How does a process used in aircraft manufacturing help metal components last longer? Shot peening, a technique that involves bombarding metal surfaces with small spherical media, can dramatically enhance fatigue resistance and shape precision. This article explores five advanced shot peening methods, including pre-stressed and digital techniques, highlighting their benefits and applications in modern engineering. By reading, you’ll gain insight into how these innovative processes are revolutionizing metalworking and extending the life of critical components.

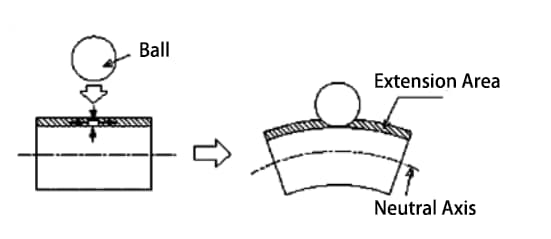

Shot peening is a forming technique that uses high-speed shot flow to strike the surface of a metal sheet, causing plastic deformation in the impacted surface and the underlying metal material, thereby gradually causing the sheet to bend towards the peened surface, achieving the desired shape.

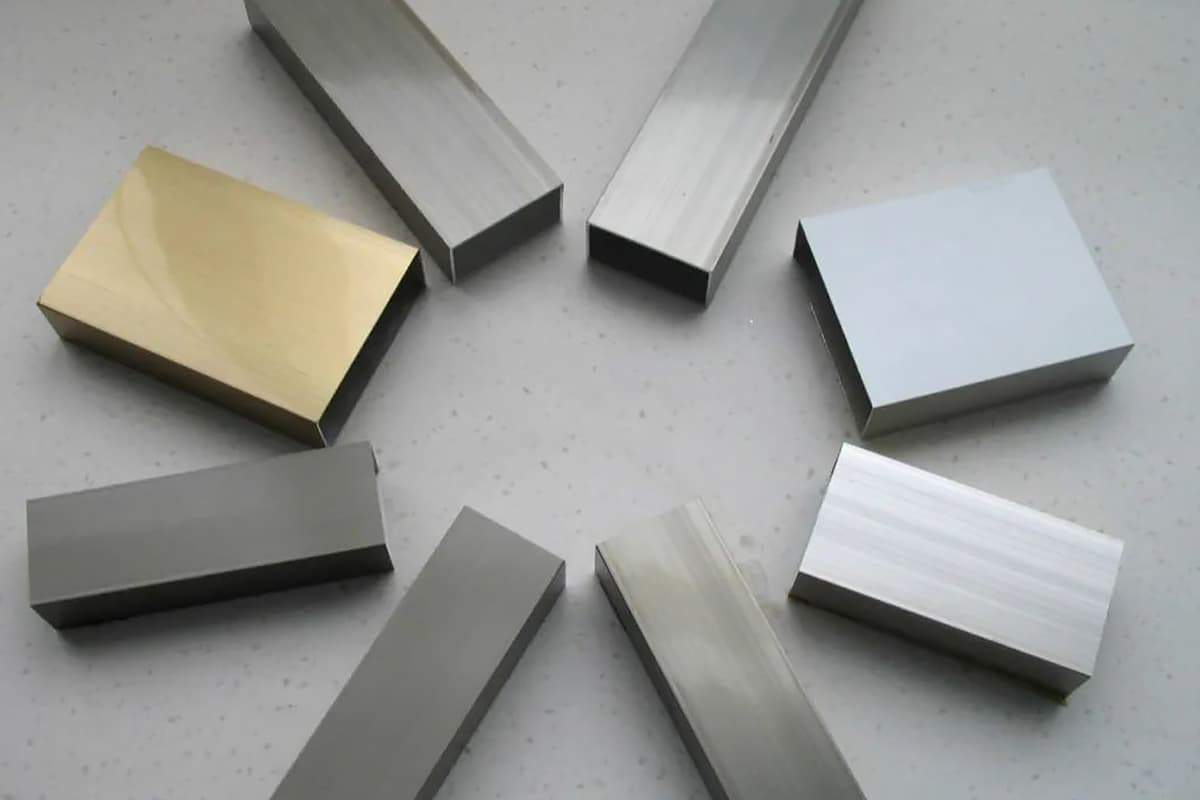

Shot Peening Diagram:

The main advantages of shot peening are:

(1) The process requires simple equipment without the need for a molding die, which keeps the manufacturing cost of the parts low and provides strong adaptability to the size of the parts.

