Have you ever wondered what makes a perfect weld? In laser welding, the secret lies in the use of shielding gas. This article explores how different gases, like nitrogen, argon, and helium, impact weld quality and why choosing the right one is crucial. Get ready to uncover the essentials for achieving flawless welds!

Shielding gas plays a crucial role in laser welding, enhancing weld quality, protecting the molten pool, and preventing damage to laser optics. Its application can be categorized into three distinct types, each serving specific functions in the welding process:

The selection and optimization of these gases significantly influence weld quality, process stability, and overall efficiency in laser welding operations. Factors such as material composition, weld joint design, and laser parameters must be considered when determining the optimal gas configuration for a specific application.

Continuous laser welding is an advanced joining process that employs high-energy laser beams as a concentrated heat source to precisely melt the surface of workpieces, creating high-quality, highly efficient welding joints.

During high-power laser welding, the intense laser beam rapidly heats the material beyond its melting point. However, the extreme temperatures generated can also cause metal vaporization, leading to the formation of metal vapor plasma in the weld zone.

This plasma plume can significantly attenuate the incoming laser energy, reducing the effective power reaching the workpiece surface. Consequently, it affects the stability of the molten pool and can compromise weld quality and consistency.

To mitigate these issues and ensure process stability, a carefully selected shielding gas with high ionization potential must be introduced during welding. Typically, inert gases like argon or helium are used. The shielding gas serves multiple critical functions:

The proper application of shielding gas results in a more stable welding process, reduced defects, and an even, smooth weld surface with improved mechanical properties.

In laser welding, the use of shielding gas will have an impact on the formation of the weld, its quality, penetration, and width.

In most situations, blowing shielding gas will result in a positive effect on the weld, but it can also have unfavorable impacts.

(1) Proper shielding gas can effectively protect the weld pool and reduce or even eliminate oxidation.

(2) It can also reduce spatter during welding.

(3) The weld pool will solidify evenly and have a uniform, attractive shape.

(4) Proper shielding gas can also reduce the shielding effect of metal vapor plume or plasma on the laser, leading to increased laser utilization.

(5) Additionally, the correct use of shielding gas can reduce weld porosity.

As long as the correct type of gas, flow rate, and blowing mode are selected, the desired results can be achieved.

However, incorrect use of shielding gas can have negative effects on welding.

(1) Incorrect use of shielding gas can result in the degradation of the weld;

(2) Choosing an inappropriate gas type may cause cracks in the weld, and can also lower the mechanical properties of the weld;

(3) The incorrect selection of gas flow rate may lead to increased oxidation of the weld (whether the flow rate is too high or too low), or the metal of the weld pool may be severely disrupted by external forces, leading to collapse or uneven formation of the weld;

(4) Selecting an incorrect method of gas flow may result in a lack of protection for the weld, or even have no protective effect at all, or have a negative impact on weld formation;

(5) The penetration of the welding seam will be impacted by the flow of shielding gas, particularly when welding thin plates.

The commonly used shielding gases for laser welding are nitrogen (N2), argon (Ar), and helium (He). Their physical and chemical properties differ, thus their effect on the weld also varies.

The ionization energy of N2 is moderate, with a value higher than that of Ar and lower than that of He.

Under the action of a laser, the ionization of N2 is generally moderate, which can reduce the formation of plasma clouds and increase the effective utilization of the laser.

However, when nitrogen reacts with aluminum alloy or carbon steel at a certain temperature, it produces nitride, which can result in a decrease in the toughness and weld brittleness and have a negative impact on the mechanical properties of the weld joint.

Therefore, it is not recommended to use nitrogen as a protective gas when welding aluminum alloy or carbon steel.

On the other hand, when nitrogen reacts with stainless steel, it can improve the strength of the weld joint and positively affect the mechanical properties of the weld.

As a result, nitrogen can be used as a shielding gas when welding stainless steel.

The ionization energy of Ar is relatively low, and under the action of a laser, its ionization degree is relatively high, which can negatively impact the control of plasma cloud formation and the effective utilization of the laser.

However, Ar’s low reactivity with common metals and its relatively low cost make it an attractive option. Additionally, its high density allows it to sink effectively above the weld pool, providing a better protective environment.

For these reasons, Ar is commonly used as a conventional shielding gas.

The ionization energy of He is the highest, and under the action of a laser, its ionization degree is very low, making it effective in controlling the formation of plasma clouds.

Laser can effectively act on metals, and He’s low reactivity and low activity make it a good shielding gas for welding.

However, the high cost of He makes it unsuitable for widespread use in mass-produced products. It is typically used in scientific research or high-value products.

