Ever wondered how to pick the perfect motor for your project? The key lies in understanding the types of motors—DC, asynchronous, and synchronous—and their unique advantages. This article breaks down the principles of motor selection, including load type, rated power, and operating environment. By the end, you’ll be equipped with the knowledge to choose the most efficient and cost-effective motor for any application, ensuring optimal performance and longevity. Read on to discover how to make the best choice for your machinery.

This must be stated in reverse order, starting from the types of motors.

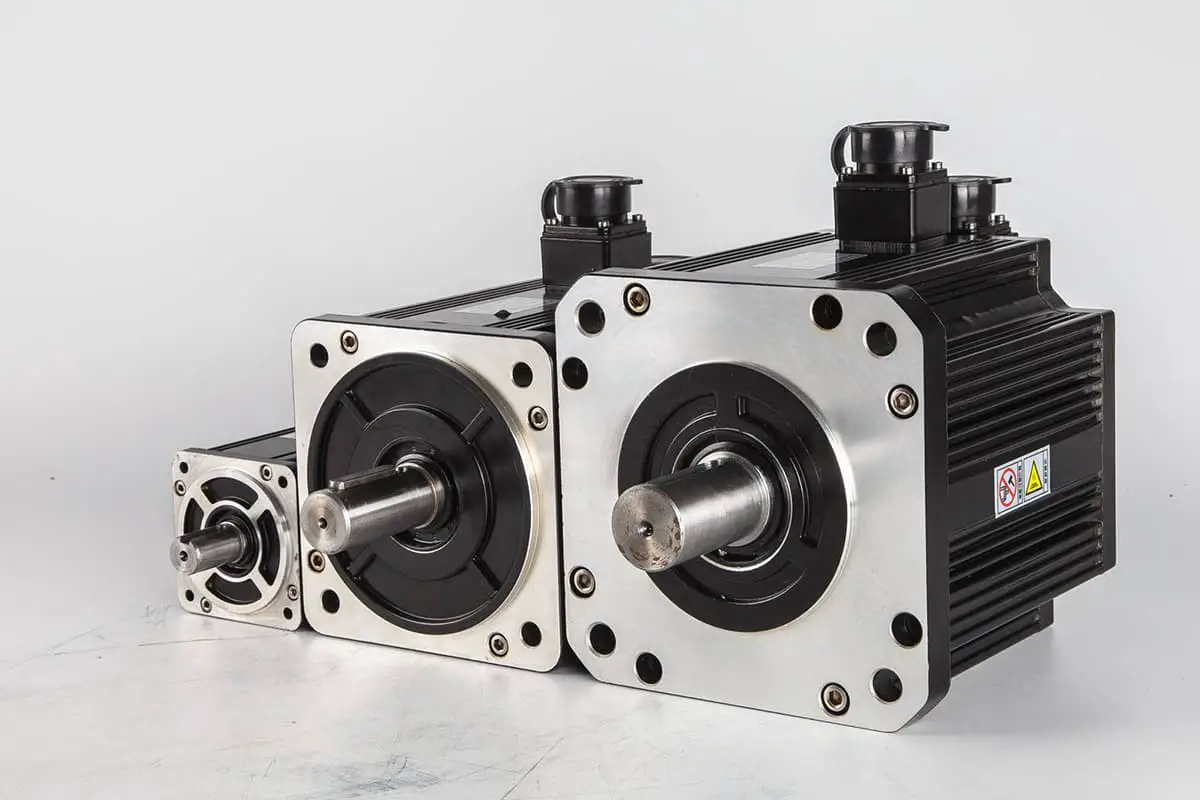

The motor can be classified into two main categories: DC motor and AC motor. The AC motor can further be divided into two types: synchronous motor and asynchronous motor.

The advantage of a DC motor is its ability to easily adjust speed by changing the voltage, providing a larger torque and making it suitable for loads that require frequent speed adjustments such as mills in steel mills and hoists in mines.

