Aluminum alloys are everywhere, but do you know their secrets? In this blog post, we’ll dive into the fascinating world of aluminum alloys, exploring their unique properties and applications. Our expert mechanical engineer will guide you through the eight series of aluminum alloys, revealing their strengths, weaknesses, and how they shape our modern world. Get ready to discover the hidden wonders of this versatile metal!

Aluminum’s unique properties make it a versatile material in metal fabrication and manufacturing:

The low specific gravity of aluminum (approximately 2.7 g/cm³, compared to 7.85 g/cm³ for steel) results in reduced springback during forming operations, allowing for more precise shaping and improved dimensional accuracy.

Despite its lightweight nature, aluminum exhibits a high strength-to-weight ratio. Some high-strength aluminum alloys can match or surpass the specific strength of quality steels, offering excellent mechanical properties with reduced mass.

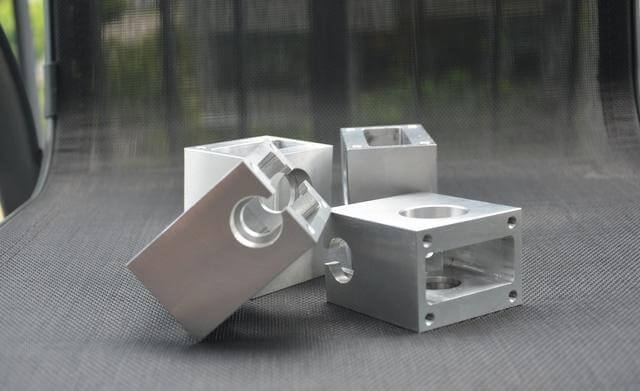

Aluminum’s good plasticity, characterized by its face-centered cubic (FCC) crystal structure, facilitates the formation of complex geometries through various processes such as deep drawing, stretch forming, and hydroforming.

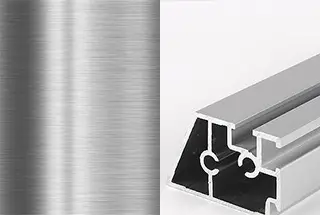

Compared to stainless steel, aluminum is generally more machinable, with lower cutting forces and better chip formation. It also boasts superior electrical conductivity (about 60% that of copper) and thermal conductivity (approximately 237 W/m·K), along with inherent corrosion resistance due to its protective oxide layer.

Modern surface treatment technologies for aluminum, including anodizing, brushing, and sandblasting, have significantly enhanced its aesthetic appeal and functional properties. These advancements have led to widespread adoption in consumer electronics, particularly in smartphone casings and internal components.

