Why is choosing the right gear material so crucial in engineering? Selecting appropriate materials ensures gears meet demands like wear resistance, durability, and efficiency. This article explores various gear materials, their properties, and their ideal applications, from steel to non-metallic options. Readers will learn how to match gear material to specific conditions, optimizing performance and longevity. Discover the key factors that influence these critical decisions, making your gear systems robust and reliable.

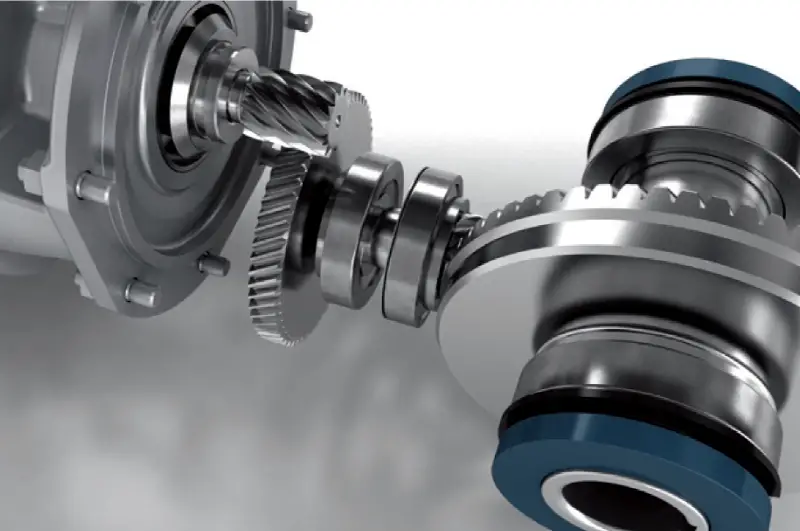

From the failure modes of gears, it is evident that gear transmission design requires careful consideration of material properties. The tooth surface must possess high resistance to wear, pitting corrosion, adhesive wear (galling), and plastic deformation, while the tooth root necessitates excellent fracture resistance.

Consequently, the fundamental requirements for gear materials can be summarized as follows:

To meet these requirements, gear designers often employ advanced materials and heat treatment processes. For instance:

The selection of appropriate gear materials and treatments must consider factors such as load conditions, operating environment, manufacturing processes, and cost-effectiveness. Advanced surface engineering techniques, like physical vapor deposition (PVD) coatings, can further enhance gear surface properties for extreme operating conditions.

