What causes your motor bearings to fail unexpectedly? Rust corrosion, driven by humid conditions and oxidative reactions, is a frequent culprit. This article uncovers the root causes of corrosion in motor bearings, its detrimental effects on performance, and practical solutions for prevention. Learn how to identify corrosion issues early and implement measures to protect your machinery from this common yet avoidable problem.

Corrosion is a common mode of failure in bearings. In the ISO standard failure analysis classification, corrosion is categorized as a type of chemical change.

Typical bearing corrosion is essentially an oxidative change triggered by humid conditions in the air reacting with bearing steel.

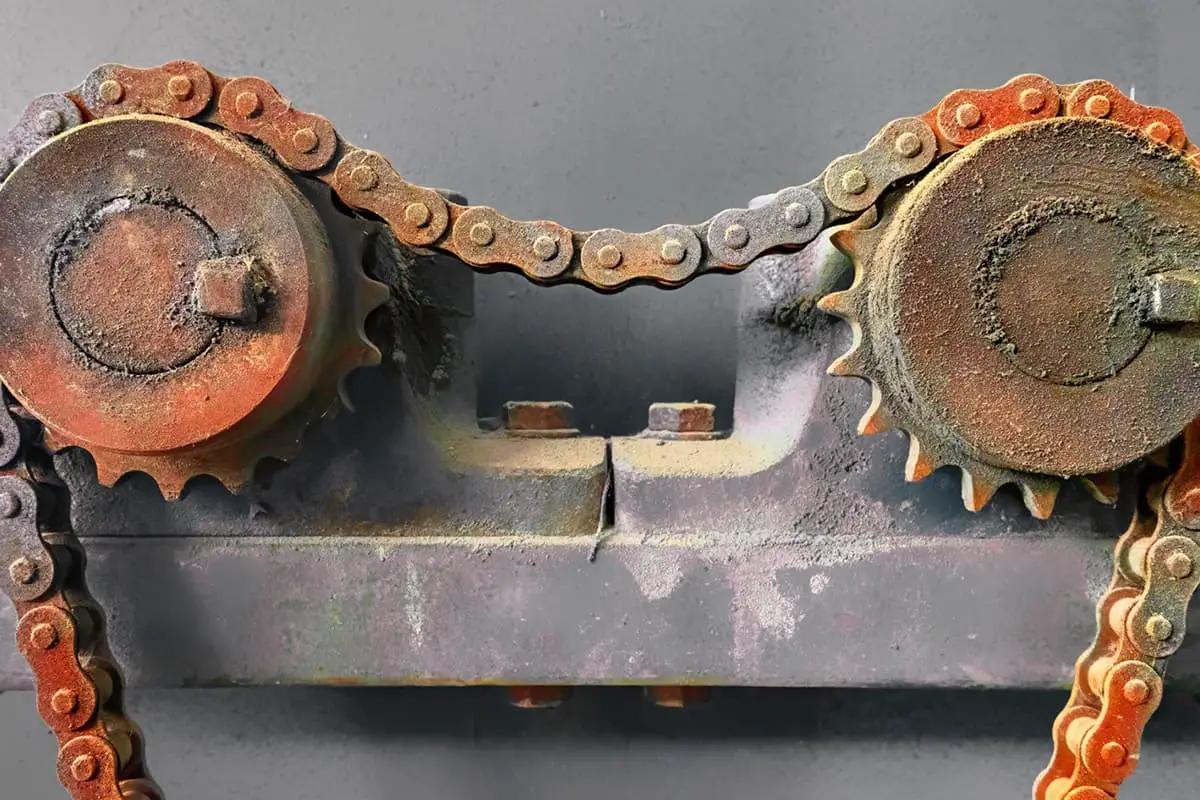

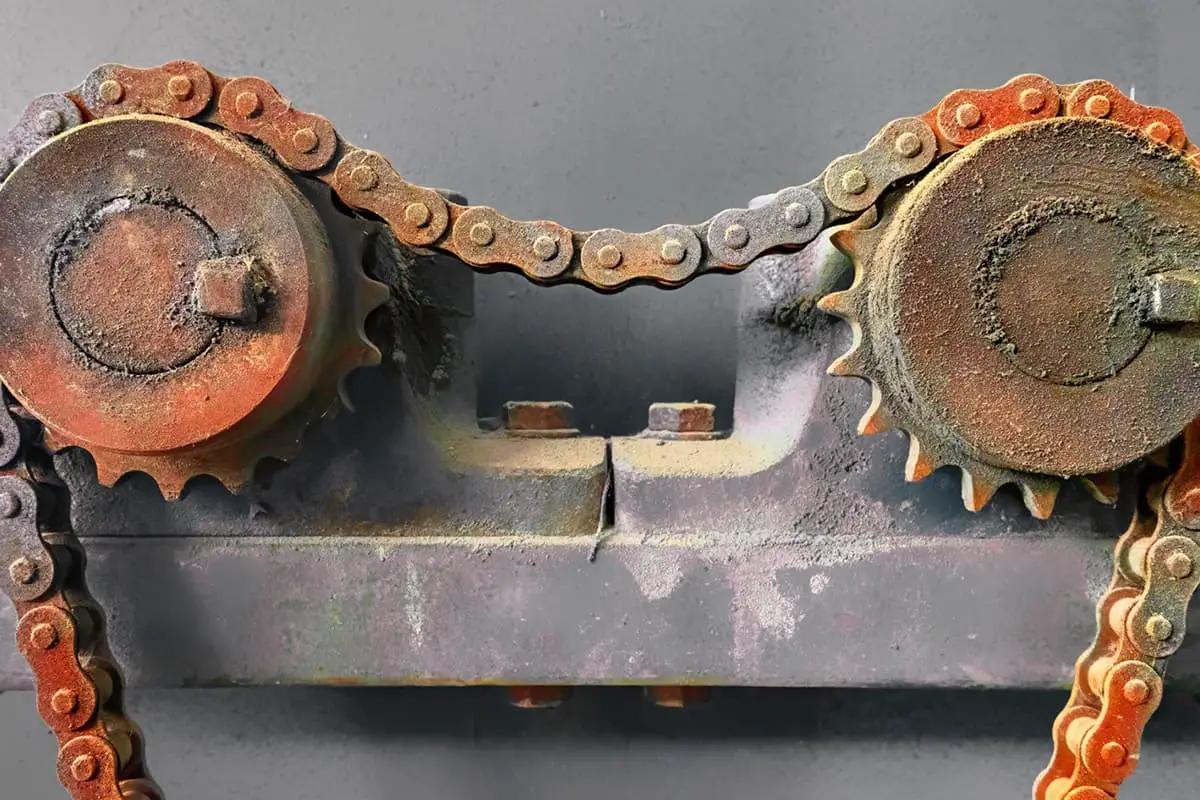

If this oxidation occurs inside the bearing raceway, when the bearing operates, the rolling elements will pass over the corroded area, resulting in noise and vibrations.

Failure will then continue to spread from the corroded area, disrupting lubrication and forming a vicious cycle with the surrounding raceway.

If corrosion occurs outside the raceway, if the oxidation continues to develop, it can affect the strength of the corresponding bearing components and could potentially lead to the bearing ring fracturing under load.

Generally, bearing corrosion occurs in non-operational parts of the bearing, or when the bearing is not in operation. Bearing operational surfaces typically do not rust while in operation.

Hence, in bearings that operate frequently, corrosion mainly occurs on non-operational surfaces, whereas for operational surfaces, corrosion generally happens when the bearing is idle.

From this, we can derive the following:

If the raceway shows signs of corrosion, and the corrosion traces correspond to the spacing between the rolling elements, the bearing corrosion likely occurred while the machine was idle.

At this point, bearing corrosion may have started before the bearing was installed, or it may have occurred when the bearing was not in operation after installation.

Typically, bearings are coated with a layer of rust-preventive oil before they leave the factory. This oil protects the bearings during storage. If the rust-preventive oil fails and condensation occurs on the contact points between the rolling elements and the raceway, corrosion can easily occur.

Similarly, when motor bearings are put into use, they are usually filled with lubricating grease.

