What makes specialty smelting so crucial in modern industry? This process is essential for producing high-quality steels and alloys used in demanding fields like aerospace and electronics. Conventional methods fall short of meeting the stringent requirements of these applications, necessitating advanced techniques such as induction melting, electro-slag metallurgy, and vacuum arc remelting. In this article, you will learn about the various specialty smelting methods and their unique advantages, helping you understand their pivotal role in manufacturing superior metal products.

Specialty smelting is a special and effective method for producing special steel, high-temperature alloys, precision alloys, and high-alloy steels.

Metal materials represented by steel have been widely used in the national economy, national defense construction, scientific and technological fields, etc.

The rapid progress in contemporary electronic technology, aerospace technology, navigation and energy technology and other fields has raised increasingly high requirements for the quality and variety of steel and alloys.

For example, it is required that steel or alloys can work reliably under the environment of high temperature, high pressure, high speed, dynamic load, high radiation, and highly corrosive medium.

However, conventional smelting methods such as converter, open hearth furnace, and arc furnace are difficult to meet actual requirements, and cannot provide products of such high quality, which requires the use of special smelting methods.

Common specialty smelting methods include induction melting, electro-slag metallurgy, plasma arc melting, vacuum arc remelting, and electron-beam melting process.

(1) Induction Melting

Induction melting is a method of heating and melting metals using the principle of electromagnetic induction.

According to frequency, it can be divided into power frequency furnace, medium frequency furnace, and high frequency furnace; according to atmosphere and structure, it can be classified into vacuum induction furnace and plasma induction furnace and other furnaces for different purposes.

Power frequency furnaces are mainly used for smelting cast iron, high-frequency furnaces are mainly used for laboratory research, while medium-frequency furnaces are mainly used for producing high-quality steel and alloys, with advantages of fast melting speed, high production efficiency, strong adaptability, flexible use, good electromagnetic stirring effect, and convenient startup operation.

Currently, induction furnace smelting has become an important method for producing special alloys such as special steel, precision alloys, electric heating alloys, high-temperature alloys, and corrosion-resistant alloys.

(2) Electro-slag Metallurgy

Electro-slag metallurgy is a special smelting method that uses the heat generated by the slag resistance caused by the current passing through the liquid slag to heat and refine the metal.

Its core is electro-slag remelting (ESR), which aims to further purify steel and alloys and improve the crystal structure of ingots on the basis of initial refining, thereby obtaining high-quality metal products.

Electro-slag remelting is suitable for the production of medium and large forgings. The product after remelting has low phosphorus and sulfur content, low non-metallic inclusions, dense structure of the remelted ingot and casting without shrinkage, greatly improving the quality of the product, as well as its mechanical properties, processing performance, and usability.

(3) Vacuum Arc Melting

Vacuum arc melting can form a low oxygen potential and high-temperature melting condition, so it was used as early as the last century for melting refractory or oxidizable metals such as platinum, tantalum, and tungsten.

With the development of the mechanical industry, the vacuum consumable electrode arc remelting method has been successfully applied to the production of titanium and its alloys, precision alloys, high-temperature alloys, and refractory metals.

This smelting method developed rapidly in the 1940s and 1950s, with increasingly large capacities. To date, in specialty smelting, vacuum arc melting is still one of the main methods for remelting and refining.

(4) Electron-beam Melting

Electron-beam remelting (EBM) is a smelting method that uses an electron gun to emit high-speed electron beams as a heat source to melt metals under conditions of high vacuum.

It started with the smelting of refractory metals (tantalum, niobium, hafnium, tungsten, molybdenum, etc.) and has now expanded to the production of semiconductor materials, high-performance magnetic alloys, and some special steels such as bearing steel, corrosion-resistant stainless steel, and ultra-low carbon pure iron.

In addition, electron beam remelting furnaces can also be used for smelting certain heat-resistant alloys, especially tungsten- and molybdenum-containing alloys with niobium or tantalum as the main component.

(5) Plasma Arc Melting

Plasma melting is a new smelting method that uses a plasma arc as a heat source to melt, refine, and remelt metals.

The potential advantages of using a plasma arc as a metallurgical heat source are: concentrated energy, high temperature (5000-300,000 K), fast ion flow rate (100-500 m/s), rapid heating and rapid reaction, etc. The gas is in an ionized state, and the reaction activity is strong.

The gas can be selected according to needs, such as using reducing gases (hydrogen, carbon monoxide, alkanes, and alkenes, etc.) to directly reduce or refine the charge, and it can also deoxidize to make the ingots free of residual deoxidation products.

Under the action of high-temperature plasma arc, impurities such as S, P, Pb, Bi, Sn, and As are easy to volatilize. It can melt metal materials and also melt non-metallic materials.

Special smelting is a special and effective method for producing advanced alloys such as special steel, high-temperature alloy, precision alloy, high-alloy steel, refractory metals and alloys, titanium and titanium alloys, electric heating alloys, etc.

(1) Precision Alloy, a kind of metal and alloy with special physical properties, is mainly used to manufacture important materials such as precision instruments, controls, telemetry, electrical appliances, accessories and electronic devices in aerospace, as well as sensors and transducers in weapon systems, based on its physical properties rather than structural components.

In China, the letter “J” is used before a number to indicate its alloy category; for example, “1J” represents soft magnetic alloy, “2J” represents permanent magnetic alloy, “3J” represents elastic alloy, “4J” represents thermal expansion alloy, “5J” represents thermal bimetal, and “6J” represents resistance alloy.

(2) High-temperature alloy (high temperature-resisting alloy or heat-resisting superalloy ) is an important metal material for aviation gas turbines, ship gas turbines, and rocket engines. It has higher resistance to creep deformation and creep fracture, as well as resistance to corrosion and thermal shock.

(1) Component Control:

In addition to controlling C, Mn, Si, P, S, which are usually controlled in steel production, component control also includes the control of alloy elements such as Cr, Ni, Mo, W, Nb, V, Al, Ti, and trace elements B, Ce, La, Zr, Mg, Ca, Hf, Y, Sm. Whether the composition can be optimally controlled depends largely on the smelting process.

(2) Purity:

The purity of steel and alloys refers to the amount of harmful impurities and gas content, mainly including the following aspects.

1. Non-metallic impurities

Non-metallic impurities usually refer to S, P, Ce, Br, I, etc. Different steel grades have different requirements for S and P content.

For example, for ordinary steel, w(S)≤0.055%, w(P)≤0.045%; for high-quality steel, w(S)≤0.045%, w(P)≤0.040%; for alloy steel, both S and P are less than 0.04%; for advanced high-quality steel, w(S)≤0.030%, w(P)≤0.035%; while for some high-temperature alloys, w(S)≤0.030%.

For Ce, Br, I, etc., some technical standards stipulate that they should be lower than 0.0025%.

2. Gas

Generally, the lower the content of oxygen, hydrogen, and nitrogen in steel and alloys, the better their performance.

3. Non-metallic inclusions

The influence of non-metallic inclusions on the performance of steel and alloys is not only related to their quantity, but also to their type, size, morphology, and distribution.

Therefore, the content and distribution status of non-metallic inclusions are one of the important indicators for evaluating the quality of steel and alloys, and conventional inspection uses standard grade comparison method.

4. Metal impurities

Metal impurities mainly refer to Pb, Sn, As, Sb, Bi, and other trace element impurities in steel and alloys. The content of metal impurities has a significant impact on the performance of steel and alloys.

5. Cast structure

The cast structure of steel and alloy ingots has an important influence on the hot working plasticity of ingots and the mechanical properties of steel.

The cast structure of good metallurgical products should have the following conditions: the specifications meet the requirements; the surface quality is good; the shrinkage is small; the ingot is dense; the composition and organizational structure are uniform, the degree of segregation is small; the crystal structure is good.

(1) Component control affects the performance of steel and alloys.

Different smelting methods have different degrees of component control, with vacuum arc furnaces being better at controlling easily oxidizable elements and electroslag remelting having less loss of volatile elements.

(2) Purity affects the performance of steel and alloys.

Vacuum melting has low harmful metal impurities and oxygen content, and electroslag remelting has good desulfurization ability and removal of oxide inclusions.

(3) Controlling the microstructure affects the performance of steel and alloys.

Electroslag remelting ingots have a columnar crystal axis development and low porosity segregation.