(2) Because shot peening forms residual compressive stress on both the top and bottom surfaces of the part along the thickness direction, it can improve the fatigue resistance of the part during the forming process.

(3) It can form parts with either single or complex double curvatures.

In recent years, with the increasing demands for the overall aerodynamic performance of modern advanced aircraft and the rapid development of computer technology, research and development of shot peening technology has been greatly promoted.

This has led to the emergence of pre-stressed shot peening technology, digital shot peening technology, and new shot peening strengthening technology, greatly expanding the processing capacity and application range of shot peening technology.

Usually, the parts are completely free before shot peening. The deformation caused by shot peening is related to the shot peening strength, shot coverage, and part thickness.

Factors affecting shot peening strength mainly include parameters related to the shot, such as the shot material, heat treatment state, and diameter, as well as parameters related to the shot peening equipment, including shot speed and spray angle.

Factors affecting shot coverage mainly include shot peening time and the material properties of the part being shot peened.

Therefore, for a certain shot peening equipment and shot, when using the maximum coverage shot peening to form specific materials and thickness parts, the deformation obtained is certain. This deformation reflects the shot peening forming limit under the corresponding conditions.

The supercritical wing is an important feature of modern advanced aircraft.

As one of the important parts constituting the wing shape, the integral wall panel has complex saddle and torsional shapes on the outside and integral reinforcement bulges, mouth frames, holes, and sinkages on the inside.

The application of the integral rib structure is also increasing.

For these parts, due to the small forming limit of free shot peening, it is difficult to meet the deformation required for the part shape. As a result, the pre-stressed shot peening technology has emerged.

