Imagine robots that can transform their shape, sense emotions, and even interact with us as naturally as another human. This article explores ten groundbreaking technologies revolutionizing robotics, from flexible materials and liquid metal to brain-computer interfaces and autonomous driving. Readers will gain insights into how these advancements are pushing the boundaries of what robots can do, opening up new possibilities in fields like healthcare, manufacturing, and disaster response. Get ready to discover how these cutting-edge innovations are shaping the future of robotics.

In recent years, the robotics industry has rapidly developed, and robots have been widely used in various fields, especially in industrial settings. It’s not difficult to see their tremendous potential.

At the same time, it’s crucial to realize that the booming development of the robotics industry is inseparable from advanced scientific research and technical support.

Below, we’ll take a look at the cutting-edge technologies of the top ten robots for your reference.

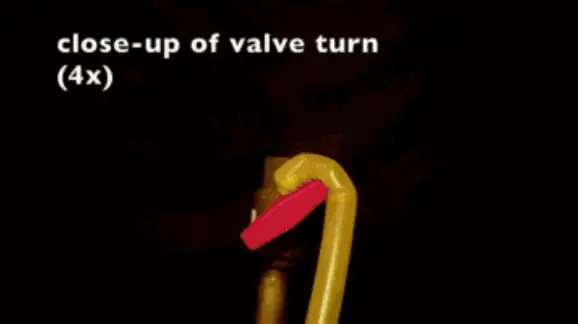

Flexible robot closes the valve

Flexible robot technology encompasses the research, development, design, and manufacturing of robots incorporating flexible materials and adaptive control systems. This innovative approach enables the creation of highly versatile and adaptable robotic systems capable of navigating complex environments and performing intricate tasks.

Flexible materials with configurable properties can be dynamically altered across a wide range of characteristics, including stiffness, shape, and conductivity. This adaptability makes flexible robots particularly well-suited for applications such as:

The development of flexible robot technology involves interdisciplinary collaboration, combining advances in materials science, control systems, sensors, and artificial intelligence to create robots that can safely and effectively operate in unstructured environments and interact with humans.

British scientists control liquid metal by programming

Liquid metal control technology is an emerging field that enables precise manipulation of liquid metal materials through the application of external electromagnetic fields. This innovative approach offers unprecedented control over the shape, movement, and behavior of liquid metals, opening up new possibilities in areas such as intelligent manufacturing, soft robotics, and adaptive systems.

Liquid metals, such as gallium and its alloys, are unique materials that combine the fluidity of liquids with the electrical and thermal conductivity of metals. At room temperature, these materials maintain a liquid state while exhibiting metallic properties. The current technical focus extends beyond traditional casting methods, encompassing advanced control and manipulation techniques.

Key aspects of liquid metal control technology include:

While fully functional liquid metal robots remain a futuristic concept, significant progress has been made in developing liquid metal-based actuators, sensors, and adaptive structures. These advancements are paving the way for soft, deformable robotic components that can change shape, navigate complex environments, and perform tasks traditional rigid robots cannot.

Potential applications of liquid metal control technology include:

As research in this field continues to advance, the gap between the current state of liquid metal technology and the vision of fully functional liquid robots is gradually narrowing, bringing us closer to realizing this fascinating potential.

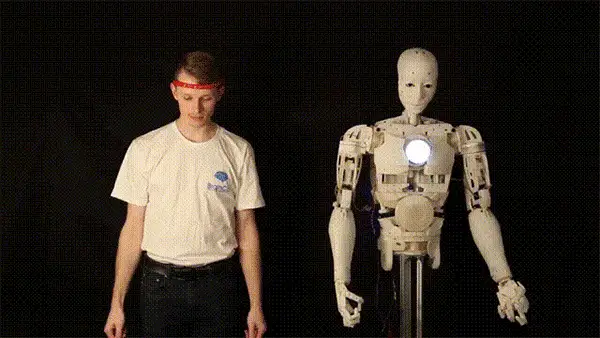

Children’s robot iCub developed by Italian Institute of Technology

Biomyoelectric control technology harnesses surface electromyography (sEMG) signals generated by the human upper limb to manipulate robotic arms, offering a groundbreaking interface between biological systems and mechanical devices. This innovative approach utilizes non-invasive electrodes placed on the skin to detect minute electrical potentials produced during muscle contractions, translating these bioelectrical signals into precise commands for robotic systems.