2.1.1 Working Principle of Induction Furnace

All types of induction furnaces, regardless of whether they are core or coreless, as well as whether they operate at low frequency, intermediate frequency, or high frequency, their basic circuit is composed of a variable power supply, capacitors, an induction coil, and metal furnace materials in the crucible (Figure 2-1).

(1) Principle of Induction Heating

The principle of induction heating is based on the following two basic laws of electricity: first, Faraday’s law of electromagnetic induction.

E=B·L·v·sin∠(v·B) (2-1)

where L is the length of the wire in the magnetic field;

(v·B) is the angle between the direction of the magnetic induction strength and the velocity direction.

The other fundamental law is Joule-Lenz law. This law is also known as the principle of electrical thermal effect. Joule-Lenz law can be expressed in the form of equation (2-3):

Q = I 2 R t (2-2)

where Q is the Joule-Lenz heat, in J; I is the current intensity, in A;

R is the resistance of the conductor, in Ω; t is the time when the conductor is energized, in s.

When an alternating current with a frequency of f flows through the induction coil of a coreless induction furnace, an alternating magnetic field is generated in the space surrounding the induction coil and its surroundings.

The polarity, magnetic induction strength, and frequency of the alternating magnetic field change with the alternating current that generates this alternating magnetic field. If the crucible is lined with the induction coil and filled with metal furnace materials, part of the magnetic field lines of the alternating magnetic field will pass through the metal furnace materials.

The alternation of the magnetic field lines is equivalent to the relative motion of the cutting magnetic field lines between the metal furnace materials and the magnetic field lines.

Therefore, an induced electromotive force (E) will be generated in the metal furnace materials, and its magnitude can be determined by the following equation:

E = 4.44 Ф· f · n (2-3)

where Ф is the magnetic flux of the alternating magnetic field in the induction coil, in Wb;

f is the frequency of the alternating current, in Hz;

n is the number of turns of the loop formed by the furnace materials, usually n=1;

From the above equation, it can be seen that to generate a larger induced voltage in the furnace materials, theoretically increasing the magnetic flux, frequency, and number of turns can be used.

However, since the magnetic field lines generated after the induction coil is energized are forced to pass through air (in the case of a coreless induction furnace), and air has a high magnetic reluctance, the magnetic flux is relatively small, making it difficult to increase the magnetic flux, and the number of turns of the furnace materials is generally equal to l.

Therefore, in order to increase the induced voltage, it is better to use the method of increasing the frequency.

As the metal furnace materials themselves form a closed loop t, the induced current (I) generated in the metal furnace materials is:

where R is the effective resistance of the metal furnace material, in Ω;

The heating rate of the furnace material depends on the induced current, the effective resistance of the furnace material, and the energizing time. The induced current depends on the magnitude of the induced electromotive force, that is, the magnitude of the magnetic flux passing through the furnace material and the frequency of the alternating current flowing through it. The magnitude of the induced current depends on the size of the furnace material block.

(2) Electromagnetic Stirring

When an induced current flows through the furnace material, it will inevitably be subjected to electromagnetic forces, causing directional movement of the metal furnace material; that is, the “electromagnetic stirring” effect. Its benefits are as follows:

1) uniform temperature of the metal liquid.

2) Homogenization of the metal liquid.

3) Improving the kinetic conditions of physical and chemical reactions.

2.1.2 Induction Furnace Working Equipment

Induction furnaces can be divided into two types: coreless and core types, with the latter rarely used in steelmaking and will not be discussed here. As for coreless induction furnaces, they can generally be classified into three types according to the power frequency: the line-frequency furnace (with a frequency of 50 or 60Hz) which is directly connected to the power grid through a transformer and mainly used for melting cast iron; the high-frequency furnace (with a frequency range of 10KHz to 300KHz) which uses a high-frequency electronic tube oscillator and is mainly used for small laboratory research; and the medium-frequency furnace (with a frequency range of 150Hz to 10000Hz) which uses a medium-frequency generator set, tripler or thyristor static frequency converter.

The complete set of equipment for medium-frequency induction furnaces includes: the power supply and electrical control part, the furnace body, the transmission device, and the water cooling system.

(1) Electromagnetic induction heating. As the heating method is different, induction furnaces do not require graphite electrodes necessary for electric arc heating, nor localized overheating zones under the arc, thus eliminating the possibility of electrode carbon increase. Induction furnaces can melt low-carbon steel and alloys that are difficult to melt in electric arc furnaces, creating favorable conditions for producing products with low gas content.

(2) There is a certain level of electromagnetic stirring in the molten pool. The metal stirring caused by electromagnetic induction promotes uniform composition and temperature, inclusion coalescence, growth and floatation in steel. The loss of alloy elements during the induction furnace melting process is relatively small, so the predicted composition is more accurate, which is conducive to component control and shortens the melting time.

(3) The ratio of the molten pool surface area is small. This is advantageous for reducing the loss of easily oxidized elements in the molten metal and reducing gas absorption. Therefore, induction furnaces have created relatively favorable conditions for melting high-alloy steels and alloys, especially those containing titanium, aluminum or boron. However, it is prone to form poor fluidity, low reaction strength, which is not conducive to the metallurgical reaction at the interface of slag and steel. For this reason, the requirements for raw materials in induction furnace melting are relatively strict.

(4) Convenient adjustment of input power. During the induction furnace melting process, the input power can be conveniently adjusted. Therefore, the melting temperature of the molten pool can be controlled more accurately, the furnace can be insulated, and the steel can be produced several times, creating conditions for melting products with different compositions in one batch.

(5) The same power source can supply power to several different capacity furnaces (but not at the same time), so the flexibility of induction furnaces is greater than that of electric arc furnaces in terms of smelting capacity.

(6) High thermal efficiency. The heating method of induction furnaces and small surface area result in less heat dissipation, thus the thermal efficiency of induction furnaces is higher than that of electric arc furnaces. However, the electrical efficiency of induction furnaces is lower than that of electric arc furnaces, so the total efficiency of the two types of electric furnaces is similar.

(7) Less smoke and small environmental pollution. When melting in induction furnaces, there is basically no flame or combustion products.

(8) Consumes more refractory material than electric arc furnaces and has a shorter crucible life. The requirement for refractory materials in the crucible is high, so the cost of refractory materials per ton of steel is also higher than that of electric arc furnaces.

2.3.1 Oxidation and Deoxidation of Elements

Oxygen exists in two states in molten steel. One is dissolved oxygen, represented by [O], and its solubility increases with the increase of temperature. The other is oxygen that exists in the form of inclusion in the molten steel. When deoxidizing elements are present in the molten steel, the dissolved oxygen in the molten steel combines with them to form oxide inclusions. The sources of oxygen in molten steel mainly include the invasion of oxygen from the atmosphere during melting and casting, oxygen brought in with raw materials, and oxygen entering from refractory materials.

(1) Deoxidation ability of elements

The degree of difficulty of oxidation of various elements is called the oxidation state, also known as the deoxidation ability. It refers to the residual oxygen content dissolved in the steel in equilibrium with a certain concentration of deoxidizing elements at a certain temperature and pressure. The lower the oxygen content, the stronger the deoxidation ability of this element. The general formula for the deoxidation reaction of an element is:

x[M]+y[O]=MxOy (2-5)

If metal oxides are considered to be pure substances that are not soluble in molten steel and the content of metal elements and oxygen is low in the molten steel, then we have:

In the formula, aMxOy represents the activity of the oxide obtained by deoxidizing the element, a[M] represents the activity of the deoxidizing element in steel, and a[O] represents the activity of oxygen in steel. When the deoxidation product is a pure oxide or in a saturated state, aMxOy equals 1. When fM=1, f0=1, or fMx.f0y=constant, then,

Let KM = 1/K. Then, KM = [%M]x.[%O]y (2-8).

The magnitude of KM can be used to determine an element’s deoxidation ability. The smaller the value of KM, the stronger the element’s deoxidation ability. Figure 2-7 and Table 2-8 provide a comparison of the deoxidation abilities of elements in molten iron and nickel at a temperature of 1600℃. Generally, in molten iron at 1600℃, the order of deoxidation ability from strongest to weakest is: Ba → Ca → Ce → La → Mg → Zr → Al → Ti → B → Si → Mn → W → Fe.

