Have you ever wondered how CNC machine tools are chosen for optimal performance? In CNC machining, the selection of cutting tools is crucial for efficiency and accuracy. This article dives into the principles of choosing the right tools and cutting parameters, discussing factors such as material types, tool structures, and specific machining requirements. By reading further, you’ll gain insights into enhancing your machining processes, improving tool life, and achieving superior results. Explore the details to master your CNC tool selection and optimize your machining operations.

The selection of tools and determination of cutting parameters in CNC machining are critical processes that differentiate it from conventional machining methods. This human-machine interface requires programmers to possess a comprehensive understanding of tool selection principles and cutting parameter optimization. To ensure efficient CNC machining, programmers must integrate their knowledge of digital manufacturing nuances into their programming strategies, enabling them to make informed decisions on tool and parameter selection.

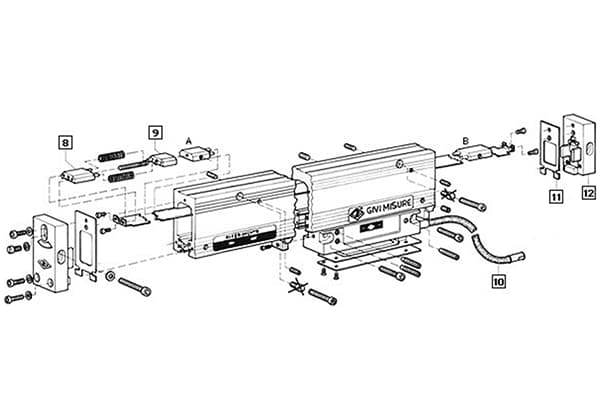

CNC machining tools are engineered to complement the high-speed, high-efficiency, and automated nature of CNC machine tools. The tooling system typically comprises three main components:

This modular approach to tooling has led to increased standardization across the industry, improving interchangeability and reducing setup times. The tool holder-spindle interface is crucial for maintaining accuracy and rigidity during high-speed machining operations.

CNC cutting tools can be categorized based on various criteria, including:

Integral (Solid) Type:

These tools are manufactured as a single piece from high-speed steel (HSS) or carbide. They offer excellent rigidity and precision for specific applications, particularly in smaller diameter tools. Examples include solid end mills, drills, and reamers.

Insert (Indexable) Type:

These tools utilize replaceable cutting inserts, typically made of carbide or ceramic materials, attached to a tool body. They can be categorized into two main subtypes:

a) Brazed Insert Tools: Inserts are permanently attached to the tool body through a high-temperature brazing process.

b) Mechanically Clamped Insert Tools:

Special Types:

a) Composite Cutting Tools: Combine different materials or structures to optimize performance, such as carbide-tipped HSS tools.

b) Vibration-Damping Tools: Incorporate special designs or materials to reduce chatter and improve surface finish in challenging machining conditions.

c) Modular Cutting Tools: Allow for customizable configurations by combining different cutting heads with standard tool bodies.

d) Coolant-Fed Tools: Feature internal channels for precise coolant delivery directly to the cutting edge.

1. High-speed steel (HSS) cutting tools:

2. Cemented carbide cutting tools:

3. Diamond cutting tools:

4. Advanced material cutting tools:

Each material offers unique properties and is selected based on the specific machining requirements, workpiece material, and cutting conditions to optimize tool life, surface finish, and overall machining efficiency.

Turning tools:

Drilling tools:

Boring tools:

Milling tools:

Broaching tools:

Grinding tools:

To meet the demands of modern CNC machining centers, the proportion of modular, adjustable, and durable cutting tools has significantly increased in recent years. These advanced tooling systems now comprise 40% to 90% of the total tooling inventory in CNC machining facilities, depending on the complexity of parts produced and the level of automation. This shift towards flexible tooling solutions enhances productivity, reduces setup times, and improves overall machining efficiency.

Integration with digital systems for real-time monitoring and optimization. Many modern NC tools incorporate sensors or RFID tags for tool life tracking, wear prediction, and process optimization.

Superior rigidity and precision, particularly in roughing tools, coupled with enhanced vibration dampening and minimal thermal deformation. This ensures consistent cutting performance even under demanding machining conditions.

Excellent interchangeability, facilitating rapid tool changes. This feature is often supported by advanced tool holding systems like HSK (Hollow Shank Keyed) or BT (Big-Plus Tooling), which provide both accuracy and quick-change capabilities.

Extended service life with stable and reliable cutting performance. This is often achieved through the use of advanced coating technologies (e.g., PVD, CVD) and optimized tool geometries that reduce wear and maintain cutting edge integrity.

Easy size adjustability, minimizing tool change setup time. Many NC tools incorporate micro-adjustable features or modular designs that allow for fine-tuning without complete tool replacement.

Efficient chip management capabilities, including chip-breaking geometries and through-tool coolant delivery systems. These features ensure reliable chip evacuation, preventing re-cutting and improving surface finish quality.

Standardization and serialization to streamline programming and tool management. This includes adherence to ISO standards for tool dimensions and cutting data, as well as compatibility with common tool management systems and CAM software.

Tool selection in NC programming is a critical process conducted through human-machine interaction. The choice of cutter and shank must be optimized based on several factors, including the machine tool’s processing capabilities, workpiece material properties, processing sequence, cutting parameters, and other relevant considerations.

The fundamental principles for tool selection prioritize ease of installation and adjustment, superior rigidity, high durability, and precision. When meeting processing requirements, shorter tool holders are preferred to enhance tool rigidity and minimize vibration during machining.