The technology’s applications span a wide range of fields, including:

The continued advancement of biomyoelectric control technology promises to revolutionize human-machine interfaces, paving the way for more intuitive, efficient, and adaptable robotic systems across various sectors of industry and healthcare.

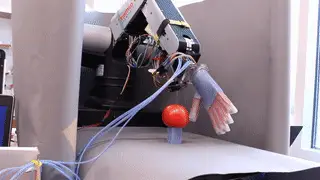

Haptic robot “Gentle Bot” grabs tomatoes

Sensitive tactile technology refers to the integration of advanced tactile sensors that enable robots to perceive and interpret physical interactions with their environment. These sensors, based on cutting-edge electrical and fine particle technologies, allow robots to accurately detect and analyze the shape, texture, and hardness of objects they encounter. This heightened sensitivity significantly expands the capabilities of robotic systems, enabling them to perform a wide range of complex tasks with unprecedented precision.

The core of this technology lies in its ability to mimic human touch, providing robots with a level of sensory feedback that was previously unattainable. By incorporating arrays of micro-sensors that can detect minute changes in pressure, temperature, and even vibration, robots can now “feel” their surroundings in a manner reminiscent of human skin.

This enhanced tactile perception opens up new possibilities in various fields:

As this technology continues to evolve, it promises to bridge the gap between human sensory capabilities and robotic precision, leading to more versatile, adaptable, and human-like robotic systems across various industries.

Robot Sophia who once threatened to destroy humans

Robots developed using advanced conversational intelligent interaction technology can not only comprehend user queries with high accuracy but also provide precise, context-aware responses. Moreover, these systems are capable of actively guiding the conversation flow, prompting for additional information when necessary, and even anticipating user needs. This proactive approach ensures a more natural and efficient interaction.

Apple’s next-generation conversational interaction technology represents a significant leap forward, aiming to transcend Siri’s traditional “question-and-answer” model. The goal is to enable Siri to initiate conversations proactively, predict user intent, and engage in more dynamic, multi-turn dialogues. This shift towards “active” communication promises to deliver a more intuitive and personalized user experience, potentially revolutionizing how we interact with AI assistants in our daily lives.

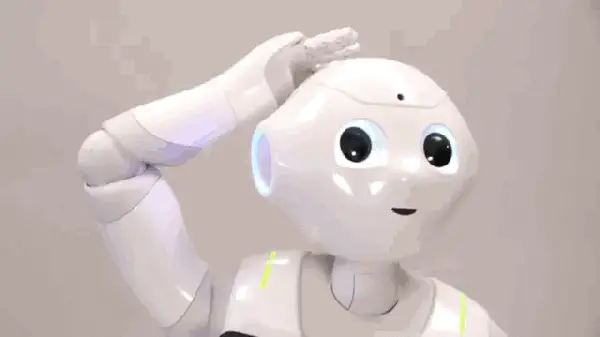

Pepper’s emotional recognition developed by Japanese SBRH

Emotion recognition technology has evolved to effectively analyze and interpret human emotions and underlying psychological states. This advancement enables robots to acquire human-like capabilities in observation, understanding, and response. By integrating sophisticated algorithms and machine learning techniques, robots can now process complex emotional cues with increasing accuracy.

The applications of this technology extend far beyond simple facial expression recognition, encompassing a wide range of potential use cases:

While facial expression recognition remains a crucial component of emotion recognition technology, modern systems also incorporate other modalities such as voice analysis, physiological measurements, and behavioral patterns. This multi-modal approach significantly enhances the accuracy and robustness of emotion detection.

As this technology continues to advance, it raises important ethical considerations regarding privacy, consent, and the potential for misuse. Striking a balance between technological progress and ethical implementation will be crucial for the responsible development of emotion recognition in robotics.

Writing with ideas with the help of focausedu

Brain-computer interface (BCI) technology represents a groundbreaking advancement in human-machine interaction, enabling direct communication between the human brain and external devices. This innovative field involves the sophisticated processes of acquisition, analysis, and interpretation of neurological signals, primarily focusing on the electrical activity generated by the central nervous system. By leveraging advanced signal processing algorithms and machine learning techniques, BCIs can translate complex neural patterns into actionable commands, allowing for the seamless control of machines and digital systems through thought alone.