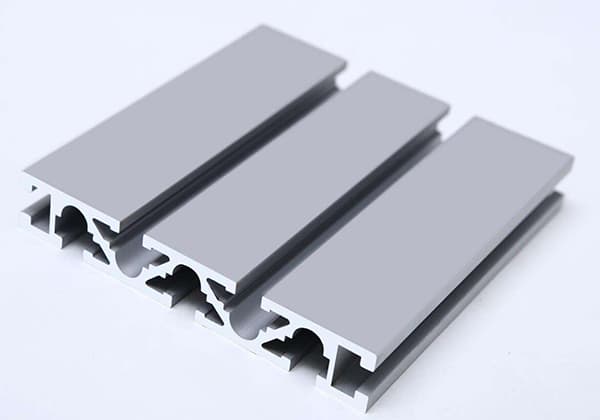

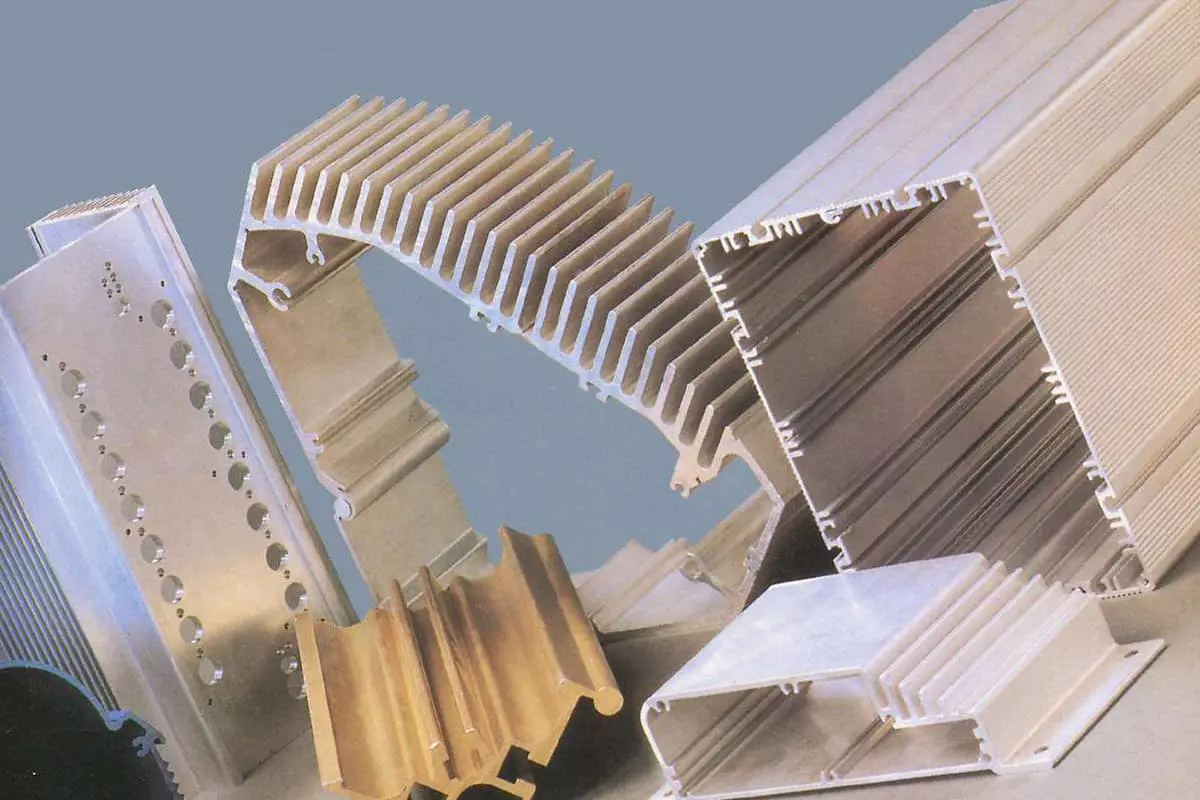

Aluminum alloys are categorized into two main types based on their primary manufacturing method: wrought alloys (deformed through processes like rolling, extrusion, or forging) and cast alloys. The Aluminum Association’s alloy designation system further classifies aluminum and its alloys into eight series (1xxx to 8xxx), each with distinct alloying elements and properties tailored for specific applications.

The International Aluminum Alloy Designation System (commonly known as the four-digit system) is widely used in the industry to classify aluminum alloys based on their primary alloying elements. This system provides a quick reference for material properties and typical applications:

1XXX: Pure aluminum series (99.00% minimum aluminum content)

2XXX: Aluminum-Copper alloy series

3XXX: Aluminum-Manganese alloy series

4XXX: Aluminum-Silicon alloy series

5XXX: Aluminum-Magnesium alloy series

6XXX: Aluminum-Magnesium-Silicon alloy series

7XXX: Aluminum-Zinc alloy series

8XXX: Miscellaneous aluminum alloys

According to the processing method, aluminum alloy can be divided into deformed aluminum alloy and cast aluminum alloy, and the serial number of aluminum and aluminum alloy is mainly divided into eight series.

Among these series, the 1000 series has the highest aluminum content, with a purity of over 99.00%. The last two digits of the 1000 series aluminum plate determine the minimum aluminum content of the series. For example, the last two digits of the 1050 series are 50, which means the aluminum content must be at least 99.5% to meet international brand naming standards.

The primary aluminum has good formability and surface treatment properties, with excellent corrosion resistance. However, its strength decreases as its purity increases.

| Alloy system | Alloy number | Summary of material properties | |

| JIS | A.A | ||

| 1000 series | 1060 | 1060 | As a conductive material, IACS guarantees 61%, and 6061 is used when strength is required |

| 1085 1080 1070 1050 1030 | 1085 1080 1070 1050 | It has good formability and surface treatment.Among aluminum alloys, its corrosion resistance is the best because it is pure aluminum with low strength.The higher the purity, the lower the strength. | |

| 1100 1200 | 1100 1200 | General purpose aluminum with Al purity of more than 99.0% is slightly white after anodizing, which is the same as the above. | |

| 1000 | The strength is slightly higher than 1100, the formability is good, and its chemical properties are the same as 1100. | ||

The ones commonly used on mobile phones are 1050, 1070, 1080, 1085, 1100, do simple extrusion molding (without bending), of which 1050 and 1100 can do chemical sand, glossy, fog, normal effect, with obvious material lines and good coloring effect; 1080 and 1085 specular aluminum are often used to do bright word, fog effect, no obvious material lines.

