Have you ever considered the game-changing potential of servo press technology in manufacturing? In this article, we’ll explore how these advanced machines are revolutionizing the industry, offering unparalleled precision, efficiency, and versatility. Our expert insights will reveal the key advantages of servo presses and how they can transform your production process. Get ready to discover the future of metal forming and take your manufacturing to the next level.

The stamping industry has witnessed a revolutionary advancement with the introduction of servo-driven presses, addressing the inherent limitations of conventional mechanical presses. This innovation leverages high-precision servo motors as direct power sources, resulting in unparalleled control over slider motion and overall press operation.

Servo presses offer a multitude of advantages, including:

These features position servo presses as the third-generation stamping technology and the current benchmark in the industry’s evolution.

The programmable nature of servo motors enables advanced motion control capabilities, allowing for:

This level of control makes servo presses ideal for a wide range of applications, including:

The integration of AC servo motor drive technology represents a significant focus in advanced forging equipment research and development. This technology is rapidly becoming the new standard for high-performance presses globally, offering:

As industries such as aerospace, automotive, high-speed rail, marine engineering, nuclear power, renewable energy, and defense sectors demand increasingly complex and high-performance components, the need for advanced stamping equipment continues to grow. Traditional mechanical presses, with their fixed stroke lengths, limited pressure control, and inflexible slider motion characteristics, struggle to meet these evolving requirements.

Servo presses effectively address these challenges by offering:

A servo press is an advanced stamping machine that utilizes servo motor technology to achieve precise control over the pressing operation. At its core, a servo press incorporates a feedback control system that accurately regulates mechanical displacement and acceleration throughout the stamping process.

The key components of a servo press include:

The servo system allows for unprecedented control over the press’s performance parameters:

This level of control offers several advantages over conventional mechanical or hydraulic presses:

Servo presses represent a significant advancement in metal forming technology, enabling manufacturers to achieve higher precision, productivity, and process optimization in their stamping operations.

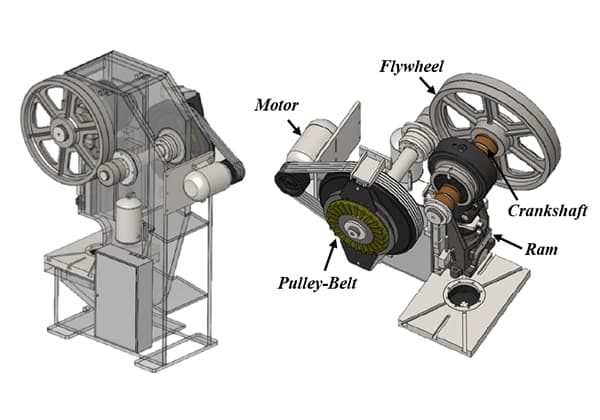

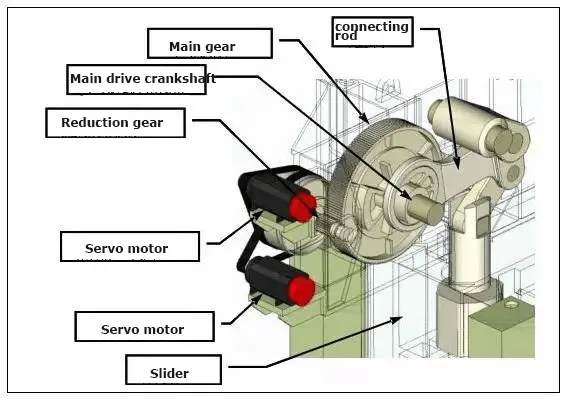

The structure of an AC servo press comprises three primary components: the main drive system, the actuator, and the auxiliary mechanism. The main drive system is responsible for transferring energy from the servo motor to the actuator, utilizing various transmission modes such as gear, belt, screw, or hydraulic systems.

The actuator, which drives the reciprocating motion of the slider to execute the forging process, typically employs either a crank slider mechanism or a crank wedge mechanism. This component is crucial for translating the rotational motion of the servo motor into the linear force required for forging operations.