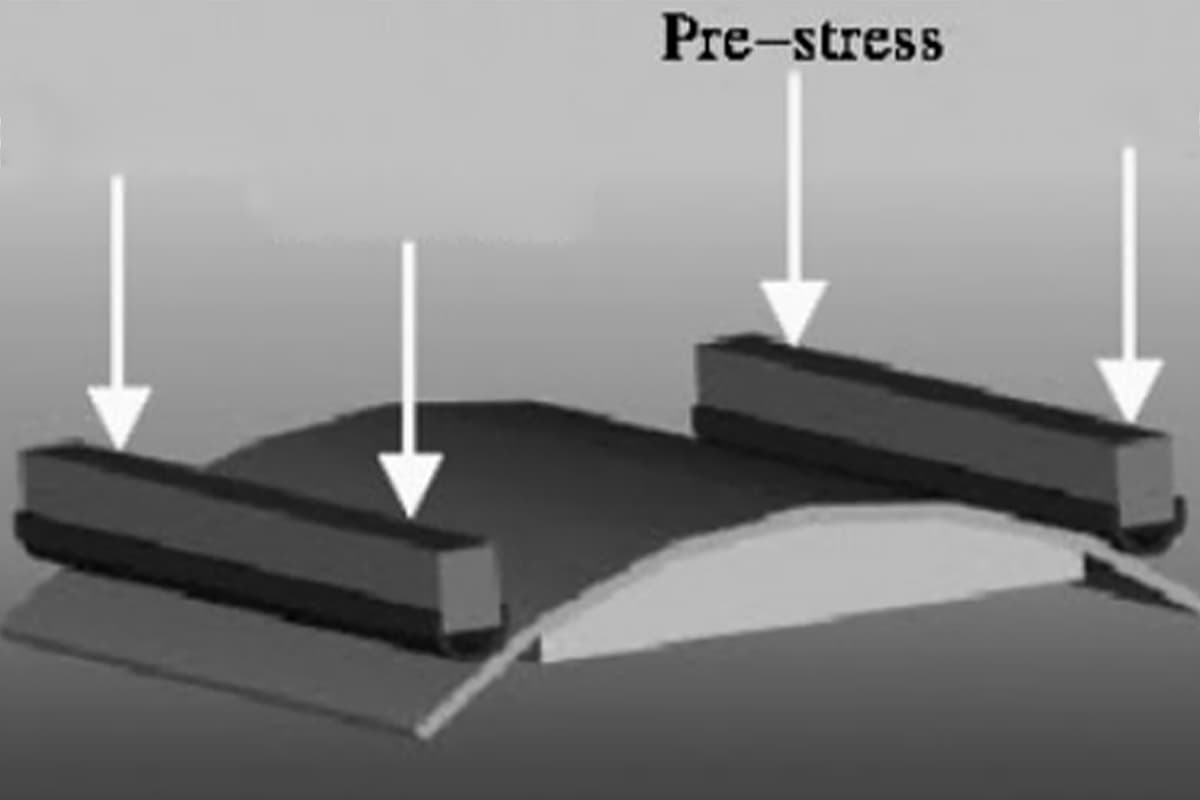

Principle diagram of prestressed shot peening:

Before shot peening the parts, a predetermined load is applied to the parts using specific jigs and fixtures, causing the parts to undergo an initial elastic deformation. Then, the tensioned surface is shot peened. Under the same peening intensity and coverage conditions, the forming limit of pre-stressed shot peening is 2-3 times that of free shot peening.

At the same time, pre-stress shot peening can effectively control the additional bending deformation along the shot peening direction.

Currently, pre-stressed shot peening technology has been applied in the manufacturing of integral wing panels for supercritical aircraft.

Canada’s R Company uses pre-stressed shot peening technology to avoid the negative impact on fatigue life brought about by mechanically bending such parts when manufacturing integral wing panels for Israel’s 5B8BZU aircraft.

Of course, to apply pre-stress to parts, it is necessary to design and manufacture specific pre-stress fixtures. These fixtures must be simple, lightweight, easy to operate, and must coordinate with the shot peening equipment being used.

Therefore, the development trend of pre-stressed shot peening technology will be to further research simple and feasible pre-stress loading methods, as well as use finite element analysis to accurately determine the size of the pre-stress applied, ensuring that the parts are completely within the elastic deformation range under pre-stress.

Digital shot peening forming technology uses digital technology to analyze the geometric information of parts digitally, select and optimize shot peening forming process parameters, simulate and control the shot peening forming process, digitally inspect the shape of formed parts, and digitally manage the shot peening forming process files and programs of parts.

This advanced forming technology aims to describe parts and their shot peening forming process in the form of digital quantities and to unify the data generated at each stage.

In terms of digital shot peening forming technology, a successful application example is the automated shot peening forming technology proposed by Germany’s P/ Company.

Furthermore, as an essential part of digital technology, the numerical simulation technology of the shot peening forming process has also achieved significant development.

The implementation of automated shot peening forming technology is divided into three stages: conceptual design and analysis stage, pre-production development stage, and production stage.

During the conceptual design and analysis stage, the 2+O numerical model of the parts is mainly analyzed and evaluated for shot peening formability, and the initial shot peening forming process plan and forming process parameters are formulated, taking into account the user’s equipment and personnel situation.

In the pre-production stage, the process is optimized through shot peening forming tests on test pieces, generating relevant process control files and programs, and necessary upgrades and adjustments are made to the user’s equipment. Also, at this stage, changes and improvements to the part design can be made concurrently.

In the production stage, automation of shot peening forming can be realized by invoking the pre-established control programs for the parts, while also accomplishing technical training for the relevant personnel.

After establishing an automated shot peening forming technology system on the user’s site during this stage, the development of new products in the future only requires offline programming, and then the relevant data and programs can be transferred to the user’s equipment for testing and production.

Automated shot peening technology mainly includes hardware and software aspects. The hardware aspect requires a multi-coordinate numerically controlled shot peening device with programmable control.

The software aspect requires shot peening forming process database technology, simulation analysis technology, digital measurement technology, virtual visualization technology, and a wealth of practical experience to quickly formulate a reasonable and correct process route.

The advantages of automated shot peening forming technology are very obvious. Users don’t need to do any programming or testing; the operator just needs to press the start button, and the equipment will automatically complete the other tasks preset in the parts program.