The first series of aluminum are relatively soft and are mainly used for decoration or interior decoration.

It is characterized by high hardness but poor corrosion resistance, among which the content of copper is the highest.

2000 series aluminum alloy represents 2024, 2A16, 2A02.

The copper content of 2000 series aluminum sheet is about 3% to 5%.

2000 series aluminum bars belong to aviation aluminum materials, which are used as structural materials, but are not often used in conventional industries at present.

| Alloy system | Alloy number | Summary of material properties | |

| JIS | A.A | ||

| 2000 series | 2011 | 2011 | Fast cutting alloy, good machinability and high strength.But the corrosion resistance is poor. When corrosion resistance is required, 6062 series alloy shall be used |

| 2014 2017 2024 | 2014 2017 2024 | Containing a large amount of Cu, the corrosion resistance is poor, but the strength is high, so it can be used for construction materials.Forged products can also be used. | |

| 2117 | 2117 | After solid solution heat treatment, it is used as hinge nail material, which is an alloy to delay the aging rate at room temperature. | |

| 2018 2218 | 2018 2218 | Alloy for forging.Good forging property and high temperature strength, so | |

| Used for forgings requiring heat resistance.Poor corrosion resistance. | |||

| 2618 | 2618 | Alloy for forging.High temperature strength is superior, but corrosion resistance is poor. | |

| 2219 | 2219 | High strength, and high temperature characteristics, excellent solubility, but poor corrosion resistance. | |

| 2025 | 2025 | Alloy for forging.Good forging property and high strength, but poor corrosion resistance. | |

| 2001 | – | Alloy for forging.It has heat resistance and high strength, but the corrosion resistance is not good | |

3000 series aluminum bars are mainly composed of manganese.

3000 series aluminum alloy representatives are 3003, 3105, 3A21-based.

The manganese content is between 1.0% and 1.5%, which is a series with good anti-rust function.

It is often used as grooves and tanks for liquid products, building workpieces, construction tools, all kinds of lamp parts, and various pressure vessels and pipes for sheet processing.

Good formability, solubility and corrosion resistance.

| Alloy system | Alloy number | Summary of material properties | |

| JIS | A.A | ||

| 3000 Series | 3003 3203 | 3003 3203 | The strength is about 10% higher than 1100, and the formability, solubility and corrosion resistance are good. |

| 3004 3104 | 3004 3104 | Higher strength than 3003, superior formability and good corrosion resistance. | |

| 3005 | 3005 | The strength is about 20% higher than that of 3003, and the corrosion resistance is also better. | |

| 3105 | 3105 | The strength is slightly higher than 3003, and other characteristics are similar to 3003. | |

Usually the silicon content is between 4.5% and 6.0%, the higher the silicon content is, the higher the strength is.

The 4000 series aluminum bars represent 4A01, and the 4000 series aluminum plates belong to the series with high silicon content.

Less solidification shrinkage, belonging to building materials, mechanical parts, forging materials, welding materials;

Low melting point, good corrosion resistance, heat resistance and wear resistance.

| Alloy system | Alloy number | Summary of material properties | |

| JIS | A.A | ||

| 4000 series | 4032 | 4032 | Good heat resistance, abrasion resistance and low coefficient of thermal expansion. |

| 4043 | 4043 | Less solidification shrinkage, treated with sulfuric acid anodizing, showing a natural gray color. | |

5000 series aluminum bar belongs to the more commonly used alloy aluminum plate series, the main element is magnesium, the magnesium content is between 3-5%.

5000 series aluminum alloy represents 5052, 5005, 5083, 5A05 series.

It can also be called aluminum-magnesium alloy.

The main characteristics are low density, high tensile strength and high elongation.

Under the same area, the weight of Al-mg alloy is lower than that of other series, so it is widely used in conventional industry.

| Alloy system | Alloy number | Summary of material properties | |

| JIS | A.A | ||

| 5000 Series | 5005 | 5005 5050 | The strength is the same as that of 3003, with good processability, solubility and corrosion resistance.The modification processing after anodizing is good, which is commensurate with the color of 6063 shape material. |

| 5052 | 5052 | It is the most representative alloy with medium strength, with good corrosion resistance, solubility and formability, especially high fatigue strength and good seawater resistance. | |

| 5652 | 5652 | The alloy that limits the impure elements of 5052 and inhibits the separation of hydrogen peroxide.Other properties are the same as those of 5052 | |

| 5154 | 5154 | The strength is about 20% higher than 5052, and other characteristics are the same as 5052 | |

