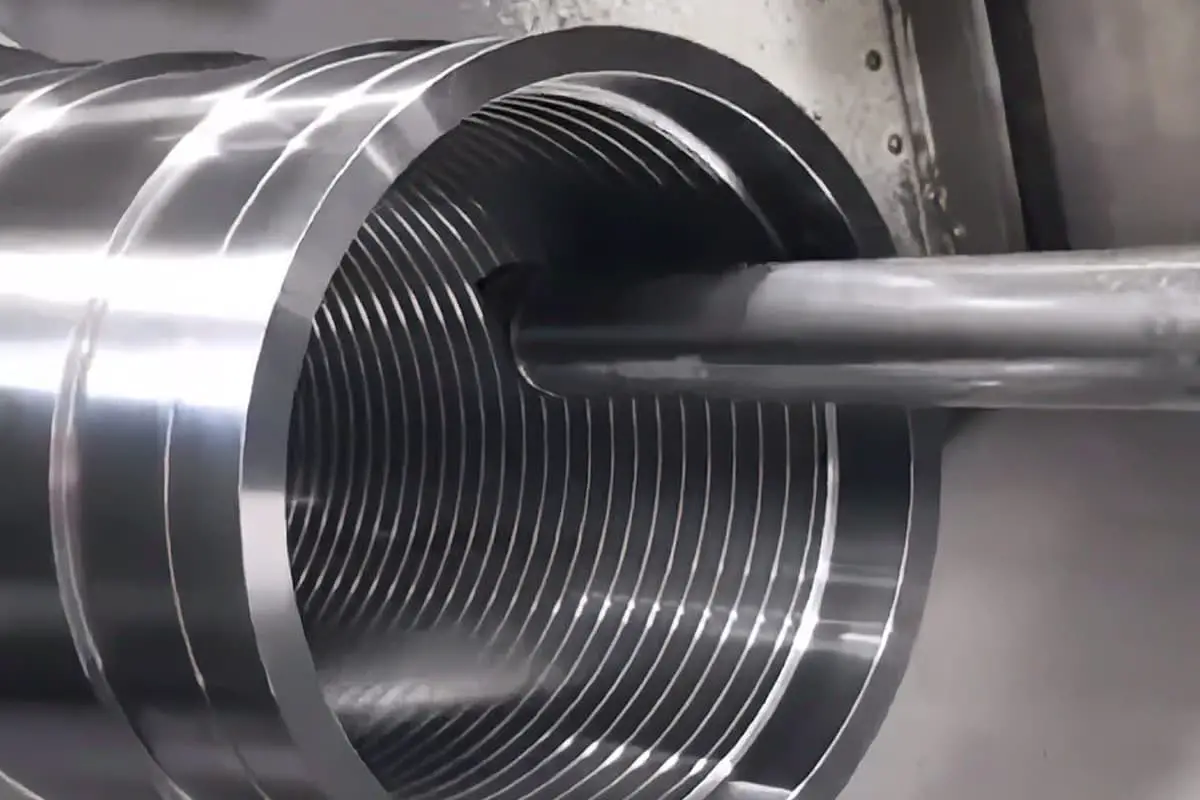

The key lies in aligning in the Z direction. Many people move the tool tip to the end face of the workpiece by feeling, as shown in Figure 1.

This method can lead to significant alignment errors, which may be acceptable for rough cuts, but not for precision cuts.

Here, I introduce a method where you can utilize an existing angle template or a self-made one, as shown in Figure 2. The distance L in the figure can be measured accurately.

During the tool setting process, as shown in Figure 3, the template is placed on the end face of the workpiece. The tool is then moved to the inner corner of the template. The Z-axis tool offset value L is then input into the system. This method of tool setting is highly accurate and is suitable for precision tool setting.

Single or small batch thread repair

If the thread part is unloaded after turning and it is found that the depth of the thread is insufficient, re-clamping is required for repair. This situation is rather troublesome. The first issue to solve is the runout problem after reassembly of the part.

An open sleeve can be made to eliminate the error of runout; most people are likely to be aware of this method, so I won’t elaborate further. The remaining issue is to ensure the tool follows the original spiral groove during cutting to prevent thread mishaps.

This issue is easily solved on ordinary lathes, but it’s more challenging on CNC lathes. The method many people use is shown in Figure 4.

After setting the tool, ensure it doesn’t touch the part, and run the unprocessed thread program at a slow speed.

Measure the distance L from the tool tip to the spiral groove, and then modify the starting position of the thread cutting in the repair program. Shift it from the original point A by a distance L to point B. Repeat the above process and adjust the distance L. Continue this process until the tool tip cuts into the thread groove.

This method requires constant adjustments of the distance L and is time-consuming. In fact, we can slightly modify the original program to solve this problem. Just change the thread length in the program to around 2mm.

After the workpiece is clamped and the tool is set, call up the program. Turn a very shallow thread, and find the starting position of the thread on the end face as shown in Figure 5.

Assuming the starting position of the newly turned thread is at point 2, and the original thread starts at point 1. Draw a line AB at point 2 on the chuck, then loosen the chuck jaws. Rotate the part from point 1 to point 2 along the mark line AB. If the workpiece shifts axially during rotation, the thread tool must be reset in the z direction.

Clamp the workpiece and change the thread length in the program back to its original value. Run the program once to perform a trial cut and check for errors. Adjust the starting position of the thread cutting based on the error.

The thread cut from point 2 is very short and can be removed through chamfering. This repair method is faster and more accurate than the previous one, with the key step being accurately rotating the part from point 1 to point 2.

If a small batch of threaded parts need repair, we can use the original program to make a new thread, find the starting position of the thread, draw a line on the chuck as a mark, and use the above method to repair.

Large batch thread repair

If a large batch of threaded parts need repair, a fast, convenient, and accurate method is needed. I have summarized a method in practice for discussion.