To enhance reliability and expand process capabilities, the AC servo press incorporates an auxiliary mechanism. This subsystem includes components such as balance cylinders for counteracting the weight of the slide, brakes for emergency stops and holding positions, jacking devices for maintenance and die changes, and position detection devices for precise control and monitoring.

The main drive system of servo presses can be categorized into two types based on the servo motor’s driving mode: direct drive and drive with a reducer. Direct drive systems utilize low-speed, high-torque servo motors directly coupled to the actuator. This configuration offers advantages such as simplified structure, high transmission efficiency, and low noise operation. However, the limited torque output of direct drive systems typically restricts their application to small tonnage servo presses, generally under 300 tons.

In contrast, the majority of commercial servo presses employ a main drive system featuring a deceleration mechanism coupled with a force-increasing mechanism. This approach allows for the use of high-speed, low-torque servo motors to power large tonnage presses, often exceeding 1000 tons. Three primary transmission structures are prevalent in this configuration:

These structures effectively amplify the motor’s torque while reducing speed, enabling precise control over large forces. The ability to utilize high-speed servo motors with reducers not only allows for greater press capacities but also offers improved dynamic response and energy efficiency. This design philosophy represents the current trend in servo press development, as it combines the benefits of servo technology with the force requirements of industrial forging and stamping operations.

Table 1 Comparison of project parameters

| Project | Robot automatic line | Automatic line of single arm manipulator | Crossbar double arm transmission high speed line | Single slider multi station production line | |

|---|---|---|---|---|---|

| Single line automation cost | About 12 million yuan | About 20 million yuan | About 30 million yuan | About 15 million yuan | |

| Line speed / SPM | 5~10 | 6~12 | 10~15 | 12~25 | |

| Production applicability | Multi variety and small batch | Multi variety, medium batch | Multiple varieties and large quantities | Variety, mass | |

| Production flexibility | high | commonly | commonly | low | |

| Production stability | low | commonly | high | ||

| Mold change time/min | 15 | 15 | 5 | 5 | |

| Requirements for press | Operation mode | Single time | Single time | Single, continuous | continuity |

| Press spacing / M | 6.5~8 | 6~9 | 4.5~7 | / | |

| Slider stroke | Small | more | large | large | |

| Mold height | Small | more | large | large | |

As shown in Table 1, the beat of the cross bar double arm transmission high-speed line is between 10 to 15 strokes per minute (SPM). By using a servo press, the beat of the high-speed line can be increased to a maximum of 18 SPM.