(2) Deoxidation effects and influencing factors of elements

1. Affinity of elements to oxygen: The stronger the affinity of an element to oxygen, the greater its deoxidation ability, which is more advantageous for improving the deoxidation effect.

2. Physical properties of deoxidizing elements: These include the melting point, specific gravity, boiling point (vapor pressure), and solubility in steel liquid.

3. Physical characteristics of deoxidation products: The melting point, specific gravity, interfacial tension of steel liquid, the ability to form low-melting-point liquid composite oxides with high-melting-point oxides, as well as the solubility in steel liquid, all have a significant impact on the deoxidation effect.

(3) Characteristics of deoxidizing elements and composite deoxidizers:

1. Aluminum deoxidation and simultaneous deoxidation with aluminum, manganese, or silicon and manganese: Aluminum is a strong deoxidizer with high affinity to oxygen, but its deoxidation ability is lower than that of calcium, magnesium, barium, rare earth elements, and higher than that of silicon, manganese, titanium, and other elements.

2. Characteristics of calcium and calcium alloys for deoxidation: Calcium is a very strong deoxidizer and also a highly effective desulfurizing element. However, due to its low boiling point (1484℃), it exists in a vapor state in molten iron, which reduces its effectiveness. In addition, the solubility of calcium in molten iron is very low, which affects its deoxidation and desulfurization effects, thus reducing its utilization efficiency.

2.3.2 Diffusion Deoxidation and Precipitation Deoxidation

(1) Diffusion Deoxidation

Principle of diffusion deoxidation: According to the law of distribution of energy, during diffusion deoxidation, oxygen can simultaneously dissolve in both slag and steel liquid. At a certain temperature, the following equilibrium relationship exists:

(FeO) = Fe(l) + [O] (2-9)

At this time, the ratio of oxygen concentration between slag and steel liquid should be constant, that is

Factors affecting diffusion deoxidation:

a) The effect of temperature on the diffusion deoxidation efficiency. The impact of temperature on the maximum saturated oxygen content in molten iron is twofold, and the relationship is expressed by the following formula: Log [%O]saturated = -6320/T + 2.734 (2-11).

b) The influence of steel slag contact conditions.

c) The influence of slag composition.

(2) Precipitation deoxidation:

Principle of precipitation deoxidation: Precipitation deoxidation refers to the addition of elements to molten steel with an oxygen affinity greater than that of iron, with the aim of reacting with dissolved oxygen to form an oxide that is insoluble in molten steel. The oxide is then removed from the molten steel by buoyancy, thereby reducing the oxygen content of the molten steel.

Types and application range of precipitation deoxidizers: Commonly used precipitation deoxidizers mainly include pure metal deoxidizers, nickel-based deoxidizers, aluminum-based deoxidizers, silicon-manganese-based and silicon-calcium-based deoxidizers. By using composite deoxidizers containing strong deoxidizing elements such as calcium, barium, and magnesium to reduce the total oxygen content, a steel liquid with a total oxygen content of ≤0.003% can be obtained. Only through the combined use of different deoxidizers can highly pure steel be achieved.

2.3.3 Alloy Desulfurization

Essentially, alloy desulfurization involves converting dissolved sulfur in molten iron into a high-melting-point compound (such as CaS, MgS, CeS) or a sulfide oxide. The solubility of these sulfides in molten iron is much lower than that of iron sulfide, ensuring the removal or dispersion of sulfur from the steel. The main methods of desulfurization are using refining agents or slag reaction.

(1) Refining Agent Desulfurization

The basic principle of refining agent desulfurization is to use substances with a high affinity for sulfur to form sulfides. These sulfides are insoluble or have very low solubility in molten iron and have a lower density than alloy liquid. The relative affinity of various elements to sulfur can be measured by the standard free energy change of each element reacting with 1 mole of sulfur. At the same temperature, the smaller the value of the standard free energy, the greater the affinity between the element and sulfur. The relative affinity of different elements to sulfur decreases in the order of La, Ca, Ba, Mg, Mn, Fe.

(2) Slag Reaction Desulfurization

Slag reaction desulfurization can only be carried out in an alkaline induction furnace. The desulfurization process can be divided into the following three steps:

1. Sulfur ions in the metal liquid diffuse to the slag interface, and oxygen ions in the slag diffuse to the slag-steel interface;

2. The following reaction occurs at the slag interface: [S] + (O2-) = (S2-) + [O] (2-12)

3. The generated sulfur atoms diffuse into the slag, and the generated oxygen atoms diffuse into the steel. Empirically, the desulfurization reaction rate is determined by the diffusion of sulfur ions in the slag. The equilibrium constant K shown in Equation 2-12 is a constant that varies with temperature. The desulfurization capability of the slag is usually expressed by the distribution coefficient Ls, which

NO2- represents the alkalinity of the slag, and higher alkalinity is more favorable for desulfurization. However, when the alkalinity is too high, the desulfurization rate may be limited due to the increased melting point and viscosity of the slag, which is not conducive to desulfurization. When the oxygen content in the metal melt is low, the content of iron oxide in the slag is also low, which is favorable for desulfurization. Experiments have shown that there is a relationship between the equilibrium content of sulfur and oxygen in pure molten iron at 1600℃: [S]/[O] = 4. Increasing the temperature is favorable for desulfurization, not only because it increases Ls but also because it can improve the flowability of the steel slag.

2.3.4 Removal of Non-metallic Inclusions

The presence of a large number of non-metallic inclusions in steel can destroy the continuity of the steel matrix, weaken the interatomic forces, promote stress concentration, and lead to crack formation. They seriously degrade the mechanical properties of the steel, especially reducing its plasticity, impact toughness, fatigue performance, and even some physical properties during cold and hot processing of alloys. This effect is not only related to their content, but also to their shape and size.

Residual hydrogen and nitrogen in alloys, in addition to forming hydrides and nitrides, are also prone to causing phenomena such as white spots, hydrogen embrittlement, and aging. [H] and [N] precipitated in gas form can form pores in the steel ingot, and can easily cause defects such as subcutaneous bubbles during strip rolling. Atmospheric induction furnaces use floating methods to remove inclusions. When the density of non-metallic inclusions is lower than that of the molten metal, the inclusions float to the interface of the molten metal and slag under buoyancy and are absorbed by the slag.

The upward velocity of inclusions can be calculated using Stokes’ law.

Requirements for raw materials: The chemical composition of the input materials should be accurate; the metal materials should be clean, dry, free from oil and rust; the block size is appropriate; all materials must be stored in a dry environment.

Types of raw materials: Steel materials: pig iron, industrial pure iron, scrap steel, return materials. Alloy materials: W, Mo, Nb and their iron alloys; Ni Cr, Co and their alloys; Si, Mn and their alloys; V, B and their alloys; Al, Ti and their alloys; rare earth metals and their alloys; special additives. Slag-making materials: lime, fluorite, clay brick fragments.

Ingredients calculation:

Based on the composition of the charge and the target composition of the smelted product, calculate the weight of each type of raw material to be added to the furnace.

Since the induction furnace mainly focuses on melting and heating processes, the requirements for ingredients calculation are more precise. Accurate calculation methods are required to calculate the recovery rate of alloying elements.

2.5.1 Classification and Quality Requirements of Induction Furnace Crucibles

(1) Classification of crucibles:

Induction furnace crucibles can be classified into three types based on their materials: alkaline, acidic, and neutral. The most widely used binder is boric acid.

The role of boric acid in the production of acidic (silica sand) or alkaline (magnesia) crucibles includes:

a. Lowering the sintering temperature.

b. Promoting the formation of spinel.

c. Reducing the volume change rate of the crucible.

Crucibles can also be classified based on their manufacturing methods: precast crucibles, in-situ formed crucibles, and refractory brick-lined crucibles.

(2) Quality requirements for crucibles

The main requirements for refractory materials of crucibles include:

High refractoriness and high-temperature structural strength.

Good resistance to rapid heating/cooling.

Good resistance to slag corrosion.

As low thermal conductivity as possible.

Good insulation performance.

No pollution, harmlessness, low volatility, strong resistance to hydration, and low cost.

2.5.2 Preparation of Crucibles

(1) Particle size ratio:

Reasonable particle size ratio can achieve the best volume density to ensure that the crucible has the minimum porosity rate, usually around 20%. The coarse, medium, and fine range of sand particle sizes depend on the capacity of the furnace.

