Ever struggled with springback issues in metal stamping and bending? This article delves into practical techniques to minimize these common problems, enhancing precision in your metalworking projects. Learn about the impact of material properties, thickness, and shape on springback, and discover effective solutions like correcting bending, heat treatment, and overbending. This guide is essential for engineers and manufacturers aiming to improve the accuracy and quality of their stamped parts. Dive in to explore these solutions and optimize your processes.

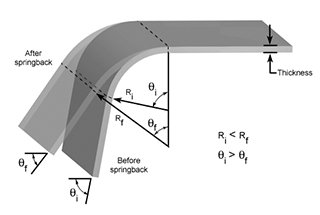

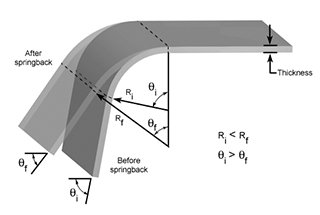

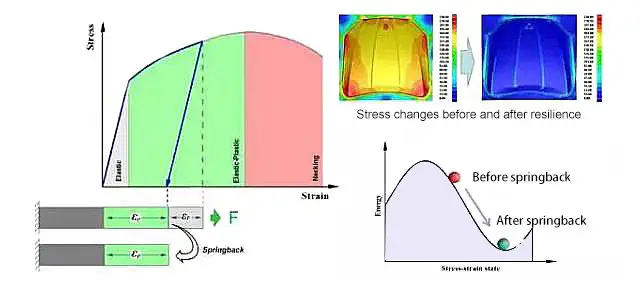

Springback is a critical phenomenon in metal forming processes, defined as the partial elastic recovery of a deformed part after the applied load is removed. This occurs due to the inherent elastic properties of metals, which cause the material to attempt to return to its original shape.

In sheet metal stamping, springback manifests as a discrepancy between the final part geometry and the intended shape defined by the stamping die’s working surface. This deviation often results in parts falling outside specified tolerance ranges, potentially compromising the assembly precision and overall quality of the final product.

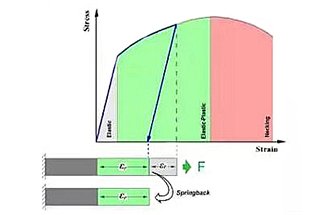

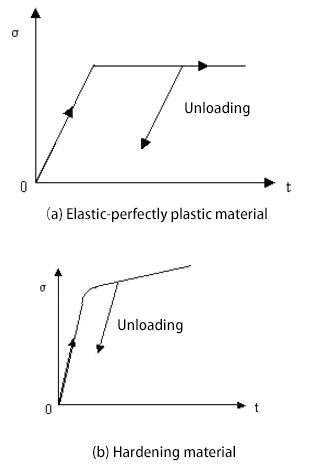

The occurrence of springback is rooted in the dual nature of metal deformation during forming processes. While plastic deformation is the primary goal in shaping the part, elastic deformation inevitably accompanies it. Upon release of the forming load, the elastic portion of the deformation reverses, leading to springback.

The magnitude of springback is influenced by various factors, including:

Addressing springback is a crucial engineering challenge in metal forming industries. Its impact on geometric precision can lead to significant issues in downstream processes, such as assembly difficulties, functional problems, and aesthetic defects. Consequently, engineers must employ various strategies to mitigate springback effects, including:

Understanding and controlling springback is essential for achieving high-precision metal formed parts and ensuring the overall quality and functionality of engineered products.

Stress change curve after load unloading

The yield strength of sheet metal varies between ordinary plates and high strength plates.

The higher the yield strength of the sheet metal, the greater the likelihood of rebound.