| 5254 | 5254 | The alloy that limits the impure elements of 5154 and inhibits the decomposition of hydrogen peroxide has the same other properties as 5154. | |

| 5454 | 5454 | The strength is about 20% higher than that of 5052, and its characteristics are roughly the same as those of 5154, but its corrosion resistance in vicious environment is better than that of 5154. | |

| 5056 | 5056 | Excellent corrosion resistance, cutting and working surface modification, good anodizing and dyeing. | |

| 5082 | 5082 | The strength is similar to 5083, and the formability and corrosion resistance are good. | |

| 5182 | 5182 | The strength is about 5% higher than 5082, and other characteristics are the same as 5082. | |

| 5083 | 5083 | Alloy for fusion construction.It is the highest strength corrosion-resistant alloy in practical non heat treated alloys and is suitable for solution bonding structures.Good seawater resistance and low temperature characteristics | |

| 5086 | 5086 | The strength is higher than that of 5154.It is a non heat treatment fusion structure alloy with good seawater resistance. | |

| 5001 | – | The strength is the same as that of 3003, and the anodizing treatment after brilliant treatment can have high brilliance.Good formability and corrosion resistance. | |

| 5002 | Alloy for hinge nail, good seawater resistance | ||

The most commonly used on mobile phones is 5052, which is the most representative alloy with medium strength, good corrosion resistance, solubility and formability, especially high fatigue strength, good sea water resistance, and is often used to do products with high strength.

But its coloring effect is not ideal, so it is suitable for sandblasting process, not suitable for chemical sand blasting, fog surface, etc., mainly using casting molding, not suitable for extrusion molding.

6000 series aluminum alloy represents 6061, which mainly contains magnesium and silicon, so it integrates the advantages of 4000 series and 5000 series.

6061 is a cold-treated aluminum forging product, which is suitable for applications requiring high corrosion resistance and oxidation resistance.

Good usability, easy coating and good processability.

| Alloy system | Alloy number | Summary of material properties | |

| JIS | A.A | ||

| 6000 Series | 6061 | 6061 | Heat treated corrosion resistant alloy.T6 treatment can have a very high endurance value, but the strength of the fusion interface is low, so it is used for screws and hinge screws |

| 6001 | The medium strength extrusion alloy has the middle strength of 6061 and 6063.It has good extrusion, stamping and quenching properties. It can be used as large thin meat shape materials with complex shapes.It has good corrosion resistance and fusion joint. | ||

| 6063 | 6063 | The representative extrusion alloy has lower strength than 6061 and good extrudability.It can be used as shape material with complex section shape, with good corrosion resistance and surface treatment | |

| 6101 | 6101 | High strength conductive material. 55% ACS guarantee | |

| 6151 | 6151 | It has excellent forging processability, corrosion resistance and surface treatment.It is suitable for complex forging products. | |

| 6262 | Corrosion resistance fast cutting alloy has better corrosion resistance and surface treatment than 2011, and its strength is the same as 6061. | ||

6061 and 6063 are mostly used on mobile phones.

The strength of 6061 is higher than that of 6063.

Casting molding can cast more complex structures and can be used as snap parts, such as battery cover, etc.

It mainly contains zinc, and 7000 series aluminum alloy represents 7075.

It also belongs to the Aviation series.

It is aluminum magnesium zinc copper alloy, heat treatable alloy, superhard aluminum alloy and has good wear resistance.

| Alloy system | Alloy number | Summary of material properties | |

| JIS | A.A | ||

| 7000 series | 7072 | 7072 | The electrode potential is low.It is mainly used for anti-corrosion covering leather materials.It is also suitable for the heat sink of heat exchanger. |

| 7075 | 7075 | One of the aluminum alloys with the highest strength, but the corrosion resistance is poor.The coating material with 7072 can improve its corrosion resistance, but the cost is increased. | |

| 7050 | 7050 | The alloy with improved quenching property of 7075 has good stress corrosion cracking resistance.It is suitable for thick plates and forged products | |

| 7001 | The alloy for welding structure has high strength, and the strength of the welding part can be returned to the strength close to the base metal when placed at room temperature.Corrosion resistance is also very good. | ||

| 7003 | 7003 | The extrusion alloy for fusion structure has slightly lower strength than 7N01, but has good extrudability.It can be used as a large shape material with thin meat.Other characteristics are roughly the same as 7N01. | |

8011 is commonly used in 8000 Series aluminum alloy, which belongs to other series.

Most applications are aluminum foil, which is not commonly used in the production of aluminum rods.