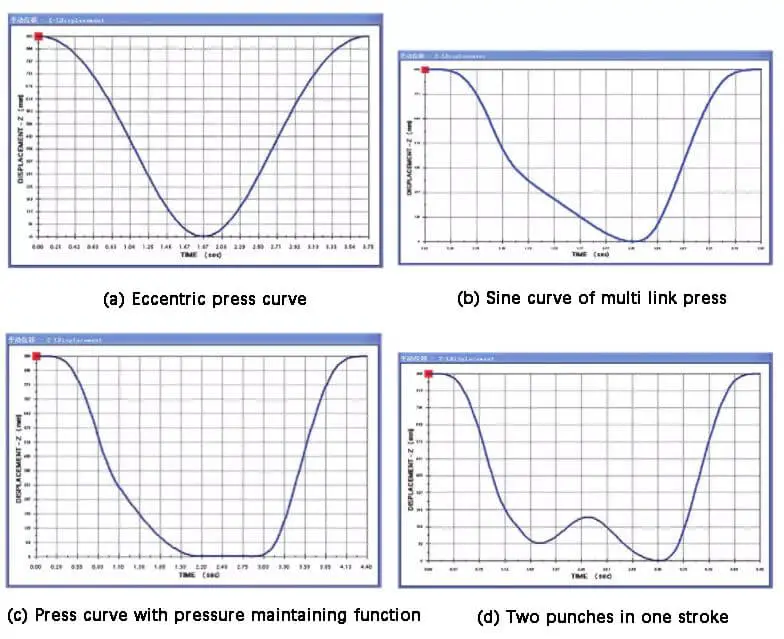

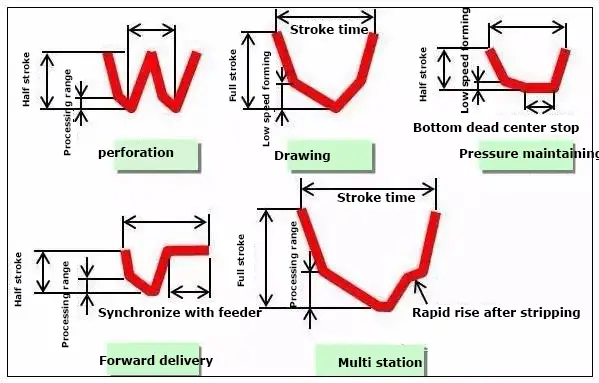

As illustrated in Figure 1, the servo press has the ability to set different curves depending on the specific situation.

Fig. 1 Servo press can set different curves

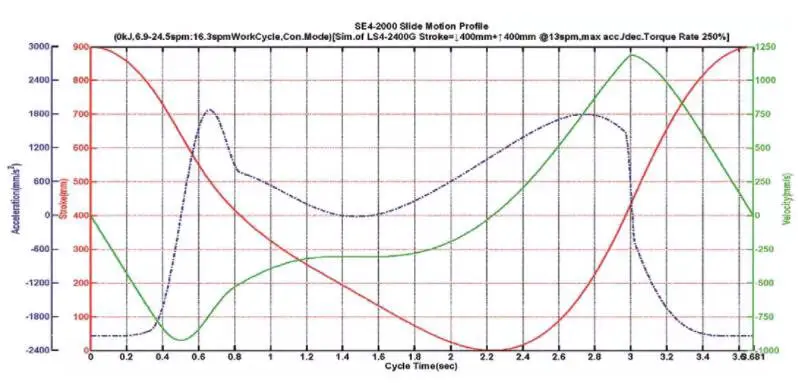

Figure 2 displays the power flow during the acceleration and deceleration phases.

Fig. 2 Current flow direction of servo motor during operation

As depicted in Figure 3, the low drawing speed reduces the impact on the die, leading to an improvement in die life and a reduction in die cost.

Fig. 3 Schematic diagram of drawing speed

Reducing the size of equipment can decrease the investment in plant, infrastructure, and other facilities. As shown in Figure 4, using the four-sequence press as an example, a traditional mechanical press production line consists of one multi-link press and three eccentric presses, requiring a foundation length of approximately 25 meters. In comparison, a production line consisting of four servo presses would only require a foundation length of approximately 16 meters.

Fig. 4 Comparison between traditional mechanical press and servo press

The stroke length can be set to the minimum required for production, and the appropriate forming speed for the processing content can be maintained.

1) Full stroke mode → bottom dead center precision can reach ± 0.02mm.

2) Half stroke mode (pendulum mode) → bottom dead center accuracy can reach ± 0.02mm, improving SPM.

3) Reverse mode → lower dead center accuracy up to ± 001mm.

The closed-loop feedback control ensures the accuracy of the bottom dead center, reducing the formation of burrs in the product and preventing the generation of defective products.

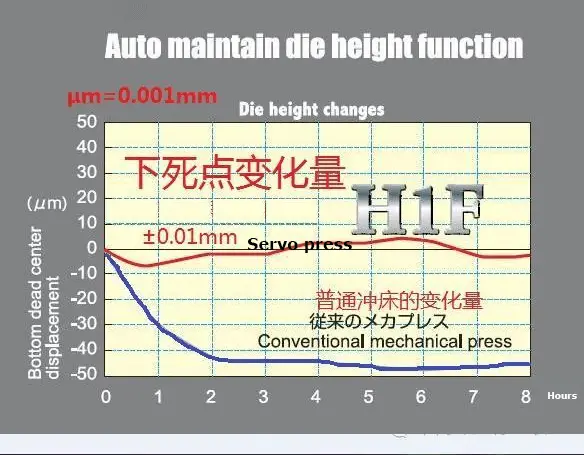

Servo unique auto die height correction function:

The position change of the slider can be measured and corrected to ±0.01mm of the preset value through the use of a linear grating scale in each stroke, ensuring a high degree of accuracy in the bottom dead center.