However, with the development of frequency conversion technology, AC motors can now also adjust speed by changing the frequency. Although the cost of a variable-frequency motor is not significantly higher than a traditional motor, it still accounts for a significant portion of the overall equipment cost, giving DC motors an advantage in being cost-effective.

The main disadvantage of a DC motor lies in its complex structure, which increases the likelihood of failures. DC motors have complex windings, such as excitation winding, commutation pole winding, compensation winding, and armature winding, as well as additional components like slip rings, brushes, and commutators. This results in high manufacturing requirements and relatively high maintenance costs.

As a result, DC motors are in a declining state in industrial applications, but still have a place in the transitional stage. If the user has sufficient funds, it is recommended to choose the scheme of an AC motor with a frequency converter, as it brings many benefits.

The advantages of asynchronous motors include their simple structure, stable performance, ease of maintenance, and low cost.

Additionally, the manufacturing process is straightforward. According to an old technician in a workshop, the man-hours required to assemble a DC motor can complete the assembly of two synchronous motors or four asynchronous motors with similar power. This is why asynchronous motors are widely used in industry.

Asynchronous motors are divided into squirrel cage and wound motors, with the main difference being in the rotor. The rotor of a squirrel cage motor is made of metal strips, such as copper or aluminum.

Aluminum is relatively cheap and widely used in low-demand applications because China is a large aluminum-mining country.

Copper, on the other hand, has better mechanical and electrical properties and is more commonly used in rotors. After addressing the issue of row breaking in technology, the reliability of squirrel cage motors has greatly improved and is now better than that of wound rotor motors.

However, squirrel cage motors have a low torque output and a large starting current, making them unsuitable for loads requiring high starting torque. Increasing the length of the motor core can increase torque, but the increase is limited.