The particle size ratio of magnesia crucibles with the same capacity

| Crucible capacity/Kg | Particle size ratio/% | ||||

| 4-6mm | 2-4mm | 1-2mm | 0.5-1mm | <0.5mm | |

| 1300 | 15 | 30 | 25 | 20 | 10 |

| 430 | 50 | 10 | 40 | ||

| 200 | 25 | 30 | 10 | 35 | |

| 10 | 15 | 15 | 55 | 15 | |

(2) Forming Methods

There are two main methods for forming an induction furnace crucible: external forming and internal forming. According to the difference of binders, the internal forming method can be divided into wet forming and dry forming.

(3) Crucible Manufacturing

For externally formed crucibles, manufacturing refers to how the crucible is installed in the induction coil and how the furnace mouth is repaired. Here, we introduce the manufacturing process of internally formed crucibles. The preparation work before production includes sand preparation and mixing, cleaning and inspection of the induction coil, preparation of the crucible mold, and preparation of forming tools and equipment.

Before each crucible is made, the induction coil is checked for leaks, water seepage, insulation damage, and whether the fasteners between the induction coil and the turns are reliable and firm.

The mold mainly refers to the crucible core, which is used to control the shape and volume inside the crucible. The induction furnace crucible core is either welded with steel plates or made of graphite.

Graphite core Vibratory molding machine

(4) Crucible Sintering

Purpose: To improve the compactness, strength, and volume stability of the crucible.

Process: The contact surface of the sand material is heated to a high temperature to form a continuous sintering network through liquid phase bonding, which connects the entire sand material together into a whole.

Sintering methods: High-temperature sintering and low-temperature sintering.

A. High-temperature sintering of magnesia crucibles (divided into four stages)

Stage 1: Sintering temperature at 850℃, mainly for dehydration reaction of the sand material and decomposition of carbonate.

Stage 2: Sintering temperature between 850-1500℃, low-melting-point compounds begin to melt, sintering network begins to form, and the crucible volume shrinks significantly. The heating rate can be increased appropriately during this stage.

Stage 3: Sintering temperature between 1500-1700℃, magnesium olivine and magnesium-aluminum spinel start to melt, new compounds begin to form, sintering network is formed, and the crucible volume shrinks sharply, with significantly increased density and strength. The heating rate should be reduced during this stage.

Stage 4: Sintering temperature between 1700-1850℃, mainly to promote the continuous growth of forsterite, and obtain the ideal sintering layer thickness and sintering structure of the crucible cross-section.

B. Low-temperature sintering of magnesia crucibles (divided into three stages)

Stage 1: Temperature at 850℃, mainly for dehydration reaction and carbonate decomposition, with a slow heating rate.

Stage 2: Temperature between 850℃-1400℃, sintering network of low-melting-point compounds containing B2O3 forms rapidly, and the crucible strength increases.

Stage 3: Temperature between 850℃-1400℃, to continue to increase the sintering layer thickness of the preliminarily sintered crucible and achieve the ideal sintering structure.

2.6.1 Melting Process

The scrap steel used for melting usually contains a certain amount of moisture and oil contamination. It is unsafe to directly add such furnace material into the furnace, especially in the case of an already formed molten pool, as it often leads to splashing. At the same time, it is also one of the main sources of oxygen in the product.

Therefore, some factories set up preheating or drying systems for scrap steel, using heating methods to remove the moisture and oil contamination attached to the scrap steel to ensure safe use and prevent hydrogen from being introduced. In addition, adding preheated scrap steel can shorten the melting time and reduce energy consumption.

(1) Charging

Raw material requirements:

a. The chemical composition of the charged material must be accurate;

b. The metal material should be clean, dry, oil-free, and have little rust;

c. Suitable size of the material blocks;

d. Dry storage.

Charging requirements:

The lower layer of the furnace material should be compact, and the upper layer should be loose to prevent bridging of the upper layer of furnace material during the melting process;

Before charging large materials, a layer of small and light material should be first laid on the bottom of the furnace;

Some alloys or steel materials with lower melting points than others should be charged first at the bottom of the furnace;

Materials with high melting points and are not easily oxidized should be charged in the upper part of the layered materials, i.e. the high-temperature zone;

The low-temperature zone at the top of the crucible should mainly be charged with steel materials;

Materials should be loosely charged to prevent bridging.

(2) Melting

The smelting of the furnace material is directly related to the change in gas content in the liquid metal and the recovery of alloy elements, while also affecting technical indicators such as smelting time, crucible life, and energy consumption. The melting period is an important stage in induction furnace smelting, with the following main tasks:

To rapidly melt the furnace material, desulfurize it, reduce the loss of alloy elements, and promptly add slag to prevent the metal melt from absorbing gas.

(3) Refining

The refining period is an important link in induction furnace smelting, completing tasks such as deoxidation, alloying and adjusting the composition and temperature of the steel liquid through refining.

Adjusting the composition of the slag to reduce the content of alloy elements in the slag.

Deoxidizing and alloying the steel liquid.

(4) Tapping and Casting

When the smelted steel or alloy meets the requirements for tapping, it can be tapped. For small-capacity furnaces, it can be directly cast. For larger capacity furnaces, it can be poured into a casting ladle first and then cast. Depending on the product requirements, it can be cast into ingots, castings, or consumable electrodes. The tapping process also requires selecting the casting method based on the quality and process flow of the product, such as whether to use vacuum or non-vacuum casting, and whether to use top pouring or bottom pouring.

Generally, electric heating alloys and high-temperature alloys need further refinement, so they are generally cast into consumable electrodes, while precision alloys are generally vacuum-cast. Vacuum casting can avoid secondary oxidation and re-absorption of the steel liquid during the casting process, and can effectively remove hydrogen and part of nitrogen, thus obtaining steel with fewer impurities and higher purity.

Chemical composition has a significant impact on the quality and performance of steel. For some types of steel, the chemical composition needs to be controlled within a more stringent range besides meeting the technical specifications, in order to meet the higher requirements for quality and performance. Chemical composition control runs through every furnace steelmaking process and is closely related to the loss of alloy elements, physicochemical properties, slag physicochemical state, steel liquid temperature, smelting method, etc.

(1) Main factors affecting the recovery rate of alloy elements

Physicochemical properties of the alloy elements themselves.

Smelting time. The longer the melting time, the greater the loss of C and Si, and the higher the loss of alloy elements when active elements are added and the time to tapping is longer.

Smelting temperature. With an increase in temperature, the free energy of the alloy elements in the steel decreases, which is conducive to the dissolution of the alloy elements. However, too high a temperature will exacerbate the loss of alloy elements.

Slag system. The physicochemical state of the slag has a significant impact on the recovery rate of alloy elements. Especially the viscosity and alkalinity of the slag have a greater influence. The higher the FeO and SiO2 content in the slag, the greater the loss of elements.

Volatile loss of elements. Attention should be paid to the volatile loss caused by oxides for W, Mo, and Mn.

Content of [O], [N], and [S] in the steel liquid. The higher the content of [O], [N], and [S] in the steel, the greater the loss of elements. The steel liquid should be fully deoxidized, desulfurized, and denitrified before adding alloy elements.

Timing, block size, and method of adding alloy elements. The earlier more active elements are added, the greater the loss. The recovery rate of alloy elements is higher when adding block-shaped alloy elements than when adding powdered ones. There is also a slight difference in the recovery rate between adding to the furnace or adding to the ladle.

(2) Methods to improve the recovery rate of alloy elements

1. Control method for low-loss elements: Alloy elements with a loss rate lower than 5% under normal smelting conditions are called low-loss elements, including Ni, Co, Mo, W, Cu, etc. Low-loss elements can generally be added together with the furnace charge, and electrolytic copper should be added at the end of melting due to its low melting point. The loss of Mo and W during their smelting is mainly due to the volatile loss of their oxides.

In addition, alloys containing tungsten cannot be smelted in a new crucible as it will lead to tungsten loss and non-conforming chemical composition due to the crucible absorbing tungsten. Tungsten-containing materials can also cause “bottoming phenomenon”, where a large amount of tungsten-containing material settles on the bottom of the crucible and cannot melt for a long time. To reduce the loss of W and Mo, sufficient melting and stirring should be ensured during smelting.