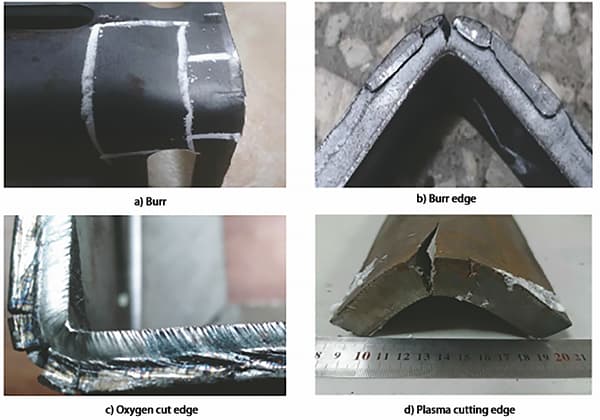

Thick plate parts are typically made from hot-rolled carbon steel or hot-rolled low-alloy high-strength steel.

Compared to cold-rolled sheet materials, hot-rolled sheet materials have poor surface quality, large thickness tolerance, unstable mechanical properties, and low elongation rate.

Stress changes before and after springback

In the forming process, the thickness of the sheet material significantly impacts its bending performance. As the plate thickness increases, the occurrence of rebound decreases.

This is due to the fact that as the sheet thickness increases, the amount of plastic deformation involved also increases, leading to an increase in elastic recovery deformation. As a result, resilience decreases.

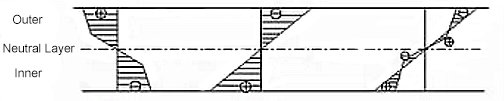

Tangential stress of sheet metal interface

As the strength level of thick plate parts continues to improve, the issue of dimension precision caused by rebound becomes increasingly severe.

Both mold design and subsequent commissioning of the technology require knowledge of the nature and magnitude of part resilience in order to implement appropriate countermeasures and remedial actions.

For thick plate parts, the ratio of bending radius to plate thickness is typically small, and the stress and its changes in the direction of plate thickness cannot be overlooked.

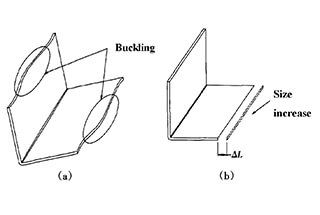

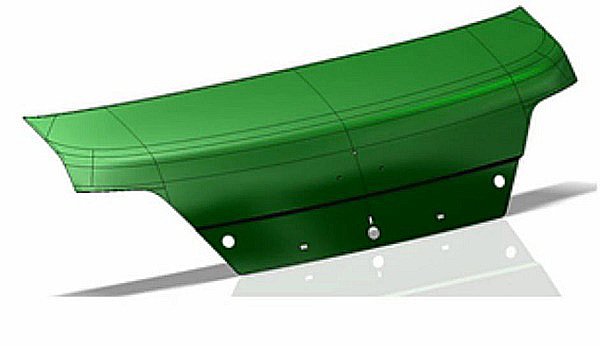

The springback of parts with different shapes varies greatly. Parts with complex shapes typically require an additional shaping process to prevent springback resulting from an incomplete forming process.

However, certain specialized shapes, such as U-shaped parts, are more prone to rebound. Therefore, springback compensation must be taken into account during the forming process.

The larger the bending center angle, the greater the cumulative value of springback, which can result in significant springback.

The deformation length of stamped parts increases as the bending center angle increases.

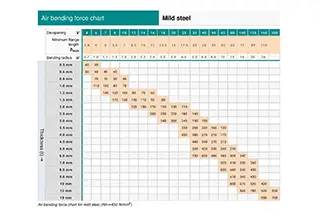

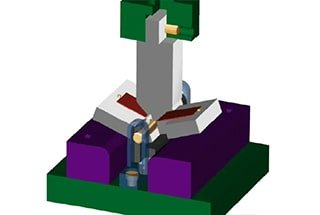

The die should be designed with a gap equal to twice the thickness of the material in the corresponding working part, and the product should fit within this gap.

To facilitate better material flow, the mold parts should be developed after the mold processing is complete, especially in the case of bending molds. The greater the clearance of the working part, the greater the springback.

If the error tolerance range for plate thickness is larger, the rebound will also be larger, making it difficult to accurately determine the mold clearance.