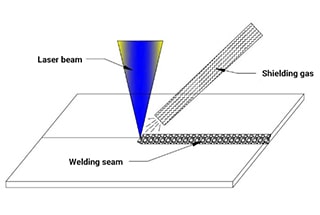

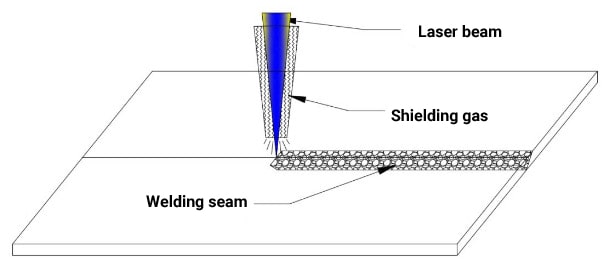

At present, there are two main methods of blowing shielding gas: one is side-shaft side-blowing shielding gas, as shown in Figure 1; the other is coaxial shielding gas, as depicted in Figure 2.

Fig. 1 Side shaft side blowing protective gas

Fig. 2 Coaxial shielding gas

Choosing between the two methods of blowing shielding gas involves a comprehensive consideration of many factors.

In general, it is recommended to use the side-blowing method of shielding gas.

First of all, it is important to note that the term “oxidation” of the weld is simply a colloquial name.

Theoretically, it refers to the chemical reaction between the harmful components in the air and the weld, which leads to a decrease in weld quality.

The common cause of this is the reaction between the weld metal and elements such as oxygen, nitrogen, and hydrogen in the air at high temperatures.

To prevent the weld from being “oxidized,” it is necessary to reduce or eliminate contact between the weld metal and these harmful components at high temperatures.

This high-temperature state encompasses not only the molten pool metal, but also the entire process from the moment the weld metal is melted to the time it solidifies and cools below a certain temperature.

For example, titanium alloys can rapidly absorb hydrogen at temperatures above 300°C, oxygen at temperatures above 450°C, and nitrogen at temperatures above 600°C.

Therefore, it is essential to protect the titanium alloy weld after solidification and the stage below 300°C, or it will be “oxidized.

It is evident from this that the use of shielding gas must not only protect the weld pool in real-time, but also the just-solidified area of the weld.

As a result, side-shaft side-blowing shielding gas, as shown in Figure 1, is generally used.

Compared to coaxial protection (Figure 2), this method provides a wider scope of protection, especially for the area where the weld has just solidified.

In practical applications, not all products can use the side-shaft side-blowing method of protection.

For some specific products, only coaxial shielding gas can be used, and the specific choice will depend on the product structure and the form of the joint.

As depicted in Figure 3, the product has a linear weld shape, with the joint form being a butt joint, lap joint, internal corner joint, or overlap welding joint.

For this product, it is more favorable to use the side-shaft side-blowing shielding gas method shown in Figure 1.

Fig. 3 Straight weld

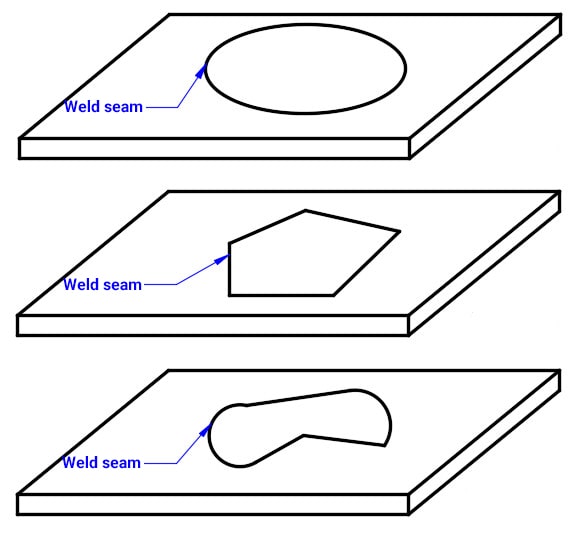

As depicted in Figure 4, the product has a weld shape that is a plane circular shape, a plane multilateral shape, a plane multi-segment linear shape, or other closed shapes, and the joint forms can be butt joints, lap joints, overlap joints, etc.

Hence, the product is more suited to use the coaxial shielding gas method shown in Figure 2.

Fig. 4 Plane closed graph weld

The selection of shielding gas has a direct impact on the quality, efficiency, and cost of welding production.

However, due to the diversity of welding materials, the selection of welding gas is more complex in actual welding practice.

To choose the most suitable shielding gas, it’s important to take into account the welding material, welding method, welding position, and desired welding outcome.

The only way to determine the best option is to conduct a welding test.

In addition to choosing the appropriate shielding gas based on the welding material, it’s also necessary to examine the impact of the blowing angle, direction, and flow rate of the shielding gas on the weld morphology.