2. Control method for medium-loss elements: Medium-loss elements refer to elements with a loss rate between 5% and 20%, including Cr, V, Si, Mn, Nb, etc., and their addition depends on the situation in the furnace. Generally, Nb is added at the end of refining and stirred sufficiently. When smelting steel containing Cr, care should be taken to prevent chromium from oxidizing into the slag. If the chromium content is not high, it is best to add it after complete deoxidation. When adding Mn to eliminate the thermal embrittlement effect of FeS, Mn/S>8 should be controlled.

3. Control method for high-loss elements: Alloy elements such as Ti, Al, Re, Zr, etc. have a loss rate greater than 20% under normal smelting conditions and are high-loss elements. Generally, they should be added after final deoxidation. The addition method depends on the deoxidation system.

In addition, the method and timing of adding alloy elements should be comprehensively considered to control the recovery rate of alloy elements. For example, when smelting high-temperature alloys, Ti needs to be added. If Ti is added in the form of titanium sponge, even if it is added after final deoxidation, the recovery rate will only be around 70%. However, if titanium is made into Ni-Ti intermediate alloy and added, the recovery rate can reach more than 95%.

Vacuum induction melting (VIM) is a method of melting materials under vacuum conditions by using electromagnetic induction to generate eddy currents for heating in metal conductors. The new vacuum induction degassing and pouring (VIDP) technology has the advantages of small melting volume, short vacuum pumping time and melting cycle, easy temperature and pressure control, easy recovery of volatile elements, accurate composition control, etc. Since its appearance in 1988, it has been listed as a key selection object for large-scale vacuum induction furnaces in developed countries.

3.1.1 Equipment of Vacuum Induction Furnace

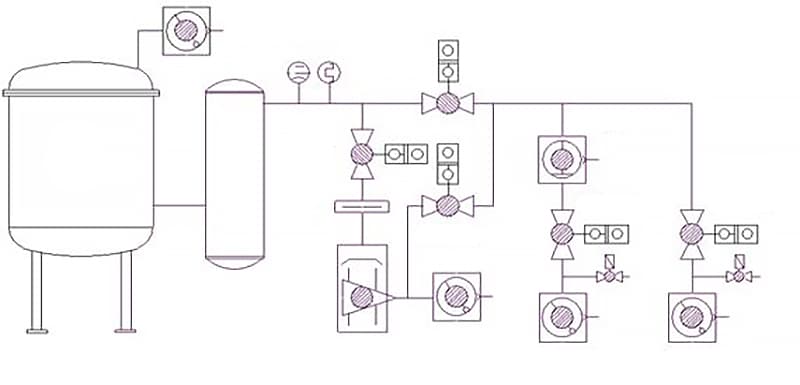

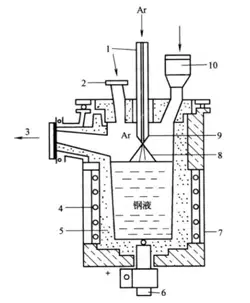

The vacuum induction furnace is an equipment used to produce superalloys. According to the operation mode, it can be divided into batch-type furnaces and semi-continuous operation furnaces. The vacuum induction furnace can be used for refining superalloys and also for casting special alloys. The supporting equipment of the vacuum induction furnace can be divided into four parts: power supply and electrical control, furnace body, vacuum system, and water cooling system, as shown in Figure 3-1 and 3-2.

3.1.2 Power Supply of Vacuum Induction Furnace

The power supply of the vacuum induction furnace has the following requirements:

(1) The terminal potential of the inductor should be low. The operating voltage used by the vacuum induction furnace is lower than that of the medium-frequency induction furnace, usually below 750V, to prevent gas discharge under vacuum caused by too high voltage and damage to insulation, causing accidents.

(2) Prevent high-order harmonics from entering the load circuit. When using a thyristor frequency conversion circuit, high-order harmonics often enter the load circuit, causing the inductor to increase the voltage to the furnace shell and cause discharge. Therefore, it is necessary to add a medium-frequency isolation transformer at the output end of the power supply to intercept the entry of high-order harmonics.

(3) The current of the oscillation circuit should be large;

1 – Vacuum induction melting chamber; 2 – roughing valve; 3 – high vacuum valve; 4 – mechanical pump; 5 – diffusion pump; 6 – valve

3.1.3 Structure of the Furnace Body of Vacuum Induction Furnace

The conventional structure of the vacuum induction furnace can be divided into a single-chamber vertical furnace and a two-chamber horizontal furnace according to the opening and closing form of the furnace body. The furnace body of the vacuum induction furnace mainly consists of a furnace shell, inductor, crucible, tilting mechanism, casting system, water cooling system, and power supply device. The structure of the furnace body includes two types: crucible rotating casting type and furnace body tilting casting type.

The furnace body of the vacuum induction furnace is equipped with accessories such as feeding, stirring, temperature measurement, and sampling devices. The greatest characteristic of the vacuum induction furnace is that the smelting and casting processes are carried out inside the furnace shell. The furnace shell is divided into a fixed furnace shell and a movable furnace shell. The furnace shell must withstand the strong pressure formed by the internal vacuum and have sufficient structural strength.

The furnace shell of small vacuum induction furnaces adopts a double-layer structure, with a non-magnetic stainless steel plate for the inner layer and an ordinary steel plate welded to the outer layer, and cooling water flowing in between. Large vacuum induction furnaces use a double-layer structure in some parts, with a single-layer steel plate cooled by water pipes on the outside. The contact surface between the movable part and the fixed part of the furnace shell must be sealed with vacuum rubber parts. The principle of the vacuum system is shown in Figure 3-3.

3.1.4 Characteristics of Vacuum Induction Furnace Melting

(1) Low gas content and high purity of the product;

(2) Precise control of the composition of the product;

(3) Strong adaptability to raw materials;

(4) It can be cast into ingots under vacuum conditions, as well as complex-shaped castings.

However, there are also some problems with vacuum induction furnace melting. During the melting process, the molten metal is in contact with the crucible refractory material for a long time, which inevitably causes contamination of the metal by the refractory material. Secondly, the solidification conditions of the molten metal and the general casting method are no different, so there are still defects such as looseness and segregation.

Table 3-1 Gas Content in SAE4340 Steel Produced by Different Melting Methods

| Melting Methods | [O]/% | [H]/% | [N]/% |

| Charge material | 0.0251 | 0.00018 | 0.0029 |

| Electric arc furnace | 0.0031 | 0.00017 | 0.0039 |

| Non-vacuum induction furnace | 0.0030 | 0.00010 | 0.0053 |

| Vacuum induction furnace | 0.0003 | 0.00001 | 0.0005 |

Table 3-2 Gas Content in SAE4340 Steel Produced by Different Melting Methods

| Steel and alloys | Oxide inclusions, % | |

| Non-vacuum induction furnace | Vacuum induction furnace | |

| Cr20 Cr16Ni25W5AlTi2 Cr10Ni65Co10W5Mo5VAl4 | 0.034~0.044 0.025 0.013~0.044 0.012 0.006~0.010 | 0.006~0.010 0.006 0.003~0.010 0.0046 0.005~0.010 |

(1) Carbon Deoxidation Under Vacuum

The ability of carbon deoxidation under vacuum increases significantly with the increase of vacuum degree. At 1600℃, when the vacuum degree is 10-3 atm, the carbon deoxidation ability has exceeded that of aluminum; When the system vacuum degree is 10-5 atm, the carbon deoxidation ability is 105 times that under atmospheric conditions. Carbon deoxidation is mainly utilized under vacuum.

(2) Gas Dissolution in Steel and Its Influencing Factors

The solubility of diatomic gas molecules in molten metal is proportional to the square root of the gas pressure in the atmosphere. Therefore, the higher the vacuum degree, the lower the solubility of gas in the metal.

At 1600℃ and PH2=100Kpa, the effect of alloy elements on the solubility of nitrogen in molten iron, as well as the effect on the solubility of hydrogen in molten iron at 1600℃ and PN2=100Kpa, should be taken into account.

The entire cycle of vacuum induction furnace smelting can be divided into several main stages, including charging, melting, refining, alloying and deoxidation, pouring, etc.