Linear grating ruler position ↓

The servo bottom dead center has an automatic correction function which ensures the accuracy of the bottom dead center at ±0.01mm even after prolonged production, thereby ensuring a high yield of products.

The low noise mode, which reduces the contact speed between the slider and the sheet metal, significantly reduces noise compared to a traditional mechanical press.

Additionally, the die experiences minimal vibration, leading to an extended service life.

Users can use this feature to create a customized slider movement mode that is suitable for their processing technology, thereby improving the accuracy and stability of the products.

This leads to an extended die life and productivity, as well as quiet blanking and the ability to process a wider range of materials, including magnesium alloys.

The servo press can be used for processes such as blanking, stretching, embossing, and bending, and can provide performance curves for different materials. The ability to pause the slider while maintaining pressure improves the quality of the formed workpiece.

The traditional mechanical press’s energy-consuming components like the flywheel and clutch have been eliminated, resulting in fewer driving parts and a simplified mechanical transmission structure.

The need for lubricating oil is reduced and the stroke is controllable. The reduced motor consumption leads to a significant decrease in operating costs.

The servo punch is mainly utilized in production processes such as drawing, blanking, bending, cold forging, embossing, and die testing.

Thanks to its utilization of PLC control, digital technology, and feedback control methods, the servo punch offers advanced precision control. This includes the ability to control the position of the press slider.

The monitoring system and compensation control enable the position of the slider to be controlled with an accuracy of ±0.01mm. The motion mode can be programmed, allowing for control of the slider’s speed and trajectory.

This reduces stamping speed, noise, and vibration, improving the stamping work environment and extending the lifespan of the die.

Additionally, the output force of the slider can be controlled with a precision of ±1.6% of the maximum output force. This allows for the formation of large panels using high-strength steel and aluminum alloy plates in the automobile industry.

Difficult-to-form materials such as magnesium alloy, aluminum alloy, and titanium alloy can be made easier to form through the combination of die design and peripheral system control.