The core functionality of BCI technology lies in its ability to capture and decipher the intricate electrical signals produced by neuronal activity. These signals, often detected through non-invasive methods such as electroencephalography (EEG) or more advanced invasive techniques like electrocorticography (ECoG), are processed in real-time to extract meaningful information. This processed data is then transformed into precise instructions that can be executed by connected devices, ranging from prosthetic limbs to computer interfaces.

The applications of BCI technology are diverse and profoundly impactful. In the realm of assistive technology, BCIs offer unprecedented opportunities for individuals with severe motor disabilities, enabling them to regain a degree of independence through thought-controlled wheelchairs, communication devices, or robotic arms. In rehabilitation medicine, BCI systems are being developed to facilitate neuroplasticity and motor recovery in stroke patients, potentially revolutionizing therapeutic approaches.

Beyond medical applications, BCI technology is finding its way into fields such as disaster response and search and rescue operations. By allowing operators to control drones or robotic explorers through mental commands, BCIs can enhance the efficiency and safety of rescue missions in hazardous environments. Furthermore, the entertainment and gaming industries are exploring BCI applications to create immersive experiences where users can interact with virtual worlds using their thoughts, promising a new frontier in human-computer interaction.

As research in this field continues to advance, the potential for BCI technology to transform various aspects of human life grows exponentially, heralding a future where the boundaries between mind and machine become increasingly blurred.

“Alfaba” Intelligent Driving Bus System

The integration of autonomous driving technology in metal fabrication and manufacturing processes has revolutionized material handling and logistics. Advanced robotic systems, equipped with sophisticated sensors and AI algorithms, now provide automated, intelligent loading and transportation solutions within factory environments. These autonomous guided vehicles (AGVs) and autonomous mobile robots (AMRs) optimize material flow, reduce human error, and significantly enhance operational efficiency.

Beyond the shop floor, this technology has far-reaching applications. In quality control, autonomous vehicles equipped with high-precision sensors conduct automated road condition testing for manufactured metal components, ensuring consistent product quality. In defense and military sectors, autonomous systems facilitate secure transport of sensitive materials and equipment, while also supporting reconnaissance and logistical operations in challenging environments.

Furthermore, the convergence of autonomous driving technology with Internet of Things (IoT) and big data analytics is paving the way for smart factories. These systems can dynamically adjust production schedules, optimize resource allocation, and predict maintenance needs, leading to unprecedented levels of productivity and cost-effectiveness in metal fabrication processes.

Clinical case of mVR virtual reality surgery planning system for spine

Virtual reality (VR) robot technology enables operators to remotely control robots through immersive virtual interfaces, revolutionizing human-machine interaction across various industries. This advanced integration of VR and robotics creates a seamless bridge between the physical and digital worlds, offering unprecedented control precision and situational awareness.

The core of VR robot technology lies in its ability to recreate highly detailed virtual scenes that mirror real-world environments. These virtual replicas are populated with real-time data from sensors on the physical robot, allowing operators to navigate and manipulate the robot as if they were present on-site. High-fidelity haptic feedback systems further enhance the operator’s sensory experience, providing tactile sensations that correspond to the robot’s interactions with its environment.

This technology demonstrates significant application value across diverse fields:

As VR and robotics technologies continue to advance, we can expect even more sophisticated applications of virtual reality robot technology. Future developments may include enhanced AI integration for semi-autonomous operation, improved haptic feedback systems for finer control, and more seamless integration with other emerging technologies such as 5G networks and edge computing.

Intelligent robots at the German Robot Show

Robot cloud service technology represents a paradigm shift in robotics, transforming robots into intelligent execution terminals that leverage cloud computing for advanced storage and processing capabilities. This innovative approach enables robots to respond instantaneously to demands, implement complex functions, and facilitate efficient data communication and knowledge sharing across networked systems.

At its core, this technology creates a symbiotic relationship between individual robots and a powerful cloud infrastructure. Robots, acting as edge devices, can offload computationally intensive tasks to the cloud, allowing for real-time processing of vast amounts of data and access to shared intelligence. This distributed architecture significantly enhances the robots’ capabilities, enabling them to perform tasks that would be impossible with onboard resources alone.

The cloud-based approach offers several key advantages:

This technology paves the way for a new era of robotic services, where interconnected robots can seamlessly collaborate, adapt to complex environments, and offer unprecedented levels of functionality and efficiency across various industries, from manufacturing and logistics to healthcare and beyond.