3.3.1 Charging

(1) Raw Material Requirements

The charge material used in the vacuum induction furnace is generally clean raw materials that have been surface derusted and degreased, with most of the alloy elements added in the form of pure metal. Wet charge materials should not be used during charging to avoid affecting the quality of the finished product and causing splashing during melting. During charging, the upper part of the charge material should be loose while the lower part should be tight to prevent “bridging” caused by the upper charge material getting stuck or welded during the melting process. A layer of small lightweight material should be laid on the bottom of the crucible before charging large-sized materials. High-melting, difficult-to-oxidize charge materials should be loaded in the high-temperature zone at the middle and lower parts of the crucible. A few active elements such as Al, Ti, Mn, B, and rare earths can be loaded into separate feeders.

(2) Charging Requirements

I. The lower layer of the charge material should be compact, while the upper layer should be loose to prevent bridging of the upper layer of charge material during the melting process; a layer of small lightweight material should be laid on the bottom of the crucible before charging large-sized materials.

II. High-melting, difficult-to-oxidize charge materials should be loaded in the high-temperature zone at the middle and lower parts of the crucible.

III. Easily oxidizable charge materials should be added under good conditions for metal deoxidation.

IV. To reduce the loss of volatile elements, alloy can be added to the metal melt in the form of an alloy or inert gas can be introduced into the melting chamber to maintain a certain furnace pressure.

3.3.2 Melting Phase

For a vacuum furnace that operates on an intermittent basis, after the charge material has been loaded, the vacuum chamber is closed and the vacuum is pumped out. When the pressure in the vacuum chamber reaches 0.67 Pa (5×10-3 mmHg), the power can be turned on to heat the charge material. For continuous production furnaces with charge materials loaded under vacuum conditions, power can be supplied to enter the melting phase as soon as the charging is completed. Considering the degassing effect of the charge material during melting, the maximum power input is not required during the initial melting stage. Instead, the power should be gradually increased according to the degassing situation of the charge material to avoid excessive degassing causing splashing. When violent boiling or splashing occurs, the input power can be reduced or the furnace pressure can be slightly increased to control it. The sign of a clear molten pool is that the surface of the molten pool is calm, with no bubbles escaping. Then it can proceed to the refining phase.

3.3.3 Refining Phase

The main tasks of the refining phase are to improve the purity of the liquid metal and to carry out alloying. At the same time, the temperature of the melt and the alloying need to be adjusted. The goal of the refining phase is to reduce gas content, remove harmful impurities, and make the steel composition qualified. The temperature of the refining phase should be controlled above 100 ℃ of the melting point of the smelted metal. The vacuum degree for large vacuum induction furnaces is usually between 15-150Pa; for small furnaces, it is between 0.1-1Pa. The refining time is 15-25 minutes for a 200 kg furnace and 60-100 minutes for around one ton.

3.3.4 Alloying

Alloying refers to the adjustment of the composition, which is done under good deoxidation and degassing conditions by adding alloy elements. The type and quantity of elements added are determined by the requirements for the alloy properties, and the order and conditions of addition are determined by the affinity and volatility of the alloy elements with oxygen. After adding each element, the power should be increased and stirred for a certain amount of time to accelerate melting and ensure even distribution.

3.3.5 Steel Casting and Pouring

After the alloying phase, when the metal liquid in the crucible reaches the target composition and temperature, and the straightness of the vacuum chamber meets the technical requirements, the steel can be cast. When pouring into the insulation cap, the vacuum is broken immediately and the heating agent and insulation agent are added to avoid shrinkage porosity entering the ingot body. For high-temperature alloys with complex compositions, they should be left in the vacuum for 15-20 minutes after casting before breaking the vacuum. For large continuous vacuum induction furnaces, the ingots can be allowed to cool under vacuum.

All metals (including some non-metals) have an equilibrium vapor pressure Poi, which depends on the physical properties of the metal, the gaseous state form (single atom, diatomic or multi-atomic molecule), and the temperature. The relationship between the vapor pressure Po of substance i and temperature is as follows: (P0 is standard pressure and needs no modification)

lg(Poi/133.3)=AT-1+BlgT+TC×10-3+D (3-1)

where the unit of Poi is Pa. The parameters A, B, C, D and other relevant physical properties of elements related to steel metallurgy are listed in Table 3-5. The higher the vapor pressure of an element, the more likely it is to volatilize during vacuum smelting. According to the data in Table 3-5, the decreasing order of Poi for each element at 1873K can be calculated as follows: Zn, Mg, Ca, Sb, Bi, Pb, Mn, Al, Sn, Cu, Cr, Fe, Co, Ni, Y, Ce, Sl, La, Ti, V, B, Zr, Mo, Nb, W, Ta.

The vapor pressure Pi of component i in an alloy or crude metal is not equal to the vapor pressure Poi of pure substance i because the concentration of i in the alloy is necessarily lower than that in the pure substance. In addition, the interaction between the molecules of i and the other component elements in the alloy is not equal to that among the i molecules. The formula for calculating Pi is:

Pi= ai .Poi,= r i .N i .Poi (3-2)

In the formula:

ai: activity of component i in the alloy

ri: activity coefficient of i

Ni: molar fractional concentration of i

In ferrous alloys, alloying elements can be divided into three categories: non-volatile, easily volatile, and impurity elements that can be removed by volatilization. Non-volatile elements include Ti, V, B, Zr, Mc (Hf), Nb, Ta, and W. Easily volatile elements include Mn, Al, Cr, Fe, Co, Ni, Cu, Ca, and Mg. Under vacuum smelting conditions, these elements will volatilize to varying degrees. Steel and alloys contain some trace metal elements that have a significant impact on the performance of steel and alloys. They are difficult to remove by conventional chemical methods. If these elements have high vapor pressure, they can be removed by volatilization during vacuum smelting. These metal elements include Sn, Pb, Bi, Sb, and Zn.

Trace elements such as magnesium, zirconium, boron, etc., are used for microalloying; trace impurities such as Pb, Bi, As, Sb, and Sn are harmful to steel and alloys. Pure magnesium has high vapor pressure at melting temperatures, low density, and strong affinity for oxygen, which makes magnesium alloying difficult.

During vacuum smelting, magnesium is added in the form of binary or ternary alloys during the later stage of melting. To improve the recovery rate of magnesium, the following points should be noted when adding magnesium:

(1) The temperature of the molten steel should be about 20°C lower than the tapping temperature before adding magnesium.

(2) The holding time should be controlled after adding magnesium, generally added within 1-5 minutes before tapping.

(3) Argon gas should be introduced into the furnace before adding magnesium to ensure high recovery rate of magnesium.

Trace harmful elements in steel and alloys are usually low-melting impurities accumulated from repeated use of scrap or contained in some iron ore. Vacuum refining is the most effective method for removing these harmful impurity elements because they generally have high vapor pressure. Due to different vapor pressures and the varying influence of other component elements, the volatilization rates of these elements differ greatly.

With the continuous development of induction furnace technology, the capacity of coreless induction furnaces has been increasing, and the vacuum and traditional induction furnaces that have been put into production have reached 60t and 40t, respectively. In the 1960s, the United States successively manufactured VIM (Vacuum Induction Melting Furnace) furnaces with capacities of 15t, 30t, and even 60t. The increase in electric furnace capacity also correspondingly increases the demand for high-purity refractory materials with special physical properties.

The operating conditions for refractory materials used in vacuum smelting are generally more stringent than those used in conventional smelting. This is because many refractory materials decompose according to their composition and react with the molten metal under vacuum conditions. On the one hand, this contaminates the molten metal, and on the other hand, it increases the corrosion of the refractory material. This is particularly evident in refractory materials containing large amounts of silica and iron oxide.

The shrinkage cracks that occur in refractory materials used in vacuum smelting are more severe than those in conventional smelting, especially in high-capacity (>2.5t) coreless induction furnaces. Therefore, refractory materials for large-scale induction furnaces should have the following characteristics:

(1) Irreversible expansion, no shrinkage cracks will occur;

(2) High purity;

(3) Good stability in a vacuum environment;

(4) Able to withstand the erosion of molten metal and slag.

Refractory materials with these characteristics include high-purity magnesia-alumina-spinel and alumina. In recent years, the batching of these refractory materials, as well as the corresponding repair materials and binders, have developed significantly.

Magnesia and alumina react to form high-purity magnesia-alumina-spinel with low density. The lining made of magnesia-alumina-spinel can be used at a temperature of 1647℃, and after being cooled to room temperature or filled with cold materials, it can be heated and used at 1647℃ without cracking after dozens of cycles. According to relevant reports, the lining of a nominal capacity 6t induction furnace is made by ramming 95% alumina. When producing 300 and 400 series stainless steel, the furnace lining can be used continuously for 150 furnaces without any treatment.