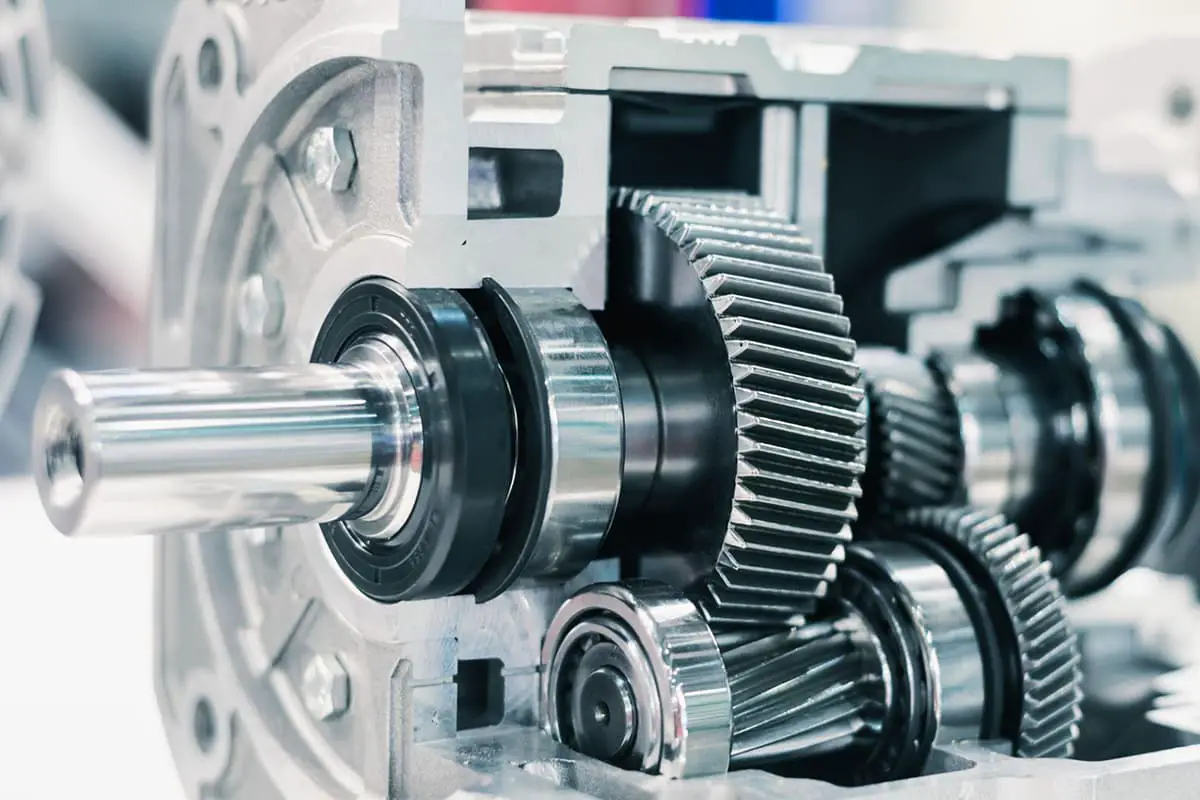

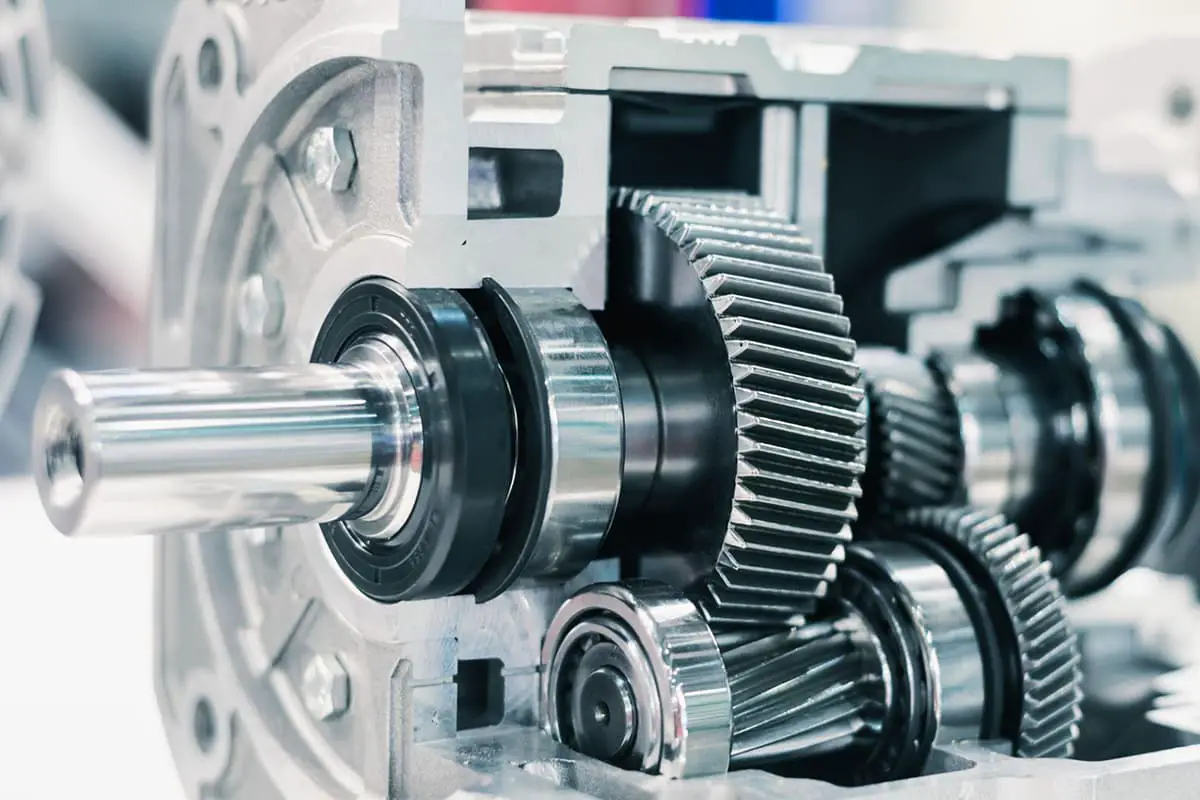

Steel is the most widely used and versatile material for gear manufacturing due to its exceptional combination of mechanical properties and processing capabilities. Its inherent toughness and impact resistance make it ideal for withstanding the cyclic loading and sudden shocks often experienced by gears in various applications.

One of steel’s key advantages is its ability to be significantly enhanced through heat treatment or thermochemical processes. These treatments can dramatically improve the gear’s mechanical properties, particularly its surface hardness and wear resistance, which are crucial for gear performance and longevity. For example:

1. Forged Steel for Gear Manufacturing

Forged steel is widely utilized in gear production due to its superior mechanical properties and structural integrity. The selection of steel grade depends on the specific gear application, with carbon and alloy steels containing (0.15 – 0.60)% carbon being the most common choices. These materials offer an optimal balance of strength, toughness, and machinability essential for gear performance.

The forged steel used in gear manufacturing can be categorized into two main types based on the final tooth surface hardness:

a) Soft Tooth Surface Gears:

These gears are typically made from lower carbon content steels (0.15 – 0.30% C) and are used in applications where moderate strength and excellent machinability are required. The tooth surfaces remain relatively soft after heat treatment, allowing for easier post-forging machining and providing good wear-in characteristics.

b) Hardened Gears:

Manufactured from medium to high carbon steels (0.30 – 0.60% C) or alloy steels, these gears undergo surface hardening treatments such as carburizing, nitriding, or induction hardening. The resulting hard tooth surface offers superior wear resistance and fatigue strength, making them suitable for high-load and high-speed applications.

It’s important to note that casting may be preferred over forging for gears with excessively large dimensions or intricate geometries, as the forging process can become economically or technically challenging in such cases. The choice between forging and casting depends on factors such as gear size, complexity, production volume, and performance requirements.

2. Soft tooth surface gears (hardness 350 HBS):