The relative bending radius is proportional to the springback value. As a result, the more curved the stamped parts, the less likely they are to bend.

The forming process is a crucial factor in determining the springback value.

Generally, correcting bending has a better springback effect than free bending.

If the same machining outcome is desired for the production of a batch of stamped parts, the bending force required for correcting bending is significantly greater than that required for free bending.

As a result, even if the same bending force is used in both methods, the final outcome will differ.

The greater the correction force required to correct bending, the smaller the springback of stamped parts. This correction force elongates the inner and outer fibers in the deformation zone, resulting in the desired forming effect.

When the bending force is released, both the inner and outer fibers shorten, but the springback direction of the internal and external fibers is opposite, reducing the springback of stamped parts to some extent.

Firstly, in terms of materials, it is advisable to choose materials with low yield strength or increase the material thickness while still meeting the product requirements.

Secondly, in terms of stamped part design, the shape of the part also plays a significant role in determining its springback. In the case of complex stamped parts with a curved shape, it is difficult to eliminate springback due to the complex stress in all directions and other factors such as friction.

Therefore, the shape of the product can be designed by combining several parts to address the springback issue in complex stamped parts.

An anti-springback bead can also be added, which is an effective solution for springback defects. The product shape can be altered by increasing the number of anti-springback beads, as required by the product and the springback value.

Finally, the springback defect can be addressed by reducing the value of the R angle of the bending part.

The use of blank holder force in the forming process is a crucial technology. By continuously optimizing the blank holder force, the flow direction of the material can be adjusted and the internal stress distribution of the material can be improved.

Increasing the blank holder force causes the parts to extend more fully, particularly in the side wall and R angle position. If fully formed, the difference in internal and external stress will decrease, leading to a reduction in resilience.

The use of draw beads is common in modern technology. Properly positioning the draw beads can effectively alter the material flow direction and distribute the feeding resistance evenly on the pressing surface, thereby enhancing the formability of the material.

Placing draw beads on parts prone to springback will result in more complete forming and more even stress distribution, reducing the springback.

Correcting bending forces concentrate the impact pressure in the bending deformation zone, causing the inner metal to be compressed. After adjustment, both the inner and outer layers are elongated, and the springback trend of the two areas after unloading can offset each other, reducing springback.

Annealing before bending can reduce hardness and yield stress, which not only decreases springback but also lowers the bending force. After bending, perform a hardening process.

In the bending production process, the deformation angle and radius of sheet metal will increase due to elastic recovery. To reduce springback, the deformation of the plate can be made to exceed the theoretical deformation degree.

Use heat bending, selecting the appropriate temperature so the material has sufficient time to soften, which will decrease the amount of springback.

The method involves applying tangential tension during sheet metal bending, altering the stress state and distribution inside the sheet metal, causing the entire section to undergo plastic tensile deformation. After unloading, the internal and external springback offset each other, reducing springback.

The local compression technique involves increasing the length of the outer plate by decreasing its thickness, so that the springback of the inner and outer layers offset each other.

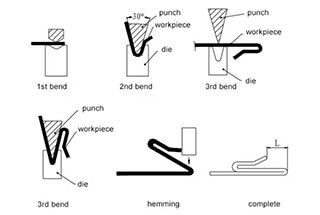

The bending is divided into many times to eliminate springback.

Compress from the inside of the bending part to eliminate springback. When the plate is u-shaped, the effect is better because both sides are symmetric.

The method of partially forming a part through bending and then stretching forming reduces springback. This method is effective for products with a simple two-dimensional shape.

During the stretching process, a local convex hull shape is added to the tool surface first, and then eliminated in a later process to change the residual stress balance in the material, thus eliminating springback.

When machining the tool surface, attempt to make the sheet material exhibit negative springback. After the upper die returns, the parts will attain the desired shape through springback.

The shape and size errors caused by springback can be corrected through the use of electromagnetic pulses to impact the material surface.