In the nearly 80 years since the induction furnace was invented, there have been significant advancements in both equipment and processes. As a result, measures have been adopted to improve induction furnace smelting in terms of production volume, productivity, product quality, and product range. These measures include magnesium treatment of alloys, low oxygen potential dephosphorization, argon blowing, powder injection, hydrogen-oxygen mixed gas decarburization, and hydrogen refining of liquid steel.

3.6.1 Magnesium Treatment of Alloys

High-temperature nickel or iron-based alloys, as well as precision alloys containing high levels of alloying elements, some of which are more reactive than others, such as aluminum and titanium, cannot guarantee satisfactory properties such as thermal plasticity, weldability, high-temperature strength, and creep resistance even when smelted under vacuum conditions. Therefore, a certain amount of magnesium is added at the end of refinement. The residual magnesium in the metal can significantly improve these properties.

The specific physicochemical properties of magnesium determine that it is difficult to control the addition method and recovery rate during the magnesium addition process. To address this issue, magnesium alloys such as Ni-Mg and Ni-Mg-Me are used to reduce the vapor pressure of magnesium and increase its melting point and boiling point. The operation process for magnesium treatment is as follows:

(1) After the refining period is over, if B and Ce need to be added, adjust the temperature of the melt so that it is 20℃ lower than the tapping temperature after adding B and Ce;

(2) Fill the vacuum chamber with high-purity argon gas to a pressure of 13-27kPa;

(3) Add magnesium in the form of a block-shaped intermediate alloy containing magnesium to the metal melt;

(4) Immediately stir vigorously after adding magnesium, and avoid stirring for too long to reduce the loss of magnesium. The steel should be tapped within 1-5 minutes after adding magnesium.

3.6.2 Low Oxygen Potential Dephosphorization

When melting alloy steel, especially when using return materials as furnace charge, it is necessary to control the oxygen potential of the furnace gas and slag during the melting and refining process to reduce the loss of alloying elements. Therefore, oxidizing methods cannot be used to dephosphorize during the smelting process. When low-phosphorus steel is required, only raw materials with a phosphorus content lower than the specification requirements can be used, which increases production costs. To solve the problem of dephosphorization during the smelting of high-alloy steel return materials, the theory and practice of low oxygen potential dephosphorization have been proposed in recent years and have also been applied in induction furnace smelting.

Calcium and phosphorus in the steel can react under the conditions of sufficient deoxidation and desulfurization of the steel liquid as follows:

3Ca+2[P] = Ca3P2 (3-3)

The product formed is calcium phosphide. The calcium involved in the reaction can be metallic calcium, calcium alloys (such as silicon-calcium alloys), or calcium compounds (such as CaC2). Due to the low melting point (839℃), high vapor pressure (P = 1.775×105 Pa at 1600℃), and low solubility in the steel liquid of metallic calcium, it quickly evaporates into vapor form after being added to the steel liquid and floats up and out in the form of bubbles. During the floating process, calcium vapor can react with the phosphorus in the steel to generate Ca3P2, but the utilization rate of calcium is very low. Calcium alloys or compounds are commonly used instead.

The Ca3P2 generated by the reaction is an insoluble compound in the steel liquid, with a melting point of 1320℃ and a density of 3.3 g/cm³. It will float up in liquid form and enter the slag at the steelmaking temperature. However, calcium phosphide is not stable under the conditions of steelmaking and is a strong reducing agent. When the oxygen potential of the furnace atmosphere is high and there are easily reducible oxides in the slag, the following reaction will occur:

(Ca3P2) + 4O2 = 3 (CaO)+ (P2O5) ; (3-4)

y (Ca3P2) + 8 (MexOy) = 3y (CaO) + y (P2O5) + 8x [Me] (3-5)

When there is water vapor in the furnace gas:

(Ca3P2)十3H2O= 3 (CaO) + 2PH3 ↑; (3-6)

PH3 is a gas that will take away phosphorus with furnace gas when there is water vapor, but this gas is toxic, and precautions should be taken to prevent this reaction from occurring during operation. Special measures should be taken to ensure safety when processing furnace slag containing Ca3P2. When the slag has a high alkalinity, CaO.P2O5 with higher stability will be produced.

3 (CaO) + (P2 O5)= (3 CaO.P2 O5) (3-7)

However, both silicon calcium and CaC2 used for low oxygen potential dephosphorization have strong reducing properties. Therefore, when there is an excess of silicon calcium or CaC2 in the slag, calcium phosphate will decompose and P2O5 will be reduced, causing phosphorus to return to the steel and reducing the efficiency of dephosphorization under low oxygen potential.

In actual operation, maintaining low oxygen potential of the steel and timely removing phosphorus-containing slag are the keys to improve the efficiency of calcium dephosphorization. When adding calcium, precautions should be taken to prevent violent gasification of calcium, which can cause splashing. When CaC2 is used as a dephosphorizing agent, it is required to cover the crucible and fill it with a reducing or inert gas to avoid oxidation of CaC2 in the slag. In the smelting of Cr12MoV mold steel, the amount of powder used is 10-15 kg/t, and the dephosphorization rate is about 0.005%. After the powder spraying ends, remove the slag immediately and make new slag.

3.6.3 Argon Blowing

Argon blowing in the ladle is already a mature technology in the smelting of ordinary steel and low-alloy steel. It relies on the upwelling of argon bubbles to stir the molten steel, promote the carbon-oxygen reaction, adhere to and promote the collision, growth, and upwelling of inclusions at the surface of the bubble, and can also de-gas under certain conditions.

When the purity of argon is high and very dry, blowing argon can remove some gases, especially hydrogen. When the argon blowing time is about 20 minutes, the dehydrogenation rate can reach about 50%. Harmful trace elements with high vapor pressure at the steelmaking temperature, such as lead and arsenic, can also be removed to different degrees through argon blowing. According to reports, blowing argon for 20 minutes can remove 70-80% of lead in steel, but the removal rate of arsenic is only 10%.

3.6.4 Powder Injection

Powder injection metallurgy is a new technology developed recently to refine molten steel. Ladle powder injection has been widely used in conventional steelmaking production, and different powder agents can be used to complete metallurgical tasks such as dephosphorization, desulfurization, deoxidation, controlling the morphology of inclusions, alloying or carbon addition. Powder injection technology is essentially a technology that adds solid materials to molten steel.

Since the powder is transported by carrier gas, the carrier gas that enters at the same time as the powder will cause agitation of the melt, thereby improving the kinetic conditions of metallurgical reactions. Therefore, powder injection is more effective than traditional solid material addition technology. Of course, this adding technique can also be used for induction furnace melting.

In the induction furnace melting, dephosphorizing agent (calcium alloy or calcium compound) or desulfurizing agent can be blown. The commonly used desulfurizing agent is mainly lime-based powder (w(CaO) 60-80%, w(CaF2) 20-40%). This desulfurizing agent is easy to obtain, cheap, and has no effect on the composition control of the molten steel, and the desulfurization rate is about 30-50%.

Another widely used desulfurizing agent is Ca-Si-CaF2 (where w(CaF2) is 20-30%), most of the silicon in this desulfurizing agent will be absorbed by the molten steel, which can increase the silicon content, and the desulfurization rate can reach 40-80%. For steels that do not require carbon addition, good desulfurization effect can also be achieved by adding a certain proportion of CaC2 to lime-based desulfurizing agents.

Bottled argon gas is commonly used as the carrier gas for powder injection. Nitrogen can also be used for steel grades that do not require nitrogen content, which can reduce costs. The working pressure is generally 0.2-0.3 MPa. Under the premise of ensuring uniform delivery of powder, the working pressure should be minimized as much as possible. A steel pipe with external refractory material is used as the injection gun and is inserted to a depth equal to the melt pool depth minus the penetration depth.

3.6.5 Argon-oxygen Decarburization

The United Carbide Corporation of the United States studied the equilibrium relationship of the Fe-Cr-C-O quaternary system in an induction furnace and found that there is a corresponding relationship between the carbon and chromium content dissolved in iron and the partial pressure of carbon monoxide (PCO) in the gas phase with temperature. Under certain chromium content, the equilibrium carbon content decreases with the increase of temperature or the decrease of PCO in the gas phase. Therefore, as long as the PCO in contact with the molten steel can be reduced, the carbon in the molten steel can be reduced to a low level at a not too high temperature, and chromium will not suffer too much oxidation loss.

