Have you ever wondered how safety valves protect industrial equipment from catastrophic failures? Safety valves are vital for preventing explosions by releasing excess pressure from boilers and pressure vessels. This article delves into the types, characteristics, and selection criteria for safety valves, offering essential tips for proper installation. By reading on, you’ll understand how to choose and maintain these crucial components to ensure operational safety and compliance with industry standards.

A safety valve is a critical safety component for boilers, pressure vessels, and other pressure equipment, as it effectively prevents explosion incidents resulting from overpressure of production devices.

As such, safety valves play a crucial role in chemical plants.

To gain a comprehensive understanding of safety valves, it’s essential to examine their classification, characteristics, selection criteria, and installation requirements.

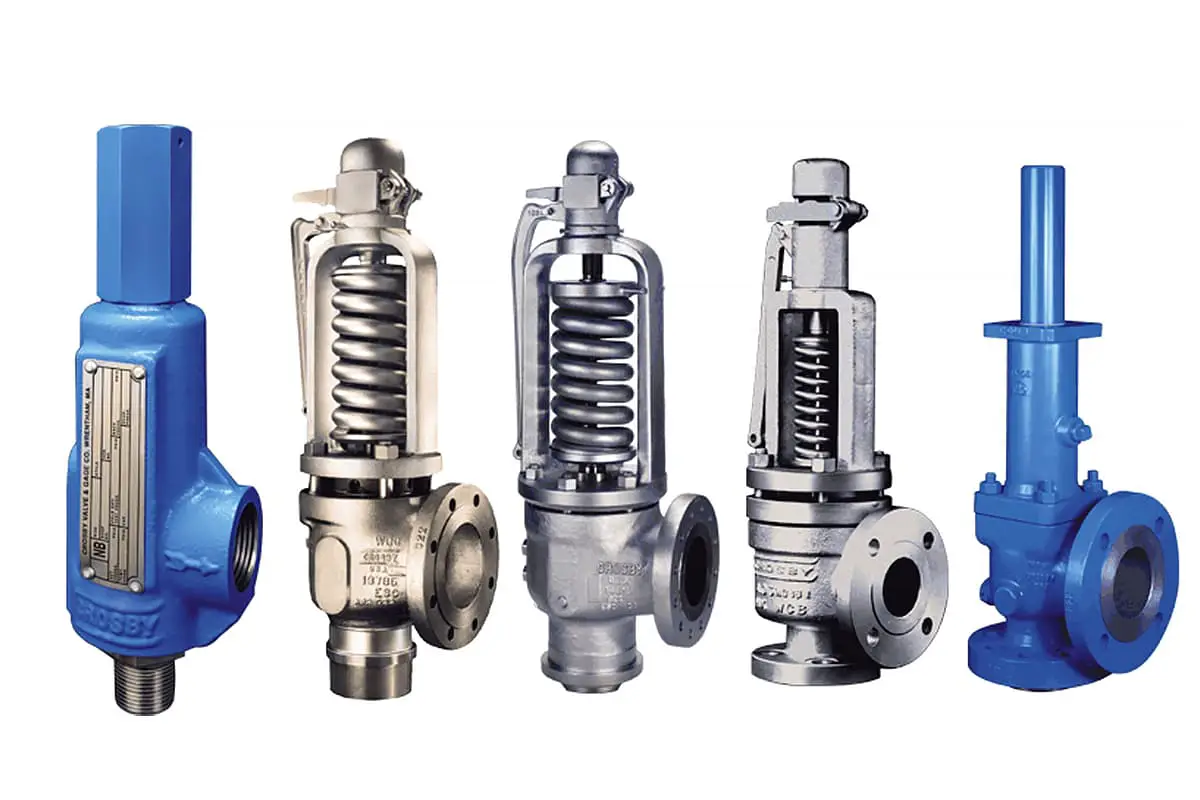

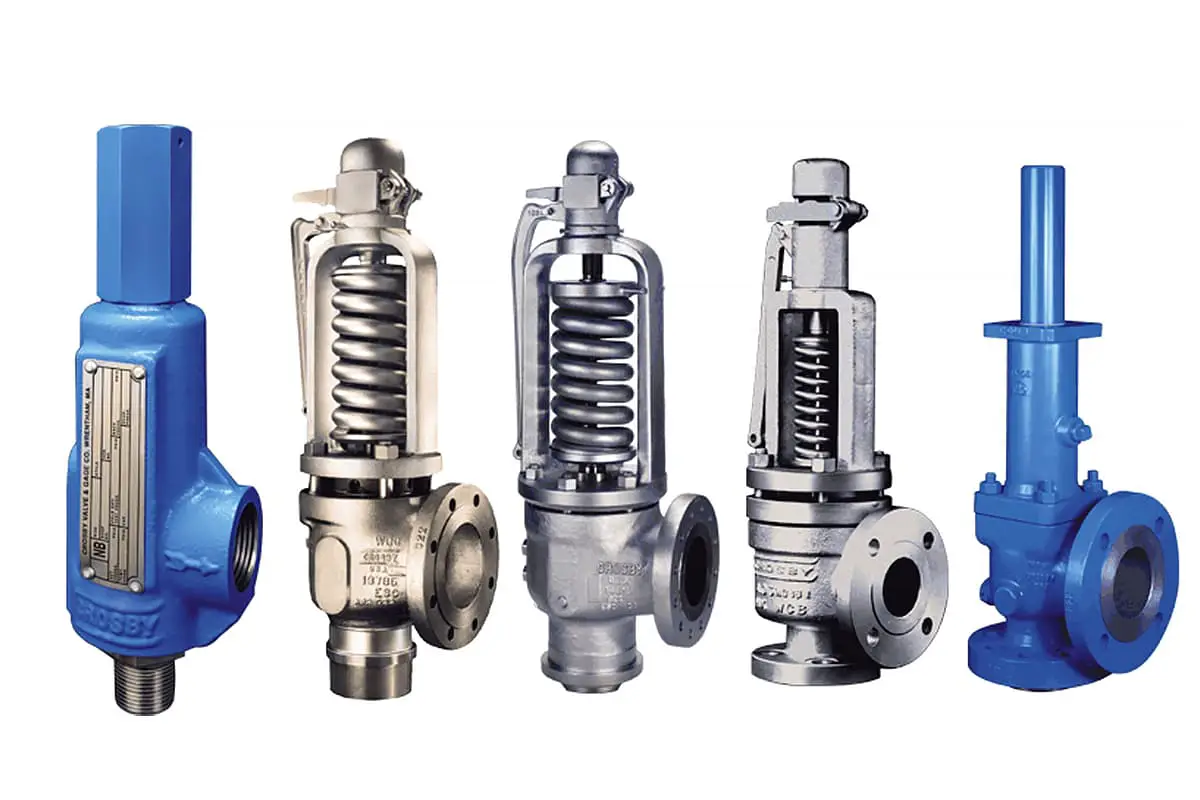

Safety valves can be categorized into three types based on their overall structure and loading mechanism: heavy hammer lever type, spring type, and pulse type.