Toggle type servo structure

Crankshaft direct drive servo structure

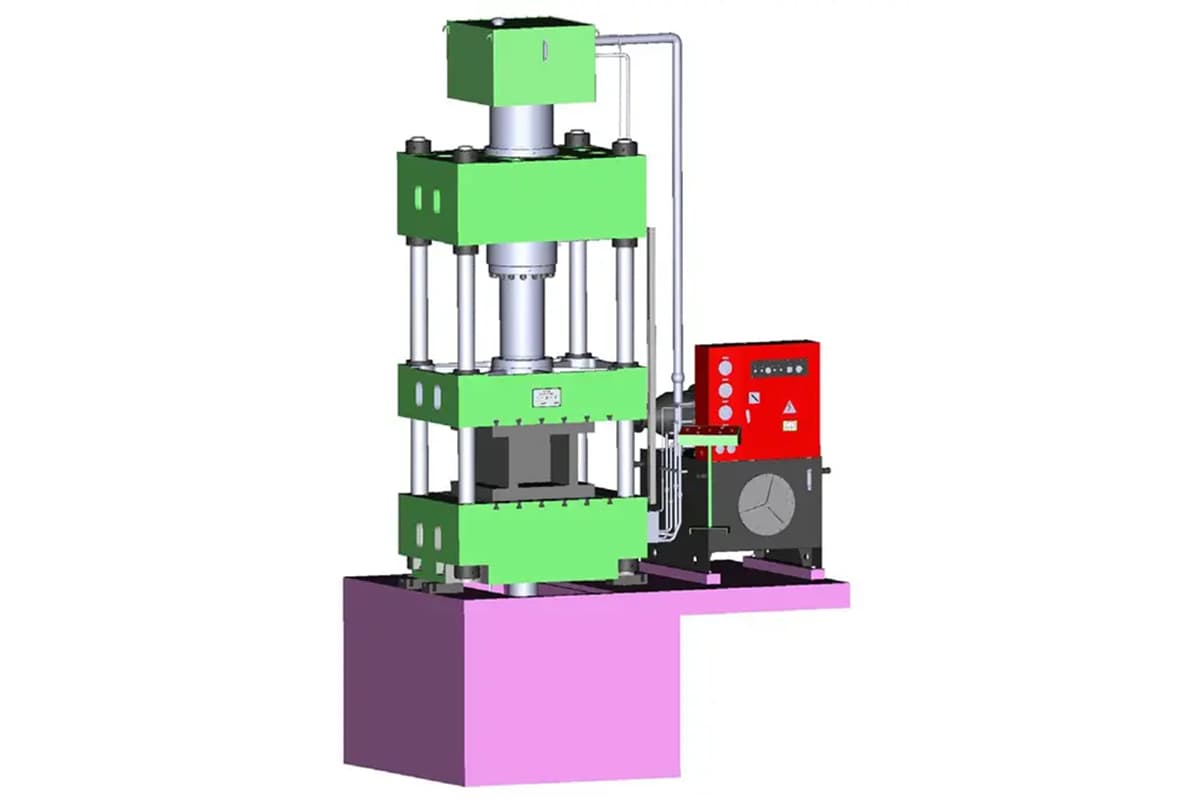

Figure 5 depicts the Schuler double servo bottom drive multi-station press.

Fig. 5 Schuler double servo bottom drive press

The double servo bottom drive press is powered by two separate groups of servo motors, one on the left and one on the right. These motors drive the four guide columns on each side, allowing for the movement of the sliding block.

The independent transmission mechanisms on both the left and right sides enable the table to have large dimensions on both sides, making it suitable for large tables and high tonnage presses, as shown in Figure 6.

Fig. 6 Double servo multi station press

The double servo bottom drive press uses the precise control of two groups of servo motors to achieve synchronous movement of the slider on both the left and right sides.

In the event of an eccentric load on the slider, the parallelism of the slider can be adjusted through electrical control, making it more flexible and adaptable to meet user requirements.

Compared to ordinary presses, the bottom drive press has better eccentric load strength and precision curves. While still meeting accuracy requirements, it offers improved resistance to eccentric loads and a larger area for eccentric load application.

When evaluating servo presses against hydraulic and pneumatic presses, it’s essential to consider several critical factors such as control, flexibility, speed, energy efficiency, and maintenance requirements.

Servo presses utilize advanced servomotors and drive systems that offer precise control over position, speed, and force. They incorporate a closed-loop feedback system, ensuring high accuracy and repeatability. For example, servo presses can achieve positional accuracy to within +/- 0.0005” and force control to within +/- 0.5%, making them highly suitable for applications requiring stringent precision. Industries such as automotive manufacturing and electronics assembly often use servo presses to ensure consistent quality in complex parts.

Hydraulic presses, while capable of delivering variable stroke lengths and full working energy at any speed, rely on fluid pressure. This can result in slightly lower accuracy due to the potential for dampened corrections in force or speed. However, with the help of sensors and linear transducers, hydraulic presses can still maintain accurate control. For instance, in the aerospace industry, hydraulic presses are often used for forming large, intricate parts where the material properties require the flexibility of hydraulic control.

Pneumatic presses generally provide less precise control over the ram’s motion. Typically, they require the ram to return to the full up position between uses of maximum specified force, which limits their precision and versatility compared to servo presses. They are commonly used in applications like small-scale assembly and packaging where high precision is less critical.

Servo presses offer significant flexibility with programmable stroke profiles, slide motion, and speed. This allows them to accommodate a wide variety of dies and part types, making them particularly useful for applications that require complex part geometries and high dimensional precision. For example, in the medical device industry, servo presses are used to manufacture components with intricate designs and tight tolerances.

Hydraulic presses are also versatile, especially in drawing and forming complex parts. They can apply full force at any point in the stroke, making them ideal for deep forming applications and parts that necessitate a dwell at the bottom of the stroke. Industries such as heavy machinery and shipbuilding benefit from the versatility of hydraulic presses for forming large and thick metal parts.