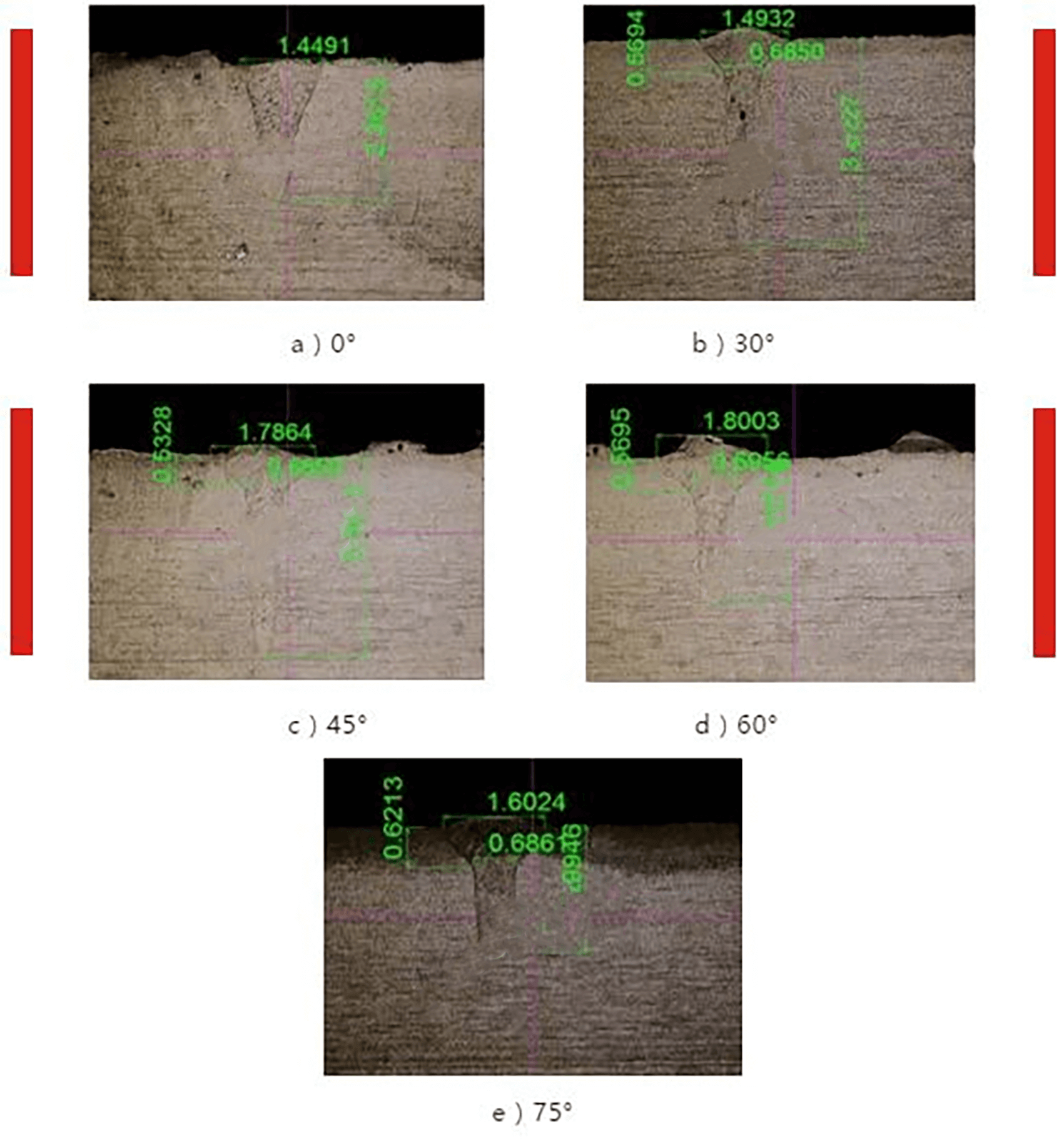

Studies have been conducted to understand the influence of different blowing angles of the shielding gas on the weld, under the same welding conditions.

The experimental results show that, under the same control of other variables, the trend of weld morphology influence remains the same under different flow rates.

However, as the flow rate increases, the effect on the weld penetration becomes more noticeable, while the impact on the weld surface and width decreases.

To specifically study the effect of the blowing angle, the flow rate was maintained at 5 L/min, while other variables were controlled, and only the blowing angle was changed.

The results of the test are shown in Figure 5, with a metallographic diagram of the cross-sectional weld morphology displayed in Figure 6.

Fig. 5 Effect of different blowing methods on weld penetration and width

Fig. 6 Weld morphology at different blowing angles

According to the experimental data, the weld penetration increases initially and then decreases as the blowing angle increases.

At 0° or above 45°, the penetration decreases significantly. The maximum penetration is achieved at a blowing angle of 30°.

The width of the weld is determined by the reduction in laser intensity caused by plasma and the effect of gas flow on the weld pool.

At a blowing angle of 0°, the melt width is the smallest. As the blowing angle increases, the width of the melt increases, but there is little change in the width of the weld when the angle is above 45°.

Result analysis

The impact of shielding gas on the weld morphology is mainly controlled by adjusting the size of the plasma, which determines the power density of the laser reaching the surface of the workpiece.

Based on the metallographic diagram of the weld cross-section, it can be seen that the weld morphology tends towards thermal conduction welding at 0° or 75°, while deep penetration welding is evident at 30° and 45°.

To conclude, under the same welding process parameters, it is recommended to use a blowing angle of 30° for increased penetration, 45° for a wider surface width, and 0° or 75° for a larger lower melting width.