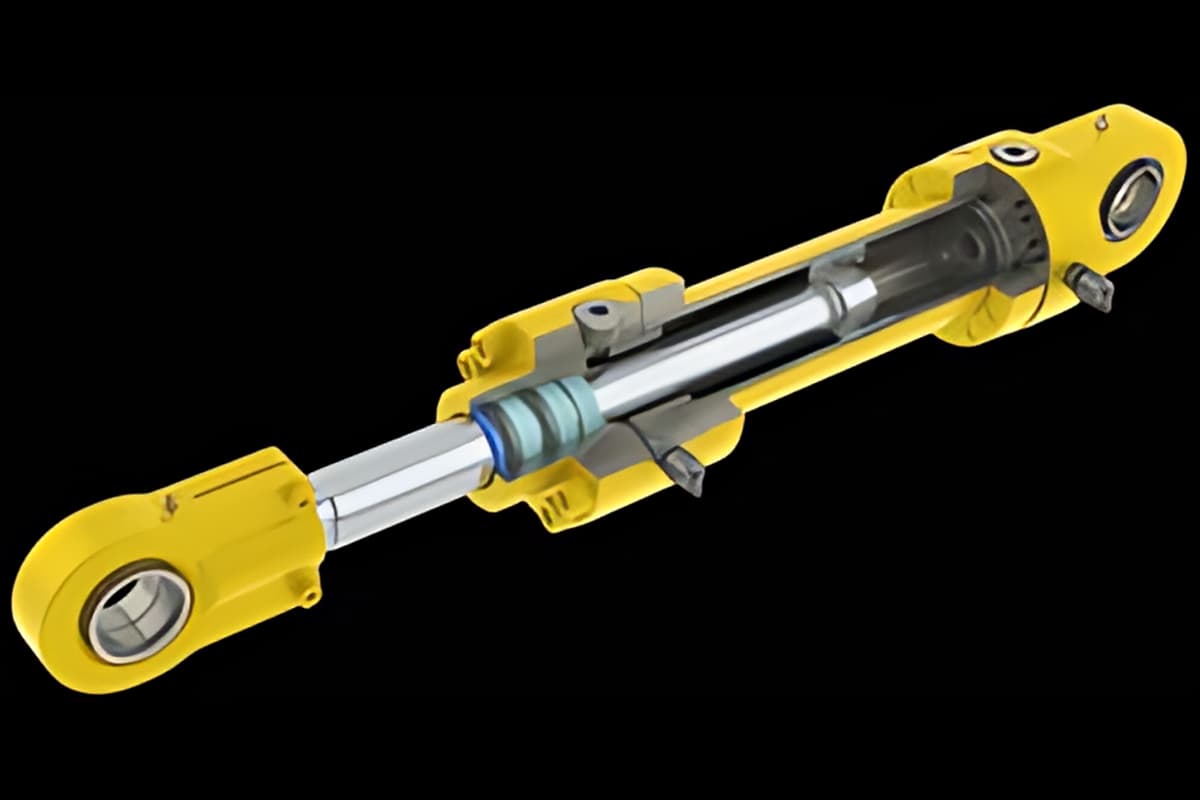

On the other hand, wound motors energize the rotor winding through slip rings to form a rotor magnetic field that moves relative to the rotating stator magnetic field, resulting in a greater torque output.

Water resistance is connected in series to reduce the starting current during the starting process, and the resistance value is controlled by an electric control device. Wound motors are suitable for applications such as rolling mills and hoists.

Compared to squirrel cage motors, wound asynchronous motors have additional components such as slip rings, water resistance, and electrical resistance, leading to a higher overall equipment cost. Asynchronous motors also have a relatively narrow speed regulation range and low torque compared to DC motors.

However, they have a significant impact on the power grid because they require reactive power from the grid to energize the stator winding, which is an inductive element. This can be seen as a drop in grid voltage and a decrease in light brightness when high-power inductive appliances are connected to the grid.

To mitigate this impact, power supply bureaus may restrict the use of asynchronous motors. Some large power users, such as steel and aluminum plants, have their own power plants to form their own independent power grids and reduce restrictions on the use of asynchronous motors.

Asynchronous motors need reactive power compensation devices to meet the requirements of high-power loads, while synchronous motors can provide reactive power to the grid through excitation devices. The greater the power, the more pronounced the advantages of synchronous motors, leading to a shift towards the use of synchronous motors.

The advantages of synchronous motors include their ability to compensate for reactive power in overexcitation states, as well as the following:

However, synchronous motors cannot be started directly and require asynchronous or variable-frequency starting methods. Asynchronous starting involves installing a starting winding similar to a cage winding of an asynchronous motor on the rotor of a synchronous motor, and connecting additional resistance (about 10 times the resistance value of the excitation winding) in the excitation circuit to form a closed circuit. Once the speed reaches subsynchronous speed (95%), the additional resistance is cut off. Variable-frequency starting is not detailed.

Synchronous motors require excitation current to operate and, without it, the motor becomes asynchronous. Excitation is a DC system added to the rotor and its rotation speed and polarity are in sync with the stator. If there is a problem with excitation, the motor will be out of step and cannot be adjusted, resulting in a “excitation fault” protection trip.

Adding excitation devices is the second disadvantage of synchronous motors. In the past, excitation was directly supplied by DC machines, but now it is mostly supplied by silicon controlled rectifiers. The more complex the structure and equipment, the more failure points and higher the failure rate.

Synchronous motors are mainly used in applications such as hoists, mills, fans, compressors, rolling mills, and water pumps. The principle of motor selection is to prioritize motors with simple structures, low prices, reliable operation, and convenient maintenance, as long as the motor performance meets production machinery requirements.

In this regard, AC motors are better than DC motors, AC asynchronous motors are better than AC synchronous motors, and squirrel cage asynchronous motors are better than wound asynchronous motors. Squirrel cage asynchronous motors are preferred for continuous operation production machinery with stable loads and no special requirements for starting and braking, and are widely used in machinery, water pumps, and fans. Wound asynchronous motors are recommended for production machinery with frequent starting and braking and requiring large starting and braking torques, such as bridge cranes, mine hoists, air compressors, and irreversible rolling mills.

