How can you ensure defect-free welds in aluminum alloys? This article dives into three expert tips to minimize porosity in laser welding aluminum. By exploring methods like surface treatment, optimizing welding parameters, and choosing the right shielding gas, you’ll learn practical techniques to enhance weld quality and integrity. Discover how to tackle the challenges of welding aluminum and achieve stronger, more reliable welds.

Aluminum alloys are prized for their low density, high strength, and good corrosion resistance, making them a popular choice in various industries, including automotive, new energy, aerospace, and construction.

Laser welding is now a widely used method in the production of aluminum alloy products, providing several benefits over traditional welding methods. These benefits include higher production efficiency, improved weld quality, and the ability to achieve high-precision welding and automate complex structures.

Laser welding is a technology that utilizes high-intensity laser radiation to melt and recrystallize metal, forming a weld through thermal coupling between the laser and metal.

Based on the thermal mechanism of laser welding, it can be classified into two types: thermal conduction welding and deep penetration welding.

Thermal conduction welding is mainly used for the welding of small or precise parts, such as package welding or micro/nano welding.

Deep penetration welding, on the other hand, is used for welding materials that require complete penetration. During the welding process, the material vaporizes, and a keyhole phenomenon occurs in the molten pool. This method is the most widely used laser welding method currently and is the preferred method for welding aluminum alloys.

Advantages of Seam Laser Welding:

Disadvantages of Seam Laser Welding:

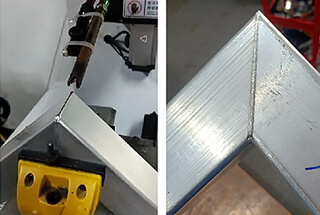

Example Application: Building Decoration Industry – Welding 5 Series Aluminum Alloy Door Frames

The inherent physical properties of aluminum alloys, such as low laser absorption, low boiling point of alloy elements, high thermal conductivity, high thermal expansion coefficient, a relatively wide solidification temperature range, high solidification shrinkage, low viscosity, and high hydrogen absorption in liquid, can make it challenging to produce defect-free laser welds.

One of the most common defects in laser welding of aluminum alloys is porosity, which can damage the integrity of the weld metal, weaken its cross-sectional area, and reduce its mechanical and corrosion resistance properties. To prevent porosity and improve the internal quality of the weld, effective measures must be taken.

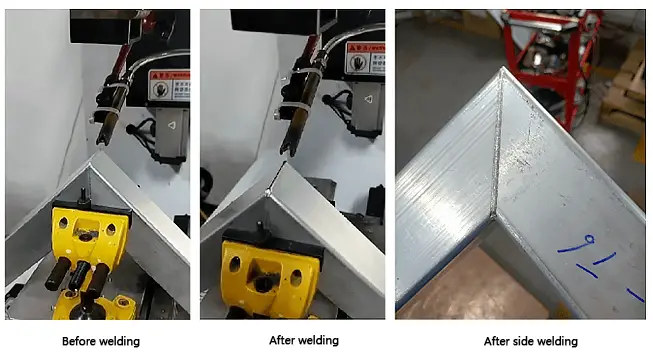

Surface treatment prior to welding is an effective way to control metallurgical pores in laser welding of aluminum alloys. This treatment typically involves either physical mechanical cleaning or chemical cleaning.

Porosity of weld after different surface treatment methods

After comparison, the best process was found to be chemical treatment, which consists of the following steps: metal cleaning agent cleaning, water washing, alkali washing, water washing, acid washing, water washing, and drying.

The alkali washing step uses a 25% sodium hydroxide (NaOH) aqueous solution to remove surface material, and the acid washing step uses a 20% nitric acid (HNO3) and 2% hydrofluoric acid (HF) aqueous solution to neutralize residual alkali.

It is important to note that the test plate should be welded within 24 hours after surface treatment. If the test plate has been sitting for an extended period after treatment, it should be wiped with absolute alcohol before welding.

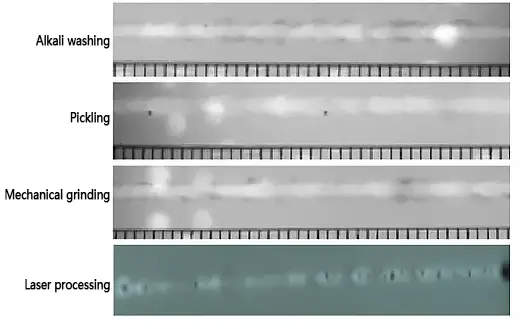

The formation of weld porosity is not only dependent on the quality of surface treatment, but also on the welding process parameters.

The impact of welding parameters on weld porosity is mainly seen in the depth of penetration, specifically the influence of the weld back width ratio on porosity formation.

Effect of weld penetration on weld porosity

The results indicate that when the back width ratio (r) is greater than 0.6, the concentration of chain pores in the weld can be effectively improved. And when the back width ratio is greater than 0.8, the occurrence of large pores in the weld can be effectively reduced and residual pores in the weld can be largely eliminated.

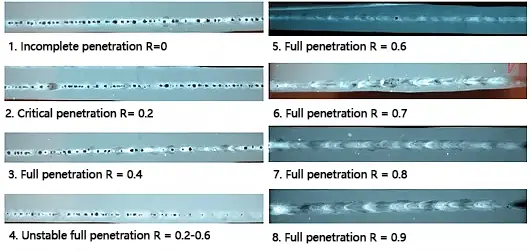

The choice of shielding gas has a direct impact on the quality, efficiency, and cost of welding.

In laser welding, the proper flow of shielding gas can effectively reduce weld porosity.

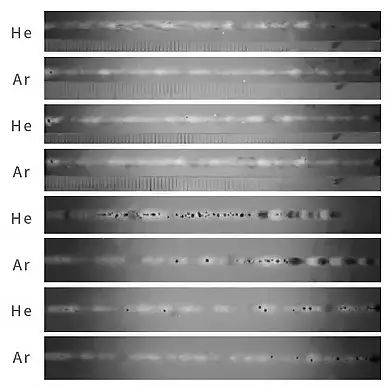

Effect of different shielding gas types on weld porosity

As shown in the figure, argon (Ar) and helium (He) are used as shielding gases to protect the weld surface during laser welding.

The difference in ionization degree between Ar and He to the laser affects the formation of the weld. The results show that the porosity in the weld with Ar as a shielding gas is lower than that in the weld with He as a shielding gas.

It’s important to note that a low gas flow rate (< 10L / min) can result in a large amount of plasma being produced and not effectively blown away, leading to an unstable welding pool and a higher probability of porosity formation. A moderate gas flow rate (around 15L / min) effectively controls the plasma and provides a good anti-oxidation effect on the solution pool, resulting in the lowest porosity. On the other hand, a high gas flow rate accompanied by high gas pressure can cause some of the protective gas to mix into the solution pool, leading to increased porosity.

Reducing porosity in laser welding of aluminum alloys is a challenging problem. Due to the properties of aluminum alloys, porosity cannot be completely eliminated in the welding process, but it can be reduced. Through process optimization before and after welding and experimental analysis, three methods to reduce porosity have been proposed and can be used as a reference by industry colleagues.