Of these three, the spring type safety valve is the most widely used.

1. Heavy hammer lever safety valve

The heavy hammer lever safety valve operates by using a heavy hammer and lever to balance the force on the valve disc.

By leveraging the lever principle, a smaller mass can generate a greater force by increasing the length of the lever, and the opening pressure of the safety valve can be adjusted by modifying the weight’s position or mass.

Advantages:

The heavy hammer lever safety valve has a simple structure and is easy to adjust accurately. The load does not increase significantly as the valve disc rises.

It is suitable for high-temperature applications and was widely used in the past, particularly in boilers and pressure vessels that required high temperatures.

Disadvantages:

However, the heavy hammer lever safety valve has a bulky structure, and the loading mechanism is prone to vibration and leaks.

Additionally, it has a low reseating pressure, making it challenging to close tightly after opening.

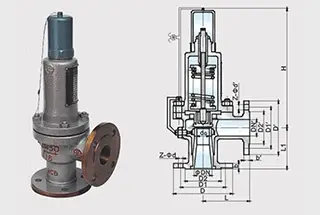

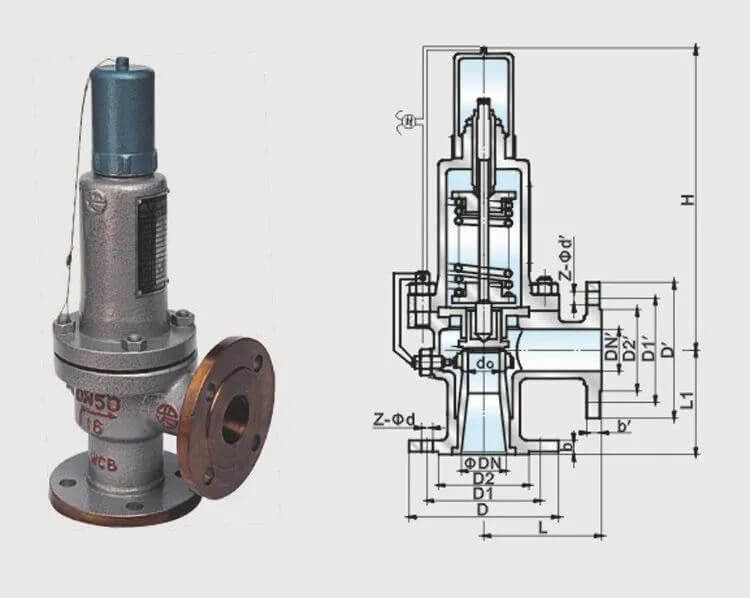

2. Spring type safety valve

The spring-loaded safety valve uses the force of a compression spring to balance the force on the valve disc.