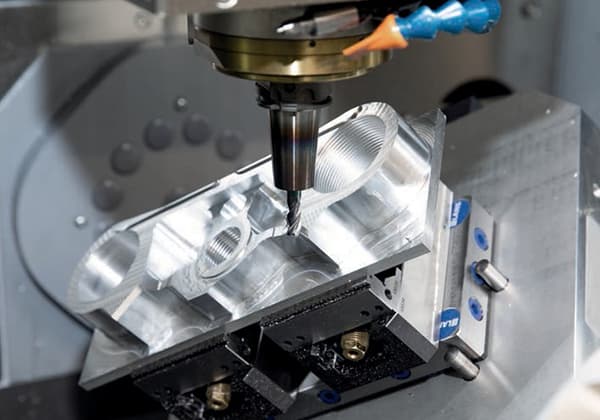

Tool selection should ensure dimensional compatibility between the tool and the workpiece surface to be processed. In production environments, end mills are frequently employed for machining peripheral contours of flat components. For milling planar surfaces, carbide-tipped face mills are recommended due to their superior wear resistance and thermal stability. High-speed milling operations often require specialized geometries such as convex or groove cutters to manage chip evacuation and heat dissipation effectively.

For rough machining of surfaces or holes, indexable corn mills with cemented carbide inserts offer high material removal rates and cost-effectiveness. Complex three-dimensional profiles and variable angle surfaces often necessitate the use of ball nose end mills, torus cutters, tapered end mills, and disc cutters, each optimized for specific geometric features.

When machining free-form surfaces, such as in mold production, it’s crucial to consider the cutting mechanics of different tool geometries. Ball end mills, while versatile, have a cutting speed of zero at their tip, which can compromise surface finish and tool life. To maintain machining accuracy, the step-over distance is often reduced, making ball end mills more suitable for finishing operations. Flat end mills generally offer superior surface quality and cutting efficiency compared to ball end mills. Therefore, whenever feasible, flat end mills should be preferred for both roughing and finishing of curved surfaces, with appropriate tool path strategies to minimize scallop height.

The durability and accuracy of cutting tools significantly impact overall machining economics. While high-quality cutting tools may increase initial tooling costs, they can substantially reduce total processing expenses by improving machining quality, reducing cycle times, and extending tool life. This holistic approach to tool selection often results in lower cost per part and improved process reliability.

In machining centers, various cutting tools are stored in the tool magazine, with tool selection and changes executed automatically according to programmed instructions. To ensure rapid and precise mounting of standard tools for operations such as drilling, boring, reaming, and milling, it is essential to utilize standardized tool holders that are compatible with the machine’s automatic tool change system.

Programmers must be well-versed in the structural dimensions, adjustment methods, and adjustment ranges of the tool holders used on the specific machine tool. This knowledge is crucial for accurately determining the radial and axial dimensions of the cutting tool during the programming phase, ensuring optimal tool performance and preventing collisions or machining errors.

In the machining process of economical CNC machine tools, manual tool handling operations such as grinding, measurement, and replacement often consume significant auxiliary time. Therefore, efficient tool arrangement is crucial for optimizing productivity. The following principles should be adhered to:

Minimize the number of tools: Utilize multi-function tools and optimize cutting strategies to reduce tool changes.

Maximize tool utilization: Once a tool is mounted, complete all possible machining operations before changing. This includes considering tool paths that allow for multiple feature machining in a single setup.

Separate rough and finish tools: Even for identical tool geometries, use dedicated tools for roughing and finishing operations. This preserves tool life and ensures consistent surface quality.

Sequence operations logically:

Prioritize tool life management: Arrange tools based on expected wear patterns, placing longer-life tools earlier in the sequence when possible.

Leverage automation: Utilize the CNC machine’s automatic tool change (ATC) capability to its full extent. This includes optimizing tool magazine arrangement for efficient changes and implementing tool breakage detection systems.

Consider cutting parameters: Group tools with similar cutting speeds and feed rates to minimize machine acceleration/deceleration cycles.

Plan for in-process measurement: If applicable, integrate touch probes or other measurement tools at strategic points in the sequence to allow for adaptive machining.

During rough machining, productivity is typically improved, but consideration should also be given to economy and processing cost. In semi-finishing and finishing, cutting efficiency, economy, and processing cost should be considered while maintaining processing quality. The specific values should be determined based on the machine tool manual, cutting parameter manual, and experience.

The following factors should be considered:

Cutting depth t: If the machine tool, workpiece, and tool rigidity allow, t is equal to the machining allowance, which improves productivity. A finishing allowance should be reserved to ensure machining accuracy and part surface roughness. NC machine tools may have a slightly lower finishing allowance than conventional machine tools.

Cutting width L: L is generally proportional to the tool diameter D and inversely proportional to the cutting depth. In the machining process of economical NC machine tools, L is generally in the range of L = (0.6 ~ 0.9) D.

Cutting speed v: Increasing v improves productivity, but it also affects tool durability. The choice of v mainly depends on tool durability, which decreases as v increases. The cutting speed also depends on the processing material. For example, when milling alloy 30CrNi2MoVA with an end milling cutter, v can be about 8 m/min, while milling aluminum alloy with the same end milling cutter, v can be over 200 m/min.

Spindle speed n (R/min): The spindle speed is generally selected based on the cutting speed v. The calculation formula is: v = πnd/1000. The NC machine tool control panel typically has a spindle speed adjustment (magnification) switch, which can adjust the spindle speed by an integral multiple during machining.

Feed speed vF: vF should be selected based on the machining accuracy and surface roughness requirements of the parts, as well as the cutting tool and workpiece materials. Increasing vF improves production efficiency. When the surface roughness requirement is low, vF can be larger. During processing, vF can also be adjusted manually through the adjustment switch on the machine tool control panel, but the maximum feed speed is limited by the equipment stiffness and feed system performance.