Many types of grease contain anti-oxidation components, and the grease also prevents the bearing steel from coming into contact with oxygen, providing a certain level of rust prevention.

Once installed, it is unlikely for raceway corrosion to occur between the rolling elements unless there is a problem with the grease application.

Another situation is when the bearing working environment is very damp, the water content in the grease increases, and corrosion can occur between the rolling elements when the bearing is idle.

On the surfaces of the bearing’s outer and inner rings, which are both mating surfaces with the shaft and bearing housing, corrosion should not occur under normal conditions.

However, if fretting corrosion appears, it needs to be carefully discerned since both fretting corrosion and rust leave similar traces of iron oxidation on the surface.

The end faces of the bearing rings typically do not participate in load bearing and may not necessarily be protected by grease. Therefore, in humid storage and operating environments, rust can occur.

Firstly, the storage environment for bearings must be strictly managed. Generally, the humidity should not be too high, and the specific humidity requirements can be obtained from the bearing manufacturer.

Additionally, the packaging of the bearings should generally be kept intact. Any damaged packaging should be promptly covered to prevent moisture ingress.

For bearings with anti-rust oil, it is generally not recommended to clean the oil off. The anti-rust oil used by most manufacturers is compatible with various grease lubricants and can be directly replenished with lubricating grease.

Bearings should only be unpacked just before use, and care should be taken to manage the condensation caused by changes in ambient temperature during bearing operation.

In damp working environments, in addition to ensuring proper lubrication to protect the bearings from the threat of corrosion, the design of seals must also be taken into account. For liquid contamination or steam pollution, appropriate seals should be used for protection.

Protection against condensation caused by some specific processes should be provided.

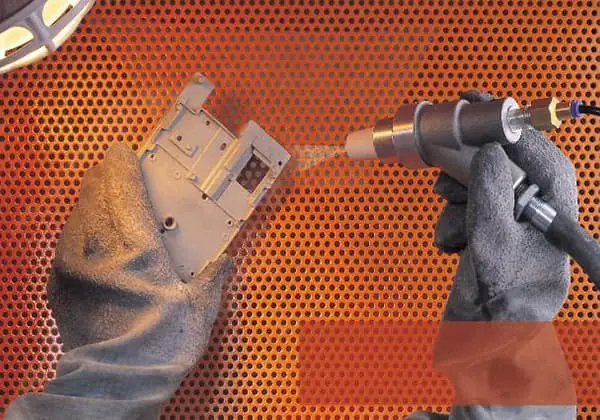

For instance, some motor factories use a cold-installation method, chilling the bearings to a certain temperature before installation.

The most crucial aspect of this operation is to prevent condensation when the cold bearing meets the air. While condensation on the bearing’s outer surface is easy to deal with, internal condensation is challenging to clean.