Due to moderate requirements for strength, speed, and accuracy, the gear blank undergoes heat treatment prior to gear cutting. This process, typically normalization or quench and tempering, facilitates machining and extends tool life by reducing wear rates during cutting operations.

The gear cutting process then directly produces the finished product.

Generally, these gears achieve a precision grade of 8 according to ISO standards. However, with precision cutting techniques, it’s possible to attain a higher precision grade of 7.

This type of gear manufacturing is characterized by its simplicity, cost-effectiveness, and production efficiency. The process flow typically involves:

The soft tooth surface approach is particularly suitable for applications where extreme hardness is not required, offering a balance between performance and manufacturability.

3. Hardened gears (hardness 350 HBS and above):

These gears are crucial components in high-speed, heavy-duty, and precision machinery, such as advanced machine tools and aerospace engines. Their exceptional performance is attributed to a combination of superior material properties, high tooth strength, and elevated tooth surface hardness (typically ranging from 58 to 65 HRC).

The manufacturing process for these high-precision gears typically follows a three-step sequence:

This sequence allows for achieving exceptional accuracy, with gears reaching ISO quality grades 5 or even 4. The finishing process, particularly gear grinding, is essential for attaining such high precision levels.

Various heat treatment methods are employed to enhance the gear’s surface properties, including:

The choice of material and heat treatment method depends on the specific application requirements and desired performance characteristics.

Alloy steels are predominantly used for these high-performance gears due to their ability to be tailored for specific properties. By carefully selecting alloying elements and their proportions, manufacturers can enhance:

Furthermore, through precise heat treatment or thermochemical processes, the mechanical properties and surface hardness can be optimized to meet demanding specifications.

For aerospace applications requiring high-speed operation, heavy load capacity, and minimal size and weight, specialized alloy steels are utilized. Examples include 20CrMnTi and 20Cr2Ni4A, which offer an excellent balance of strength, durability, and weight efficiency.