The compression of the spring can be adjusted by turning the adjustment nut, allowing the opening (setting) pressure of the safety valve to be modified as needed.

Advantages:

The spring-loaded safety valve has a lightweight and compact structure, is highly sensitive, can be installed in any position, and is resistant to vibration. It is ideal for use on mobile pressure vessels.

Disadvantages:

However, the load on the safety valve changes as the valve opens, meaning that as the valve disc rises, the compression of the spring increases, and the force on the valve disc also increases. This can impact the rapid opening of the safety valve.

Additionally, prolonged exposure to high temperatures can reduce the elasticity of the spring, making it necessary to consider thermal insulation or heat dissipation when used on containers with high temperatures. This makes the structure more complex.

3. Pulse safety valve

The pulse type safety valve is composed of a main valve and an auxiliary valve, and it operates by utilizing the pulse action of the auxiliary valve to drive the main valve.

Its structure is complex, and it is typically only suitable for boilers and pressure vessels that require a large safety discharge capacity.

Based on the mode of medium discharge, safety valves can be classified into three types: fully closed, semi-closed, and open.

1. Fully closed safety valve

The fully enclosed safety valve discharges all the gas through the exhaust pipe, preventing any medium from leaking outside when it operates.

This type of safety valve is primarily used in containers that contain toxic and flammable gases.

2. Semi closed safety valve

In a semi-closed safety valve, part of the discharged gas passes through the exhaust pipe while the remaining portion leaks through the gap between the valve cover and the valve stem.

This type of safety valve is mostly used in containers that contain gases that will not harm the environment.

3. Open safety valve

The open safety valve has an open valve cover that connects the spring chamber to the atmosphere, facilitating the reduction of spring temperature.

This type of safety valve is mainly used in containers that contain steam as the medium or high-temperature gases that do not harm the atmosphere.

The safety valve is primarily divided into micro-open safety valves and full-open safety valves based on the ratio of the maximum opening height of the valve disc to the flow path diameter of the safety valve.

1. Micro lift safety valve

The opening height of a micro-open safety valve is less than 1/4 of the channel diameter, usually 1/40 to 1/20 of the channel diameter.

This type of safety valve operates through proportional action and is mainly used in liquid applications, and sometimes in gas applications with low discharge.

2. Full lift safety valve

The opening height of a full-open safety valve is equal to or greater than 1/4 of the flow channel diameter.

The discharge area of a full-open safety valve is equal to the minimum cross-sectional area of the valve seat throat.

This type of safety valve operates through two-stage action and requires a lifting mechanism to fully open. It is mainly used in gas medium applications.

The safety valve can also be classified into direct action safety valves and indirect action safety valves based on the action principle.

1. Direct acting safety valve

The direct acting safety valve operates by the direct action of the working medium, meaning that the pressure of the working medium opens the valve by overcoming the mechanical load imposed by the loading mechanism on the valve disc.

This type of safety valve has a simple structure and quickly operates with high reliability. However, due to limitations in its structure, it is not suitable for high-pressure and large-diameter applications.

2. Non direct acting safety valve

The direct acting safety valve can further be divided into two types: pilot safety valves and safety valves with power auxiliary devices.

Determination of various parameters of safety valve:

Choose the nominal pressure based on the valve material, operating temperature, and maximum working pressure.

The working pressure level should be selected based on the design pressure and design temperature of the pressure vessel.

It’s important to note that the working pressure of the safety valve has a different meaning from the working pressure of the spring.

The working pressure of the safety valve refers to the static pressure in front of the valve during normal operation, which is equivalent to the working pressure of the protected system or equipment.

In contrast, the working pressure level of the spring refers to the allowable pressure range of the spring.

Within this range, the opening pressure (i.e., setting pressure) of the safety valve can be adjusted by changing the preload compression of the spring.

Safety valves with the same nominal pressure can have different working pressure levels based on the spring design requirements.

When selecting a safety valve, it’s crucial to determine the working pressure level based on the required opening pressure value.

The discharge pressure of a safety valve is typically 1.1 times the set pressure (opening pressure), while the discharge pressure of a steam boiler safety valve is 1.03 times the set pressure.

The discharge capacity of the safety valve should be determined based on the necessary discharge, and the discharge capacity of the safety valve should be equal to or greater than the necessary discharge.

The necessary discharge of the protected system refers to the amount that must be expelled to prevent overpressure in case of an abnormal overpressure of the system.

