As a general rule, drilling a small hole in the sheet metal is necessary for any hot cutting process, with only a few exceptions where cutting can start from the edge of the sheet metal.

In the past, a hole was punched using a punch mold in a laser stamping machine before the laser cutting process began.

There are two fundamental methods for laser cutting without the use of a stamping device:

During continuous laser irradiation, the material forms a pit in the center, which is then quickly removed by the oxygen flow accompanying the laser beam, resulting in the formation of a hole.

The size of a typical hole is determined by the plate thickness.

The average diameter of the blasting perforation is roughly half the thickness of the plate, meaning that perforations in thicker plates are larger and not circular.

This method should not be used on parts that require high precision in machining, and is only suitable for scrap material.

Additionally, the oxygen pressure used during the perforation process is the same as that used in cutting, which results in excessive splashing.

A pulsed laser with a peak power is utilized to melt or vaporize a small amount of material. Common air or nitrogen is employed as an auxiliary gas to reduce the expansion of the hole due to exothermic oxidation. The gas pressure is lower than that used in cutting with oxygen. Each pulse of the laser produces small particles that are expelled and penetrate gradually. As a result, perforating a thick plate can take several seconds.

Once the perforation is complete, the auxiliary gas is immediately replaced with oxygen for cutting. This results in a smaller perforation diameter and a higher quality perforation compared to blasting. To achieve this, the laser must not only have a higher output power, but also precise time and space characteristics of the beam. The general flow CO2 laser does not meet these requirements.

Additionally, pulse perforation requires a reliable gas control system to regulate the type of gas, pressure, and perforation time. To achieve high-quality cuts during pulse perforation, transitioning from pulse perforation to continuous cutting must be taken seriously.

In theory, cutting conditions such as focal length, nozzle position, and gas pressure during the acceleration period can be altered. However, in industrial production, it is more practical to change the average power of the laser. This can be achieved by altering the pulse width, frequency, or both. Research has shown that the latter approach yields the best results.

The reason for this is because when machining a hole, the high-power laser cutter does not use the method of blasting perforation, but instead employs pulse perforation (soft puncture). This leads to laser energy being too concentrated in a small area, causing the non-processing area to char and resulting in deformation of the hole and degradation of processing quality.

In this case, it is necessary to switch from pulse perforation (soft puncture) to blasting perforation (ordinary puncture) in the processing procedure to resolve the issue.

On the other hand, for less powerful laser cutting machines, it is advisable to use pulse perforation to achieve a better surface finish for small hole cutting.

According to the working and design principles of CO2 laser cutting, the following are analyzed as the main reasons for the formation of burrs on the workpiece:

In case of the above situation, when cutting low-carbon steel, you should initially consider the factors that may cause burrs.

However, simply increasing the cutting speed may not necessarily solve the issue, as the increase in speed may not always allow for piercing the plate. This is especially prominent when processing aluminum-zinc plates.

In such a scenario, other factors of the laser cutting machine should also be taken into consideration, such as the need for replacing the nozzle and checking the stability of the guide movement.

After analysis, the following are identified as the main causes of unstable processing:

Incorrect selection of laser nozzle for plate thickness;

Cutting speed is too high and needs to be decreased.

It’s also crucial to note that when cutting a 5mm carbon steel plate with a laser cutting machine, it is necessary to replace the 7.5″ focal length laser lens.

This situation can have an impact on the quality of the cut sections of the parts. If other parameters are normal, you should consider the following potential causes:

The Working Principle of Laser Beam Cutting:

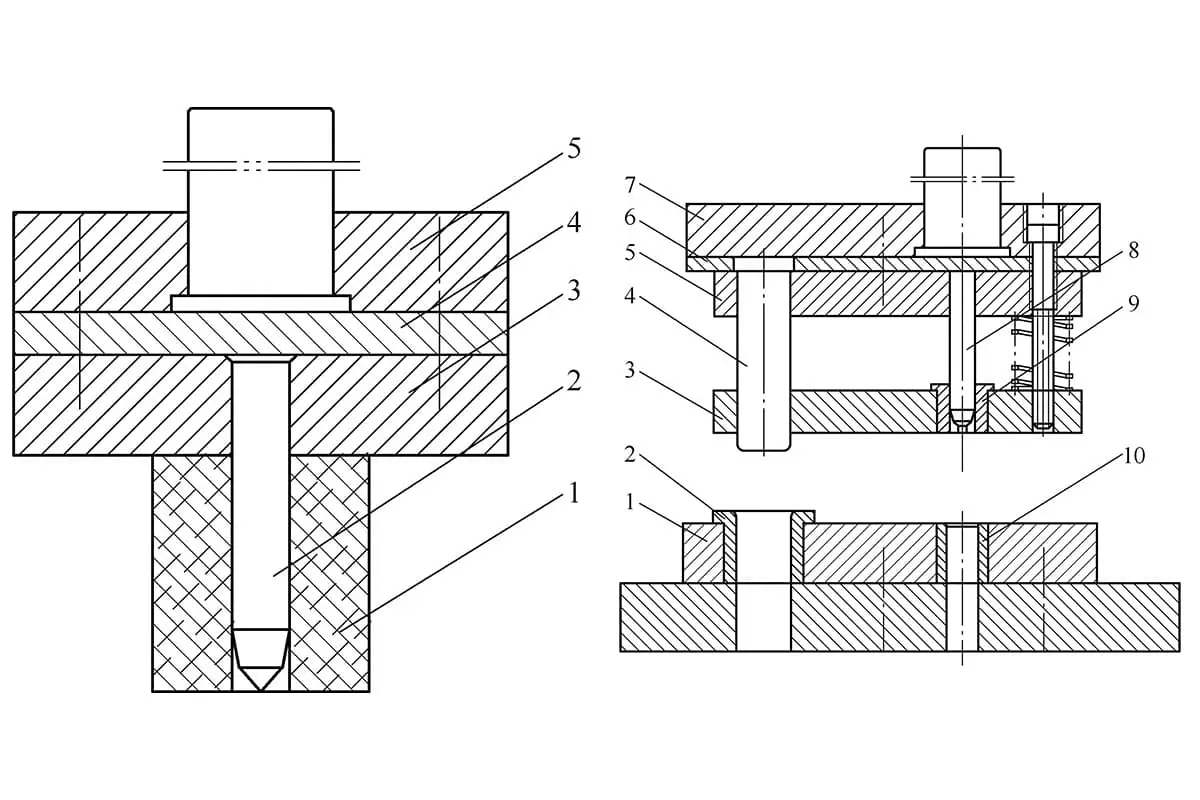

During the cutting process, the material is subjected to continuous laser radiation, which results in a depression in the center. The working airflow with the laser beam then removes the melted material quickly, creating a hole. This hole resembles a threaded hole in thread cutting.

The laser beam uses this hole as the starting point for contour cutting. Usually, the direction of the laser beam in the flight path is perpendicular to the tangent direction of the cut contour of the processed part.

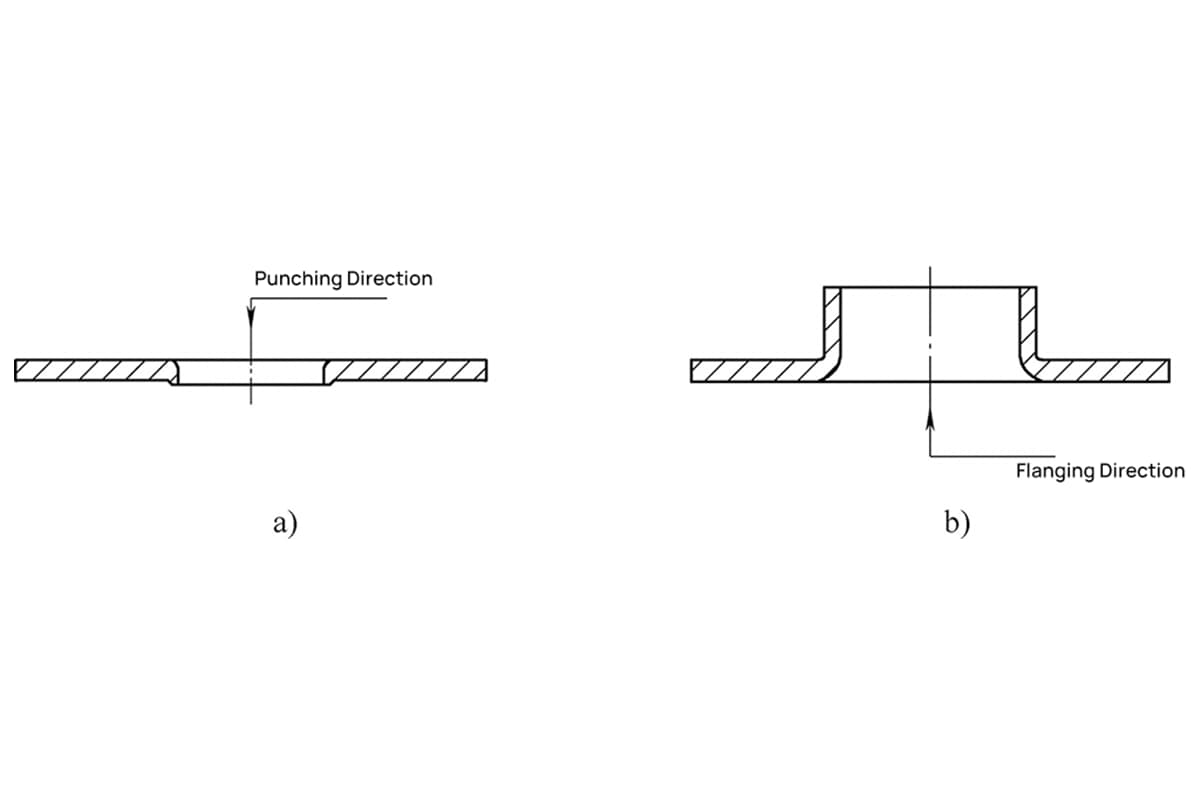

As a result, from the moment the laser beam penetrates the steel plate to the time of cutting the contour, there is a big change in the cutting speed in the direction of the vector. Specifically, the vector rotates 90°, causing the tangential direction perpendicular to the cut profile to overlap with the cut contour. In other words, the angle with the contour tangent becomes 0°.

This rapid change in the direction of the vector movement of the laser beam results in a rough cut surface on the cut section of the processed material.

In general, when there are no roughness requirements for the surface cutting in the design, manual control will not be set in the laser cutting programming, and the control software will automatically generate puncture points. However, when the design requires a high roughness for the cutting section, it is important to take this issue into consideration.

Manual adjustment of the starting position of the laser beam, i.e., the manual control of the puncture point, is usually necessary. This involves moving the puncture point generated by the laser program to a reasonable position that meets the surface precision requirements of the machined parts.

As the founder of MachineMFG, I have dedicated over a decade of my career to the metalworking industry. My extensive experience has allowed me to become an expert in the fields of sheet metal fabrication, machining, mechanical engineering, and machine tools for metals. I am constantly thinking, reading, and writing about these subjects, constantly striving to stay at the forefront of my field. Let my knowledge and expertise be an asset to your business.