The resulting hardened gears exhibit a hard tooth surface combined with a tough core, providing an optimal combination of wear resistance and impact strength. This makes them ideal for critical applications where reliability and performance are paramount.

4. Cast Steel

Cast steel offers excellent wear resistance and high strength, making it a valuable material for industrial applications. However, to optimize its mechanical properties and microstructure, post-casting heat treatments are essential. Annealing and normalizing are primary processes applied to cast steel components.

Annealing involves heating the cast steel to a specific temperature, holding it for a predetermined time, and then slowly cooling it. This process reduces internal stresses, improves ductility, and enhances machinability. Normalizing, on the other hand, involves heating the steel above its critical temperature and then air cooling. This treatment refines grain structure, increases strength and toughness, and provides more uniform properties throughout the casting.

For applications requiring even higher strength and hardness, cast steel can undergo quenching and tempering. This two-step heat treatment process is particularly beneficial for large-size gears subjected to high loads and wear. Quenching rapidly cools the heated steel, typically in oil or water, to form a hard martensitic structure. Subsequent tempering at lower temperatures relieves internal stresses and improves toughness while maintaining much of the hardness gained during quenching.

Gray cast iron is characterized by its unique microstructure, containing graphite flakes in a pearlitic or ferritic matrix. This structure imparts specific mechanical properties:

Gray cast iron is typically employed in applications requiring:

Common applications include:

When selecting gray cast iron for a specific application, it’s crucial to consider the grade (determined by tensile strength) and the specific loading conditions to ensure optimal performance and longevity.

To mitigate noise and vibration in gear systems, engineers often employ non-metallic materials for the pinion, while retaining steel or cast iron for the larger gear. Common non-metallic options include high-performance polymers such as polyoxymethylene (POM), polyamide (nylon), and phenolic resins (e.g., bakelite). These materials offer excellent damping properties, reduced weight, and self-lubricating characteristics, contributing to quieter operation and improved efficiency.

The selection of non-metallic materials for gears requires careful consideration of factors such as load capacity, operating temperature, and environmental conditions. For instance, reinforced grades of these polymers, incorporating glass fibers or carbon fibers, can significantly enhance strength and dimensional stability, making them suitable for more demanding applications.

While non-metallic gears offer numerous advantages, the mating steel or cast iron gear still requires appropriate surface hardness to ensure adequate wear resistance and pitting corrosion resistance. The recommended surface hardness range for the metallic gear typically falls between 250 and 350 HBS (Brinell Hardness Scale). This hardness range provides a balance between wear resistance and toughness, essential for prolonged gear life and reliable performance.

To achieve the desired surface hardness, various heat treatment processes can be employed, such as induction hardening, carburizing, or nitriding, depending on the specific material and application requirements. Additionally, surface treatments like shot peening can further enhance fatigue resistance and stress distribution across the gear teeth.

The selection of gear materials is a critical process influenced by multiple factors. The following key considerations should guide this selection:

The gear material must align with the specific operational requirements:

The operational environment and performance requirements should be the primary considerations in material selection.

Alloy steels are preferred for gears subjected to high speeds, heavy loads, and significant impact forces due to their superior strength, toughness, and fatigue resistance.

Aerospace gears demand high-strength alloy steels with surface hardening treatments to maximize power density and minimize weight.

By carefully considering these factors, engineers can select the most appropriate gear materials to ensure optimal performance, longevity, and reliability in diverse applications.

In conclusion, gear selection is highly dependent on the specific application and operating environment. Different use cases demand varying considerations, with material choice playing a crucial role in each scenario.

When designing gears, careful attention must be paid to material selection to ensure optimal performance, longevity, and reliability. Factors such as load capacity, wear resistance, operating temperature, corrosion resistance, and cost-effectiveness should all be taken into account. For instance, carbon steels might be suitable for general-purpose gears, while specialty alloys or even non-metallic materials like high-performance polymers could be necessary for extreme conditions.

Moreover, the gear’s intended function within a system, be it power transmission, precision positioning, or noise reduction, will further influence material and design choices. By meticulously matching gear materials and designs to their specific applications, engineers can create gears that are not only practical and durable but also highly efficient and tailored to excel in their intended roles.