This value is determined by the working conditions, capacity, and potential overpressure of the system or equipment.

The material of the safety valve should consider the working temperature and pressure of the medium, the properties of the medium, and the feasibility and cost-effectiveness of the material.

Determination of the Special Structure of Safety Valves

① For steam with an opening pressure greater than 3 Mpa or gas with a medium temperature greater than 320 ℃, a safety valve with a radiator (fin) should be selected.

② In the case of a safety valve that is bearing additional back pressure, and if the change in back pressure exceeds 10% of the set pressure, a bellows safety valve should be chosen. Additionally, for a safety valve that handles a corrosive medium, a bellows safety valve should also be selected to prevent corrosion of the spring and guide mechanism by the medium.

③ For flammable, highly toxic, or extremely hazardous media, a closed safety valve must be utilized. If a safety valve with a lifting mechanism is required, a closed safety valve with a wrench should be used.

④ For non-hazardous media such as air, hot water, or steam above 60 ℃, a safety valve with a wrench should be adopted.

⑤ For liquefaction tank (tank) trucks, a built-in safety valve should be adopted.

⑥ For working conditions with a large discharge capacity, the full open type should be selected. For working conditions with a stable working pressure and small discharge capacity, the micro start type should be chosen. For high-pressure conditions with a large discharge capacity, an indirect starting type such as a pulse safety valve should be selected. For vessels longer than 6m, two or more safety valves should be set.

⑦ For fixed vessels with low working pressure, a static weight type (pressure cooker) or a lever weight type safety valve can be used. For mobile equipment, a spring type safety valve should be adopted.

⑧ If the medium is thick and prone to blocking, a series combined relief device of a safety valve and bursting disc should be selected.

① The safety valve must be installed vertically upwards.

② The installation position should be as close as possible to the protected equipment or pipeline.

③ The safety valve should be installed in a location that is easy for maintenance and adjustment, with sufficient space around it.

④ The safety valve for a pressure vessel should be installed in the gas phase space above the liquid level of the vessel or on the pipeline, with the connection point located in the gas phase space of the pressure vessel.

⑤ For containers and equipment containing flammable, toxic, or viscous media, a stop valve can be installed in front of the safety valve. However, the flow area of the stop valve must not be less than the minimum flow area of the safety valve, and a lead seal must be installed to ensure that the stop valve is fully open and normally open.

⑥ To reduce the influence of self-gravity of the valve and avoid stress fatigue and discharge vibration fatigue, the safety valve should be installed in reverse with the stop valve.

⑦ If the safety valve may be blocked or corroded by materials, a bursting disc should be placed in front of its inlet, an inspection valve should be installed between the safety valve and the bursting disc, and anti-blocking measures, such as back purging, heat tracing, or thermal insulation, should be taken on its inlet pipeline.

⑧ The safety valve installed on the pipeline should be placed at a location where the fluid pressure is relatively stable and a certain distance away from the fluctuation source. It should not be installed at the dead corner of the horizontal pipeline.

⑨ For pipelines, heat exchangers, or pressure vessels with a liquid medium, when the valve is closed, thermal expansion may result in high pressure. To address this, the safety valve can be installed horizontally to discharge the liquid directly downwards.

⑩ For air emergency discharge, the pipe orifice should be flat, non-sharp, and free of burrs to prevent electrostatic discharge.

The installation point of the safety valve must not subject it to excessive back pressure and must be within the specified allowable range. The valve body of the safety valve must be supported stably.

For containers with extremely hazardous or flammable and explosive media, the outlet of the safety valve must be led to a safe place and properly handled.

If more than two safety valves share a discharge pipe, the cross-sectional area of the discharge pipe must not be less than the sum of the cross-sectional areas of the outlets of all safety valves. However, oxygen or combustible gas and other two gases that can produce a chemical reaction with each other cannot share a discharge pipe.

① For corrosive media, the safety valve should be installed in combination with a bursting disc.

② For highly toxic media, a safety valve with good sealing should be selected.

③ For high-temperature media, the high temperature can have a significant impact on the spring, so spring-loaded safety valves should be avoided.

④ For important safety valves or those that are vulnerable to fire, a spray protection system should be set up.

⑤ For safety valves for spherical tanks, double safety valves should be installed, and the pressure relief capacity of any one safety valve should be sufficient to meet the safety pressure relief requirements of the spherical tank.

⑥ The safety valve should be equipped with an electrostatic jumper.

⑦ To prevent the safety valve from repeatedly opening and closing, causing flutter and damaging the valve, the pressure drop in the inlet pipeline of the safety valve should be reduced. This can be achieved by increasing the inlet pipe diameter and shortening the inlet pipe section.