Synchronous motors are ideal for applications with no speed regulation requirement, constant speed, or power factor improvement, such as medium to large capacity water pumps, air compressors, hoists, and mills.

For production machinery with a speed regulation range greater than 1:3 and requiring continuous, stable, and smooth speed regulation, it is recommended to use separately excited DC motors, squirrel cage asynchronous motors, or synchronous motors with variable-frequency speed regulation, such as large precision machine tools, gantry planers, steel rolling mills, and hoists.

Production machinery requiring large starting torque and soft mechanical characteristics should use series or compound excitation DC motors, such as trams, electric locomotives, and heavy cranes.

The rated power of a motor refers to its output power, also known as its shaft power or capacity. It is the key parameter that quantifies the motor’s driving load capacity and must be provided when selecting a motor. Other important factors in motor selection include the rated voltage, rated current, power factor (cos θ), and efficiency (η).

The goal of correctly selecting the motor capacity is to determine the power of the motor in an economical and reasonable manner, ensuring that it can meet the load requirements of the production machinery. If the power is too large, the equipment investment increases, leading to waste and a low efficiency and power factor for the AC motor. On the other hand, if the power is too small, the motor will overheat and suffer from premature damage.

The main factors that determine the motor’s power include:

To select the rated power, the load power is first calculated based on the machinery’s heating, temperature rise, and load requirements. Then, the rated power is pre-selected based on the load power, working system, and overload requirements. The heating, overload capacity, and starting capacity must be verified to ensure they are qualified.

If not, the motor must be re-selected until all criteria are met. The working system is also a required factor, with the conventional S1 working system being adopted by default if not specified. Motors with overload requirements must also provide an overload multiple and corresponding operation time.

When an asynchronous squirrel cage motor drives a fan or other high moment of inertia load, the moment of inertia of the load and the starting resistance moment curve must be provided to check the starting capacity.

The rated power selection assumes a standard ambient temperature of 40 ℃. If the ambient temperature changes, the rated power must be corrected. The ambient temperature should be checked in areas with extreme weather conditions, such as India where the ambient temperature can reach 50 ℃.

High altitude can also impact the motor power, with a higher altitude resulting in a higher motor temperature rise and lower output power. The corona phenomenon should also be considered for motors used at high altitude.

For reference, the following are some examples of motor power ranges in the current market:

The rated voltage of a motor refers to the line voltage under its rated operating conditions.

The choice of the rated voltage of the motor depends on the power supply voltage of the power system and the motor’s capacity.

The selection of the voltage level for an AC motor primarily depends on the power supply voltage level at the location of use.

Typically, the low-voltage network operates at 380V, so the rated voltage can be 380V (Y or Δ connection), 220/380V (Δ/Y connection), or 380/660V (Δ/Y connection).

When the power of a low-voltage motor reaches a certain level (such as 300KW/380V), it becomes difficult to increase the current due to limitations in the conductor’s bearing capacity, or it would become too costly to do so.

Higher power output is achieved by increasing the voltage.

The power supply voltage of high-voltage power grids is typically 6000V or 10000V, although there are also voltage levels of 3300V, 6600V, and 11000V used in other countries.

High-voltage motors have the advantage of high power and strong impact resistance, but their disadvantage is that they have large inertia and are difficult to start and stop.

The rated voltage of a DC motor should also match the power supply voltage.

The common voltage levels for DC motors are 110V, 220V, and 440V.

220V is the most commonly used voltage level, and high-power motors can be increased to 600 to 1000V.

When the AC power supply voltage is 380V and a three-phase bridge silicon-controlled rectifier circuit is used for power supply, the rated voltage of the DC motor should be 440V.

When a three-phase half-wave silicon-controlled rectifier power supply is used for power supply, the rated voltage of the DC motor should be 220V.