Pneumatic presses, while more affordable and simpler, are generally less versatile. They are best suited for lighter tasks such as assembly, riveting, punching, and marking. For instance, in the consumer goods industry, pneumatic presses are often used for assembling small plastic components.

Servo presses can operate at faster speeds than hydraulic presses, often approaching the production speeds of traditional mechanical presses. They can achieve variable slide velocities within a single cycle and maintain high production rates, making them suitable for high-speed manufacturing environments. For example, in the electronics industry, servo presses are used to produce high volumes of precision parts quickly.

Hydraulic presses are generally slower, with their speed constrained by the shifting of hydraulic valves, typically achieving fewer than 30 strokes per minute (SPM). Despite this, they are valuable in applications where high force and control are more critical than speed, such as in metal forming and forging.

Pneumatic presses can operate quickly but are usually limited to lighter applications and may not match the production speeds of servo or hydraulic presses. They are commonly used in repetitive tasks that require quick cycle times but lower force, such as packaging and labeling.

Servo presses are highly energy-efficient, consuming energy only on-demand. This results in significant energy savings, typically ranging from 20-50% compared to hydraulic presses. They do not require oil, which reduces maintenance costs and environmental impact. For instance, automotive manufacturers have reported substantial reductions in energy consumption and costs by switching to servo presses.

Hydraulic presses consume significantly more energy, even when idle, due to the continuous operation of pumps and motors. However, energy-efficient technologies such as variable frequency drives (VFDs) can help mitigate this to some extent. Industries that require heavy-duty forming processes, such as steel manufacturing, often implement VFDs to improve energy efficiency.

Pneumatic presses are generally more energy-efficient than hydraulic presses but may not offer the same level of energy savings as servo presses. They are often used in applications where energy consumption is less of a concern, such as in small-scale manufacturing operations.

Servo presses have lower maintenance requirements due to their electro-mechanical design, eliminating the need for hydraulic fluid and reducing the risk of costly leaks and disposal fees. They also provide instant feedback for diagnostics and maintenance. This makes them particularly attractive for high-precision industries such as aerospace and medical device manufacturing.

Hydraulic presses require regular maintenance, including monitoring oil pressure, efficiency, and performing tasks such as filter changes and oil cleanliness checks. This can lead to significant downtime and increased maintenance costs. However, they are indispensable in industries that demand high force and flexibility, such as automotive and heavy equipment manufacturing.

Pneumatic presses are relatively simple and have lower maintenance costs compared to hydraulic presses. However, they may still require occasional checks and replacements of components like air lines and valves. They are commonly used in industries where simplicity and cost-effectiveness are key, such as in small-scale assembly operations.

Servo presses are generally safer due to lower operating temperatures and the absence of hydraulic fluid, which can cause premature component failure and create unsafe working conditions if not properly managed. This makes them suitable for environments where safety and cleanliness are paramount, such as in pharmaceutical manufacturing.

Hydraulic presses can pose safety risks due to high operating temperatures and the potential for high-pressure hose leaks or bursts. Industries that use hydraulic presses must implement stringent safety protocols to mitigate these risks, particularly in high-force applications like metal forging.

Pneumatic presses are generally safer than hydraulic presses but may still have some risks associated with compressed air systems. They are often used in environments where safety and simplicity are prioritized, such as in light manufacturing and assembly lines.

As competition in the manufacturing industry intensifies, there is a growing demand for servo presses capable of producing high-precision, high-quality products with enhanced efficiency. This demand is driven by the servo press’s unique advantages, which align closely with the future trajectory of forging machine development.

Servo presses offer a multitude of benefits, including:

The servo press’s ability to dynamically adjust stroke and forming speed allows for fine-tuned control over the forming process. This precise control ensures exceptional accuracy at the bottom dead center, significantly reducing the occurrence of product burrs. Furthermore, the reduced die vibration resulting from optimized motion profiles extends die life, lowering tooling costs and improving overall equipment effectiveness (OEE).