Based on this, the AOD method of diluting PCO partial pressure with argon was proposed, that is, argon-oxygen mixed gas blowing decarburization. This method overcomes the disadvantages of high temperature, large chromium loss, increased carbon content of graphite electrodes, low furnace lining life, and large consumption of low-carbon chromium iron or metallic chromium when smelting chromium stainless steel by oxygen blowing in arc furnaces, and has been rapidly developed and widely used.

Since the AOD method was developed on the induction furnace, the argon-oxygen decarburization method should also be applicable to induction furnace melting. When smelting chromium or nickel-chromium stainless steel in an induction furnace, argon-oxygen mixed gas can be blown to remove carbon from the steel.

Electric slag remelting (ESR) is a widely used secondary refining method for the production of high-quality steel and alloys. This process utilizes the heat generated from the electrical resistance of the slag to remelt the consumable electrode in a water-cooled crystallizer. Compared to vacuum consumable electrode arc melting, ESR does not require a vacuum system and often uses an AC power source, making it a simpler and more easily operable process with compact and high-quality ingots.

4.1.1 Electric Slag Remelting Equipment

Compared to vacuum consumable electrode arc melting, electric slag remelting equipment is relatively simple and consists of several components, including a power transformer and short circuiting device, a consumable electrode lifting system, a crystallizer with a bottom water tank, a measurement and control system, and a supply and dust removal system. Here, we will only introduce the power transformer, crystallizer, bottom water tank, and various types of electric slag furnaces.

(1) Power Transformer

The unique feature of the electric slag remelting process is its use of high current and low voltage AC or DC power sources. Therefore, it is necessary to choose a suitable transformer to convert the high voltage input into low voltage (40-100V) output that matches the capacity of the electric slag furnace.

(2) Crystallizer

The crystallizer is the most important component of the electric slag furnace. During the ESR process, the consumable electrode melts inside the crystallizer, and the liquid metal is forcibly cooled and crystallized to form a metal ingot or casting. The crystallizer is both the melting chamber of the furnace and the mold for metal solidification. It has a complex shape and structure, and there are three main types: ingot-type crystallizer, sliding-type crystallizer, and combined-type crystallizer (as shown in Figure 4-4).

1-Consumable Electrode; 2-Slag Pool; 3-Metal Melt Pool; 4-Metal Ingot;

1-3 Ingot Mode Crystallizer;

4-5 Sliding Type Crystallizer; 5-Crystallizer; 6-Bottom Water Box

6-7 Detachable Type; 8-Mobile Type

4.1.2 Basic Principles of Electric Arc Remelting

(1) Basic principle of remelting

During the electric arc remelting process, the current passes through the consumable electrode, slag, metal melt pool, solidified metal ingot and bottom water box, and finally flows through the short circuit, transformer, etc., forming a loop (see Figure 4-6). For a bipolar series electric arc furnace, the current flows from one of the consumable electrodes through the slag (a small part of the current also flows through the metal melt pool, and then back to the slag), then passes through the other consumable electrode, and finally returns to the transformer to form a loop.

The process of electric arc remelting includes the formation of a slag pool, melting of the consumable electrode, solidification of the remelted metal, and repair and shrinkage of the remelted ingot, all of which are performed in a continuous working procedure.

When the current passes through the slag, due to the high resistance of the slag, strong Joule heating is generated in the slag pool. The heat Q precipitated in the slag pool per unit time is expressed as follows:

Q = I2R (4-1)

Where: Q – Joule heat generated per unit time, J/s;

I – current intensity of the electrically conductive slag, A;

R – resistance of the slag pool at the melting temperature, Ω.

As the consumable electrode is inserted into the slag layer, the insertion portion of the consumable electrode is heated by the high temperature of the slag and exceeds its own melting point. As a result, the surface layer of the electrode tip begins to melt, forming a thin layer of liquid metal, which attaches to the upper part of the electrode tip. At the same time, under the action of gravity g, electromagnetic force R, and the scouring force of slag pool movement F, it flows downward along the surface of the electrode end and concentrates in the central part of the electrode to form molten droplets. Gravity causes the molten droplets to fall downward, while the interfacial tension δ between the slag and the molten droplets prevents the molten droplets from falling (see Figure 4-7).

The melting of the consumable electrode and the transition of metal droplets during the remelting process can be divided into the following three stages:

1) Liquid metal film is formed at the end of the consumable electrode;

2) Aggregated into molten droplets and transitioned to the metal melt pool through the slag layer;

3) Entered the surface of the metal melt pool.

1 – slag pool; 2 – melted liquid layer; 3 – metal melt pool; 4 – slag skin; 5 – electric slag ingot; 6 – crystallizer;

7 – bottom water box; 8 – transformer; 9 – short circuit; 10 – holder; 11 – consumable electrode

Compared with general smelting methods, the electric arc remelting process differs in that the remelting process, including the formation of slag pool, melting of consumable electrode, solidification of remelted metal, and repair and shrinkage of remelted ingot, are all performed in a continuous working procedure. Therefore, it has a series of advantages.

(1) The remelted metal can be effectively refined by the slag.

(2) Improve the crystallization conditions of the metal ingot and increase the yield of the metal.

(3) The equipment is simple, the production cost is low, and the operation is easy to master.

(4) There are many product varieties and wide application range.

(5) Electric arc remelting also has a major advantage, which can produce metal ingots with different cross-sections, such as round, square, rectangular, and metal ingots with large width-to-length ratios. It can also produce hollow pipes and castings with different shapes, such as hollow tube blanks, rolling mill billets, high-pressure vessels, large high-pressure valves, and crankshafts.

However, there are some drawbacks to electric arc remelting, such as low productivity, high electricity consumption, poor degassing effect, difficulty in accurately controlling the chemical composition when remelting steels with high Ti and Al elements, and higher production costs compared to general smelting methods.

4.3.1 Raw Materials for Electric Arc Remelting

(1) Consumable Electrode

The consumable electrode used in electric arc remelting is generally a metal ingot smelted by an arc furnace or induction furnace, which is made into a metal rod after rolling or forging. Its cross-section can be circular, square, or rectangular, and its variety should be the same as that of the finished product after remelting. In order to avoid the oxidation and burning of easily oxidizable elements during the remelting process, it is required that the surface of the consumable electrode should be free of rust and oxide skin, especially when remelting steels and alloys containing Al, Ti, B, and other elements. During the remelting process, except for easily oxidizable elements (such as Ti, Al, etc.) that may be burned, other elements basically do not change. For these easily oxidizable elements, they should be controlled within a certain range when preparing the consumable electrode according to the burning amount during the remelting process. To avoid the eccentricity of the consumable electrode during the remelting process, it is required to be as straight as possible, with a bend radius not exceeding 6mm per meter.

(2) Ingot protection plate

At the beginning of remelting, in order to prevent the bottom water box from being burned through, a metal plate called an ingot protection plate can be placed under the crystallizer and above the bottom water box. The ingot protection plate is made of the same material as the consumable electrode. The surface of the ingot protection plate should not have oxide skin and rust, and it should be very flat, so as to ensure close contact with the surface of the bottom water box and achieve good conductive effect. The thickness of the ingot protection plate is generally selected as 12-18mm.

(3) Ignition slag material

As we all know, when electric arc remelting, the molten slag has a certain conductivity. When the slag material is solid, its conductivity is poor and cannot be used to conduct heat and establish a slag pool directly. If solid slag is used as the ignition slag material, a slag with sufficient conductivity in the solid state must be found. In practice, it has been found that when the solid slag contains a certain amount of TiO2, it can meet this requirement. Therefore, for a considerable period of time, solid slag containing TiO2 was used as the ignition slag material for electric arc remelting.

(4) Remelting slag material

The slag plays an important role in the electric arc remelting process. The commonly used slag systems are mainly composed of fluorite (CaF2), alumina (Al2O3), lime (CaO), and magnesia (MgO), etc. (see Table 4-1).

4.3.2 Selection of Process Parameters for Electric Arc Remelting

(1) Size of electric slag ingot