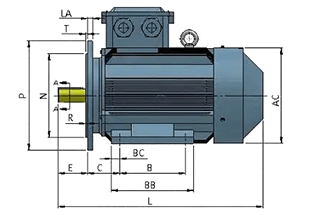

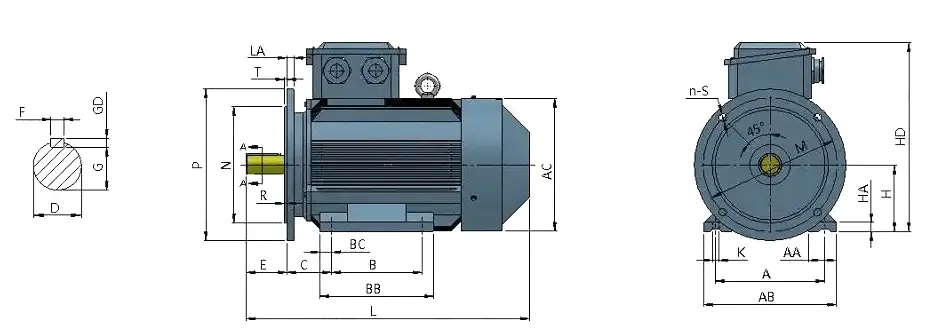

The rated speed of the motor refers to the speed at which it operates under normal conditions. Both the motor and the machinery it drives have a rated speed.

When choosing the speed of the motor, it’s important to keep in mind that it shouldn’t be too low, as this will result in a larger motor with more stages and a higher price. On the other hand, the speed shouldn’t be too high as it can make the transmission mechanism complicated and difficult to maintain.

It’s also important to note that when power is constant, the motor torque is inversely proportional to the speed. As a result, those with low requirements for starting and braking can compare different rated speeds in terms of initial investment, equipment footprint, and maintenance cost before determining the ideal rated speed.

For applications that require frequent starting, braking, and reversing, the speed ratio and rated speed of the motor should be selected based on minimizing the loss during the transition process, rather than just considering the initial investment. For instance, elevator motors require frequent forward and reverse rotation with high torque, so they have a low speed and are bulky and expensive.

When the motor speed is high, it’s crucial to consider the critical speed of the motor. During operation, the rotor may vibrate and its amplitude will increase with the speed. At a certain speed, the amplitude reaches a maximum value (known as resonance), and the amplitude will decrease and stabilize at a certain range when the speed increases further.

This speed with the maximum amplitude is called the critical speed of the rotor and is equal to its natural frequency. If the rotor operates at its critical speed, it can result in violent vibrations and significant bending of the shaft, leading to long-term deformation or even fracture.

Generally, the first-order critical speed of the motor is above 1500 RPM, so it’s not a concern for conventional low-speed motors. However, for high-speed 2-pole motors, if the rated speed is close to 3000 RPM, the impact of the critical speed should be considered and the motor should not operate at its critical speed for extended periods.

Wrap it up

Generally, the specifications of a motor can be estimated by providing information about the type of load it will drive, its rated power, voltage, and speed. However, these basic parameters are not sufficient to fully meet the load requirements.

Additional parameters that need to be considered include frequency, operating system, overload requirements, insulation and protection grades, moment of inertia, load resistance moment curve, installation method, ambient temperature, altitude, and outdoor requirements, among others. These parameters must be specified based on the specific application.

The primary criteria for motor selection include:

Motor selection should be based on the following conditions:

When selecting the motor type, voltage, and speed, the requirements of the power transmission of the production machine, such as the frequency of starting and stopping, whether speed regulation is required, etc., should be considered first. This will determine the type of current for the motor, i.e., whether to choose an alternating current motor or a direct current motor.

Next, the size of the motor’s rated voltage should be selected based on the power supply environment. Then, its rated speed should be selected based on the speed required by the production machine and the requirements of the transmission equipment.

After that, the structure and protection type of the motor should be determined based on the assembly location of the motor and the surrounding environment.