The innovative design of servo presses represents a paradigm shift from traditional mechanical presses. By eliminating components such as the flywheel, clutch, and brake, servo presses not only reduce machine operating costs but also minimize maintenance requirements and improve reliability. This simplification of the drive train allows for more compact designs and easier integration into smart manufacturing environments.

As Industry 4.0 and smart manufacturing initiatives gain momentum, servo presses are poised to play an increasingly critical role in key manufacturing sectors. Their adaptability and precision make them particularly valuable in industries such as:

Moreover, the data collection and analysis capabilities inherent in servo press systems align well with the trend towards predictive maintenance and real-time process optimization, further enhancing their appeal in precision manufacturing fields.

First, consider the required accuracy of the servo press.

Accuracy refers to the precision with which the press achieves specified pressure and position setpoints. It is influenced by several factors, including driver resolution, pressure transducer sensitivity, servo motor precision, and overall system response time.

As servo motor and driver control technologies have matured and become more integrated, the repeatability of servo presses has significantly improved. This has expanded their application across various industries and processes.

For applications demanding high accuracy, careful attention must be paid to the press configuration. Key components to evaluate include:

Second, consider the structural design of the servo press.

Manufacturers offer various servo press structures to suit different applications. Common configurations include:

The selection of press structure should be based on factors such as workpiece size, required access, available floor space, and process requirements.

Servo presses can perform a wide range of functions, including:

Each function may require specific structural features or capabilities. For example, a deep-draw operation might necessitate a press with a longer stroke and higher tonnage capacity compared to a simple stamping application.

When selecting a servo press, it’s crucial to analyze your specific product and process requirements. Consider factors such as:

By carefully evaluating these factors and matching them to the available servo press options, you can ensure optimal performance, efficiency, and quality in your metal forming operations.

Below are answers to some frequently asked questions:

The main advantage of using a servo press over a hydraulic press is its superior precision and control. Servo presses utilize electric servo motors that provide a closed-loop feedback system, enabling highly accurate and rapid adjustments to the speed and position of the press’s ram. This precision is crucial for applications that demand tight tolerances and consistent quality. Additionally, servo presses are more energy-efficient, consuming power only during motion, which reduces operational costs. They also offer faster production rates, lower maintenance requirements due to fewer moving parts, and greater flexibility with programmable stroke, speed, and energy profiles. These benefits make servo presses an ideal choice for modern manufacturing environments where efficiency, accuracy, and versatility are paramount.

Servo presses achieve precise control in operations through the use of advanced servo motor technology, which is managed by sophisticated electronic control systems. These systems enable the precise regulation of the press’s movement and force, ensuring highly accurate and programmable motion profiles. The core component, the servo motor, works in conjunction with gearboxes and linear actuators to deliver the necessary pressing force. Real-time monitoring and adjustments to the ram force, speed, and position are made possible by the control system, ensuring consistency and precision throughout each cycle.

In addition, servo presses are equipped with load cells that provide feedback on the force exerted, enabling precise force control with high repeatability. This feedback mechanism ensures that the press operates within the desired parameters, maintaining accuracy.

Another key feature is the ability to create and execute complex motion profiles, which allows for variable speed and force during operations. This flexibility is crucial for applications such as material forming and deep drawing. Servo presses also offer multiple control modes, including speed and force control, which can be tailored to specific application needs.

High-resolution encoders further enhance precision by eliminating the need for a reference point during commissioning after an emergency shutdown, thus avoiding the need for battery maintenance and replacement. This ensures reliable and continuous operation without the need for frequent recalibration.

Servo presses are also energy-efficient, using power only when needed, which makes them more sustainable and cost-effective compared to traditional hydraulic presses. Their adaptability allows them to be easily reprogrammed and reconfigured for different tasks, reducing downtime and increasing productivity.

Comprehensive application software and integration capabilities further enhance the precision and efficiency of servo presses. This software facilitates the setting of program parameters, data collection for quality control, and seamless integration into existing assembly lines.