In recent years, some new shot peening methods have emerged that differ from traditional shot peening techniques. Among them, the development and application of double-sided shot peening, laser shot peening, ultrasonic shot peening, and high-pressure water shot peening have received widespread attention and concern.

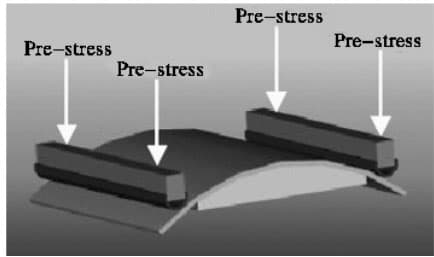

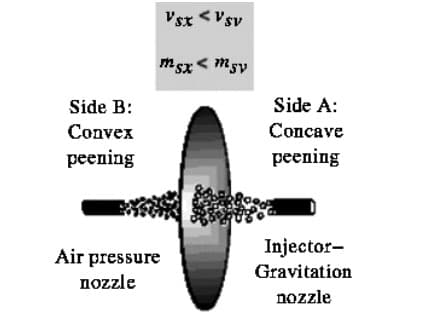

The double-sided shot peening technique was first proposed in 2002 by R.KOPP of the Aachen University of Technology in Germany. The basic principle involves using projectiles of different sizes to simultaneously blast the top and bottom surfaces of a part at different speeds, thereby improving shot peening capabilities and efficiency.

As shown in the figure below:

The method allows achieving a curvature radius as small as 1000mm. The double-sided shot peening forming technology has high requirements for shot peening equipment. It not only needs to have the function of simultaneously spraying shots of different sizes but also requires strong matching and control of the speed and flow of two sizes of shots to achieve the expected results.

The laser shot peening forming technology was first proposed around 1965. The basic principle is to use high-frequency, high-power, short-pulse laser beams to impact the surface of the workpiece coated with a semi-transparent ablation material placed in laminar water.

The laser pulse passes through the laminar water and is absorbed by the ablation layer, creating a plasma cloud on the laminar water. Within 10ns~100ns, the plasma rapidly expands on the surface of the workpiece, generating a pressure of 1Gp~10Gp and forming a planar shock wave, thereby causing plastic deformation on the surface of the workpiece.

Compared with traditional shot peening, laser shot peening generates larger residual stress values, and the distribution area of residual stress is 3~5 times deeper than that of traditional shot peening.

Therefore, laser shot peening is used for surface strengthening of metal parts. Laser shock hardening can greatly improve the fatigue resistance and stress corrosion resistance of parts. When used for forming thin-walled parts, it can achieve greater deformation ability than traditional shot peening.

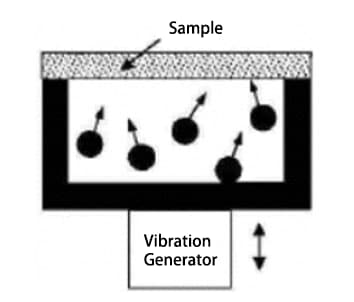

Ultrasonic shot peening mainly uses ultrasonic waves to induce mechanical vibrations in the shots, thereby driving the shots to perform shot peening treatment on the workpiece.

The basic principle is as follows:

Ultrasonic shot peening uses not only steel shots as the peening medium, but also spray needles with different curvature radii at their ends.

The advantage of ultrasonic shot peening is that it can achieve a deeper residual stress layer than traditional shot peening, and the value of the residual stress is also greater, while the surface roughness is better than that of traditional shot peening.

SONATS, a French company, started researching this technology in 1996 and has now developed a set of ultrasonic shot peening technology and corresponding ultrasonic shot peening equipment, which is widely used in the aerospace, shipbuilding, and automotive industries.

Shot peening forming also has obvious limitations, such as the trend of spherical deformation, limited deformation, stringent restriction conditions, and numerous influencing factors.

However, the excellent characteristics of shot peening forming make people constantly seek new ways and methods to break through its limitations, continuously explore the inherent potential of shot peening forming technology, and continuously meet the forming and special performance requirements of components that are becoming increasingly demanding, represented by large and medium-sized aircraft complex metal wing integral panels.