Finally, the rated power (capacity) of the motor should be determined by the power required by the production machine.

After considering all these factors, select a motor from the product catalog that meets these requirements. If the motors listed in the catalog cannot meet the special requirements of the production machine, you can custom order from the motor manufacturer.

The choice of motor is considered from the aspects of AC and DC, machine characteristics, speed regulation and starting capabilities, protection, and price. Therefore, the following guidelines should be observed when choosing:

(1) First, consider selecting a three-phase squirrel cage induction motor.

This is due to its simplicity, durability, reliability, low cost, and easy maintenance. However, its disadvantages are difficult speed regulation, low power factor, high starting current, and small starting torque. Therefore, it is mainly suitable for general production machines and drives with relatively rigid machine characteristics and no special speed regulation requirements, such as general machine tools and production machines such as water pumps or fans with power less than 100KW.

(2) The price of wound rotor motors is higher than that of cage motors.

However, its machine characteristics can be adjusted by adding resistance to the rotor, thereby limiting the starting current and increasing the starting torque. Therefore, it is suitable for situations where the power supply capacity is small, the motor power is large, or speed regulation is required, such as certain lifting equipment, hoisting elevators, forging presses, and moving the crossbeam of heavy machine tools.

(3) When the speed regulation range is less than 1:10 and smooth speed regulation is required, a slip motor can be selected first.

This motor can be divided into horizontal and vertical types according to its assembly position. The shaft of a horizontal motor is horizontally assembled, while the shaft of a vertical motor is vertically assembled in high altitude, so the two types of motors cannot be used interchangeably. Under normal circumstances, a horizontal motor should be chosen whenever possible, and a vertical motor should only be considered when vertical operation is required (such as vertical deep well pumps and drilling rigs) to simplify the transmission assembly (because it is more expensive).

There are multiple protection types for motors, and the appropriate type should be selected based on different operating environments. The protection types for motors include open, protective, enclosed, explosion-proof, submersible, and several others. An open type is typically chosen for everyday environments due to its affordability, but it’s only suitable for dry and clean conditions.

For damp, corrosion-prone, dusty, flammable, or corrosive environments, an enclosed type should be selected. If the environment is dusty and harmful to motor insulation but can be blown clean by compressed air, a protective type may be chosen. For submersible pump motors, a fully sealed type should be chosen to ensure that moisture does not intrude during operation underwater. In environments with fire or explosion risks, an explosion-proof type must be selected.

When choosing a motor for existing production machinery in an industrial setting, the rated voltage of the motor should be equivalent to the factory’s distribution voltage. For new factories, the voltage selection for the motor should be considered in line with the chosen distribution voltage.

The decision should be made based on the most economically viable option after comparing different voltage levels. The low voltage standard in our country is 220/380V, while high voltage is mostly 10KV. Most motors with smaller capacities are high-voltage, with rated voltages of 220/380V (D/Y connection method) and 380/660V (D/Y connection method). When the motor capacity exceeds approximately 200KW, it is recommended to choose high-voltage motors of 3KV, 6KV, or 10KV.

The selection of the motor’s (rated) speed should be considered based on the requirements of the production machinery being driven and the conditions of the transmission assembly. The number of motor revolutions per minute usually includes 3000, 1500, 1000, 750, and 600.

The rated speed of an asynchronous motor is typically 2% to 5% lower than these speeds due to slip rate. From a manufacturing perspective, if a motor of the same power has a higher rated speed, its electromagnetic torque form will be smaller, thus lowering its cost and weight.

Moreover, high-speed motors have higher power factors and efficiency than low-speed motors.

Choosing a motor with a higher speed is more economical. However, if this results in a significant speed difference between the motor and the driven machinery, more speed-increasing transmission stages will be needed, increasing equipment costs and energy consumption. The optimal choice should be made after a careful comparison.

Most motors we typically use are 4-pole 1500r/min motors because these motors have a wide range of applications and superior power factors and operating efficiency.