Preventive maintenance features, such as temperature monitoring and motor overload warnings, along with ongoing support from manufacturers, ensure the longevity and optimal performance of servo presses. These combined technologies and features enable servo presses to achieve precise control, making them ideal for high-accuracy and repeatability applications in modern manufacturing.

Yes, servo presses can handle high-strength materials effectively. They are designed to manage the increased energy demands and stresses that come with forming advanced high-strength steel (AHSS) and other ultrahard materials. Servo presses offer precise control over slide velocity and dwell times, which can be programmed to optimize the forming process, reduce friction, and extend die life. Their ability to manage energy and force efficiently, coupled with advanced cooling systems to handle heat, ensures they can maintain performance even under the demanding conditions required for high-strength materials. Additionally, their precision and flexibility allow for the accurate forming of complex geometries, making servo presses a suitable choice for various manufacturing applications involving high-strength materials.

Servo presses are widely utilized in various manufacturing processes due to their precision, programmability, and flexibility. Typical applications include metal stamping and forming, where they are used for operations such as blanking, piercing, bending, and forming, particularly with high-strength materials in the automotive and aerospace industries. In assembly and joining, servo presses provide precise force and position control for tasks like bearing assembly and insertion of seals. They are also ideal for riveting and fastening, allowing for adjustable force levels and speeds to ensure reliable joint integrity.

In material forming processes such as deep drawing, embossing, and extrusion, servo presses offer programmable motion profiles and precise force control, enabling the creation of complex shapes with high accuracy. They are used in plastic and composite molding to ensure consistent results and reduce cycle times. Additionally, servo presses are employed in testing and quality control to perform material property evaluations, ensuring the quality and reliability of manufactured parts.

In electronics and microelectronics assembly, servo presses provide the precise force application necessary for delicate components, accommodating various bonding techniques. The medical device manufacturing industry benefits from the high precision and force control of servo presses for high-tolerance applications. Furthermore, servo presses are extensively used in the aerospace and automotive industries for sheet metal forming, assembly, testing, and fastening, meeting stringent quality and performance requirements. They are also applied across a wide range of general manufacturing processes, including cutting, bending, crimping, and joining operations where press force control and position accuracy are crucial.

When choosing a servo press for your business, several key factors must be considered to ensure the selected press meets your specific needs and operational requirements. First, assess the tonnage and pressure requirements. The press should operate efficiently within 10%-90% of its range to maintain accuracy. The table size and worktable dimensions must accommodate the largest molds and workpieces you plan to handle, ensuring convenient mold installation and loading/unloading of workpieces. Evaluate the stroke and opening daylight to ensure they are suitable for your application.

Consider the mold installation mode, typically involving fixed molds at the upper and lower ends, with the upper end using the die head/die platen and the lower table surface featuring T-slot installation. Accuracy and precision are crucial; ensure the press’s capabilities align with your production requirements. Servo presses offer high accuracy due to advanced drive systems, pressure transmitters, and servo motor precision.

Programmability and flexibility are significant advantages of servo presses, allowing for programmable control over slide position, speed, and pressure, making them ideal for complex and varied tasks. Energy efficiency is another benefit, as servo presses draw current only on demand, leading to significant energy savings compared to pneumatic or hydraulic systems.

Evaluate cycle times and productivity, as servo presses can improve cycle times by running faster during non-work portions of the cycle, enhancing parts per minute output. Maintenance and skill level requirements should also be considered, as servo presses necessitate higher technical knowledge for operation and maintenance.

Consider the initial investment and total cost of ownership, recognizing that while servo presses have a higher initial cost, they offer long-term benefits such as reduced setup times, improved tool life, and enhanced productivity. Measurement and control technologies, such as LVDT or encoders, should be chosen based on the precision and repeatability needed for your application.

Finally, consider the type of mechanical modules and drive systems, including servo motor mounting and linear screw types, based on maintenance, load handling, and efficiency. Ensure adequate support and service, especially if the assembly station will be shipped internationally, to maintain technical support and replacement parts availability.

By carefully evaluating these factors, you can select a servo press that aligns with your operational goals, technical capabilities, and specific needs.